When you build a rifle and you know all the components that go into the build diagnosing problems becomes really easy.

Diagnosing problems is based on assumptions based on facts and experience. The big elephant in the room - the shooter, is looked at first. Powerful cartridges require more from the shooter. So, can the shooter handle the recoil? If the shooter is experienced with large cartridges then there might be a problem with the rifle. Simple process of elimination. And so on...

Then to the rifle. Assuming (but tested assumptions) that the rifle is put together correctly the next question is - was there a gunsmith involved, and if so, did that person have a good track record, and most importantly, experience with chambering the particular cartridge?

Diagnose from most likely to less likely. In my personal experience it tends to go that way. The latest problem I personally encountered was the result of a problem with the contact between the stock and the rear bag. Way down the list but it did not take very long to find.

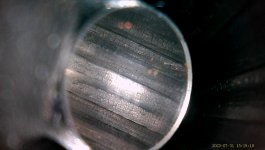

All that said and done, the barrel is usually the culprit. And that includes the gunsmith if there was one involved.

Diagnosing problems is based on assumptions based on facts and experience. The big elephant in the room - the shooter, is looked at first. Powerful cartridges require more from the shooter. So, can the shooter handle the recoil? If the shooter is experienced with large cartridges then there might be a problem with the rifle. Simple process of elimination. And so on...

Then to the rifle. Assuming (but tested assumptions) that the rifle is put together correctly the next question is - was there a gunsmith involved, and if so, did that person have a good track record, and most importantly, experience with chambering the particular cartridge?

Diagnose from most likely to less likely. In my personal experience it tends to go that way. The latest problem I personally encountered was the result of a problem with the contact between the stock and the rear bag. Way down the list but it did not take very long to find.

All that said and done, the barrel is usually the culprit. And that includes the gunsmith if there was one involved.

Last edited: