I have a PTG Tactical bolt knob for my SA 700 I need to install, and was wondering if anyone knew where I could rent a jig to do it in a lathe or mill. My buddy's a machinist, but he said he has no way to follow the angle of the handle unless he makes a jig. Any ideas?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Bolt handle threading jog rental?

- Thread starter chefcam864

- Start date

Send it to a smith that already has the tooling. I doubt if anyone here will rent out their jig for threading bolt handles in a lathe. Too many things that could go wrong.

I have a PTG Tactical bolt knob for my SA 700 I need to install, and was wondering if anyone knew where I could rent a jig to do it in a lathe or mill. My buddy's a machinist, but he said he has no way to follow the angle of the handle unless he makes a jig. Any ideas?

Just have him bore a .700" hole in a piece of plastic, aluminum or steel and split it. Guess that amounts to a jig but it's simple and it works.

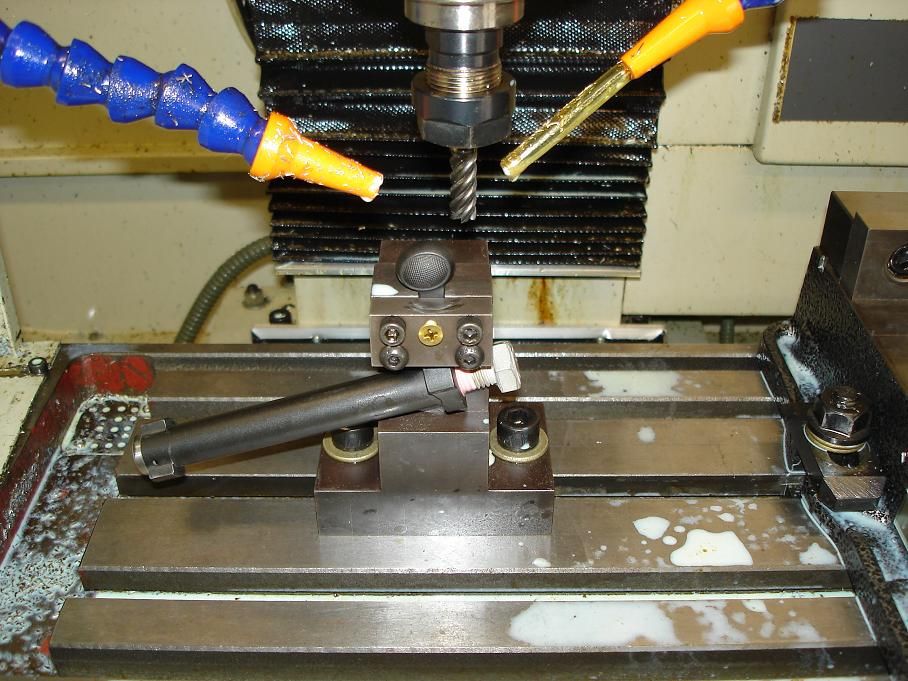

Never thought about doing it in a lathe. My mill has a computer drive so it will cut the OD as needed. What kind of mill does your machinist have?

Last edited:

I'm not sure what kind of mill, but it's CNC. He's going to write a program to machine the factory knob to a boss and thread it. The problem is that my bolt handle has a slight angle to it ( like most Remy handles), and the he's gonna have to machine the boss 90 degrees to the receiver because he can't chuck the bolt in his vice at the angle. Now I'm no machinist, so if what I'm saying sounds stupid, that's just my ignorance not his. He said he would chuck it in an index head, which he described as kind of like a 3-jaw chuck, but he couldn't follow the angle of the handle. The factory knob is also at a 90 degree angle to the receiver, but most of the pics of tactical bolt knob installs are done at an angle that leaves the knob slightly swept back and inline with the bolt handle. Am I making a bit of sense?

^ I've been thinking about doing it that way if he cant machine it.

I can email you some pics to share w/ your machinist if you'd like. Looked into posting pics here again and remember the pain I had last time. Gonna have to prove something to go thru that again. I'm not too good with computers.

He got it done for me, and it looks pretty good. I just had to use a file to round the end of the handle up blend it with the knob. Here are a few pics of it after paint.

I was happy with the way it turned out. He was able to follow the angle of the handle after all. I have less than $30 in the handle and install, so I'm pleased with that to say the least. The $6.99 PTG Tactical knob feels and looks fantastic! It's a definite

alternative to spending $40 on a badger...

Her's a better close up

I painted the handle in flat-black AlumaHyde II, but they look mismatched in the photo.

alternative to spending $40 on a badger...

Her's a better close up

I painted the handle in flat-black AlumaHyde II, but they look mismatched in the photo.

Just have him bore a .700" hole in a piece of plastic, aluminum or steel and split it. Guess that amounts to a jig but it's simple and it works.

Never thought about doing it in a lathe. My mill has a computer drive so it will cut the OD as needed. What kind of mill does your machinist have?

i'd recommend holding the handle, not the bolt body.

That's a much better approach considering how easy they come off. Just offering a simple holding solution for a 1 off.

Show off!!

For setting up a one-off, it doesn't take anything more than a set of V-blocks to clamp the bolt body in the vise and a couple basic measurements to figure out the setup angle. Hell - scribe a line down the center of the handle, line it up by eyeball, and it'll be good enough for the intended purpose (not advocating that approach, but simply acknowledging that it'd get the job done to the satisfaction of most users).

I agree that holding the handle and not the bolt body is preferable, but I'd also think that if the solder joint were to let go during the machine process, then it'd also eventually let go in the field. I'd be pissed if it happened in the shop, but less so than if I happened when I was actually using the rifle.

I think the last one I did took maybe 15 minutes to setup and cut with a 11/16" OD (5/16" ID) hollow end mill.

I agree that holding the handle and not the bolt body is preferable, but I'd also think that if the solder joint were to let go during the machine process, then it'd also eventually let go in the field. I'd be pissed if it happened in the shop, but less so than if I happened when I was actually using the rifle.

I think the last one I did took maybe 15 minutes to setup and cut with a 11/16" OD (5/16" ID) hollow end mill.

By the time you pay shipping twice, and a rental fee, you might has well just buy the tool from Dave Kiff. It seems his stuff resells on eBay for damn near retail, so if you don't want to keep it, you'll probably recuperate the vast majority of your money.

Just to rub it in, this is where I'll be trying out the new knob in the field tomorrow morning:

Hallowed ground indeed...

Hallowed ground indeed...

Anyone here know of a trusted Gunsmith who can attach a factory Remington 700 bold handle to a bolt ?

I do around 20+ a week.

That particular bolt is at your shop now being fluted. Had I seen the group buy before I started this, I would have had you guys do the knob as well.

I think the last one I did took maybe 15 minutes to setup and cut with a 11/16" OD (5/16" ID) hollow end mill.

Any ideas where I might find a hollow end mill for this purpose? Are they called something else? I can't seem to find them.

Any ideas where I might find a hollow end mill for this purpose? Are they called something else? I can't seem to find them.

I believe you are looking for an annular cutter.

Rotabroach Annular Cutters for Mag Drills, Sheet Metal, and Industrial Applications

Similar threads

- Replies

- 8

- Views

- 991

- Replies

- 19

- Views

- 2K