Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrel fluting - what is it good for?

- Thread starter garandman

- Start date

A roll of pennies weighs 4.1 - 4.2 ounces. Several companies state fluting removes half a pound so 8 ounces, 2 rolls of pennies. If carrying around 2 rolls of pennies is difficult for a grown ass man then he needs to hit the gym and focus on some dead lifts. They do look nice though.

Absolutely nuthin'... Say it again...

Damn, you beat me to it!

In all seriousness, there are only two good reasons to flute a barrel. The first is for grins and giggles. Some people think they're cool, I guess. The second is when you have an overweight competition rifle and you need to shave a few ounces off and don't want to chop the barrel.

If its not already fluted from the manufacture, dont waste your money getting it done. It DOES aid in cooling because it creates more surface area for the air to come in contact with, but that being said you cant punch enough rounds through a bolt action at a rate of fire fast enough to require any assistance or modifications in cooling the barrel.

If its not already fluted from the manufacture, dont waste your money getting it done. It DOES aid in cooling because it creates more surface area for the air to come in contact with, but that being said you cant punch enough rounds through a bolt action at a rate of fire fast enough to require any assistance or modifications in cooling the barrel.

I was pretty much going to say this after someone earlier mentioned "basic physics" yet didn't mention the increase in surface area.

Any time you make a groove, cut, hole, or even crack or break something you increase it's surface area. Anytime that is increased, regardless what it is, changes it's temperature transferring ability.

You could even say the increased surface area "could" make it stronger, but an engineer could probably give the specifics on that. There are probably a lot of variables.

Since the added surface area could make it more rigid, and your barrel flexes when you shoot it, what's to say it's not more prone to breaking because it becomes somewhat more brittle? Who knows

As far as fluting goes tho, I'm not sure any of that makes a noticeable difference on a firearm, as they are just not under the amount of stress and temp to really affect it.

Sent from my Galaxy Nexus

Fluting does not make the barrel stiffed than it was before fluting but it will be stiffer than unfluted barrel of the same length and weight. I did the physics on this a while a go and do not want to reproduce it here but I think varmintals.com has an excellant analysis of why a barrel is not stiffer after fluting, only stiffer than a barrel of the same length and weight that is not fluted.

Some competitors ask whether they should flute their barrels and I say no unless you need to do it to make weight as the barrel will be shot out before you know it.

Some competitors ask whether they should flute their barrels and I say no unless you need to do it to make weight as the barrel will be shot out before you know it.

Fluting does not make the barrel stiffed than it was before fluting but it will be stiffer than unfluted barrel of the same length and weight. I did the physics on this a while a go and do not want to reproduce it here but I think varmintals.com has an excellant analysis of why a barrel is not stiffer after fluting, only stiffer than a barrel of the same length and weight that is not fluted.

Some competitors ask whether they should flute their barrels and I say no unless you need to do it to make weight as the barrel will be shot out before you know it.

^^^^^^^^^^^^^^^

As above, for a given mass (<-the important given), the flutes make a stiffer barrel in a specific direction, not in all angles using the bore as an axis. Has to do with the stress focused at the ridges. So it will be stiffer in certain angular rotations than others. From what I remember, the flutes concentrate the forces along the edge. Same as using a filet to reduce the stress in a corner. The filet, opposed to a sharp edge, spreads the forces along the radius of the filet. I don't know if you can measure the stiffness advantage of a fluted barrel without bending them so this might be academic. (I take that back, fix the breech end, hang 20lbs on the muzzle and using a dial indicator, measure the drop at the muzzle for various angles using the bore as the axis.)

Greater surface area aids in cooling but a lighter barrel will heat faster. They engineers are supposed to trade-off heating vs cooling effectiveness as there is an efficiency to be gained. So if it cools off faster (with flutes) than it heats (without the equivalent mass) you win. For some reason, I doubt most gunsmiths have the time or equipment to measure all this as even with all the "stuff" I have, I couldn't do it, maybe in software. I guess you can test this by inductively heating the barrel with a rod in the bore measuring the heating/cooling curve. So if some young whipper snapper is going to mechanical engineering graduate school they can take these two challenges and write their thesis.

so all in all, if I had to vote, I think after-market flutes add to the appearance and have very little to do with any practical application, either cooling or stiffness.

It makes for good arguments on the internet...

HAhahahahahahahah!

AI did a test (sniper magazine, 2013) with a regular barrel, and a fluted one.

They shot a round every 8 seconds. Believe they tested with .338LM

According to their results, fluting hurts accuracy. They then continue to theorize it's because the fluted barrel changes shape/warps more due to the irregular surface compared to a normal barrel.

So while it may be cooler, besides possibly having minor benefits in less perceived mirage, it's worse for accuracy.

QUOTE: Sniper / Tom Beckstrand

“ ….. One design change that resulted from AI’s exhaustive accuracy testing and development for the PSR is the removal of flutes from the barrel. Engineers at AI decided to isolate the barrel flutes to see what impact they had on accuracy. The Engineers attached a laser to the rifle’s receiver, the barrel, and scope. All three dots were zeroed to the same point, then they started shooting the rifle. They discovered that no matter which fluted barrel they used the dots would diverge as the barrel heated. The dots from the lasers mounted to the scope and receiver would stay in place, but the barrels laser would manifest a POI shift. The POI shift from the warming barrel greatly diminished when they used barrels without flutes. Engineers determined that the flutes never heated evenly causing the POI shift. I hope that the results of this test gain wide circulation through the Sniper and Long Range Shooting Communities to help eliminate some of the ignorance that surrounds the perceived advantages of barrel flutes. …..”

They shot a round every 8 seconds. Believe they tested with .338LM

According to their results, fluting hurts accuracy. They then continue to theorize it's because the fluted barrel changes shape/warps more due to the irregular surface compared to a normal barrel.

So while it may be cooler, besides possibly having minor benefits in less perceived mirage, it's worse for accuracy.

QUOTE: Sniper / Tom Beckstrand

“ ….. One design change that resulted from AI’s exhaustive accuracy testing and development for the PSR is the removal of flutes from the barrel. Engineers at AI decided to isolate the barrel flutes to see what impact they had on accuracy. The Engineers attached a laser to the rifle’s receiver, the barrel, and scope. All three dots were zeroed to the same point, then they started shooting the rifle. They discovered that no matter which fluted barrel they used the dots would diverge as the barrel heated. The dots from the lasers mounted to the scope and receiver would stay in place, but the barrels laser would manifest a POI shift. The POI shift from the warming barrel greatly diminished when they used barrels without flutes. Engineers determined that the flutes never heated evenly causing the POI shift. I hope that the results of this test gain wide circulation through the Sniper and Long Range Shooting Communities to help eliminate some of the ignorance that surrounds the perceived advantages of barrel flutes. …..”

Last edited:

I'm going to let the experts over at fulton armory speak on my behalf for this topic

Fulton Armory FAQ: What's the deal with fluted barrels? Do I want one?

Fulton Armory FAQ: What's the deal with fluted barrels? Do I want one?

It would be cool to see this on mythbusters. Here's my take on it. More surface area means faster cooling. I like heavier barrels but don't like the weight. Usually a #5 contour barrel fluted will weigh about what a #4 contour does without the flutes. Since I usually shoot 5 or so shots and let my barrel cool flutes make sense to me and that's why I flute my barrels. Most custom barrels these days shoot way better than most people can even shoot them. I'd like to try a helical fluted barrel.

Fulton's conclusion is inline with the statements above:

"Conclusion: the fluted barrel is significantly more rigid, and has much more surface area than a solid barrel of the same weight." (<-note the same weight).

Also, the leading paragraph where they enumerate the disadvantages of a fluted barrel are spot-on. I particularly like this one:

"Fourth, the very process of fluting can disturb the bore's internal, and actually diminish the quality of the bore. Again, you pay more for less."

Anyone that has ever cut steel knows that internal stress is never homogenous within a billet, especially in cold-rolled steel.

If I had an old fluted barrel, I would chuck up one end in a lathe, add 20lbs or less to the end, rotate the lathe to various positions and measure the deflection.

I wonder if this is what causes my sometimes diagonally striped groups as I am using a tri-fluted barrel? Being the sub-par shooter I am, I would like to think so.

"Conclusion: the fluted barrel is significantly more rigid, and has much more surface area than a solid barrel of the same weight." (<-note the same weight).

Also, the leading paragraph where they enumerate the disadvantages of a fluted barrel are spot-on. I particularly like this one:

"Fourth, the very process of fluting can disturb the bore's internal, and actually diminish the quality of the bore. Again, you pay more for less."

Anyone that has ever cut steel knows that internal stress is never homogenous within a billet, especially in cold-rolled steel.

If I had an old fluted barrel, I would chuck up one end in a lathe, add 20lbs or less to the end, rotate the lathe to various positions and measure the deflection.

I wonder if this is what causes my sometimes diagonally striped groups as I am using a tri-fluted barrel? Being the sub-par shooter I am, I would like to think so.

Reduce weight, Ive seen as much as 1 pound removed. average for a M40/MTU contour is 6-10oz depending on barrel length and type of fluting. More surface area for better cooling. if your worried about weight then just get a smaller contour barrel. if you already have a light weight barrel dont expect to loose much weight with fluting. Is the weight reduction or cooling effects worth the money? Probably not but, thats where the sexiness of fluting will be the deciding factor.

Cancelled the fluting for my 338 Norma Magnum build. MY primary goal for this gun is extreme accuracy, not coolness factor.

CNCjerry is correct that adding edges does add stiffness in certain directions. Thank you for explaining this. There are many structures that can be strengthened by cutting holes or patterns in it. The important thing is that there are obviously other factors at work here and this info exchange is pretty great ! Seriously interesting.

Don't flute your barrel or you might go blind !

Don't flute your barrel or you might go blind !

There are many structures that can be strengthened by cutting holes or patterns in it.

How about a few examples?

How about a few examples?

Sometimes, you can eliminate failure points by cutting away material so that load is diverted elsewhere in the structure. So technically, that's correct. But in general, and specifically with barrel flutes, removing material

1. weakens the barrel (both in bending and in hoop stress).

2. makes the barrel less stiff (it will bend more when you push on the end.

3. makes the barrel vibrate at a slower rate.

4. makes the barrel vibrate *differently*. Flutes can introduce a bias to certain directions (this can be good or bad and is not explored much for some reason).

1 is not a big deal unless you go crazy with flute depth, at which point it becomes a very big deal.

2 is also not a big deal, except that it is the cause of 3, which is a small deal because it changes the way the rifle moves when fired. I will not go as far as the above video that J_530 posted that says stiffer is always better, but generally, that would appear to be the case. Sometimes you want the right stiffness, not just more stiffness. 4 could be a big deal at the hyper-accuracy end of things. I could see asymmetric barrels helping with long range benchrest, for example. But you'd have to work out what you were trying to accomplish and how.

The video is also a little obtuse about the heat dissipation. While it's clear the author understands what's going on, he gets a little lost in detail. Surface area DOES speed up heat removal from the barrel. But not that much. Flutes are effectively very poorly designed cooling fins. If you wanted cooling fins, you'd make them annular, not length-wise, and you'd want lots of thin ones of a pretty significant height. It would be very George Jetson (and awfully impractical). The bigger effect of fluting losing mass, which causes the barrel to heat up more with each shot, but even that is pretty small.

All in all, flutes are a strange obsession in the shooting world. There are other factors with the same or greater effects that are hardly ever talked about. Like barrel length - nobody ever worries about the decreased stiffness (and increased heat dissipation) due to a longer barrel, but for flutes, it's all of a sudden a big conversation.

How about a few examples?

Without stirring up another controversy I recommend looking on Dan Lilja's web site under FAQs and he has a very good explanation

about what Fluting does for you.

He explains the weight savings and what it does for strength. He is one of the best barrel makers and knows his stuff so his explanation should answer

all of your questions.

www.Lilja@ rifle barrels.com

J E CUSTOM

How about a few examples?

Go to GeoVario LLC - Web Access barrels and look under FAQs. he has a very good description of what fluting actually does for a barrel.

J E CUSTOM

Without stirring up another controversy I recommend looking on Dan Lilja's web site under FAQs and he has a very good explanation

about what Fluting does for you.

I have read that more than once.

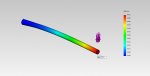

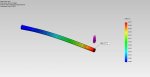

Here you go. I did a quick analysis that might help to clear things up. I took a 24 in barrel with a 6.5mm bore and fluted it. The barrel with flutes is 416 stainless material. I fixed the action end and applied a 25lb load at the other end. The barrel deflection at the end is .070"

I then removed the flutes left the material the same and the length the same just reduced the diameter of the barrel until it's weight was 5.1 lbs (same as fluted). Ran the analysis and the deflection was slightly more .072"

Therefore a fluted barrel is stiffer than a non fluted barrel of the same weight.

I then removed the flutes left the material the same and the length the same just reduced the diameter of the barrel until it's weight was 5.1 lbs (same as fluted). Ran the analysis and the deflection was slightly more .072"

Therefore a fluted barrel is stiffer than a non fluted barrel of the same weight.

Attachments

Last edited:

Yes if the weights the same the barrel with flutes will be stronger, but the barrel with the same contour will be stronger then the same contour with flutes.

I'm curious, was this a simulation? If so I'd be curious to know what happens with a Remington VTR style barrel vs flutes, none flutes but same weight, and non flutes same contour.

I'm curious, was this a simulation? If so I'd be curious to know what happens with a Remington VTR style barrel vs flutes, none flutes but same weight, and non flutes same contour.

Yes, it's a simulation in Solidworks. I've seen those VTR barrels, but I don't know the specs. I am guessing the VTR barrel will be slightly stiffer but when I get a second I'll run another study and post the results.

How about a few examples?

The simplest example is to drill a hole in the end of a running crack. The hole distributes the forces around the circumference and will help keep the crack from running. So there you go, taking away made it stronger.

Another example is if you leave a square block where there should be a filet, like when you forget to put the ball end tool in the machine, the square block will crack whereas if you were to filet the same corner taking away the material, it will be stronger. Hard to explain, but when you run a machine program up to an edge and specify to leave a bottom and side thickness on the last pass in anticipation of the ball tool doing the finish filet, you leave a stress point.

First thing Id say is look at benchrest rifles and see how many are fluted vs not fluted...

Im running a 1.25 straight barrel.... losts more surface area for cooling than a fluted varmint barrel...

Anytime you remove material it becomes weaker. If you take a 1 inch straight barrel it will be stronger than a 1 inch straight that has flutes if you bend them....

One thing that no one has mentioned is barrels have a spine... just like a fishing rod has a spine... if the barrel gets fluted incorrectly and this spine gets cut it will hinder accuracy of the barrel. Not my info here.. this is what my gunsmith told me and they are world renound for benchrest competitions...

As for me I dont flute. If I want a decorative barrel I find a design I like and have it bead blasted to engrave the prettiness.... where it gives me a polished stainless barrel contrasting a bead blast.. looks cool and isnt popular yet..

Im running a 1.25 straight barrel.... losts more surface area for cooling than a fluted varmint barrel...

Anytime you remove material it becomes weaker. If you take a 1 inch straight barrel it will be stronger than a 1 inch straight that has flutes if you bend them....

One thing that no one has mentioned is barrels have a spine... just like a fishing rod has a spine... if the barrel gets fluted incorrectly and this spine gets cut it will hinder accuracy of the barrel. Not my info here.. this is what my gunsmith told me and they are world renound for benchrest competitions...

As for me I dont flute. If I want a decorative barrel I find a design I like and have it bead blasted to engrave the prettiness.... where it gives me a polished stainless barrel contrasting a bead blast.. looks cool and isnt popular yet..

The simplest example is to drill a hole in the end of a running crack. The hole distributes the forces around the circumference and will help keep the crack from running. So there you go, taking away made it stronger.

Another example is if you leave a square block where there should be a filet, like when you forget to put the ball end tool in the machine, the square block will crack whereas if you were to filet the same corner taking away the material, it will be stronger. Hard to explain, but when you run a machine program up to an edge and specify to leave a bottom and side thickness on the last pass in anticipation of the ball tool doing the finish filet, you leave a stress point.

Are you confusing fatigue resistance with ultimate strength?

Are you confusing fatigue resistance with ultimate strength?

No, actually I was being somewhat of a wise ass as I don't necessarily agree with the statement above about removing metal to make it stronger, but jumped to the challenge.

Fatigue has to do with flex, stress, compression, expansion, etc which are components of ultimate strength in my book. But if you were to cut a slot in a beam and run it thru FEM/FEA analysis as was done with the barrel, above, it will fail more quickly with square corners than round, even if you made the slot deeper to account for the radius of the filet, within reason. Not in all cases, but in the greater number of them. So yes, I can see where taking away metal, in the narrow defined case, will improve both fatigue and ultimate strength but not in all cases.

The filet example is the best, as in the example I gave where you leave the unfinished side/bottom of a pocket. A cut out tab in that case will bend and fracture more readily at the sharp joint where the forces are concentrated, most of the time, unless you design it that way, then it won't.

Also, in the barrel FEM model, it would be interesting to rotate the barrel to various angles as the force distribution now concentrated in the flute edges have to come from somewhere and that means in certain axial (bore) rotations the fluted barrel should be weaker. I can't remember and never studied it in depth, only worked with Bethlehem Steel for about 6yrs on quality related statistical analysis and we left all that to the PHDs. If this was posted up on CNCZONE all the Dr.s would have a field day.

And I just noted Ducks & Bucks comment on the spine, yes, there ya go, a fluted barrel will have multiple spines and it should be mounted to result in a flex up at the muzzle so the bullet always leaves at the highest muzzle flex, or so I've been told.

At least this thread has more constructive input and comments from smart people than when I was in a debate on archerytalk over the color of string making an arrow faster. And just to note, the strings had an immeasurable difference in weight.

Yes, it's a simulation in Solidworks. I've seen those VTR barrels, but I don't know the specs. I am guessing the VTR barrel will be slightly stiffer but when I get a second I'll run another study and post the results.

Cool thanks, I don't have one but I was just curious. If it's to much trouble don't worry about it.

I think it's safe to say, for an all out competition rifle used for BR, it may be best to not flute, but for other rifles that have some beef, fluting will cut some weight, and assuming done right, little negative effect will be seen on accuracy. Not sure if the 'Cooling' benefit is significant, tests could determine.

In the end, if one wants to flute, for looks or weight specs, it's more a personal choice. I think the diff in accuracy is more up to the shooter, conditions, and load than if a bbl if fluted. I have owned and had built both. Both shot well.

In the end, if one wants to flute, for looks or weight specs, it's more a personal choice. I think the diff in accuracy is more up to the shooter, conditions, and load than if a bbl if fluted. I have owned and had built both. Both shot well.

Some posters are mixing up material strength and stiffness. Standard stiffness analysis states bending stiffness is equal to the product of the elastic modulus E and the area moment of inertia I. The elastic modulus is an intrinsic property of the material so it will be the same for a fluted and unfluted barrel of the same material. The moment of inertia is driven by the cross-sectional shape and dimensions. For barrels of the same contour the moment of inertia is greater for the unfluted barrel, that is the only way the math will work out that is why unfluted barrels are stiffer when they start out from the same contour. This is straight physics that has been verified and tested for a long time, and physics is really hard to argue with and you always lose. This is a standard exercise for a 2nd year mechanical engineer.

I doubt Mythbusters would waste time and money testing a well known result known by most mechanical engineers and others.

I doubt Mythbusters would waste time and money testing a well known result known by most mechanical engineers and others.

^^^^^^^^^^*^

Remember when I mentioned those process PHDs how they always made us commoners look like idiots?

Well done, Wade. Maybe you can comment on whether a fluted barrel has a spine and if it would make sense to orient it in a specific direction? Also was wondering if the length of a barrel matters given a twist ratio and if flutes would have an impact? It would be nice to have a lightweight, neutral barrel that wasn't load sensitive. In barrels, it seems like mass solves all problems.

Remember when I mentioned those process PHDs how they always made us commoners look like idiots?

Well done, Wade. Maybe you can comment on whether a fluted barrel has a spine and if it would make sense to orient it in a specific direction? Also was wondering if the length of a barrel matters given a twist ratio and if flutes would have an impact? It would be nice to have a lightweight, neutral barrel that wasn't load sensitive. In barrels, it seems like mass solves all problems.

I think it's safe to say, for an all out competition rifle used for BR, it may be best to not flute, but for other rifles that have some beef, fluting will cut some weight, and assuming done right, little negative effect will be seen on accuracy. Not sure if the 'Cooling' benefit is significant, tests could determine.

In the end, if one wants to flute, for looks or weight specs, it's more a personal choice. I think the diff in accuracy is more up to the shooter, conditions, and load than if a bbl if fluted. I have owned and had built both. Both shot well.

Since this gun is 338 Norma Magnum, weight is a good thing.

The shoulder I save will be my own.

^^^^^^^^^^*^

Remember when I mentioned those process PHDs how they always made us commoners look like idiots?

Well done, Wade. Maybe you can comment on whether a fluted barrel has a spine and if it would make sense to orient it in a specific direction? Also was wondering if the length of a barrel matters given a twist ratio and if flutes would have an impact? It would be nice to have a lightweight, neutral barrel that wasn't load sensitive. In barrels, it seems like mass solves all problems.

My intent was not to insult anyone I was just trying to get us out of the noise and apply physics to the problem at hand. I do not see any impact of fluting a spined barrel, they are all spined to one degree or another.

If I had the recipe to a lightweight neutral barrel that was not load sensitive I would probably be marketing my magic barrels. In many applications mass is a good thing.

Similar threads

- Replies

- 1

- Views

- 191

- Replies

- 7

- Views

- 577

- Replies

- 24

- Views

- 1K

- Replies

- 2

- Views

- 318