Well, actually it's a Rock Island Arsenal but you know what I mean. Below are the pics of my newly acquired US Rifle Model of 1903. My plans for it include acquiring a leather sling and learning to shoot it. The owner of a local shop shoots Service Rifle and offered to teach me how to shoot with a leather sling. Please don't tell me what it's worth. I probably paid too much and I don't want to know. I think the pictures will tell the whole story. And to think, I was a little upset that I couldn't buy the Husqvarna M38 that another shop had for the same price.

Here she is. The grain of the stock is nice but I would like to put the straight grip away and replace it with a scant grip. No cartouche.

Close up of the receiver.

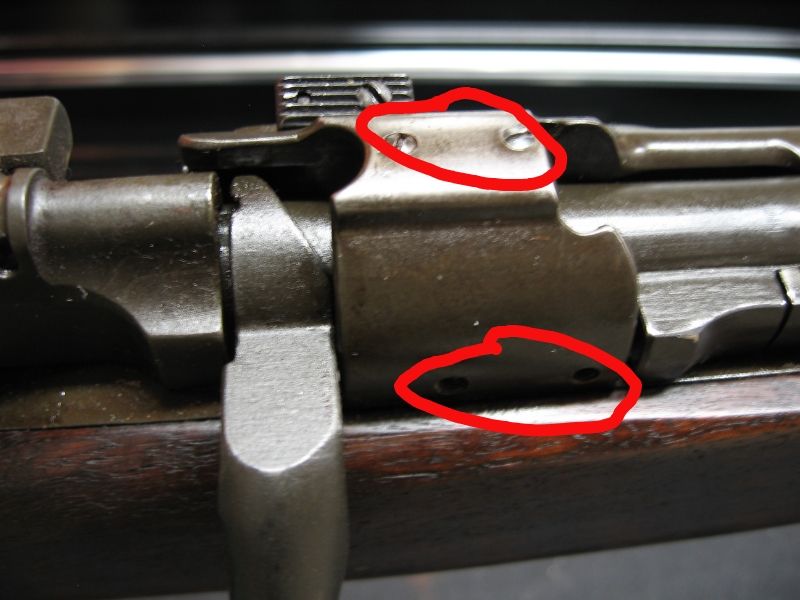

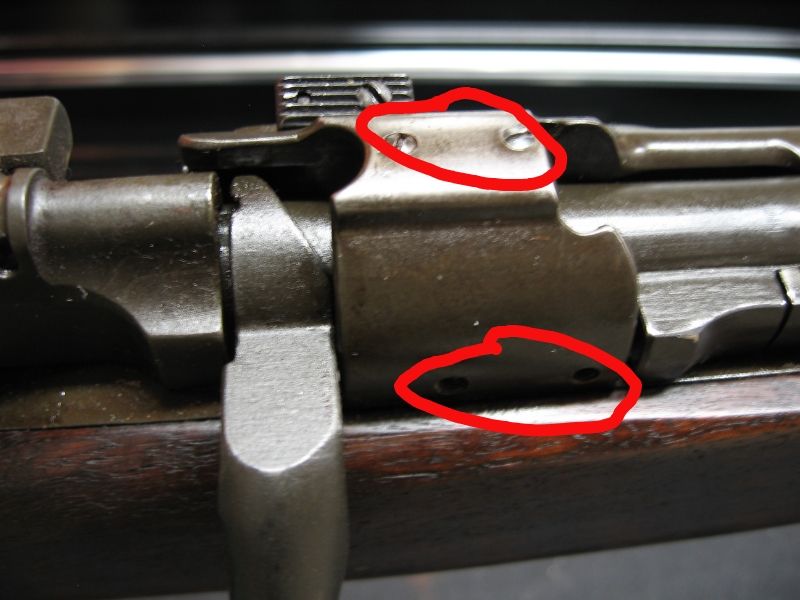

The first two of six reasons why I got it a little cheaper.

And the other four.

This is a scope I would like to put on it but probably won't get around to. At present, it won't clear the bolt handle. Nor am I certain the holes are even straight.

And last, here we have the muzzle and the barrel stamping.

Here she is. The grain of the stock is nice but I would like to put the straight grip away and replace it with a scant grip. No cartouche.

Close up of the receiver.

The first two of six reasons why I got it a little cheaper.

And the other four.

This is a scope I would like to put on it but probably won't get around to. At present, it won't clear the bolt handle. Nor am I certain the holes are even straight.

And last, here we have the muzzle and the barrel stamping.