Any thoughts about Annealing your brass before resizing it to make it a little more formable? I didn't see where you said how many firings you had on the brass that split the Die...

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can't stop breaking sizing dies !

- Thread starter Florentoutang

- Start date

Did I say his chamber is cut wrong?

What is cracking his die is outward pressure from the case being sized, not from the shell holder pushing on the bottom of the die.

Then I am not sure why you responded the way you did to me, as I never suggested it was due to contact with the shell holder, just that the die was adjusted too low. The OP needs less confusion, not more, and his current idea to fire form then measure pre and post resize and adjust until 0.002” shoulder setback is a great next step. He doesn’t need to setback and rechamber his barrel with a tighter chamber as you mentioned, unless we find its oversized which is very unlikely vs. poorly adjusted dies.

You’re the one that’s confused. Adjusting the die too low does not cause it to crack. That is ridiculous. What causes a die to crack is excessive sizing pressure. Do you even understand how this shit works?

Man this thread has been a dumpster fire from the start. I died a little inside when I saw his post about measurements. I told him a month ago he was sizing his brass too much and causing excessive force on his die. .0115 headspace, ffs I'd advise the dude to either buy some factory ammo if he can or just stop altogether.You’re the one that’s confused. Adjusting the die too low does not cause it to crack. That is ridiculous. What causes a die to crack is excessive sizing pressure. Do you even understand how this shit works?

Or he can get bigger 1 1/4-12 dies and a press to match. But a tighter chamber and smaller brass is much easier to size. I run euro rifles and they all have fat chambers that are almost incompatible with American dies.

I think that maybe you are the one that is confused. Do you not think that sizing his brass headspace down by over 0.010” would cause excessive sizing pressure. That brass has to go somewhere. By your own definition of the problem you are supporting his argument.You’re the one that’s confused. Adjusting the die too low does not cause it to crack. That is ridiculous. What causes a die to crack is excessive sizing pressure. Do you even understand how this shit works?

But please, do go on. After all, we all realize that you and you alone can be correct on the subject of reloading.

I think that maybe you are the one that is confused. Do you not think that sizing his brass headspace down by over 0.010” would cause excessive sizing pressure. That brass has to go somewhere. By your own definition of the problem you are supporting his argument.

But please, do go on. After all, we all realize that you and you alone can be correct on the subject of reloading.

This is your least intelligent post to date.

An 1-1/4" die might help but I'm not sure what the die size has to do with blindly not measuring anything, throwing in a max charge, and fuckin lettin er rip. I'm surprised he hasn't grenaded his rifle yet. I mean you can size 300 Norma Magnum in the dies he is destroying if you have half a clue what you are doing.

Gonna go back a bit to the last actual data.

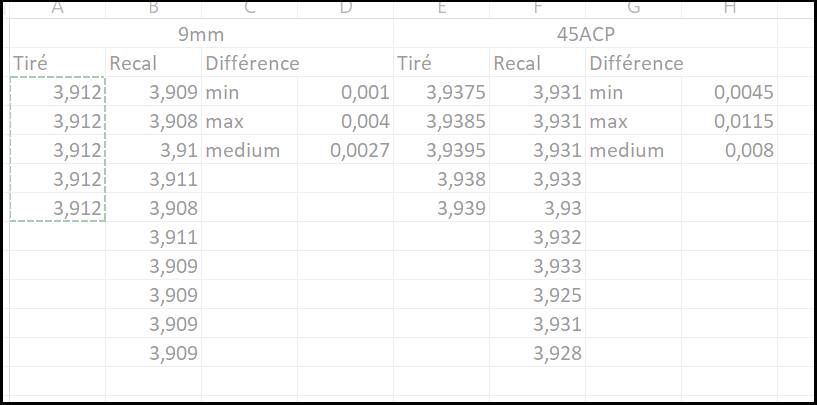

Whats Tire? Whats Recal? I assume fired and sized? Why do you have 5 of the tire and 10 of recall? That signals me that its not fired and sized since theres no consistent before and after. SO what is it?

If it is and you just didnt care to write the fired dimension 5 more times then I get it, its just not clear.

Whats astonishing to me is that the 9mm case is consistent and the 45 case measurements are wild. I suspect thats due to the 45 case being just about as wide as the rounded shoulder leading to the inconsistency. I would be inclined to believe the 9mm case numbers of .001" min and .004 max as that seems reasonable to me for a locked down die compared to .011 from the 45 case.

Can you confirm that I am on the right track, @Florentoutang ? If I am and you are sizing the cases only .001-.004 then the case shoulder set back (or cartridge headspace clearance) is not your issue, at least it shouldnt be.

What are some base/case head diameters of the fired vs sized cases? Diameters right in front of the extractor groove?

I dont know what to think of those measurements or what they even actually are. And I think thats why most people are flying right past them.I Made some measurements of that whith 2 cases I have : 9mm para and 45 ACP. These two cases permits me to measure at the smallest point of the shoulder (9mm) and at the middle of the shoulder (45 auto). Unfortunately, I am not able to measure the base of the shoulder.

Do not take a look on the value, I did not zeroed my tool. Just take a look on the differences.

I compilated all my measurements in excel to have a clear view of what's happening, you should have a picture.

What do you think about that ?

Whats Tire? Whats Recal? I assume fired and sized? Why do you have 5 of the tire and 10 of recall? That signals me that its not fired and sized since theres no consistent before and after. SO what is it?

If it is and you just didnt care to write the fired dimension 5 more times then I get it, its just not clear.

Whats astonishing to me is that the 9mm case is consistent and the 45 case measurements are wild. I suspect thats due to the 45 case being just about as wide as the rounded shoulder leading to the inconsistency. I would be inclined to believe the 9mm case numbers of .001" min and .004 max as that seems reasonable to me for a locked down die compared to .011 from the 45 case.

Can you confirm that I am on the right track, @Florentoutang ? If I am and you are sizing the cases only .001-.004 then the case shoulder set back (or cartridge headspace clearance) is not your issue, at least it shouldnt be.

What are some base/case head diameters of the fired vs sized cases? Diameters right in front of the extractor groove?

Last edited:

An 1-1/4" die might help but I'm not sure what the die size has to do with blindly not measuring anything, throwing in a max charge, and fuckin lettin er rip. I'm surprised he hasn't grenaded his rifle yet. I mean you can size 300 Norma Magnum in the dies he is destroying if you have half a clue what you are doing.

I agree. But consider this: You should not have to down load your rounds to prevent your sizing dies from cracking. I get that cases subjected to high pressure are difficult to size and that is one of the factors causing the die failure, but we’re talking about an ELR cartridge. People aren’t going to run that slow.

And another thing: I notice many people jump into reloading big rounds without first learning on small rounds. This causes all sorts of problems.

I

Wait, all of those measurements were on the same piece of brass? I still assume the variance in the 45 case is due to it being as wide as the shoulder so youre having to measure on that rounded shoulder, not good.Non hypothetical measurements, measurements on only 2 brass, one fired one resized.

On my measurements you can see fluctuations then, I calculated average, min and max differences.

A solid comparator will hep you get more consistent measurements as will practice to develop a consistent touch and practice of spinning the round while you settle it down to it lowest consistent point.

.004 of base sizing is a lot. With a round that fat and with the die material limited in how thick it can be by the external threads I can see that being an issue, the die material only has so much tensile strength and so the fatter the round and the thinner the die material the easier it breaks.Measuring the base of the case was the first thing I dit when I saw that I was not able to chamber back. I have a difference around 0,003", 0,004" maximum.

If I cannot chamber, I was forced to full full full resize to be able to chamber, because of the bottom of the brass.

Ill be damned, looks like 918v read the posts too and jumped to whats probably my same conclusion eventually, a mismatch between die and chamber, a new chamber to match the existing die or a new die to match the existing chamber if it is the problem. But I want some real measurements of those bases first. Maybe Ill get to those posts next lolHis cases are too fat after firing and the die walls are too thin to handle the pressure from sizing. If he had a tighter chamber his brass would come out skinnier and would be easier to size.

Are we really sure that the shoulder is getting pushed back that far? Im not.I think that maybe you are the one that is confused. Do you not think that sizing his brass headspace down by over 0.010” would cause excessive sizing pressure. That brass has to go somewhere. By your own definition of the problem you are supporting his argument.

But please, do go on. After all, we all realize that you and you alone can be correct on the subject of reloading.

I agree with all that but I also know people shooting ELR measure, everything, always.I agree. But consider this: You should not have to down load your rounds to prevent your sizing dies from cracking. I get that cases subjected to high pressure are difficult to size and that is one of the factors causing the die failure, but we’re talking about an ELR cartridge. People aren’t going to run that slow.

And another thing: I notice many people jump into reloading big rounds without first learning on small rounds. This causes all sorts of problems.

I

You’re the one that’s confused. Adjusting the die too low does not cause it to crack. That is ridiculous. What causes a die to crack is excessive sizing pressure. Do you even understand how this shit works?

How do you adjust how much sizing a FL die does to a piece of brass? What increases force (read: pressure) on die walls when resizing brass?

I assure you, I understand how this works. There are WAY too many variables right now to make any assumptions about the root cause of this problem. It's just a heck of a lot easier to adjust a die and see what happens vs. setting back a barrel and cutting a new chamber when you have no way of knowing what the problem is, yet. We have no idea how anything is setup because nobody has gotten anywhere near the information they need to determine what is actually going on.

The chamber could be cut quite large, and the dies may be quite small, but with another owner having had none of these issues, that's *less likely* than a simple die misadjustment with someone who clearly is missing a lot of fundamentals. Just measuring the brass after fire forming, then adjusting die for proper sizing, and seeing how things look is the appropriate next step based on everything we've seen so far. Not jumping to setting back a barrel and cutting a new chamber...

This thread is derailed enough, I hope the OP has good luck with the next steps, he had a good plan in place before we went down this rabbit hole. I'll quit adding to the derailment, apologies OP.

“How do you adjust how much sizing a FL die does to a piece of brass? What increases force (read: pressure) on die walls when resizing brass?”

In the OP’s case, it is the amount of case diameter reduction at the base. In the OP’s case, whether he bumps the shoulder .002” or .012” will have no measurable effect on the amount of base sizing the die will accomplish.

He’s sizing the base of his cases .004” and bumping the shoulder .004”-.011”. That’s not so extreme as to crack a sizing die. If he were to set his die to get a solid repeatable .002” on the shoulder bump I bet his die would still crack.

There is a huge difference in trying to size .004” on a .300 NM case than on something like a 308. The case walls on a NM case are much thicker. It’s simply too much case for a 7/8x14 die unless you run a tight chamber in which case you’re not sizing very much.

In the OP’s case, it is the amount of case diameter reduction at the base. In the OP’s case, whether he bumps the shoulder .002” or .012” will have no measurable effect on the amount of base sizing the die will accomplish.

He’s sizing the base of his cases .004” and bumping the shoulder .004”-.011”. That’s not so extreme as to crack a sizing die. If he were to set his die to get a solid repeatable .002” on the shoulder bump I bet his die would still crack.

There is a huge difference in trying to size .004” on a .300 NM case than on something like a 308. The case walls on a NM case are much thicker. It’s simply too much case for a 7/8x14 die unless you run a tight chamber in which case you’re not sizing very much.

“How do you adjust how much sizing a FL die does to a piece of brass? What increases force (read: pressure) on die walls when resizing brass?”

In the OP’s case, it is the amount of case diameter reduction at the base. In the OP’s case, whether he bumps the shoulder .002” or .012” will have no measurable effect on the amount of base sizing the die will accomplish.

He’s sizing the base of his cases .004” and bumping the shoulder .004”-.011”. That’s not so extreme as to crack a sizing die. If he were to set his die to get a solid repeatable .002” on the shoulder bump I bet his die would still crack.

There is a huge difference in trying to size .004” on a .300 NM case than on something like a 308. The case walls on a NM case are much thicker. It’s simply too much case for a 7/8x14 die unless you run a tight chamber in which case you’re not sizing very much.

I completely understand where you are coming from, but I also do not have the same faith in these measurements being anywhere near correct to advocate a radical solution until proper measurements are performed and dies are adjusted properly. If the base is still showing a 0.004” reduction when the die is setting back shoulders 0.002” then it becomes an obviously different situation. The brass has to flow somewhere, and I have seen cracked dies due to improper adjustment, not chamber and brass sizing. I was merely suggesting die adjustment be step one before rechambering. Seems we are on the same page! Good luck OP.

something screwy with his initial load data....

says he used 91gn of 2217 with no pressure problems.

also says his preferred load is 86 to 89gn of 2225 but seems to be having pressure problems.

91gn of 2217 is a *MUCH* hotter load than 86gn of 2225, so wtf?

using "gordons reloading tool"

his 2217 load is over max pressure.

the tool doesnt have 2225 in the library, but vitavhouri 24n41 is equivalent according to adi... and his 86gn load should be quite moderate - BUT his (measured?) muzzle velocity is way higher than predicted.

I'm thinking that he doesnt know what pressure signs are, and (by some of his descriptions) his load is excessively hot - leading to way overstretched brass that he's trying to resize in a badly adjusted die thats overcamming the press distorting the frame causing the ram to apply pressure to the die very unevenly?

I'm wondering just how his entire reloading process goes, and how accurately he measures his powder etc - we've already seen reluctance to measure things.... plenty of people here seem to be trying to get him to get back to basics and measure and confirm setup.

says he used 91gn of 2217 with no pressure problems.

also says his preferred load is 86 to 89gn of 2225 but seems to be having pressure problems.

91gn of 2217 is a *MUCH* hotter load than 86gn of 2225, so wtf?

using "gordons reloading tool"

his 2217 load is over max pressure.

the tool doesnt have 2225 in the library, but vitavhouri 24n41 is equivalent according to adi... and his 86gn load should be quite moderate - BUT his (measured?) muzzle velocity is way higher than predicted.

I'm thinking that he doesnt know what pressure signs are, and (by some of his descriptions) his load is excessively hot - leading to way overstretched brass that he's trying to resize in a badly adjusted die thats overcamming the press distorting the frame causing the ram to apply pressure to the die very unevenly?

I'm wondering just how his entire reloading process goes, and how accurately he measures his powder etc - we've already seen reluctance to measure things.... plenty of people here seem to be trying to get him to get back to basics and measure and confirm setup.

Caming over on the die doesn't cause problems. Caming over on the base of the die eliminates problems you might get from your press flexing. The problem is usually once you get to the shell holder you are bumping the shoulder too much. Unless you use Redding Comp shell holders.

I know this post is old but read this thread. https://www.longrangehunting.com/threads/the-prc-die-problem.253223/

It will help you better understand what is going on

It will help you better understand what is going on

See attached SAAMI cartridge and chamber print. In your drawing, you said that your fired brass base diameter was 14,96 to 15,0x. In the SAAMI print, the max base diameter is 14,845. The base of your brass is at least 0,1150 mm (0.004 inches) oversize [(14,96 - 14,845)/25.4].

You said that your case overall length is 63,38 to 63,45. In the SAAMI print, the max case length is 63,30. Your brass is at least 0,08 mm (.003 inches) too long. [(63,38 - 63,30)/25.4]

You said that the length from base to beginning of the shoulder is 48,50 to 48,68. The SAAMI specification is 48,01. So your brass is at least 0,49 mm (0.019 inches) too long. [(48,50 - 48.01)/25.4]

I also looked at the diameter at the beginning of the shoulder. The SAAMI dimension is 14,344. You report that the small dimension is 14,23 - good but the larger dimension is 14,37 - not good.

I am not especially worried about the case overall length problem but the base diameter and base-to-shoulder dimensions are important. It would be asking a lot of a sizing die to reduce the base diameter by .004 or .005 inches. It would be asking a lot for a sizing die to reduce the shoulder length by .020 inches.

Is it possible that your brass was fired in a chamber that is both larger than your chamber (so your brass won't fit into your chamber) and much larger than your sizing dies? If true, you can either

You said that your case overall length is 63,38 to 63,45. In the SAAMI print, the max case length is 63,30. Your brass is at least 0,08 mm (.003 inches) too long. [(63,38 - 63,30)/25.4]

You said that the length from base to beginning of the shoulder is 48,50 to 48,68. The SAAMI specification is 48,01. So your brass is at least 0,49 mm (0.019 inches) too long. [(48,50 - 48.01)/25.4]

I also looked at the diameter at the beginning of the shoulder. The SAAMI dimension is 14,344. You report that the small dimension is 14,23 - good but the larger dimension is 14,37 - not good.

I am not especially worried about the case overall length problem but the base diameter and base-to-shoulder dimensions are important. It would be asking a lot of a sizing die to reduce the base diameter by .004 or .005 inches. It would be asking a lot for a sizing die to reduce the shoulder length by .020 inches.

Is it possible that your brass was fired in a chamber that is both larger than your chamber (so your brass won't fit into your chamber) and much larger than your sizing dies? If true, you can either

- buy new brass

- buy a barrel that fits your brass and a custom sizing die

- rechamber your barrel to fit this brass and buy a custom sizing die.

Attachments

Similar threads

- Replies

- 6

- Views

- 237

- Replies

- 41

- Views

- 2K