Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Anybody know how to make a barrel vice?

- Thread starter jdbfish

- Start date

Re: Anybody know how to make a barrel vice?

If it were me:

Approach this with the mindset that a barrel vise is probably the single most used tool in a gunshop. With that in mind address this need knowing that the better you make it, the less time your going to spend dickering around to get a job done. It's not a sexy tool, it's not fancy like a lathe/mill, but it will/can make or break you in a day's work.

1st: Ditch the Aluminum. Don't make the same mistake I did.

"Anything worth making is worth making out of steel."

-a quote from a good friend of mine who's pretty much the smartest man on planet earth.

Oversize everything. Bolts, hardware, etc. At some point you'll run into a stubborn barreled action that just doesn't want to split apart. Heavy, large, hardware won't pull/stretch the way smaller stuff will. Consider 3/4" bolts for everything.

Make your two halves large enough to accomidate the biggest barrel you'll ever encounter. Even if you don't plan on working on 50's, build it so you can.

Make your collets from heat treated tool steel. just buy a stick of prehard 4140.

On the bottom, stick a 3/8 dowel pin in the saddle and drill a hole in one of your collets. This will save you time down the road by indexing the clock position of the collet. On top, counterbore and glue in a couple rare earth magnets to hold the top collet in place while fitting/assembling.

Mount to a rigid stand. This is one place where I did it right. 1/4" wall 4x4 box tubing to 3/4" base plates.

I have a brand new floor with radiant heat. I was too chicken to drill holes and install lag bolts. I scuffed/cleaned the floor and the bottom of the plate with a 90* grinder and roloc disk. I then mixed up some acraglass liquid resin and glued the base to the floor.

I fear I may never be able to remove it. It's pretty stout.

Last: Take the time to round all your edges. Nothing is more frustrating than to have a rifle 100% done and nick/ding it up due to a sharp edge on a barrel vise. Consider powdercoating or maybe that parts dip chit that puts the rubber coating on it. (not sure how that last one would work though as it'll change the fit of the collets/hardware.

Build it once and as if your grandkids are going to get it.

Good luck.

C.

If it were me:

Approach this with the mindset that a barrel vise is probably the single most used tool in a gunshop. With that in mind address this need knowing that the better you make it, the less time your going to spend dickering around to get a job done. It's not a sexy tool, it's not fancy like a lathe/mill, but it will/can make or break you in a day's work.

1st: Ditch the Aluminum. Don't make the same mistake I did.

"Anything worth making is worth making out of steel."

-a quote from a good friend of mine who's pretty much the smartest man on planet earth.

Oversize everything. Bolts, hardware, etc. At some point you'll run into a stubborn barreled action that just doesn't want to split apart. Heavy, large, hardware won't pull/stretch the way smaller stuff will. Consider 3/4" bolts for everything.

Make your two halves large enough to accomidate the biggest barrel you'll ever encounter. Even if you don't plan on working on 50's, build it so you can.

Make your collets from heat treated tool steel. just buy a stick of prehard 4140.

On the bottom, stick a 3/8 dowel pin in the saddle and drill a hole in one of your collets. This will save you time down the road by indexing the clock position of the collet. On top, counterbore and glue in a couple rare earth magnets to hold the top collet in place while fitting/assembling.

Mount to a rigid stand. This is one place where I did it right. 1/4" wall 4x4 box tubing to 3/4" base plates.

I have a brand new floor with radiant heat. I was too chicken to drill holes and install lag bolts. I scuffed/cleaned the floor and the bottom of the plate with a 90* grinder and roloc disk. I then mixed up some acraglass liquid resin and glued the base to the floor.

I fear I may never be able to remove it. It's pretty stout.

Last: Take the time to round all your edges. Nothing is more frustrating than to have a rifle 100% done and nick/ding it up due to a sharp edge on a barrel vise. Consider powdercoating or maybe that parts dip chit that puts the rubber coating on it. (not sure how that last one would work though as it'll change the fit of the collets/hardware.

Build it once and as if your grandkids are going to get it.

Good luck.

C.

Re: Anybody know how to make a barrel vice?

One of the area smiths has a 20 press with lead plates with a couple different grooves in them. He has been spinning barrels off with it for many a decades. I built mine similar to chads because I thought mels was too hilbilly. It ain't much to look at, but it works good with no fuss. I do keep lead flashing handy to fit odd barrels.

One of the area smiths has a 20 press with lead plates with a couple different grooves in them. He has been spinning barrels off with it for many a decades. I built mine similar to chads because I thought mels was too hilbilly. It ain't much to look at, but it works good with no fuss. I do keep lead flashing handy to fit odd barrels.

Re: Anybody know how to make a barrel vice?

Build it once and as if your grandkids are going to get it.

Mr Dixon, that's a piece of advise for making gunbuilding tools if I ever heard one.

I too made my barrel vise very stoutly and have never rgretted it. Bore the halves for an an easily available size of collet stock like 3".

I mount mine in a 40 Ton Carolina press, along with a lot of other things. It is a very secure holding device and you can find them used for little more than the price of a good vise. I got mine for $500 and it looked like it had been used once or twice.

Build it once and as if your grandkids are going to get it.

Mr Dixon, that's a piece of advise for making gunbuilding tools if I ever heard one.

I too made my barrel vise very stoutly and have never rgretted it. Bore the halves for an an easily available size of collet stock like 3".

I mount mine in a 40 Ton Carolina press, along with a lot of other things. It is a very secure holding device and you can find them used for little more than the price of a good vise. I got mine for $500 and it looked like it had been used once or twice.

Re: Anybody know how to make a barrel vice?

I have a brand new floor with radiant heat. I was too chicken to drill holes and install lag bolts. I scuffed/cleaned the floor and the bottom of the plate with a 90* grinder and roloc disk. I then mixed up some acraglass liquid resin and glued the base to the floor.

I fear I may never be able to remove it. It's pretty stout.

Please post photo of stand

I have a brand new floor with radiant heat. I was too chicken to drill holes and install lag bolts. I scuffed/cleaned the floor and the bottom of the plate with a 90* grinder and roloc disk. I then mixed up some acraglass liquid resin and glued the base to the floor.

I fear I may never be able to remove it. It's pretty stout.

Please post photo of stand

Re: Anybody know how to make a barrel vice?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 671RTO9513</div><div class="ubbcode-body">Build it once and as if your grandkids are going to get it.

Mr Dixon, that's a piece of advise for making gunbuilding tools if I ever heard one.

I too made my barrel vise very stoutly and have never rgretted it. Bore the halves for an an easily available size of collet stock like 3".

I mount mine in a 40 Ton Carolina press, along with a lot of other things. It is a very secure holding device and you can find them used for little more than the price of a good vise. I got mine for $500 and it looked like it had been used once or twice. </div></div>

can you ellaborate on what you mean by collet stock?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 671RTO9513</div><div class="ubbcode-body">Build it once and as if your grandkids are going to get it.

Mr Dixon, that's a piece of advise for making gunbuilding tools if I ever heard one.

I too made my barrel vise very stoutly and have never rgretted it. Bore the halves for an an easily available size of collet stock like 3".

I mount mine in a 40 Ton Carolina press, along with a lot of other things. It is a very secure holding device and you can find them used for little more than the price of a good vise. I got mine for $500 and it looked like it had been used once or twice. </div></div>

can you ellaborate on what you mean by collet stock?

Re: Anybody know how to make a barrel vice?

I have a press. not sure how to mount it in press or what size hole or groove to drill for a universal fit on the barrels. any body got any pics or drawing they can share> Great ideas so far so keep em coming please!!!!

I have a press. not sure how to mount it in press or what size hole or groove to drill for a universal fit on the barrels. any body got any pics or drawing they can share> Great ideas so far so keep em coming please!!!!

Re: Anybody know how to make a barrel vice?

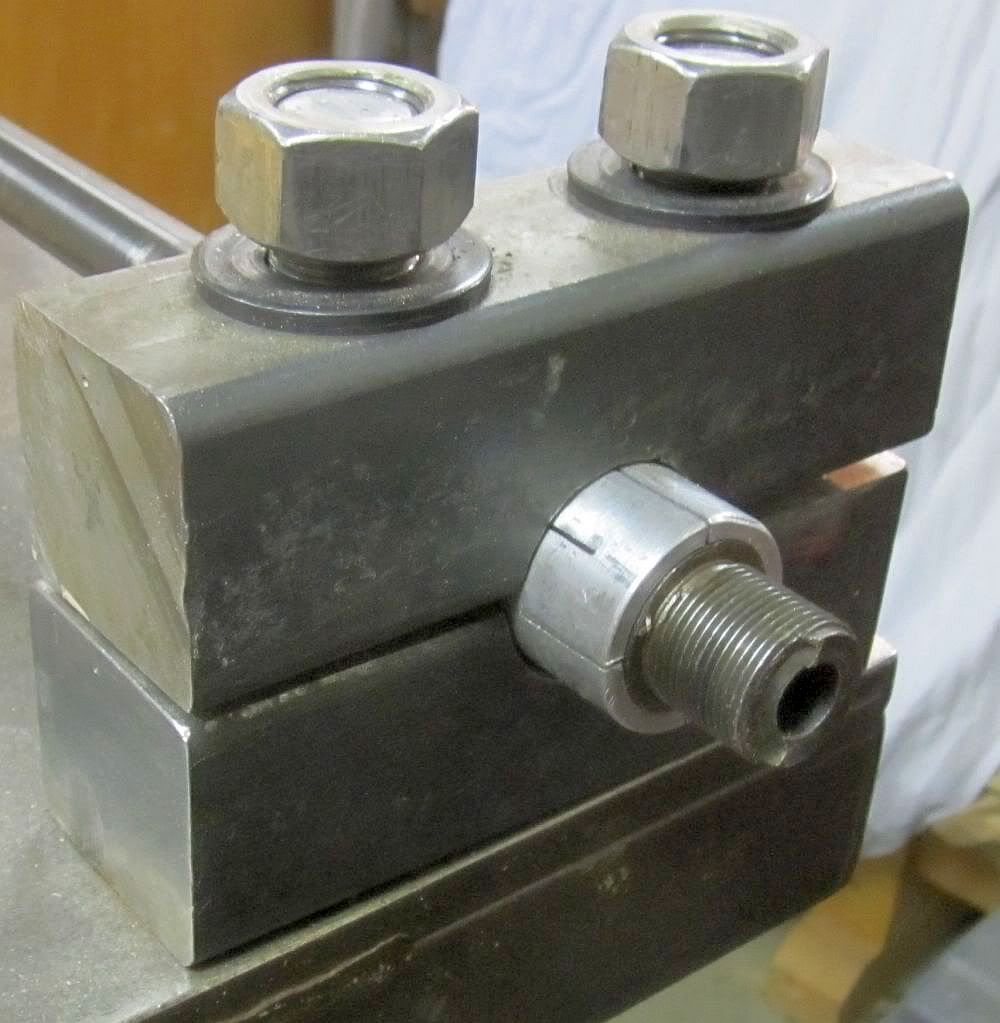

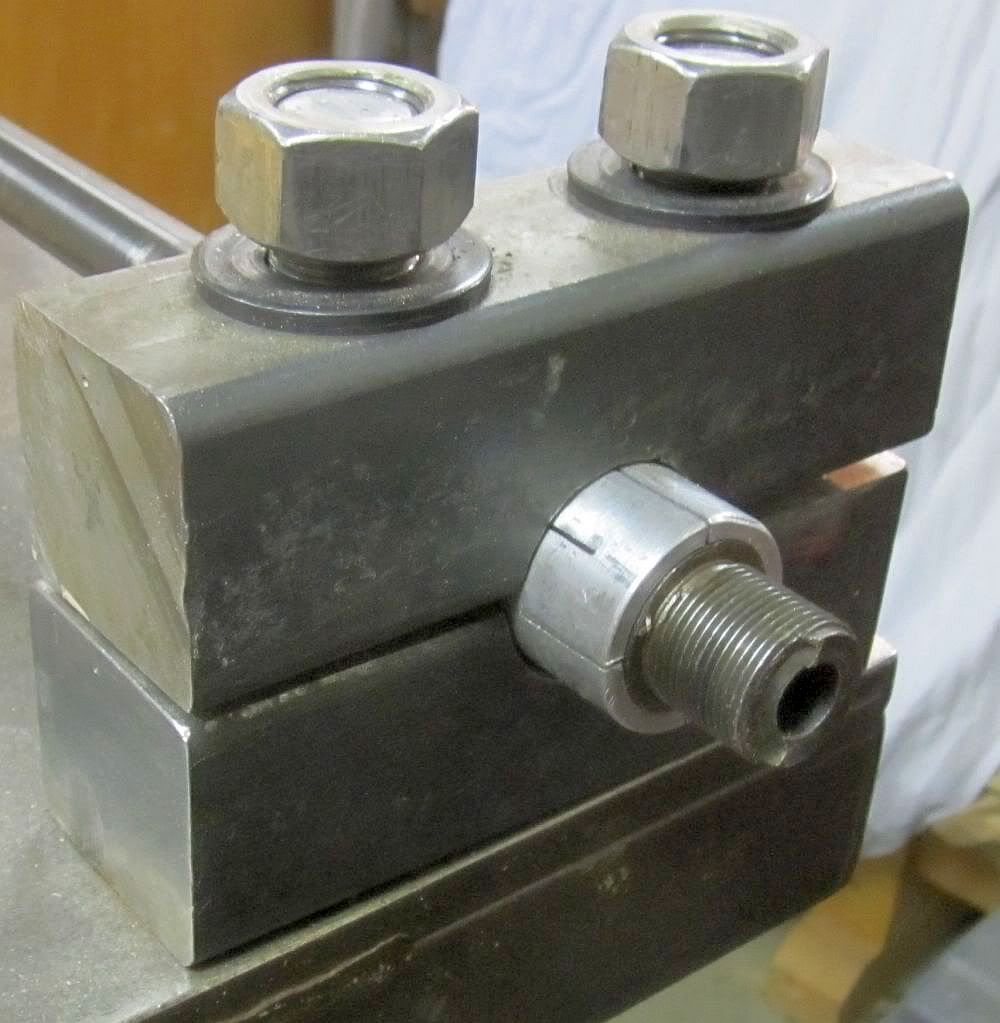

My barrel vise system has evolved to get a grip on the barrel adequate for 600 foot pounds of torque for old rusted up surplus rifles. [After having snapped off a number of grade five 1/2-13 bolts]

I put two steel blocks, 2"x2"x6" on the face plate of the lathe, gapping the two blocks with a 0.125" spacer. I then drill and bore a 1.5" hole.

The vise is drilled and tapped for 1/2-13 threads on the bottom of the bottom block, to clamp to a 1/2" thick steel bench top.

The top of the bottom block is drilled and tapped for 7/8-14 threads.

The top block is clearanced for 7/8-14 threaded rod.

I buy 1.5" diameter 6061 Aluminum round stock from MSC in 6 foot lengths. From this I make collets. Some of them are internally tapered to match the barrel shank's taper.

The 7/8-14 nuts are tightened with a 3/4" drive socket wrench with a 16" handle, and I pull on that wrench as hard as I can. That pencils out to a clamping force of ~100,000 pounds. Meanwhile the shear at the barrel- collet interface at the threshold of slipping is ~15,000 pounds. That mean we have a lousy coefficient of friction [remember, from grade school?], so I put powdered sugar there.

Here is a video where I measure the torque needed to unscrew a 91/30 barrel after 73 years. You can skip the 1 minute video, the answer is 540 foot pounds.

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/YOjYro4w0Bc"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/YOjYro4w0Bc" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

Q: How long does it take a 60 year old man to hack saw through 2"x2" pieces of steel?

A: 10 minutes for the first cut, 20 minutes for the second cut.

My barrel vise system has evolved to get a grip on the barrel adequate for 600 foot pounds of torque for old rusted up surplus rifles. [After having snapped off a number of grade five 1/2-13 bolts]

I put two steel blocks, 2"x2"x6" on the face plate of the lathe, gapping the two blocks with a 0.125" spacer. I then drill and bore a 1.5" hole.

The vise is drilled and tapped for 1/2-13 threads on the bottom of the bottom block, to clamp to a 1/2" thick steel bench top.

The top of the bottom block is drilled and tapped for 7/8-14 threads.

The top block is clearanced for 7/8-14 threaded rod.

I buy 1.5" diameter 6061 Aluminum round stock from MSC in 6 foot lengths. From this I make collets. Some of them are internally tapered to match the barrel shank's taper.

The 7/8-14 nuts are tightened with a 3/4" drive socket wrench with a 16" handle, and I pull on that wrench as hard as I can. That pencils out to a clamping force of ~100,000 pounds. Meanwhile the shear at the barrel- collet interface at the threshold of slipping is ~15,000 pounds. That mean we have a lousy coefficient of friction [remember, from grade school?], so I put powdered sugar there.

Here is a video where I measure the torque needed to unscrew a 91/30 barrel after 73 years. You can skip the 1 minute video, the answer is 540 foot pounds.

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/YOjYro4w0Bc"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/YOjYro4w0Bc" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

Q: How long does it take a 60 year old man to hack saw through 2"x2" pieces of steel?

A: 10 minutes for the first cut, 20 minutes for the second cut.

Re: Anybody know how to make a barrel vice?

wow, very nice. I wish i had access to a lathe but i dont. any other ideas out there? just need something simple for a remington 700 sporter weight barrel. probably wont use it more than 2*3 times.eed ideas on an action wrench to...

wow, very nice. I wish i had access to a lathe but i dont. any other ideas out there? just need something simple for a remington 700 sporter weight barrel. probably wont use it more than 2*3 times.eed ideas on an action wrench to...

Re: Anybody know how to make a barrel vice?

This is what I did. Works great http://www.gunbroker.com/Auction/ViewItem.aspx?Item=264082970

This is what I did. Works great http://www.gunbroker.com/Auction/ViewItem.aspx?Item=264082970

Re: Anybody know how to make a barrel vice?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: jdbfish</div><div class="ubbcode-body">wow, very nice. I wish i had access to a lathe but i dont. any other ideas out there? just need something simple for a remington 700 sporter weight barrel. probably wont use it more than 2*3 times.eed ideas on an action wrench to... </div></div>

without machine tools, my recommendation is to buy the wrench and vise.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: jdbfish</div><div class="ubbcode-body">wow, very nice. I wish i had access to a lathe but i dont. any other ideas out there? just need something simple for a remington 700 sporter weight barrel. probably wont use it more than 2*3 times.eed ideas on an action wrench to... </div></div>

without machine tools, my recommendation is to buy the wrench and vise.

Re: Anybody know how to make a barrel vice?

Drill the size hole you want in the aluminum block. Drill the clamping bolt holes.

Cut it in half with a hack saw jig saw or bandsaw. After having numerous gunsmiths

tell me they couldn't turn my SAA barrel without marring it I built one. Aluminum

won't mar the barrel (if it's not painted) I had to flair the ends on an adjustable reamer to match the barrel taper on the pistol. I mount the thing in my floor mounted vise. My frame wrench is a couple of flat plates with inserts I made out

of bondo over saran wrap on the SAA frame itself.

Drill the size hole you want in the aluminum block. Drill the clamping bolt holes.

Cut it in half with a hack saw jig saw or bandsaw. After having numerous gunsmiths

tell me they couldn't turn my SAA barrel without marring it I built one. Aluminum

won't mar the barrel (if it's not painted) I had to flair the ends on an adjustable reamer to match the barrel taper on the pistol. I mount the thing in my floor mounted vise. My frame wrench is a couple of flat plates with inserts I made out

of bondo over saran wrap on the SAA frame itself.

Re: Anybody know how to make a barrel vice?

I made one from 2 railroad plates, oak blocks, with lead shims. It's pretty redneck, but works OK. I put bolts through all of the holes. Once, I still couldn't get it to bite, so I put an extra bench vice on it, as well.

No machine tools required.

I've upgraded since then, but I've still got the oak blocks laying around.

CW

I made one from 2 railroad plates, oak blocks, with lead shims. It's pretty redneck, but works OK. I put bolts through all of the holes. Once, I still couldn't get it to bite, so I put an extra bench vice on it, as well.

No machine tools required.

I've upgraded since then, but I've still got the oak blocks laying around.

CW

Re: Anybody know how to make a barrel vice?

If a barrel vise gets Aluminum onto bluing, often rubbing Alcohol on a Q-tip gets it off.

If a barrel vise gets Aluminum onto bluing, often rubbing Alcohol on a Q-tip gets it off.

Re: Anybody know how to make a barrel vice?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: ugsly</div><div class="ubbcode-body">

Now I just need to bolt it to the floor. Seems to work pretty well, haven't had any problems taking barrels off or putting them on.

Kc</div></div> Chad is your stand like this one ? If so I am impressed that acra glass is all that is holding it to the floor.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: ugsly</div><div class="ubbcode-body">

Now I just need to bolt it to the floor. Seems to work pretty well, haven't had any problems taking barrels off or putting them on.

Kc</div></div> Chad is your stand like this one ? If so I am impressed that acra glass is all that is holding it to the floor.

Re: Anybody know how to make a barrel vice?

Good God Chad. Anything worth building is worth building on a CNC... Damn perfectionists.

Good God Chad. Anything worth building is worth building on a CNC... Damn perfectionists.

Re: Anybody know how to make a barrel vice?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: C. Dixon</div><div class="ubbcode-body">

</div></div>

</div></div>

Nothing to say but envy, lol

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: C. Dixon</div><div class="ubbcode-body">

Nothing to say but envy, lol

Re: Anybody know how to make a barrel vice?

try the search function, there is a thread on this with a bunch of home brewed stuff. i made mine for under $20 if that. used stuff i had around and only had to but nuts and springs. it wasnt an everyday use item, and im a cheap bastard.

try the search function, there is a thread on this with a bunch of home brewed stuff. i made mine for under $20 if that. used stuff i had around and only had to but nuts and springs. it wasnt an everyday use item, and im a cheap bastard.

Similar threads

- Replies

- 6

- Views

- 181

- Replies

- 14

- Views

- 731

- Replies

- 0

- Views

- 181