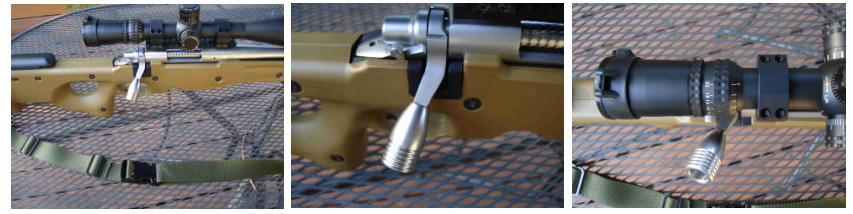

Re: cnc bolt handle threading

Of course you can do it in 5 flat. Its a pity the guy that did in 3 posted the video straight away. He should have mentioned he could do it in 3 minutes first and wait for the experts to chime in with there votes of impossibility then hit them with the silencer. I look forward to getting a few bolt knob conversions in then we'll see what they have to say.

Of course you can do it in 5 flat. Its a pity the guy that did in 3 posted the video straight away. He should have mentioned he could do it in 3 minutes first and wait for the experts to chime in with there votes of impossibility then hit them with the silencer. I look forward to getting a few bolt knob conversions in then we'll see what they have to say.