The word I get is that the more popular aftermarket composite stock companies have elected to avoid the Howa Mini 1500 action. My suspicion is that doing so would require some significant costs with retooling molds as the tang geometry is a fairly large departure from what is typical these days.

So, smelling fertile soil, we dove in headfirst to see what it takes to make it run. Our little FB LRI "Clip of the Day" vid covers the cliff notes on what we have going on and how we got there. As mentioned, the tang took a little work to get right. Fortunately working with composite materials is a low-risk thing for us.

The stock hasn't gone to finishing yet, but the heavy lifting is all done now. Kinda cool. We'll be adding this to our lineup from here out.

Thanks for looking.

C.

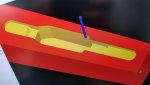

Step one: Getting everything modeled up so that we have some idea of how the toolpaths need to be applied.

Two: Test pieces. New jobs like this are always vetted with lumber. We kill quite a few trees here... Top and bottom

2.1: Test fitting and killing more trees.

Four: Inlet and make a "skin graft" to cover up the scab on the tang.

So, smelling fertile soil, we dove in headfirst to see what it takes to make it run. Our little FB LRI "Clip of the Day" vid covers the cliff notes on what we have going on and how we got there. As mentioned, the tang took a little work to get right. Fortunately working with composite materials is a low-risk thing for us.

The stock hasn't gone to finishing yet, but the heavy lifting is all done now. Kinda cool. We'll be adding this to our lineup from here out.

Thanks for looking.

C.

Step one: Getting everything modeled up so that we have some idea of how the toolpaths need to be applied.

Two: Test pieces. New jobs like this are always vetted with lumber. We kill quite a few trees here... Top and bottom

2.1: Test fitting and killing more trees.

Four: Inlet and make a "skin graft" to cover up the scab on the tang.

Attachments

-

thumb_9202_1600_0_0_0_crop.jpg236.9 KB · Views: 152

thumb_9202_1600_0_0_0_crop.jpg236.9 KB · Views: 152 -

thumb_9201_1600_0_0_0_crop.jpg167.8 KB · Views: 138

thumb_9201_1600_0_0_0_crop.jpg167.8 KB · Views: 138 -

thumb_9203_1600_0_0_0_crop.jpg287 KB · Views: 134

thumb_9203_1600_0_0_0_crop.jpg287 KB · Views: 134 -

thumb_9205_1600_0_0_0_crop.jpg273.8 KB · Views: 135

thumb_9205_1600_0_0_0_crop.jpg273.8 KB · Views: 135 -

thumb_9233_1600_0_0_0_crop.jpg127.6 KB · Views: 134

thumb_9233_1600_0_0_0_crop.jpg127.6 KB · Views: 134 -

thumb_9231_1600_0_0_0_crop.jpg160.1 KB · Views: 147

thumb_9231_1600_0_0_0_crop.jpg160.1 KB · Views: 147 -

thumb_9232_1600_0_0_0_crop.jpg195.9 KB · Views: 135

thumb_9232_1600_0_0_0_crop.jpg195.9 KB · Views: 135 -

thumb_9235_1600_0_0_0_crop.jpg252.4 KB · Views: 137

thumb_9235_1600_0_0_0_crop.jpg252.4 KB · Views: 137

Last edited: