Hi,

I bought a used 5.56 gun (1500 rnds thru) and after brief inspection and shooting 1-200 rounds through it I figured I clean it throughly to see what is up with the barrel.

During cleaning process I could feel my brush had a lot more friction near the chamber. The reason were copper bits that had sharp edges to them

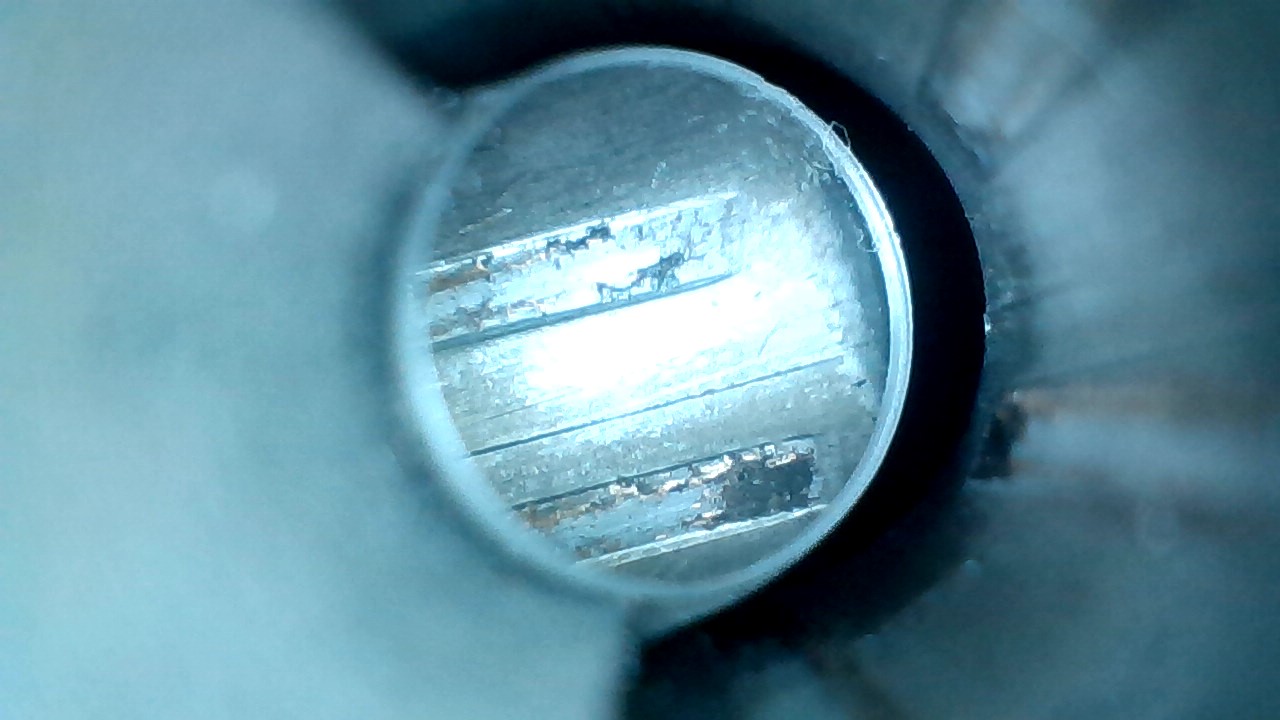

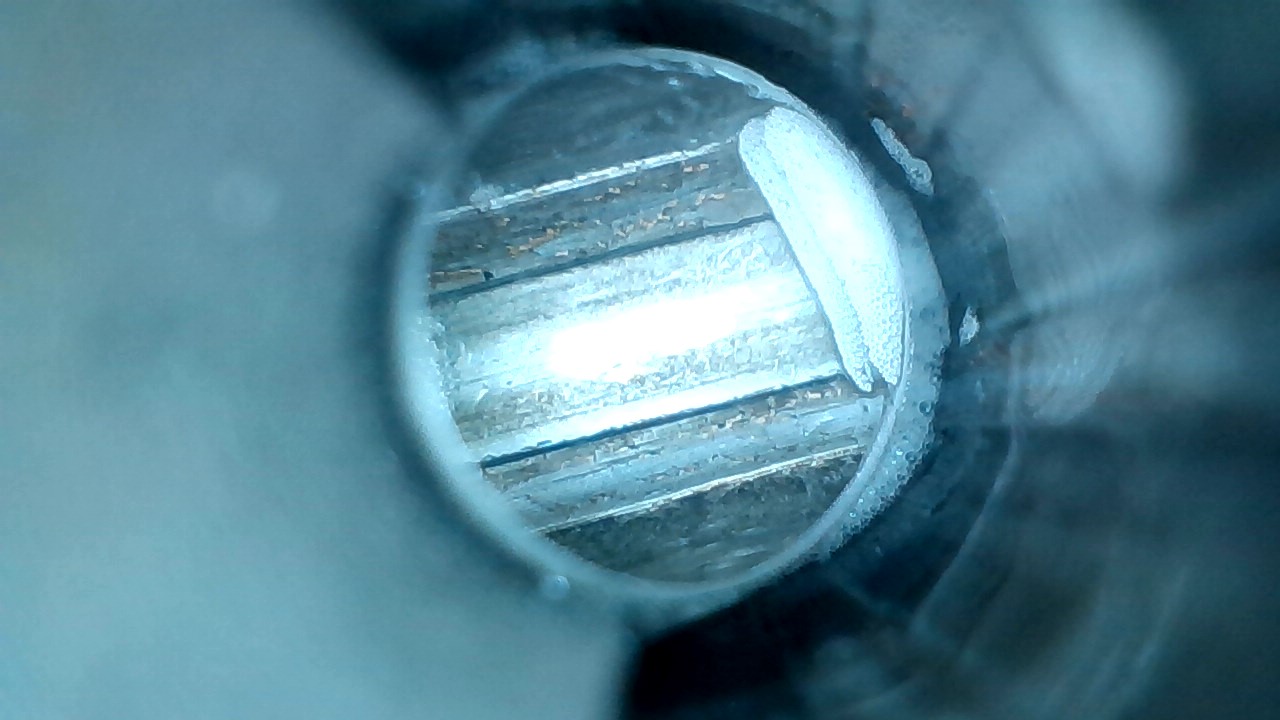

But I continued and really cleaned and borescoped it and it showed me that the barrel inside was chipping after the chamber.

Few images of the ragged copper bits:

Video of the cleaned bore:

I now have total understanding of the gun's condition but I wonder..

How should I go about to re-copper the gun? Is there any preferred rhytm to best get an even copper fouling? Because the previous copper deposit was not smooth at all.

I have a feeling I am overthinking this but I would like to get the barrel conditions the best I can.

Should I just go as I tend to and just blast few mags for starters?

I bought a used 5.56 gun (1500 rnds thru) and after brief inspection and shooting 1-200 rounds through it I figured I clean it throughly to see what is up with the barrel.

During cleaning process I could feel my brush had a lot more friction near the chamber. The reason were copper bits that had sharp edges to them

But I continued and really cleaned and borescoped it and it showed me that the barrel inside was chipping after the chamber.

Few images of the ragged copper bits:

Video of the cleaned bore:

I now have total understanding of the gun's condition but I wonder..

How should I go about to re-copper the gun? Is there any preferred rhytm to best get an even copper fouling? Because the previous copper deposit was not smooth at all.

I have a feeling I am overthinking this but I would like to get the barrel conditions the best I can.

Should I just go as I tend to and just blast few mags for starters?