Hey guys. Hoping for a reality check. Buddy a mine just got a new barrel for his precision AR. He's gonna have two different uppers to do longer range AR15 shooting with. Anyway, this is the barrel for the 2nd upper and I've got some questions for the group if you will indulge me.

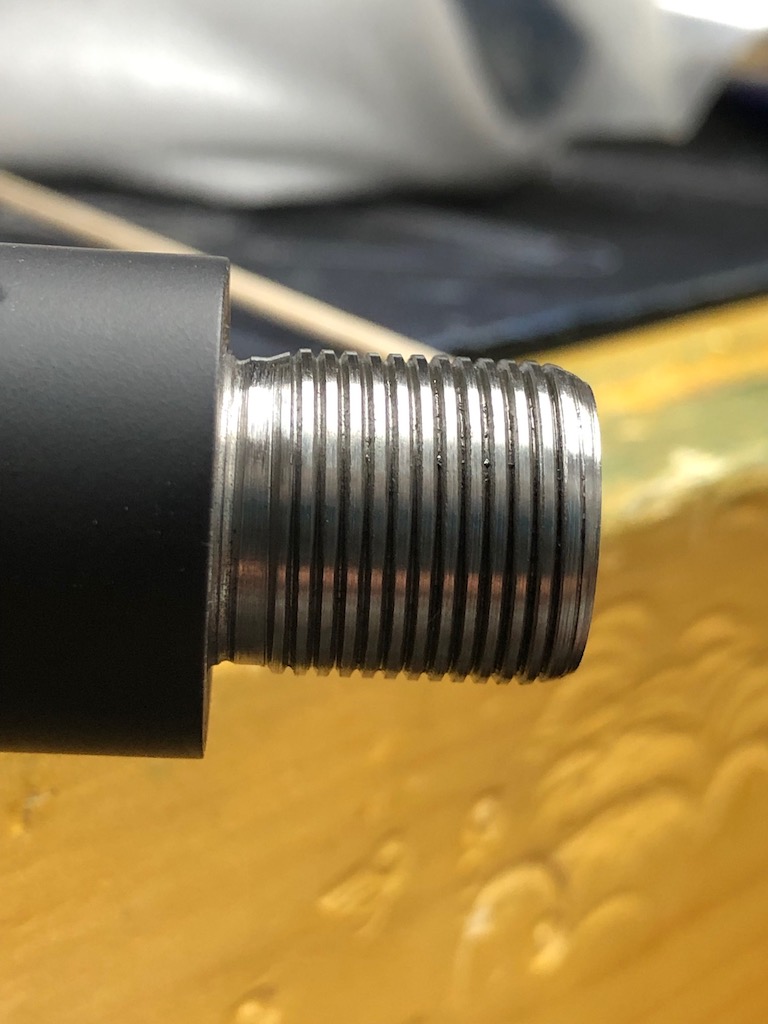

When he showed it to me the muzzle threading looked way off to me but I'm not a long gun guy. Here's what we're dealing with. It's threaded 5/8x24 and this is the exact condition as received.

Pic 1

Pic 2:

Pic 3:

I thought these threads looked way to flat but again I'm not an expert. I did a little looking around for how to measure threads and purchased a Brown and Sharpe thread wire set to measure the pitch diameter. Should be here in a few days. My friend intended to shoot this thing suppressed with his 30 cal direct thread thunder beast. I told him definitely not until we get some info on these threads.

I took a couple initial measurements and as it sits right now the threads are .604" OD. I'll get the pitch diameter dimension when the wire set gets here.

I also measured from the face of the muzzle to the shoulder and it was .668". I watched the video by Thunderbeast saying this dimension should be .600" to prevent the threads from protruding into the can and getting caked up making removal a pain.

Finally, here is a short video of the barrel with my friends TB can threaded most of the way on. Is this movement normal? My can is a CB mount so I have nothing to compare it to.

I don't want to say where he got the barrel from until they have a chance to address it. This barrel was expensive though, over $800 with a bolt and gas tube. I'm also concerned that the machining is so poor on the shoulder that even if the threads were ok it could shift the can one way or another as it seats.

Thanks in advance for any help.

When he showed it to me the muzzle threading looked way off to me but I'm not a long gun guy. Here's what we're dealing with. It's threaded 5/8x24 and this is the exact condition as received.

Pic 1

Pic 2:

Pic 3:

I thought these threads looked way to flat but again I'm not an expert. I did a little looking around for how to measure threads and purchased a Brown and Sharpe thread wire set to measure the pitch diameter. Should be here in a few days. My friend intended to shoot this thing suppressed with his 30 cal direct thread thunder beast. I told him definitely not until we get some info on these threads.

I took a couple initial measurements and as it sits right now the threads are .604" OD. I'll get the pitch diameter dimension when the wire set gets here.

I also measured from the face of the muzzle to the shoulder and it was .668". I watched the video by Thunderbeast saying this dimension should be .600" to prevent the threads from protruding into the can and getting caked up making removal a pain.

Finally, here is a short video of the barrel with my friends TB can threaded most of the way on. Is this movement normal? My can is a CB mount so I have nothing to compare it to.

I don't want to say where he got the barrel from until they have a chance to address it. This barrel was expensive though, over $800 with a bolt and gas tube. I'm also concerned that the machining is so poor on the shoulder that even if the threads were ok it could shift the can one way or another as it seats.

Thanks in advance for any help.