Re: cnc bolt handle threading

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Red_SC</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mikki</div><div class="ubbcode-body"> It all looks very impressive on the cnc but absolutely totally impractical. </div></div>

Apparently George at GA Precision would disagree with you.

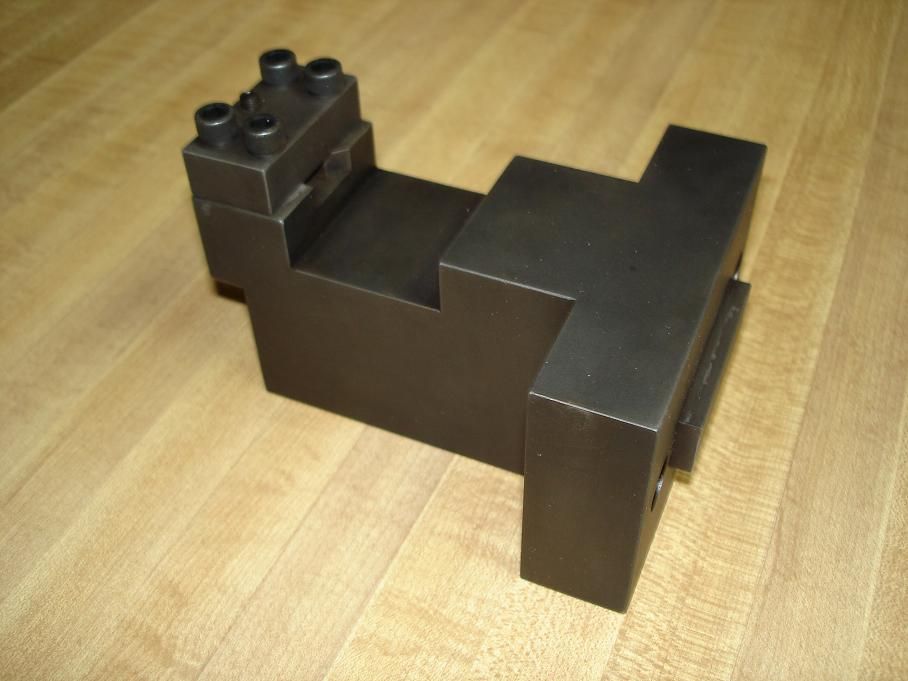

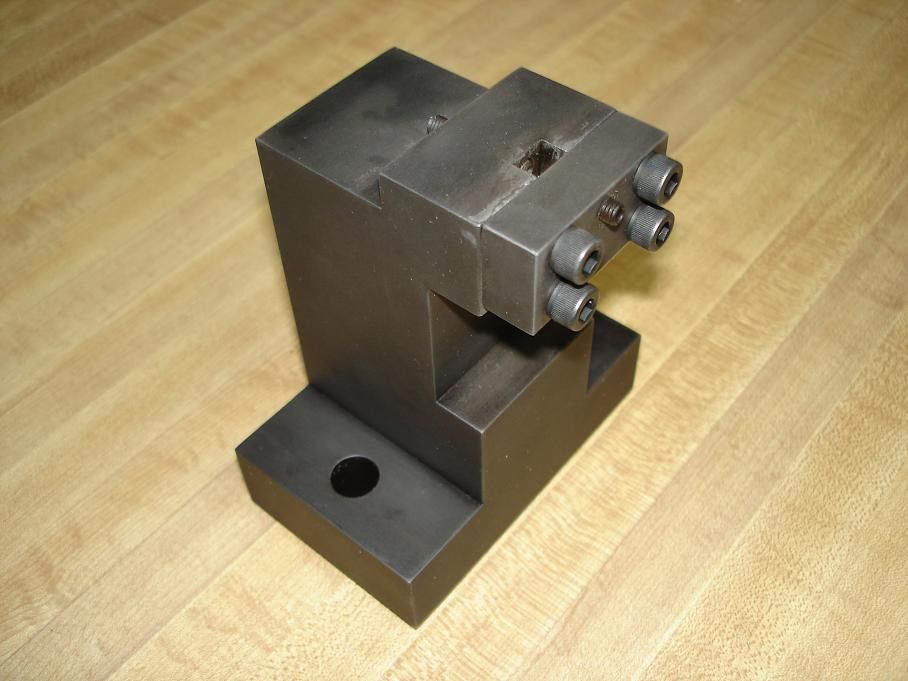

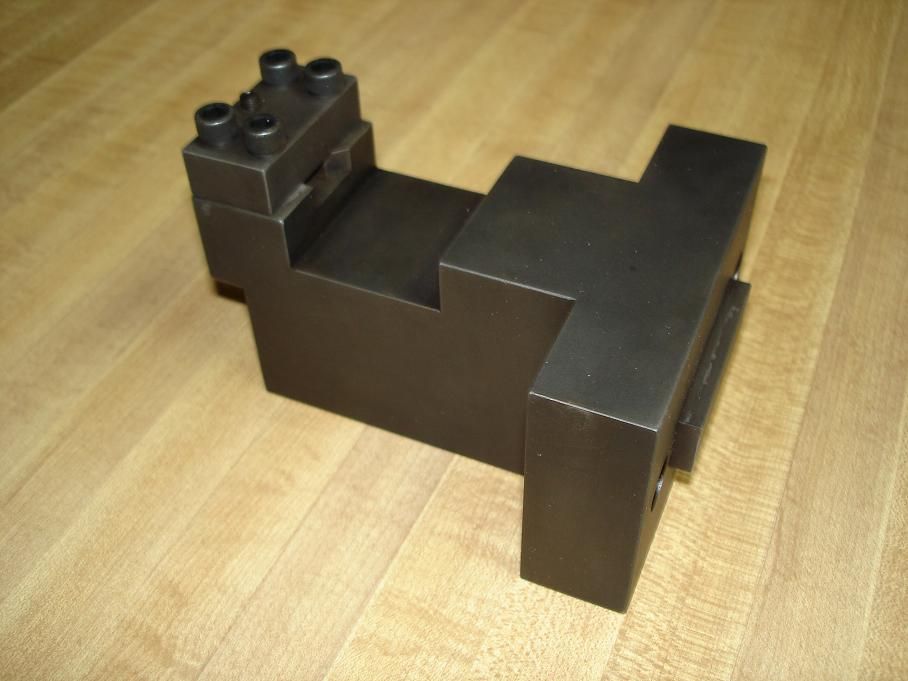

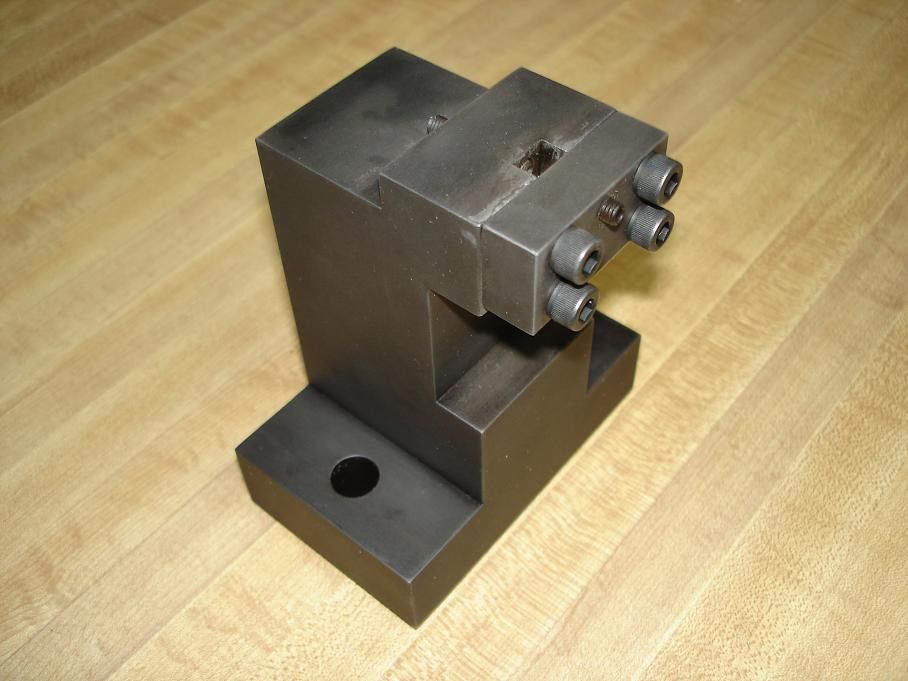

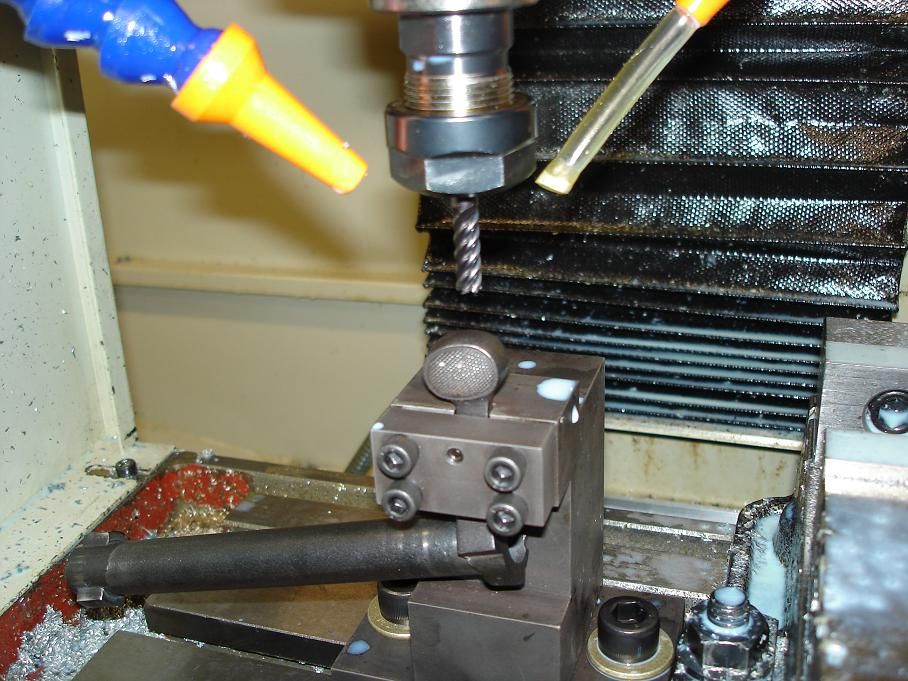

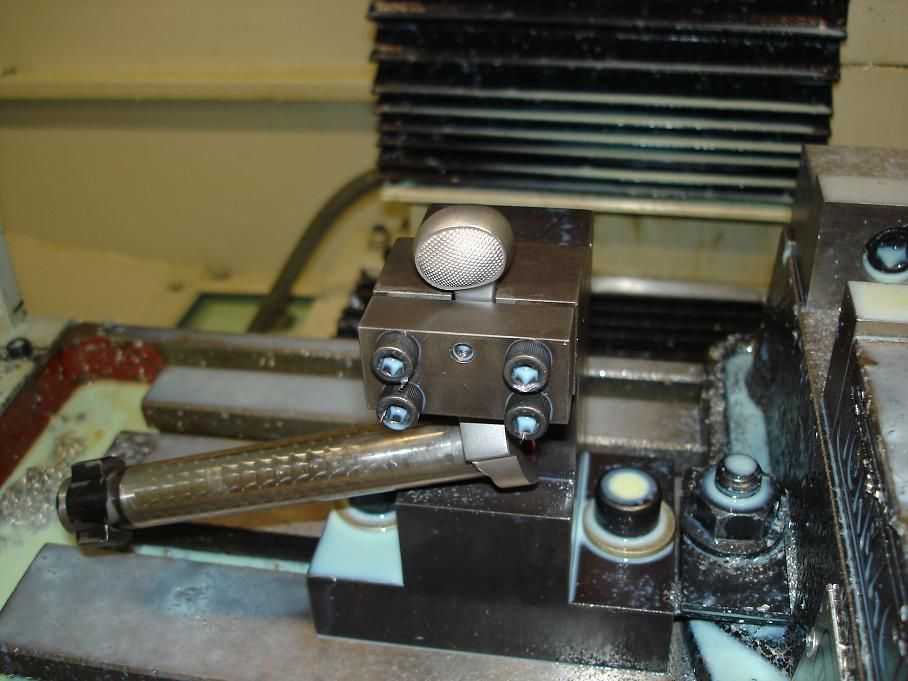

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: A10XRIFLE</div><div class="ubbcode-body"> <object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/gdHvhQ9dVX0"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/gdHvhQ9dVX0" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

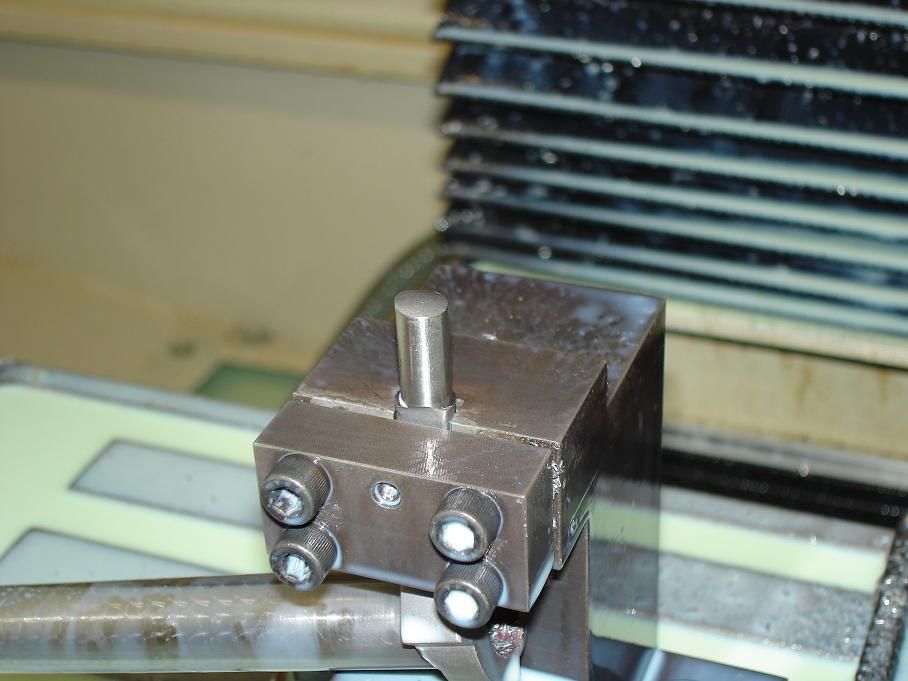

This is how we can offer same day turnarround on bolt knobs. The Mori-Seiki can mill down and thread the bolt in 1 minute 45 seconds. </div></div> </div></div>

That video sure brings back some memories.......I believe George is runing a Mori Seiki MV-Junior vertical mill. That's the first CNC I ran and ours was a 1985 model.

mikki, I have no idea what your experience level is in regards to manual lathe work or CNC, but I've been cranking handles and pushing buttons nearly all my life. Your first, second and perhaps third bolt handle would be ahead of me on the first CNC milled handle, but after that, I'd be stacking them alongside you, till you didn't have room to walk around manual lathe.

If you're eating tooling up faster on a CNC than you are on a manual machine, there are a couple of things that aren't being considered. One, you're getting more work out the door with the CNC, which is why you're using more tooling, which also makes the price per part less relative to disposable tooling costs.

Two, you're pussyfooting around with your manual machine, which will also get back to less parts out the door. Three, your fixturing sucks and or speeds and feeds on your CNC.

If you're eating tooling like crazy on a CNC, your speeds and feeds, tooling selection, or fixturing is need of a change. Quite simply, the best way to determine how good of tool life you'll get from any tool is not by cranking something by hand, but by operating it at a consistent SFM with a consistent chip load. You cannot do that on a manual lathe period.

As for thread milling, I've done tens of thousands of tapped holes using a thread mill and the tool life is outstanding. My old bottom metal used a 1/4-28 thread milled hole in the trigger guard to attach the rail section and I routinely would get 3000 or more holes out of a single thread mill. That of course was running at a speed that was 10 times what Gardner had in his video. That bolt mod was going at the speed of smell, compared to what it could be ran at. That bolt handle could run all day at around 45 sec. start to finish. When you can keep up with that on a manual lathe, I've got a spot open for the next 10 guys you've trained.