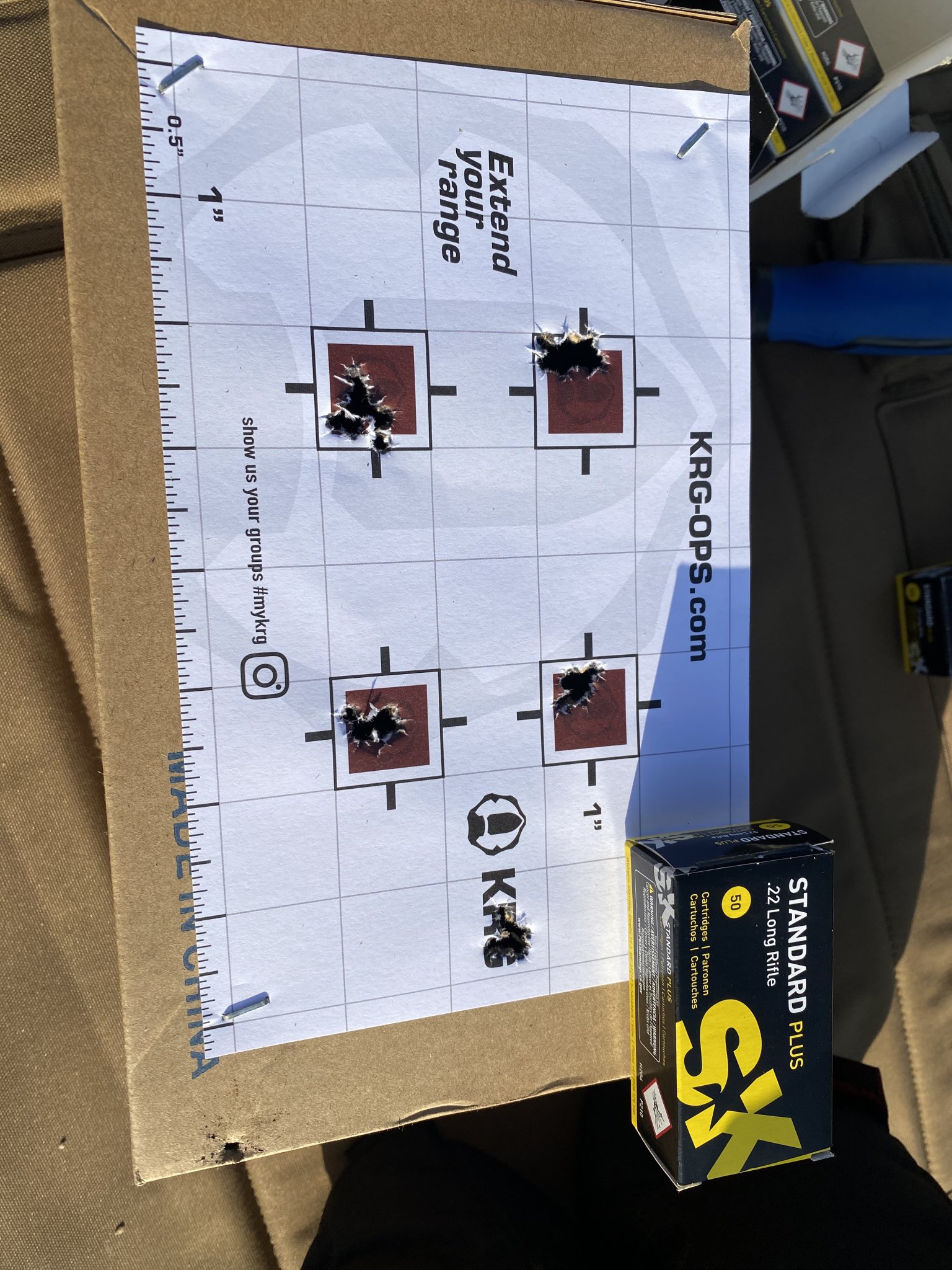

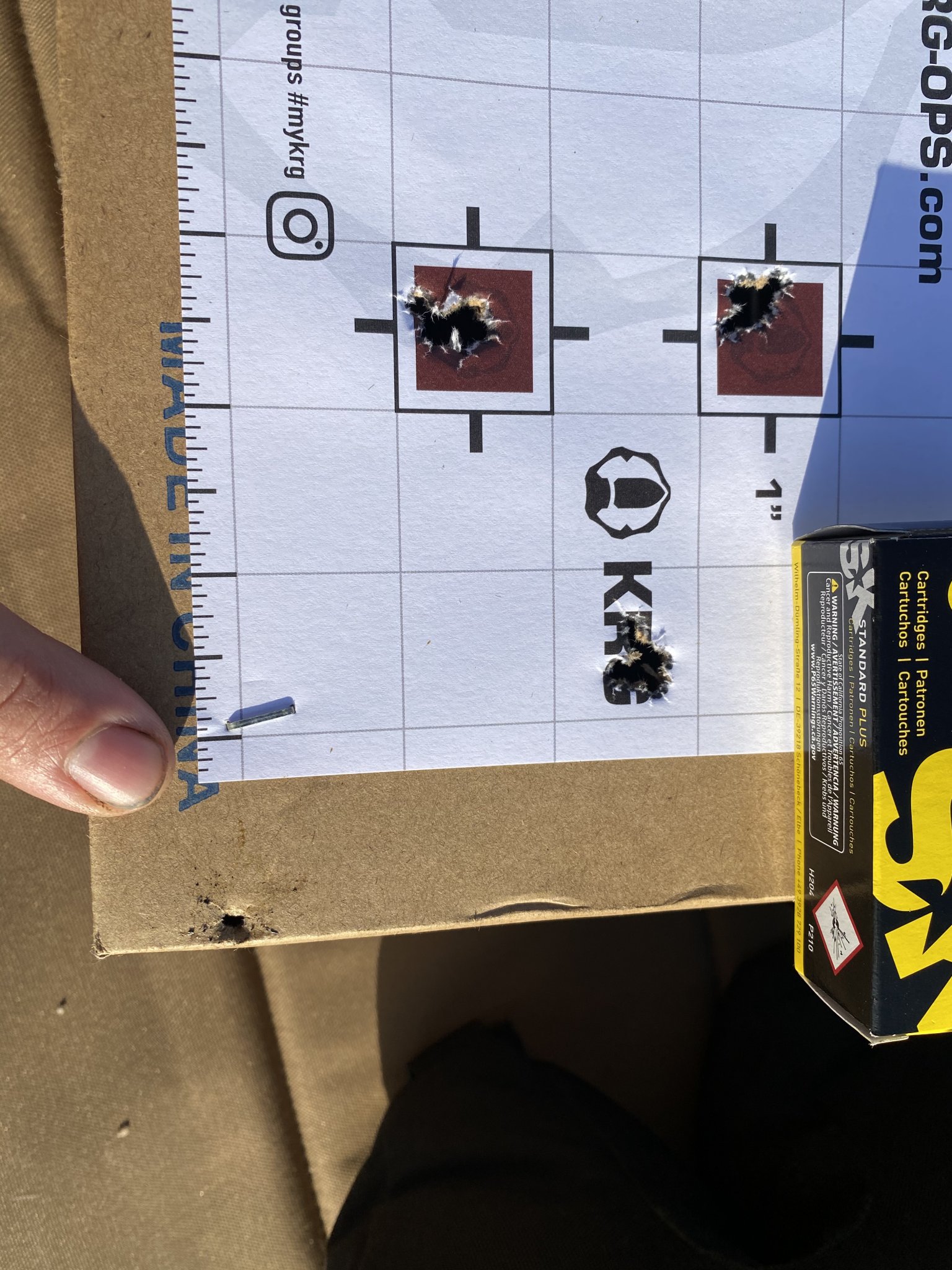

I’ve been playing around with torque settings on my action screws. I shot close to 30 ten shot groups, and all I did was try different action screw torque settings. It was incredible how much just a few inch pounds would make to a group!!! All of my groups were shot prone, and at 80 yards. I wanted to do 100, but the wind was not cooperating. So I shot 80, because I could use a metal building and hay bails as a wind break. I found that 18-20 inch pounds pretty much got rid of all my flyers!! So I put a tiny bit of blue loctite on my action screws, set them to 20 inch pounds, and let it cure over night. This morning I shot it again, and walla, no flyers! Here’s my 5 groups this morning. I shot the top left first. Although the wind was blocked, still needed a little bit of right adjustment. My first group (top left) shows that. I shot the second group (top right) with .1 added for the wind. I shot the 3rd group (bottom left), and added .1 more for wind. Then I shot the bottom right target 4th. The 5th group was my best. I placed a small stick in the target and aimed for it. I shot it out! Just as I was about to call it quits, a big horse fly landed on the box. I smoked him!

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Flyers and action screw torque

- Thread starter PowellSixO

- Start date

I started at 45 like the instructions say. It shot well honestly. But again, out of 10 shots there just seemed to be one flyer. So went up to 55, and worked my way back down. Here’s a group at 100 yards with the action screws at 45. I was surprised honestly that it liked them so low. I was worried that set that low they’d come loose. That’s the only reason I added loctite. Usually I wouldn’t add loctite to the action screws.The instructions for the bravo say 45 in/lbs. it’s weird that you’re getting the best results at 1/3 of the spec.

what did you start at?

I knew they said it made a difference on my hs precision stocks. However, like you I don’t get why so much less torque would make that much difference. Must have something to do with the harmonics

High torque numbers on action screws can and will put stress on a action causing misalignment between bolt face and barrel which in turn can hurt accuracy or cause flyers.I knew they said it made a difference on my hs precision stocks. However, like you I don’t get why so much less torque would make that much difference. Must have something to do with the harmonics

. This will happen if the area between the action screws of the stock does not match the shape of the receiver exactly. Lower torque numbers relieves this stress and allows the receiver to remain in alignment with the barrel. Stressing a receiver can happen with any stock made of any material. A properly bedded action will eliminate this problem.

Great explanation man. I never really thought about it before but everything you said makes sense. I can visualize the twist being relieved as the torque is reduced. If I understand you correctly it’s because of misaligned holes between the chassis and action that cause it. Surely the misalignment issue would need correcting before bedding would benefit anything.High torque numbers on action screws can and will put stress on a action causing misalignment between bolt face and barrel which in turn can hurt accuracy or cause flyers.

. This will happen if the area between the action screws of the stock does not match the shape of the receiver exactly. Lower torque numbers relieves this stress and allows the receiver to remain in alignment with the barrel. Stressing a receiver can happen with any stock made of any material. A properly bedded action will eliminate this problem.

Does a chassis like the OP's Bravo need to be bedded? It has a built in machined bedding surface. In theory action screw torque changes shouldn't affect accuracy with that type of bedding. But it's hard to argue with those pictures.

Probably not, but it depends on how precise their inletting is. My reply to the flyers and action screw torque post was to explain why lighter torque settings could actually improve accuracy and help eliminate flyers. If your gun is a shooter and you're satisfied with it I wouldn't bother. If you're not it's an area to look at for possible problems.Does a chassis like the OP's Bravo need to be bedded? It has a built in machined bedding surface. In theory action screw torque changes shouldn't affect accuracy with that type of bedding. But it's hard to argue with those pictures.

It’s not an action screw alignment issue. I believe the mating surface between the action and the bedding block in the stock just aren’t a perfect match. So the tighter I torque the action screws, the more stress I’m putting on the action.Great explanation man. I never really thought about it before but everything you said makes sense. I can visualize the twist being relieved as the torque is reduced. If I understand you correctly it’s because of misaligned holes between the chassis and action that cause it. Surely the misalignment issue would need correcting before bedding would benefit anything.

I’m going to look into this. I’m going to inspect the action and stock to see if anything jumps out at me. If not, I’m going to look into having it bedded.Does a chassis like the OP's Bravo need to be bedded? It has a built in machined bedding surface. In theory action screw torque changes shouldn't affect accuracy with that type of bedding. But it's hard to argue with those pictures.

You nailed it!!It’s not an action screw alignment issue. I believe the mating surface between the action and the bedding block in the stock just aren’t a perfect match. So the tighter I torque the action screws, the more stress I’m putting on the action.

I guess I’ve been lucky with my bravos but I’m definitely taking my torque wrench shooting from here out. Thanks guys awesome information.Does a chassis like the OP's Bravo need to be bedded? It has a built in machined bedding surface. In theory action screw torque changes shouldn't affect accuracy with that type of bedding. But it's hard to argue with those pictures.

Try multiple torque valves.i will try 20 lbs/in too, thanks for the precious info...

FWIW, it is well known w/ competitive smallbore shooters that action torque values impact rifle accuracy - even for rifles that have been bedded (with or w/o pillars).

We torque test starting at about 15 in-lbs up to about 15% less than the max value recommended by the action manufacturer. Note that it IS important to obtain the top end value from the actual manufacturer and not an internet keyboard kommando recommendation. If you torque too high, it is possible to strip out the action threads.

In addition, a very light lube should be used on the action screws vs dry interface. Non-lubed thread torque can be up to 50% higher vs lubricated.

Hope this helps.

We torque test starting at about 15 in-lbs up to about 15% less than the max value recommended by the action manufacturer. Note that it IS important to obtain the top end value from the actual manufacturer and not an internet keyboard kommando recommendation. If you torque too high, it is possible to strip out the action threads.

In addition, a very light lube should be used on the action screws vs dry interface. Non-lubed thread torque can be up to 50% higher vs lubricated.

Hope this helps.

Last edited:

To be more clear, lubricated threads require less torque to get the bolt properly tight.Non-lubed thread torque can increase by up to 50% vs non-lubricated.

Hope this helps.

Thanks for catching that...I edited my original post to make it clear.To be more clear, lubricated threads require less torque to get the bolt properly tight.

Wouldn't this invalidate OP's experiment.Thanks for catching that...I edited my original post to make it clear.

"I found that 18-20 inch pounds pretty much got rid of all my flyers!! So I put a tiny bit of blue loctite on my action screws, set them to 20 inch pounds, and let it cure over night. This morning I shot it again, and walla, no flyers!"

Wouldn't the torque during the test be different than the torque with the loctite?

Great experiment and reporting.

I may have misread but it looks like the 20 in/lb were 5 shot groups at 80 yd and the 45 in/lb were 10 shot groups at 100 yd???

I may have misread but it looks like the 20 in/lb were 5 shot groups at 80 yd and the 45 in/lb were 10 shot groups at 100 yd???

Quite likely .... but few of the experiments cited around here are sufficiently rigorous to be statistically relevant.Wouldn't this invalidate OP's experiment.

"I found that 18-20 inch pounds pretty much got rid of all my flyers!! So I put a tiny bit of blue loctite on my action screws, set them to 20 inch pounds, and let it cure over night. This morning I shot it again, and walla, no flyers!"

Wouldn't the torque during the test be different than the torque with the loctite?

All groups were 10 shot groups. But yes, my best groups were at 20 in/lb at 80 yards. The groups with the flyers were at 45 in/lb and 100 yards.Great experiment and reporting.

I may have misread but it looks like the 20 in/lb were 5 shot groups at 80 yd and the 45 in/lb were 10 shot groups at 100 yd???

No not necessarily. I understand torquing bolts. I always lubricate my action screws before torquing. So it should be very similar between the lube vs the loctite.Wouldn't this invalidate OP's experiment.

"I found that 18-20 inch pounds pretty much got rid of all my flyers!! So I put a tiny bit of blue loctite on my action screws, set them to 20 inch pounds, and let it cure over night. This morning I shot it again, and walla, no flyers!"

Wouldn't the torque during the test be different than the torque with the loctite?

My post was a general comment on action screw torque and not necessarily to the OP or their process.Wouldn't this invalidate OP's experiment.

"I found that 18-20 inch pounds pretty much got rid of all my flyers!! So I put a tiny bit of blue loctite on my action screws, set them to 20 inch pounds, and let it cure over night. This morning I shot it again, and walla, no flyers!"

Wouldn't the torque during the test be different than the torque with the loctite?

As for putting Loc-Tite (of any level) on action screws....never heard of anyone doing that in my 40 years of shooting competitively. But again, to each their own.....

I know it’s not the norm, but I’ve used this particular loctite in other applications. It’s very mild, but works as intended. It is also easy to clean and remove. I’ve never used it on action screws before, but I was just nervous that at 20 in/lb they’d come loose. I have a big match coming up, and it’s shooting so good, I really don’t want them coming loose. LolMy post was a general comment on action screw torque and not necessarily to the OP or their process.

As for putting Loc-Tite (of any level) on action screws....never heard of anyone doing that in my 40 years of shooting competitively. But again, to each their own.....

edit: I realize that the correct action here would be to bed the action, so that I can torque the action screws properly. I just don’t have time before the match to do it.

The ammo shown in the pictures, SK Standard Plus, will often produce groups in a variety of sizes. That can make it challenging to accurately assess the impact of action screw torque on results.

Of the ammo I’ve tested it’s one of the more consistent. But I haven’t tried every ammo out there. Right now I’ve got over 10k rounds of it, so I’ll be shooting it for at least several months. I’ve been surprisingly accurate out to 400 yards with it. I can’t dial past 400 at this time, because I run out of adjustment.The ammo shown in the pictures, SK Standard Plus, will often produce groups in a variety of sizes. That can make it challenging to accurately assess the impact of action screw torque on results.

I shot a 30 round group at 305 yards last night. Flyers remain under control. I had a 15 mph right to left cross wind. I put about .5 mil too much in for wind. But a decent little group. A little under 6”. I was rushed, and really just trying to prove my 300 yard dope for a match this weekend.

Conversely, a good lot may be “lights out”The ammo shown in the pictures, SK Standard Plus, will often produce groups in a variety of sizes. That can make it challenging to accurately assess the impact of action screw torque on results.

The ammo gods are smiling on you! I would kill for a group like that.I shot a 30 round group at 305 yards last night. Flyers remain under control. I had a 15 mph right to left cross wind. I put about .5 mil too much in for wind. But a decent little group. A little under 6”. I was rushed, and really just trying to prove my 300 yard dope for a match this weekend.

Unfortunately, being what any SK variety of ammo is, which is at best an entry level ammo, those "lights out" lots of SK ammo are very few and far between. For serious shooters, it's good for practice, but I expect it's not often used in top level competition. It can be tough enough to find "lights out" CX or M+. Of course, depending on where the bar is set, it can be plentiful.Conversely, a good lot may be “lights out”

It’s a good thing I bought 7000 rounds of the same lot.Unfortunately, being what any SK variety of ammo is, which is at best an entry level ammo, those "lights out" lots of SK ammo are very few and far between. For serious shooters, it's good for practice, but I expect it's not often used in top level competition. It can be tough enough to find "lights out" CX or M+. Of course, depending on where the bar is set, it can be plentiful.

You might win a money shoot with a good lot, against experts who “expect”It’s a good thing I bought 7000 rounds of the same lot.

I know you’re right, but there are exceptions to every rule. The ARA Factory class national champ this year was shooting SK.Unfortunately, being what any SK variety of ammo is, which is at best an entry level ammo, those "lights out" lots of SK ammo are very few and far between. For serious shooters, it's good for practice, but I expect it's not often used in top level competition. It can be tough enough to find "lights out" CX or M+. Of course, depending on where the bar is set, it can be plentiful.

I know this is a necro, but i have read numerous things about lubing fasteners/bolt/action screws, but no one ever really mentions what lube?

Im convinced it is a good idea vs dry, but unsure what product (without buying some specialty lube) is recommended.

Is standard Permatex anti-sieze ok/good/bad?

Some just said a good gun grease.

Blue loctite acts as a lube (then helps it stay put after drying) as I understand.

I can grab a .5oz packet of "ARP Ultra-Torque Fastener Assembly Lube" from an auto parts store or Amazon.

What is an OK lube and what should be avoided on rifle action screws? (I am actually asking for a centerfire rifle action if it makes a difference)

Thanks in advance

Im convinced it is a good idea vs dry, but unsure what product (without buying some specialty lube) is recommended.

Is standard Permatex anti-sieze ok/good/bad?

Some just said a good gun grease.

Blue loctite acts as a lube (then helps it stay put after drying) as I understand.

I can grab a .5oz packet of "ARP Ultra-Torque Fastener Assembly Lube" from an auto parts store or Amazon.

What is an OK lube and what should be avoided on rifle action screws? (I am actually asking for a centerfire rifle action if it makes a difference)

Thanks in advance

Last edited:

“Lubricated” torque values vary depending on the lube used, base materials and finishes. Too many combinations to list. I would not use a product just to use a product. If you’re trying to alleviate a problem, use the right solution.

Anti-seize comes in many flavors. Nickel based being the most common in consumer products. Generally safe for the steels we use and the temps we see, but can cause galvanic corrosion due to dissimilar metals.

Yes, loctite can act as a lubricant until it cures.

I don’t advise using any lube. If your action screws are loosening, torque should be higher or your stock is shrinking and in need of pillars. If the screws are rusting, keep your gun dry. If you insist on using lube, decrease your torque wrench setting by ~30% to prevent stripping the fastener or your action.

Anti-seize comes in many flavors. Nickel based being the most common in consumer products. Generally safe for the steels we use and the temps we see, but can cause galvanic corrosion due to dissimilar metals.

Yes, loctite can act as a lubricant until it cures.

I don’t advise using any lube. If your action screws are loosening, torque should be higher or your stock is shrinking and in need of pillars. If the screws are rusting, keep your gun dry. If you insist on using lube, decrease your torque wrench setting by ~30% to prevent stripping the fastener or your action.

It's really odd that adjusting torque values makes such a difference, since you're using a chassis. I can understand the benchrest guys doing it to eek out every bit of accuracy they can, but adjusting the torque on your action screws to get rid of fliers sounds like the bedding block in your stock isn't a perfect fit to your action.

Were you shooting the same lot before and after testing torque values?

I'm using a standard Varmint stock that I added a pistol grip to. I also added pillars are bedded it. Since I did that, my rifle doesn't care if the screws are torqued to 20 in/lbs or 35. It shoots the same.

Maybe try skim bedding your action to the bedding block. I suppose you could just leave it as is, but something ain't right. 20 in/lbs is typically the sweet spot for actions in woods stocks without pillars or bedding, since too much torque can deform the wood and induce torque or twisting in the action.

Were you shooting the same lot before and after testing torque values?

I'm using a standard Varmint stock that I added a pistol grip to. I also added pillars are bedded it. Since I did that, my rifle doesn't care if the screws are torqued to 20 in/lbs or 35. It shoots the same.

Maybe try skim bedding your action to the bedding block. I suppose you could just leave it as is, but something ain't right. 20 in/lbs is typically the sweet spot for actions in woods stocks without pillars or bedding, since too much torque can deform the wood and induce torque or twisting in the action.

Makes perfect sense if you think about it in the high tolerance mindset. Every action made will have variations in dimensions, likewise every stock. Since we cannot “lap” the parts together for a perfect fit, that means something somewhere is getting compressed or flexed as things get tightened. Now throw in a one piece scope rail which also will have the same tolerance differences, and you can see yet another place where stress can develop. Stress does funny things to guns just like people. Add in temperature changes, and just like in people, less stress means less reaction to those temperature changes.It's really odd that adjusting torque values makes such a difference, since you're using a chassis. I can understand the benchrest guys doing it to eek out every bit of accuracy they can, but adjusting the torque on your action screws to get rid of fliers sounds like the bedding block in your stock isn't a perfect fit to your action.

Were you shooting the same lot before and after testing torque values?

I'm using a standard Varmint stock that I added a pistol grip to. I also added pillars are bedded it. Since I did that, my rifle doesn't care if the screws are torqued to 20 in/lbs or 35. It shoots the same.

Maybe try skim bedding your action to the bedding block. I suppose you could just leave it as is, but something ain't right. 20 in/lbs is typically the sweet spot for actions in woods stocks without pillars or bedding, since too much torque can deform the wood and induce torque or twisting in the action.

The most consistent accuracy comes from firearms with the least amount of stresses in their assembly. Stresses in metals also change over time with the changes in temperature and other environmentals. This could be a contributing factor in the accuracy we see in older quality firearms of decades ago.

Since the goal is repeatable clamping force via a bit of fastener stretch, and stiction is a variable, take a page from the Carroll Shelby book. Moly grease.I know this is a necro, but i have read numerous things about lubing fasteners/bolt/action screws, but no one ever really mentions what lube?

Im convinced it is a good idea vs dry, but unsure what product (without buying some specialty lube) is recommended.

Is standard Permatex anti-sieze ok/good/bad?

Some just said a good gun grease.

Blue loctite acts as a lube (then helps it stay put after drying) as I understand.

I can grab a .5oz packet of "ARP Ultra-Torque Fastener Assembly Lube" from an auto parts store or Amazon.

What is an OK lube and what should be avoided on rifle action screws? (I am actually asking for a centerfire rifle action if it makes a difference)

Thanks in advance

Similar threads

- Replies

- 9

- Views

- 334

- Replies

- 62

- Views

- 4K