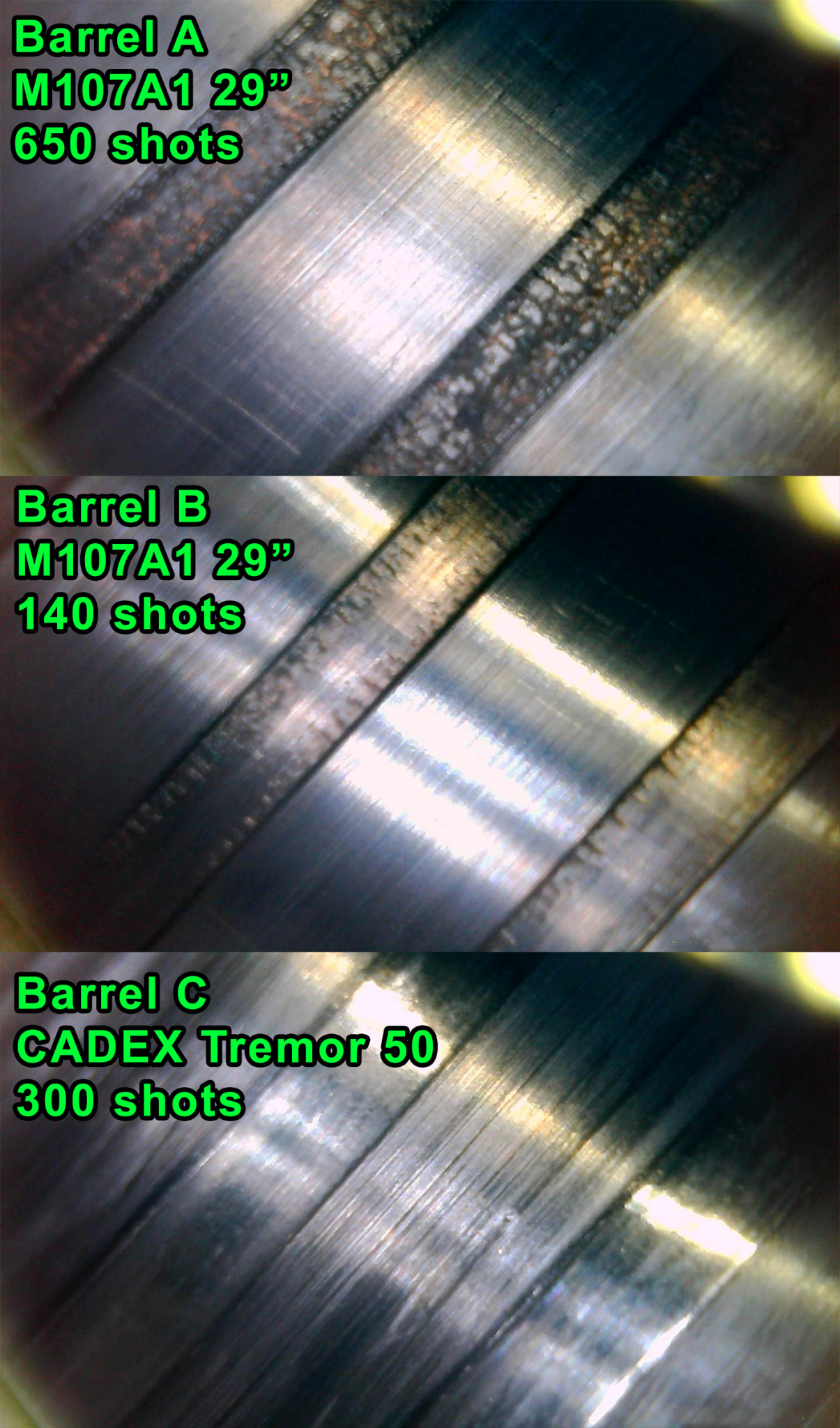

Have two chrome barrels that are destroying themselves faster than a stainless. All 3 are shot under the same conditions. I don't let them get hot enough to burn my hand. Tried getting support from Barrett and their answer is semi autos have more moving parts so throat wears faster....which makes no sense to me. What is going on here?

The cracking makes it foul bad after 20 shots, have to spend hours cleaning to get back accuracy.

The cracking makes it foul bad after 20 shots, have to spend hours cleaning to get back accuracy.