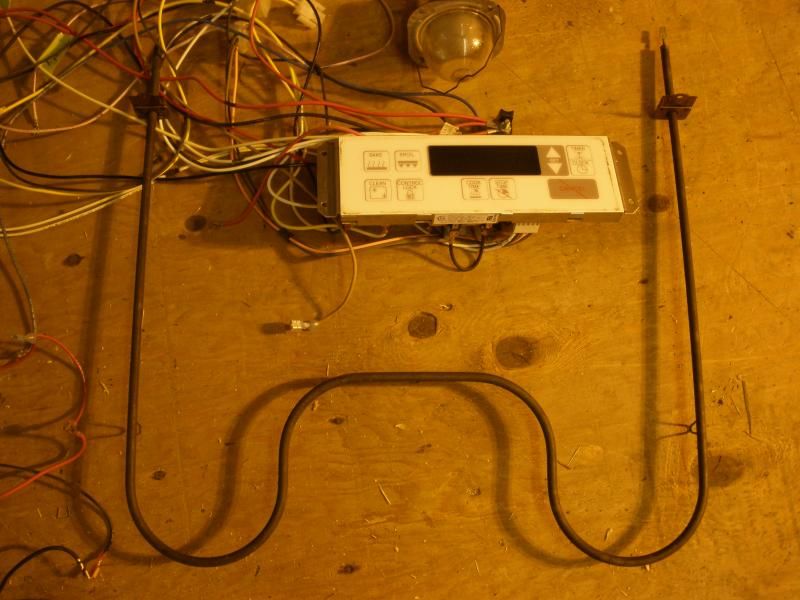

Well, anything worth doing is worth doing on a grand scale. I set out to build a paint oven for our stock manufacturing and painting targets. What we needed was a large oven, enough to bake multiple actions and stocks simultaneously. First, I found a LARGE cabinet, which measures 8'x3.5'x3.5' and is 1/8" steel with a full size door. It was actually the computer box that housed Melltrum controls for some of our other automated controls in the shop that we had retired, perfect donor for a mammoth oven. I figured I would post pics of the project as it progresses, it will be a fairly fast transition since it is planned to be in full use in 14 days or less. For electronics, I am using a digital oven 220v control panel and heating element.

Here is a pic of the housing, more pics and updates will follow

Here is a pic of the housing, more pics and updates will follow