I like the geissele handguards a lot, hopefully they will have a 308 line pretty soon.

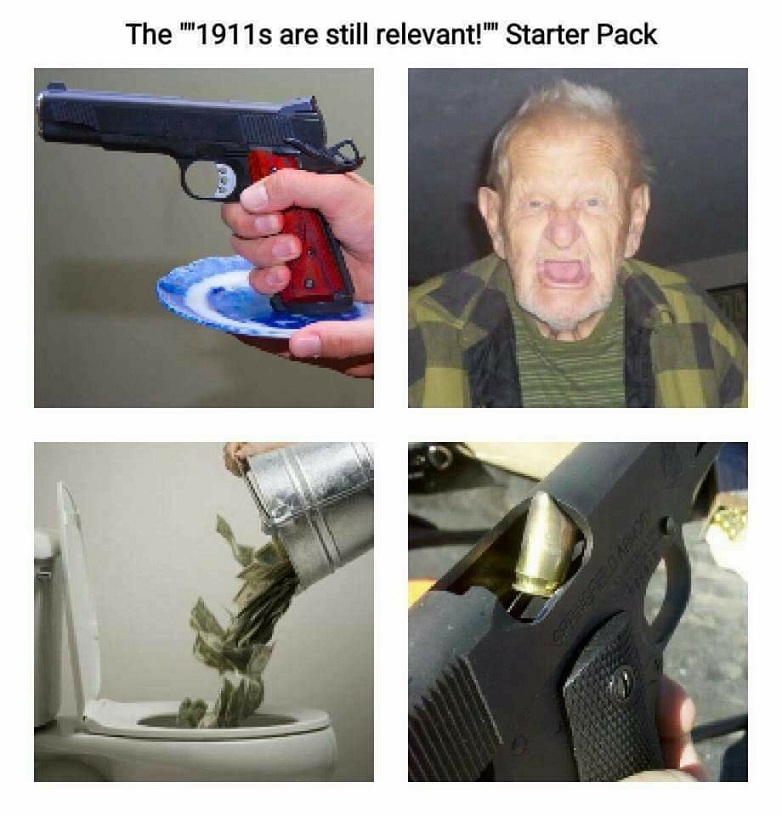

The 1911 game is a black hole

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

The 1911 game is a black hole

The new MK18 with integrated arca rail is awesome.I like the geissele handguards a lot, hopefully they will have a 308 line pretty soon.

View attachment 8404786

Can't take a joke?Its hilarious when nobody loser faggots talk shit about people they A. Don't know and B. Give a TON back to the community. One of the nicest dudes out there.

I believe FN , LaRue, SIG and LMT.... and apparently others.What other company's submitted rifles to be tested?

Bizarre sense of humorDamn. That's almost funny.

Just curious, did you fire anyone over that oversight?

That you 2 were the joke? Just guessingLol, what do you think?

Woof!We'll pretty much always participate in programs that are in our wheel-house.

As far as our participation in MRGG-S, we were already on contract for upgrade kits for M110s in 6.5 when the first MRGG program came out (the vast majority of observers are unaware that the M110 6.5 kits and MRGG were/are separate programs). MRGG round 1 stopped and was respun into two separate programs, MRGG-S (Sniper) and MRGG-A (Assault), with similar but different requirements. When it comes to competitive opportunities, not meeting a requirement can immediately disqualify a submission. MRGG-A (first spin) and MRGG-S had hardware delivery for initial down-select at the same time. KAC's MRGG-S submission was delivered with a buttstock that did not have an adjustable cheek piece, so we were not able to progress. The MRGG-A hardware was compliant (did not have an adjustable cheekpiece requirement) and we moved forward to the following phases before it was also stopped and respun.

So that's pretty much it; an error during assembly and packing (stocks weren't swapped to the intended submission hardware) wasn't caught by my department on final inspection and we were booted from MRGG-S without firing a single shot.

*Cue sad violin noises*

It sounds like a multi point failure and within a small team environment there would likely be some history and loyalty unless it was a multiple repeat.I'm serious. I don't think we fire people enough. It's a conundrum in my current job. Just curious what constitutes standards at KAC for fuckups. What's that saying? "The baseline of your culture is the worst thing that you allow". What's your baseline for competency? What's the worst fuckup your company will allow? Costing you a slot at a large DOD procurement when you're a defense company? Is that bad enough?

6.5 Creedmoor Round Expands in SOF Applications

4/12/2024 ByScott R. Gourley

The world of suckersIn a world where a $4800 gun still needs $1000 put into it a 6500 rifle doesn't seem too bad. $1600 Magnus suppressors, $4500 scopes, $3000 progressive presses, $3200 AR15's. Meh, how many people paid $7000 for an AXMC or $10K for an AXSR? It's up there but not unheard of.

Damn. That's almost funny.

Just curious, did you fire anyone over that oversight?

…

So that's pretty much it; an error during assembly and packing (stocks weren't swapped to the intended submission hardware) wasn't caught by my department on final inspection and we were booted from MRGG-S without firing a single shot.

In the DoD research realm, that is the vast majority of program requirements. MOEs and MOPs. The non-performance based requirements usually only crop up when hardware or software needs to be designed a specific way for integration reasons into existing systems.…

Not to mention a pure Performance work statement using performance based objectives instead of design critera would allow industry the latitude to come up with true innovative products….

That's absolutely wild....We'll pretty much always participate in programs that are in our wheel-house.

As far as our participation in MRGG-S, we were already on contract for upgrade kits for M110s in 6.5 when the first MRGG program came out (the vast majority of observers are unaware that the M110 6.5 kits and MRGG were/are separate programs). MRGG round 1 stopped and was respun into two separate programs, MRGG-S (Sniper) and MRGG-A (Assault), with similar but different requirements. When it comes to competitive opportunities, not meeting a requirement can immediately disqualify a submission. MRGG-A (first spin) and MRGG-S had hardware delivery for initial down-select at the same time. KAC's MRGG-S submission was delivered with a buttstock that did not have an adjustable cheek piece, so we were not able to progress. The MRGG-A hardware was compliant (did not have an adjustable cheekpiece requirement) and we moved forward to the following phases before it was also stopped and respun.

So that's pretty much it; an error during assembly and packing (stocks weren't swapped to the intended submission hardware) wasn't caught by my department on final inspection and we were booted from MRGG-S without firing a single shot.

*Cue sad violin noises*

Damn. That's almost funny.

Just curious, did you fire anyone over that oversight?

It sounds like a multi point failure and within a small team environment there would likely be some history and loyalty unless it was a multiple repeat.

Well, it sounds like Jack is still there so I guess it doesn't fall into "responsible for everything the patrol does and fails to to do" category

Didn't they miss out on the Brit contract that LMT won for the L129 from a silly mistake (brought wrong guns/barrel length or something)?... Def not the first time KAC missed out; maybe hire some rabid fanbois/cloners with OCD level attention to detail?

I’m going to say this while trying not to sound insulting, as I’ve had my fair share of screw ups in both the mil and civ work environment.

But as an engineer who has worked a number of DoD proposals and test events, that is a very easy-to-avoid error. I hope processes, to include checklists and requirements verification, have been updated. I’m guessing I’m stating the obvious and KAC has already implemented lessons learned. But regardless, I appreciate the openness.

I am not going to make this post any better but I have brought products to market and as a manufacturer you have to recoup your development cost. I searched for Geissele patents and counted at least 11 separate patents that went into this rifle. There is no telling how much money they have spent on the hardened BCG and the steel formula for the barrel. No idea how much money they spent changing the throat of the barrel to help stop erosion, how much they spent on tuning the gas and recoil system.'[;

Uh no. Comparing some shitty parts gone slapped together by a chad to a engineered/tested weapon system that has been ran through SOCOM testing, beat all comparable products from proven companies AND does things no other semi auto SWS does from the factory is a massive difference.

Show me Another Chrome lined barrel that has over 6K on the tube and still (if it ever did) holds half moa with FACTORY ammo. The gun was not babied either, it was used as a demo to a bunch of pro shooters who shot the piss out of it, running stages back to back, without it cooling off. Show me another phased gas array that not only changes the entire recoil impulse, making the shoot super soft both with a can and without, but no longer suffers from port erosion the way a legacy barrel would. So now instead of port erosion/gas system issues being the limiting factor when you need to pull a barrel, it will be the actual accuracy degradation and MV loss like a bolt gun.

Oh and that gun with 6K+ on it still holding half MOA, its still going.

There is a ton of a proprietary tech in the gun, so stop showing your ignorance.

Just about everything you state is incorrect. There are people on this site who have tested the MRGG and are testing the small frame version of this gun in a bunch of calibers right now. They can't talk about it for the obvious but you have zero idea what your talking about.

This gun has zero in common with the MRAD or its solicitation. MRAD was a massive compromise to get US military wide adoption so Big army would pay for it instead of SOCOM dollars. This system is being paid for with SOCOM O&M and as such, they are getting exactly what they want.

Hire Kevin Boland back. He will get shit sorted outNo, I did not see it as a sufficient reason to terminate employment for those involved.

It was a combination of errors mostly due to a compressed timeline with several other projects happening at the same time. Definitely not an excuse for those at fault, but a contributing factor on why the "normal" process was not followed.

It's my job to bear the brunt of the fallout from a failure, but just as I did not see it reasonable to terminate good employees that made a mistake (that they certainly learned from), my value was seen as greater then the failure of a program that falls under my portfolio.

The L129 disqualification was due to a miscommunication between our then UK rep and the sales team here in the US. A 20" M110 SASS was requested, when a 16" rifle was desired. This (MRGG-S) was the first time since I have been here (2012) that something like this has happened. Attention to detail is a defining requirement for folks that work in this environment, and the only criticism of the project that I can accept of my team is that my personal involvement should have been higher in the final stages.

Yes, an avoidable error that disqualifies a submission from competition does not pass quietly into the darkness to be forgotten. Things like this normally fall entirely under my direct involvement. While not a desired situation, the lessons learned by the personnel involved have ensured that they never repeat the same, and will be proactive on problem identification early in the process.

I have known Kevin since before I came to KAC, Kevin is a friend of mine, and I have nothing negative to say about Kevin.Hire Kevin Boland back. He will get shit sorted out

Tis a joke. Relax holmes.I have known Kevin since before I came to KAC, Kevin is a friend of mine, and I have nothing negative to say about Kevin.

But I don't find that comment helpful.

Tis a joke. Relax holmes.

I'm serious. I don't think we fire people enough. It's a conundrum in my current job. Just curious what constitutes standards at KAC for fuckups. What's that saying? "The baseline of your culture is the worst thing that you allow". What's your baseline for competency? What's the worst fuckup your company will allow? Costing you a slot at a large DOD procurement when you're a defense company? Is that bad enough?

Your a class act and have demonstrated some impressive leadership skillsNo, I did not see it as a sufficient reason to terminate employment for those involved.

It was a combination of errors mostly due to a compressed timeline with several other projects happening at the same time. Definitely not an excuse for those at fault, but a contributing factor on why the "normal" process was not followed.

It's my job to bear the brunt of the fallout from a failure, but just as I did not see it reasonable to terminate good employees that made a mistake (that they certainly learned from), my value was seen as greater then the failure of a program that falls under my portfolio.

The L129 disqualification was due to a miscommunication between our then UK rep and the sales team here in the US. A 20" M110 SASS was requested, when a 16" rifle was desired. This (MRGG-S) was the first time since I have been here (2012) that something like this has happened. Attention to detail is a defining requirement for folks that work in this environment, and the only criticism of the project that I can accept of my team is that my personal involvement should have been higher in the final stages.

Yes, an avoidable error that disqualifies a submission from competition does not pass quietly into the darkness to be forgotten. Things like this normally fall entirely under my direct involvement. While not a desired situation, the lessons learned by the personnel involved have ensured that they never repeat the same, and will be proactive on problem identification early in the process.

My 16 inch 6 ARC (LMT MWS with Proof barrel by Wilson) shoots softer and with less mill adjustment at 1k yards then my 308 which is 4 pounds heavier.If It was my money, today, I would buy a 6 ARC GFR or wait for the 22arc that's currently being tested to roll out.

Beauty is in the eye of the beholder, but that FN is gorgeous! I wonder if the lower is compatible with the SCAR-H. Needs to get rid of that Vortex optic though. Someone from FN probably had a freebie from a trade show or gas gun competition lying around.I believe FN , LaRue, SIG and LMT.... and apparently others.

Given the effort from those companies.. maybe ( ?) we could see those released to the public ?

https://soldiersystems.net/2022/05/10/mdm-22-fn-america-mrgg/

https://soldiersystems.net/2023/10/11/ausa-23-sig-medium-range-gas-gun-sniper-program-submission/

https://lmtdefense.com/contracts/lm...elivery-to-ussocom-mrgg-s-down-select-trials/

https://static.larue.com/media/downloads/4467e1379ab54e47ba33719ff8274342.pdf

Adjustable cheek piece in the field?We'll pretty much always participate in programs that are in our wheel-house.

KAC's MRGG-S submission was delivered with a buttstock that did not have an adjustable cheek piece, so we were not able to progress.

Yes, adjustable cheek piece:Adjustable cheek piece in the field?

WTF

They know what they’re doing over there in Titusville and they know when a program is designed to fail so they submit it the way it should be and let some other crew put their name on a money pit.

Apparently, even Aero "dabbled" in it as well.

And if you'd like to watch a full auto 6.5CM being fired.

I was walking around with a gas mask that could never seal properly. I'll take any functional gear I can get.How about a Rem 700? With a BDL bottom metal.

Friends, remember this day. Tis’ the day this dude stepped on his winky with one of the big dogs at KAC. He then attempted to obviously walk it back with the whole, “it was a joke, relax…” bullshit and then proceeded to further rectify his winky-smashing by blessing us all with a soliloquy on how KAC changed the large frame world.KAC was dug in tight with the unit since the 90s. Its nice when a big part of your R&D is the best funded special operations unit in the world, with their own huge R&D budget and operations. We can in large part thank KAC and Delta for the reinvention of the large frame AR in the 90s and the development, advancement and standardization through the 00s and 10's. I think with the K2 generation of guns, we kind of hit peak performance and it wasn't until some radical changes (such as phased gas array and a barrel that can shoot that tight for that long) that we see improvement with the large frame.

The other thing is the advancements in the small frame with calibers like the 6 and 22 arc, are really taking away the advantage of a large frame AR, unless you need the energy downrange. They are much smaller, lighter, standardized, easier to shoot and have way more options for build out. There are going to need to be serious advancements with the large frame to make it worth it. But the funny thing is all the advancements that make the MRGG so great, are being rolled into the GFR small frame.

If It was my money, today, I would buy a 6 ARC GFR or wait for the 22arc that's currently being tested to roll out.

Because he can't fight backRay Charles can also see that DBD has been banned, so what’s the point of directing comments at him?

What in the boomer comment bullshit is this? We all know several things that apparently you don't. First is, Ray Ray can see that DBD is still reading these posts. Secondly, Ray Ray can see that 99% of my comment was directed at everyone except DBD. Thirdly, Ray Ray can see what a VPN is.Ray Charles can also see that DBD has been banned, so what’s the point of directing comments at him?

"The optic package on this MRGG-A is a Gen 3 Vortex Razor 1-10×24 in a Badger C1 mount and Leupold Delta Point Pro back up sight." That may have been the FN specific trial rifle. Not sure if all of them are using the same setup.What’s the optic for the MRGG-A?

The Geissele submission is equipped with a 1-8 ATACR and RMRWhat’s the optic for the MRGG-A?

Vendors did not submit with optics.The Geissele submission is equipped with a 1-8 ATACR and RMR

Hey I was teaching some guys today and one of them had a KAC 14.5 6.5 which is first one I have seen in civilian handsVendors did not submit with optics.

Optics used in these programs are from previous and ongoing optics programs, such as S-VPS (NF 1-8X ATACR).

What weight on the bullet and details on the scope please. Come up?Hey I was teaching some guys today and one of them had a KAC 14.5 6.5 which is first one I have seen in civilian hands

Damm that rifle shot well. Had him at 1300 yards like it was 600

Very nice work

MRGG-A will greatly outperform a lot of the 6ARC options, especially when coupled with higher pressure capable cases.

I’m waiting to hear more about bolt dimensions. The magazine is one thing, but the bolt is another. Until both are addressed 6ARC just appeal to me - especially at the pressures it’s loaded to from the factory. Too heavy a pill for the powder load.No one is debating this. A 6.5 CM will always outperform a 6mm ARC. But is the increased performance worth the significant penalty in weight and bulk of the rifle, magazine, ammo, spare parts? And the increased recoil?

It becomes a much more dubious proposition.

I won't pretend to be an SME on DOD small arms procurement, but it strikes me that 6mm ARC (especially if it were in the ICAR magazines and reveivers) is a far more logical choice to achieve the army's stated goals of the NGSW program and the abortion of the new .277 Sig Fury rifle.

I know they are not all the same (bolts) but the Geissele bolt seems to be doing well. They have their own secret sauce steel but it is not a particularly difficult engineering problem.I’m waiting to hear more about bolt dimensions. The magazine is one thing, but the bolt is another. Until both addresses 6ARC just appeal to me - especially at the pressures it’s loaded to from the factory. Too heavy a pill for the powder load.