Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carbon Ring…is this one?

- Thread starter LC 6.5 Shooter

- Start date

If that's the mouth of a piece of brass at the top.....then yep. When you pull the brass back, you should see more carbon build up there.

Hard to tell from the contrast in the pic. But the carbon buildup in front of the transition into the freebore doesn't look too bad.

That might be a shadow, .... or heavy carbon.Is the dark black line at the neck to freebore transition carbon or just the transition?

Hard to tell from that picture. Might help if you started cleaning the barrel, and then checked again. The carbon ring will be more difficult to get rid of than the other fouling, so it should become obvious if you have one.

I had the same issue in a 6.5 AI barrel recently. I let it go close to 800 rounds without a cleaning (foolish of me), and started to get pressure signs, wild velocity spikes, and degradation of accuracy. Boretech C4 and a brush cleaned up the ring without too much difficulty.

I had the same issue in a 6.5 AI barrel recently. I let it go close to 800 rounds without a cleaning (foolish of me), and started to get pressure signs, wild velocity spikes, and degradation of accuracy. Boretech C4 and a brush cleaned up the ring without too much difficulty.

Ive got ~230-240 rounds on it. I clean with boretech c4 after every range session. Its been cleaned at least 5x’s since starting load development.Hard to tell from that picture. Might help if you started cleaning the barrel, and then checked again. The carbon ring will be more difficult to get rid of than the other fouling, so it should become obvious if you have one.

I had the same issue in a 6.5 AI barrel recently. I let it go close to 800 rounds without a cleaning (foolish of me), and started to get pressure signs, wild velocity spikes, and degradation of accuracy. Boretech C4 and a brush cleaned up the ring without too much difficulty.

I believe I took that pic on a dirty barrel when I first got the borescope to test it out. I have cleaned it good and checked it with it still having that dark line at the transition. I even tried soaking that in c4 a couple hours and then hitting it with a brass brush and it was still there.

Wet the area and let it sit overnight. Then wet/poly-brush/patch/wet with C4 again and let it sit 12 hours. Repeat for two more days then check.

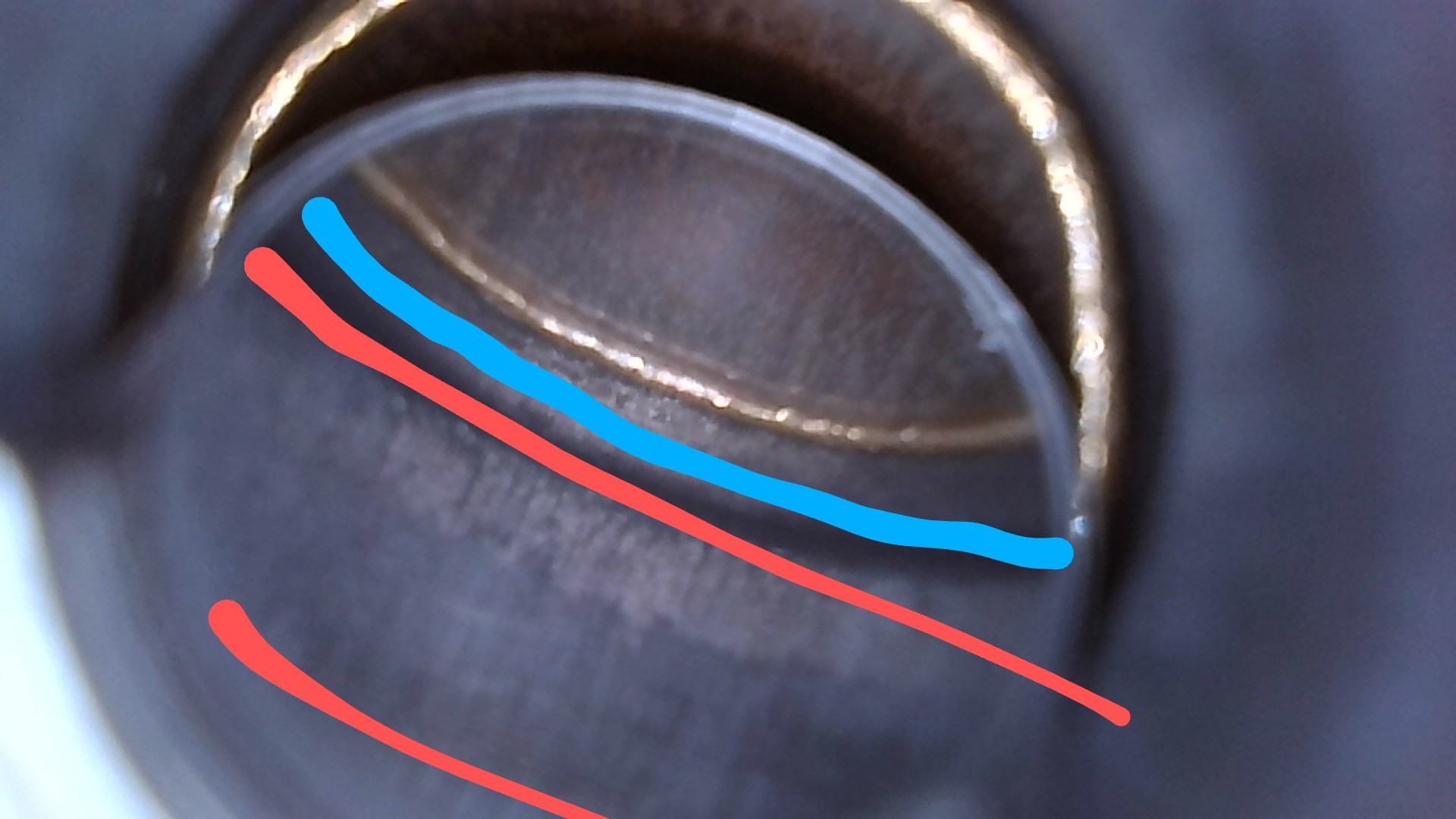

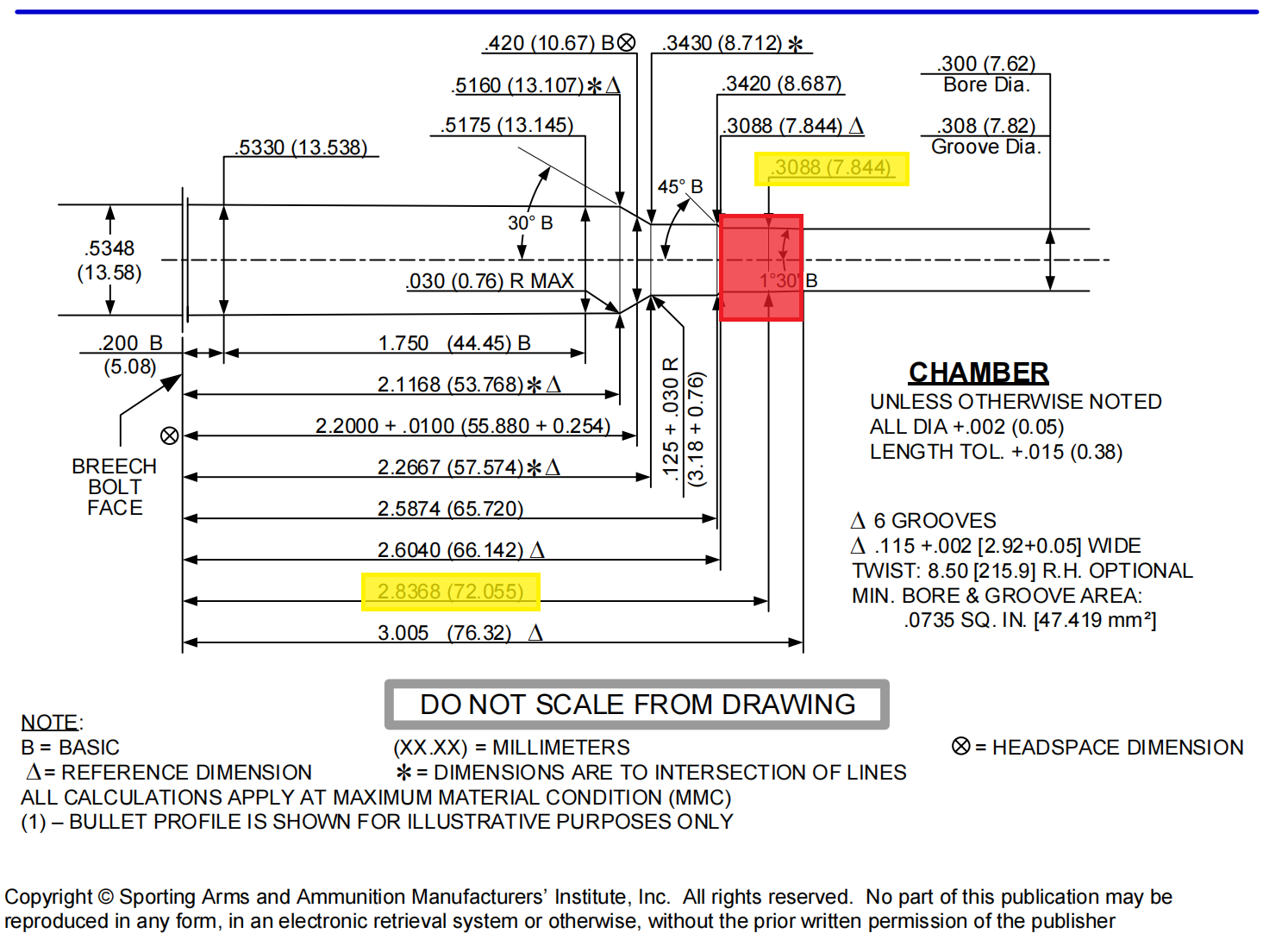

Here you go.. blue line is the end of the chamber and the start of the freebore.

Between the red lines is where you see a carbon ring form if your brass is trimmed properly.

Between the red lines is where you see a carbon ring form if your brass is trimmed properly.

Last edited:

So with that do you think there is a carbon ring in my barrel?Here you go.. blue line is the end of the chamber and the start of the freebore.

Between the red lines is where you see a carbon ring form if your brass is trimmed properly.

View attachment 8255525

Cant tell how hard the carbon is to tell if it would constitute a "ring" but thats definitely not a clean looking throat. Keep hammering more carbon on top of whats already there and youll have one soon enough if tis not already hardened.So with that do you think there is a carbon ring in my barrel?

I like to think of it as coal, you can have lignite (soft carbon deposits) that can be easily cleaned and moved etc. BUT if you take that soft lignite and put its carbon content to extreme heat and pressure you form the hardened for of coal called anthracite that is much tougher to deform.

Or graphite and diamonds, same shit, just pressed harder hotter longer making a more dense structure.

So you take your soft carbon fouling, press it to the barrel with extreme temps and pressure with each shot fired and just layer more and more on top of it making it press harder and harder with more and more and eventually that carbon in the throats going to get real stubborn and difficult to remove, thus the "ring" that stick around.

Without a case in the chamber, we might be able to see that area better. That is a good bit of carbon there and into the throat area. Lot of powder and small hole will do that and it will not take long either. I like to not let it build up. I'm not from the let'er eat til she don't want no more club.

I believe I took that pic with a dirty barrel. Ive got about 230 ish rounds and have cleaned it 4-5 times. I clean it after every range session. Ill do what I think is a good cleaning and get some more pics after without a chambered piece of brassWithout a case in the chamber, we might be able to see that area better. That is a good bit of carbon there and into the throat area. Lot of powder and small hole will do that and it will not take long either. I like to not let it build up. I'm not from the let'er eat til she don't want no more club.

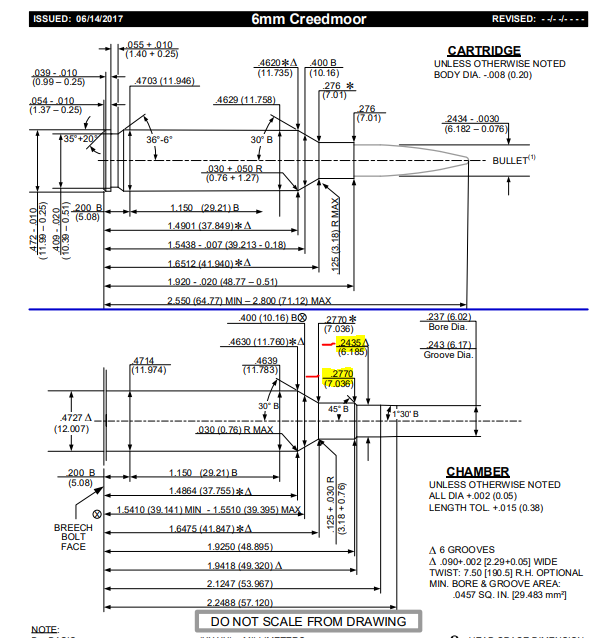

It’s just the transition. If you look at a chamber reamer diagram you will see it on there. It is the transition to the neck diameter to the throat diameter. Random reamer print I found below and your area of concern circled in red, but that “black line” is this transition.Is the dark black line at the neck to freebore transition carbon or just the transition?

Attachments

ThanksIt’s just the transition. If you look at a chamber reamer diagram you will see it on there. It is the transition to the neck diameter to the throat diameter. Random reamer print I found below and your area of concern circled in red, but that “black line” is this transition.

Did a thorough clean. Let boretech C4 soak in the neck/freebore area for 24+ hours. Scrubbed with 6.5 nylon brush. Patched out. Used simichrome to scrub freebore area. Cleaned with bore tech c4 again.

Used boretech copper on wet patches. Let it soak for an hour. Scrubber with nylon 6.5 brush. Patches till clean.

This remained in freebore area. Is that a carbon ring. It obviously didn’t clean up with methods done above.

Used boretech copper on wet patches. Let it soak for an hour. Scrubber with nylon 6.5 brush. Patches till clean.

This remained in freebore area. Is that a carbon ring. It obviously didn’t clean up with methods done above.

Attachments

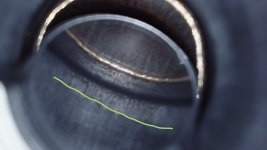

The carbon ring does NOT form in the freebore, it forms in front of the case mouth before the step up to the freebore. You are looking at hard carbon that won’t affect anything. You 100% do not have a carbon ring in that picture. If there was one starting to form it’s gone. Don’t under trim your brass and you won’t have to worry about one anytime soon. The green line is where it forms

Attachments

The carbon ring does NOT form in the freebore, it forms in front of the case mouth before the step up to the freebore. You are looking at hard carbon that won’t affect anything. You 100% do not have a carbon ring in that picture. If there was one starting to form it’s gone. Don’t under trim your brass and you won’t have to worry about one anytime soon. The green line is where it forms

Sorry but that is incorrect. Where you placed the green line is not the freebore/throat/lead. It is still in the chamber where his brass would be. Where your red arrow is, is where a carbon ring typically forms unless you are really overtrimming your brass.

Op and yes there typically will always be some discoloration there but it looks ring free to me. Another thread with a good diagram and pic for reference

The carbon ring does NOT form in the freebore, it forms in the chamber between the end of the case mouth and before the step up to the freebore hence why trimming brass too short exacerbates the problem. This area is where the green line is drawn albeit it is a little off because it’s just for reference but that is the general area. @Huskydriver Even your picture you posted says in the caption “with carbon ring formed at the end of the chamber neck area”Sorry but that is incorrect. Where you placed the green line is not the freebore/throat/lead. It is still in the chamber where his brass would be. Where your red arrow is, is where a carbon ring typically forms unless you are really overtrimming your brass.

Op and yes there typically will always be some discoloration there but it looks ring free to me. Another thread with a good diagram and pic for reference

Last edited:

If you let your brass grow you will mitigate the growth in the future. Do do you have the chamber print for your reamer used on your rifle? You can use that to get the specific trim length for your gun versus just using book data, if not, the same way you took a picture with the brass in the chamber in your first post, use the borescope in the same manor to find a piece of brass that gets close to the step up to the freebore with a little buffer, measure that piece, and then that is your trim length. The brass from your first pic is way too short. Let me see if I can find a good picture from the google for you, or if you have your chamber reamer print, post that and I’ll show you were to get your trim length from

Here is a comparison showing a better trim length vs your first picture. Note how much closer the case gets to the step up to the freebore. You do need to make sure it is not touching the transition however as that will cause you pressure problems too as it can essentially add a crimp. This is to slow the growth and size of the ring.

Attachments

Ok thanks. Speaking of pressure problems. Thats what got me down this rabbit hole chasing carbon rings in the first place.

The barrel is a proof carbon 20” 8 twist chambered in 22 creedmoor with 0.080” freebore. .257” neck.

When I first got it I ran it all the way to 42.7g of h4350 before seeing pressure signs. Heavy bolt lift. Ejector stamping.

Backed off to 41.7g as there was a velocity node there. Began having pressure issues. Very heavy bolt lift and ejector stamping so hard it was leaving a burr.

Ive had to back off to 38.9g currently and the other day it was pressuring up bad again.

Didn’t know if my Thunderbeast was causing it because it was worse with it on vs with it off. But thunderbeast dudes assured me peak chamber pressure happened way before anything at the muzzle.

A measure round is .254” so it doesnt seem like a tight neck.

No carbon ring.

I have no idea whats going on. This isnthe weirdest barrel Ive ever had and first time ever experiencing something like this.

The only thing I can think now is I just measured a fired case vs a sized case because I just sized last time where the die has been. I thought my should bump was 0.0015” but it is more like 0.005”.

Would that cause bolt thrust or some issue that was a false pressure sign?

The barrel is a proof carbon 20” 8 twist chambered in 22 creedmoor with 0.080” freebore. .257” neck.

When I first got it I ran it all the way to 42.7g of h4350 before seeing pressure signs. Heavy bolt lift. Ejector stamping.

Backed off to 41.7g as there was a velocity node there. Began having pressure issues. Very heavy bolt lift and ejector stamping so hard it was leaving a burr.

Ive had to back off to 38.9g currently and the other day it was pressuring up bad again.

Didn’t know if my Thunderbeast was causing it because it was worse with it on vs with it off. But thunderbeast dudes assured me peak chamber pressure happened way before anything at the muzzle.

A measure round is .254” so it doesnt seem like a tight neck.

No carbon ring.

I have no idea whats going on. This isnthe weirdest barrel Ive ever had and first time ever experiencing something like this.

The only thing I can think now is I just measured a fired case vs a sized case because I just sized last time where the die has been. I thought my should bump was 0.0015” but it is more like 0.005”.

Would that cause bolt thrust or some issue that was a false pressure sign?

Did you leave oily residue in your chamber from cleaning it? Was your brass still covered in lube? If so you didn’t get a good grip from the brass to the chamber wall this increased bolt thrust. After cleaning, and right before shooting I clean the chamber out with a bore mop and acetone, that way you don’t have any residual oil in there causing pressure issues

Also, velocity nodes don’t exist

For sure not on brass as it is wet tumbled after lubing and resizing. I usually use a chamber mop too after cleaningDid you leave oily residue in your chamber from cleaning it? Was your brass still covered in lube? If so you didn’t get a good grip from the brass to the chamber wall this increased bolt thrust. After cleaning, and right before shooting I clean the chamber out with a bore mop and acetone, that way you don’t have any residual oil in there causing pressure issues

Yes it does.The carbon ring does NOT form in the freebore, it forms in the chamber between the end of the case mouth and before the step up to the freebore hence why trimming brass too short exacerbates the problem. This area is where the green line is drawn albeit it is a little off because it’s just for reference but that is the general area. @Huskydriver Even your picture you posted says in the caption “with carbon ring formed at the end of the chamber neck area”

As several have tried to correct you on.

You are simply describing a dirty chamber.

I wish people would stop trying to change the meaning of terms to fit misconceptions.

If a carbon ring was located on the chamber mouth then how would it grow large enough to be impinging on the bullets bearing surface? It can’t.

Last edited:

The carbon ring does NOT form in the freebore, it forms in front of the case mouth before the step up to the freebore. You are looking at hard carbon that won’t affect anything. You 100% do not have a carbon ring in that picture. If there was one starting to form it’s gone. Don’t under trim your brass and you won’t have to worry about one anytime soon. The green line is where it forms

Back up the tip of the arrow a hair and there is where the carbon ring will be . Not in the chamber , As you can see, a Ring and then more carbon and fire cracking .

It grown in the gap between the end of the case mouth and the step up to the freebore. And when it grows large enough, it becomes thicker than the case neck thickness thus causing you to have to seat the bullets through it as the bullet enters the freebore. This is why trimming short brass makes the problem worse. I know people have tried to correct this but it is not entirely correct. If you have any documentation that supports your claim please share it, I’m not saying my mind can’t be changed but from everything I have seen, experienced and researched it supports the carbon ring grown in that gap.Yes it does.

As several have tried to correct you on.

You are simply describing a dirty chamber.

I wish people would stop trying to change the meaning of terms to fit misconceptions.

If a carbon ring was located on the chamber mouth then how would it grow large enough to be impinging on the bullets bearing surface? It can’t.

Here is just one article on the topic

www.reloadingallday.com

www.reloadingallday.com

What is Carbon Ring? How Do You Remove it?

Carbon ring Carbon ring is one of the more controversial topics when it comes to shooting. What really is it? Is it bad? How does it form? Does the carbon ring cause velocities to become erratic? Let's dive in and talk about what is going on and how to mitigate it. Let’s say in a scenario you...

www.reloadingallday.com

www.reloadingallday.com

@spife7980 here are three more videos that back up my claim. All saying the exact same thing I have been

So you and other idiots really think that the carbon ring is where you get enough carbon built up in the chamber to go beyond the thickness of the brass and then scratch ogive of the bullet? Yet also still allow that same brass to be chambered even with all that filth in it?

.277-.2435=.0335/2=.01675 of build up between the chamber wall to tangential contact with the bullets bearing surface

The free bore is often only a thou or two max over bullet diameter, .2435 in the above example so only half a thou over bullet diameter according to saami for the 6 creed.

The leade goes from that half a thousandth wider down to .237 which is 6 thou under bullet diameter or 3 thou of engraving per land.

Carbon deposited there repeatedly over time without cleaning is what causes a carbon "ring", you get the rest of the chamber and barrel clean but its still a swath of hard carbon in the throat. Its why you can feel and see the imprints of it on a bullets ogive below the end of the bearing surface when chambering. Its why seating those same bullets deeper removes the feeling when its built up on the leade. If it were the case mouth then seating depth would make no difference in ones ability to detect and diagnose a carbon ring.

When I said I wish people would "stop trying to change the meaning of terms", what I really meant was "I wish people would stop trying to redefine simple math."

If you have a dirty chamber and it pinches the case mouth tighter on the bullet thats just a dirty chamber, regardless of what youtube retards that also wrote an article on their own website say. And your chamber sure as shit doesnt have lump of shit in it the thickness of your brass and still be somewhat functional.

You can prove this to yourself by using a bore scope and seeing that the crud built up in the chamber mouth isnt taller than the step up to the throat. Notice none of those guys actually show it, they just show a dirty chamber and call it a ring for hits.

.277-.2435=.0335/2=.01675 of build up between the chamber wall to tangential contact with the bullets bearing surface

The free bore is often only a thou or two max over bullet diameter, .2435 in the above example so only half a thou over bullet diameter according to saami for the 6 creed.

The leade goes from that half a thousandth wider down to .237 which is 6 thou under bullet diameter or 3 thou of engraving per land.

Carbon deposited there repeatedly over time without cleaning is what causes a carbon "ring", you get the rest of the chamber and barrel clean but its still a swath of hard carbon in the throat. Its why you can feel and see the imprints of it on a bullets ogive below the end of the bearing surface when chambering. Its why seating those same bullets deeper removes the feeling when its built up on the leade. If it were the case mouth then seating depth would make no difference in ones ability to detect and diagnose a carbon ring.

When I said I wish people would "stop trying to change the meaning of terms", what I really meant was "I wish people would stop trying to redefine simple math."

If you have a dirty chamber and it pinches the case mouth tighter on the bullet thats just a dirty chamber, regardless of what youtube retards that also wrote an article on their own website say. And your chamber sure as shit doesnt have lump of shit in it the thickness of your brass and still be somewhat functional.

You can prove this to yourself by using a bore scope and seeing that the crud built up in the chamber mouth isnt taller than the step up to the throat. Notice none of those guys actually show it, they just show a dirty chamber and call it a ring for hits.

Last edited:

Carbon ring that affects your pressure is in the freebore area where the diameter is larger than bullet diameter. Where and how wide it forms depends on chamber specs, bullet shape and seating depth. Some cartridges are more susceptible to issues than others.

The simplest way I can explain it:

You have a hypothetical brand new barrel that has freebore length 0.010" and freebore diameter larger than bullet/groove diameter. Carbon builds up at the half way point (0.005") and fills the clearance completely. So now you have a ring that is at 0.005" and narrowed diameter to the equivalent of your bullet/groove diameter at that section, which essentially cuts your initial available freebore volume by 50%.

It would mimic the effects of having a short or narrow freebore machined into the barrel to begin with and the associated increased chamber pressure. For more information, look into the pressure effects of freebore.

Pic below - Somewhere inside the red area is where the carbon ring will form, starting from the end of the second shoulder of the chamber neck area on forwards towards the lands/grooves.

The simplest way I can explain it:

You have a hypothetical brand new barrel that has freebore length 0.010" and freebore diameter larger than bullet/groove diameter. Carbon builds up at the half way point (0.005") and fills the clearance completely. So now you have a ring that is at 0.005" and narrowed diameter to the equivalent of your bullet/groove diameter at that section, which essentially cuts your initial available freebore volume by 50%.

It would mimic the effects of having a short or narrow freebore machined into the barrel to begin with and the associated increased chamber pressure. For more information, look into the pressure effects of freebore.

Pic below - Somewhere inside the red area is where the carbon ring will form, starting from the end of the second shoulder of the chamber neck area on forwards towards the lands/grooves.

Last edited:

So based on your opinion do you think I have a carbon ring in the freebore area? Based on the pics I posted above post cleaning.Carbon ring that affects your pressure is in the freebore area where the diameter is larger than bullet diameter. Where and how wide it forms depends on chamber specs, bullet shape and seating depth. Some cartridges are more susceptible to issues than others.

The simplest way I can explain it:

You have a hypothetical brand new barrel that has freebore length 0.010" and freebore diameter larger than bullet/groove diameter. Carbon builds up at the half way point (0.005") and fills the clearance completely. So now you have a ring that is at 0.005" and narrowed diameter to the equivalent of your bullet/groove diameter at that section, which essentially cuts your initial available freebore volume by 50%.

It would mimic the effects of having a short or narrow freebore machined into the barrel to begin with and the associated increased chamber pressure. For more information, look into the pressure effects of freebore.

Pic below - Somewhere inside the red area is where the carbon ring will form, starting from the end of the second shoulder of the chamber neck area on forwards towards the lands/grooves.

View attachment 8257788

No carbon ring that I can see.

As for your pressure issues, a suppressor increases back pressure/bolt thrust and can create false peak chamber pressure signs, those signs being sticky bolt lift, marks on "softer" case heads, etc. You very well may be within safe limits peak pressure limits. As you noted in your test, the issue appears worse with the suppressor than without.

With regards to sizing, if you're not annealing after firing, your die will have to be adjusted according to how your brass behaves (brass properties such as springback, etc.). Consistency in the sizing process also matters such as dwell time, not too much lube/too little lube, loose die lock ring, so on and so forth.

Bumping the shoulder back too far decreases your case volume size and changes the cartridge/chamber headspace relation which changes your pressure curve. Excessive headspace creates pressure signs (and other issues such as light primer strikes, case head marks from case thrusting backwards onto bolt face, etc). Continuous excessive sizing also causes excessive brass stretch (firing forming) which weakens brass (lowering the maximum life of the brass case).

The inconsistency in the shoulder bump combined with the back pressure/bolt thrust from the suppressor will muddle the ability to analyze and discern the source of the issue.

My suggestion for you to troubleshoot and isolate potential sources of the problem -

1a. size brass consistently, measure each piece to ensure you are achieving 0.0015" (if that's your desired bump) and seat bullets at the same CBTO. Use 38.9gr.

1b. size brass consistently, measure each piece to ensure you are achieving 0.005" and seat bullets at the same CBTO. Use 38.9gr.

2. Shoot the ammo loaded with consistency without the suppressor and note case head appearance, then attach suppressor and shoot the ammo and compare the two.

This will show you the difference (for your particular barrel) between both 0.0015" shoulder bump and 0.005" shoulder bump, as well as with suppressor and without.

Edit - remember to take pictures in case you need to use them as reference for more questions.

As for your pressure issues, a suppressor increases back pressure/bolt thrust and can create false peak chamber pressure signs, those signs being sticky bolt lift, marks on "softer" case heads, etc. You very well may be within safe limits peak pressure limits. As you noted in your test, the issue appears worse with the suppressor than without.

With regards to sizing, if you're not annealing after firing, your die will have to be adjusted according to how your brass behaves (brass properties such as springback, etc.). Consistency in the sizing process also matters such as dwell time, not too much lube/too little lube, loose die lock ring, so on and so forth.

Bumping the shoulder back too far decreases your case volume size and changes the cartridge/chamber headspace relation which changes your pressure curve. Excessive headspace creates pressure signs (and other issues such as light primer strikes, case head marks from case thrusting backwards onto bolt face, etc). Continuous excessive sizing also causes excessive brass stretch (firing forming) which weakens brass (lowering the maximum life of the brass case).

The inconsistency in the shoulder bump combined with the back pressure/bolt thrust from the suppressor will muddle the ability to analyze and discern the source of the issue.

My suggestion for you to troubleshoot and isolate potential sources of the problem -

1a. size brass consistently, measure each piece to ensure you are achieving 0.0015" (if that's your desired bump) and seat bullets at the same CBTO. Use 38.9gr.

1b. size brass consistently, measure each piece to ensure you are achieving 0.005" and seat bullets at the same CBTO. Use 38.9gr.

2. Shoot the ammo loaded with consistency without the suppressor and note case head appearance, then attach suppressor and shoot the ammo and compare the two.

This will show you the difference (for your particular barrel) between both 0.0015" shoulder bump and 0.005" shoulder bump, as well as with suppressor and without.

Edit - remember to take pictures in case you need to use them as reference for more questions.

Last edited:

Everyone is just arguing about different areas than can build up carbon and cause issues. You can have carbon rings anywhere from where the brass ends, all the way to the end of the freebore.

Anywhere that can essentially act as a defacto lands/rifling will raise pressure.

The articles and videos focus on the area just after the case mouth because there's the step/lead area which can start building carbon which gets "skipped" over by just running a patch or three every now and then, where that method usually cleans the freebore out.

To simplify, think of it this way......anytime/anywhere hard carbon builds up and starts touching the bullet where there's normally nothing touching (hard carbon being the key word) is generally going to be bad for pressure and other things.

Anywhere that can essentially act as a defacto lands/rifling will raise pressure.

The articles and videos focus on the area just after the case mouth because there's the step/lead area which can start building carbon which gets "skipped" over by just running a patch or three every now and then, where that method usually cleans the freebore out.

To simplify, think of it this way......anytime/anywhere hard carbon builds up and starts touching the bullet where there's normally nothing touching (hard carbon being the key word) is generally going to be bad for pressure and other things.

If you've ever had to scrape the gas plug of an M240 clean, then you'll know that carbon will build up just as thick as it is allowed to. I'm not trying to argue with the internet, because everyone can find something there to support their opinion, but the only place I've ever had a carbon ring try to form was where the neck of my brass ended just short of the transition from the chamber to the freebore. YMMV

So the cracked mountain just north of the green line is the start of the chamber not carbon ring?

Yes. It probably would make more sense looking at it if, either, the camera was pushed in further (to see what's on the other side of the "cliff") or the camera had come at it from the other end. Checking out the other side of the "cliff" tells you whether there's a ring or not.

Last edited:

That is not a carbon ring. Carbon ring forms around the top of the case mouth, not in front of the case mouth.22 creed. Having weird pressure issues. Is this a carbon ring?

Video Explanation

There is one thing that i hate a lot, and that is that fucking carbonring.

There is not a single person out there, that would not have this sucker on the barrel, well not those titty cheeks, who do not shoot with them guns, like they should be done.

Just think of these guys & girls out there, who do not have borescope, they are messing around with pressure problems, nothing helps, but if they would have a cheap borescope, so many problems would be solved instantly.

I think that every gun owner should have a bore scope, it will tell everything what´s going on in your barrel.

There is not a single person out there, that would not have this sucker on the barrel, well not those titty cheeks, who do not shoot with them guns, like they should be done.

Just think of these guys & girls out there, who do not have borescope, they are messing around with pressure problems, nothing helps, but if they would have a cheap borescope, so many problems would be solved instantly.

I think that every gun owner should have a bore scope, it will tell everything what´s going on in your barrel.

If you shoot rifles, then you are one of only two types of people:

(1) people who have a carbon ring (or are getting one) and know it (so they take care of it),

or,

(2) people who have a carbon ring (or are getting one) and do not know it (because they are dumb).

(1) people who have a carbon ring (or are getting one) and know it (so they take care of it),

or,

(2) people who have a carbon ring (or are getting one) and do not know it (because they are dumb).

Similar threads

- Replies

- 27

- Views

- 923

- Replies

- 4

- Views

- 677