Very nice!Alignment mandrel for clocking the rings for soldering.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M40 scope base project by LRI

- Thread starter LRI

- Start date

All soldered up. Now to cool and then cleanup in the "Blast-a-tron."

Great progress! Looks like these will be ready to be paired up with the new stocks in no time.

Not only will your logo keep people from trying to pass these off as legit pieces, it will help to identify them as a quality part, and not one made by someone else that is of sub-standard quality.Here's a finished base.

3 steps left:

Split the rings.

Solder the rings to the base.

Finish with parkerize solution.

Hopefully my dern saw blades arrive today.

Talking with Ryan awhile back, I made the decision to engrave our logo on the bottom of the rear bridge pad. This is an attempt to thwart any of the nefarious types who might be tempted to try and pass these off as legit pieces.

I put it in a place that won't be seen once assembled.

DW

And of sub-par quality as a human being.Not only will your logo keep people from trying to pass these off as legit pieces, it will help to identify them as a quality part, and not one made by someone else that is of sub-standard quality.

DW

Chad just texted me photos of the finished mount, it looks amazing! I've requested that he does a comparison with the new old stock Unertl mount I gave him. I'll let him post pics, hopefully he'll do so soon because you guys need to see how great these repro Unertl mounts are!

As requested. A legacy piece next to our stuff.

You be the judge.

You be the judge.

Attachments

-

20231013_162107.jpg1,001.8 KB · Views: 254

20231013_162107.jpg1,001.8 KB · Views: 254 -

20231013_162111.jpg662.6 KB · Views: 228

20231013_162111.jpg662.6 KB · Views: 228 -

20231013_162115.jpg820.9 KB · Views: 225

20231013_162115.jpg820.9 KB · Views: 225 -

20231013_162120.jpg787.8 KB · Views: 222

20231013_162120.jpg787.8 KB · Views: 222 -

20231013_162127.jpg785.7 KB · Views: 234

20231013_162127.jpg785.7 KB · Views: 234 -

20231013_162211.jpg1,005.3 KB · Views: 232

20231013_162211.jpg1,005.3 KB · Views: 232 -

20231013_162213.jpg846.1 KB · Views: 224

20231013_162213.jpg846.1 KB · Views: 224 -

20231013_162221.jpg969.1 KB · Views: 226

20231013_162221.jpg969.1 KB · Views: 226 -

20231013_162226.jpg958.1 KB · Views: 237

20231013_162226.jpg958.1 KB · Views: 237

Looks awesome. I will patiently wait for them to go one sale.

Thanks Chad and Ryan

Thanks Chad and Ryan

Looks really nice. Maybe too nice. Maybe a custom option of tossing it in the dryer inside a bag of rocks? Gain that realistic look. Lol.

Just kidding. Really just waiting for a release date. Patience is a virtue I’m told.

Just kidding. Really just waiting for a release date. Patience is a virtue I’m told.

Stone washed Unertl clones? Or maybe a brief run through a brass tumbler to give the finish a well worn look? Might be just the thing to match some surplus scopes. LRI 'Levi' finish? That would probably have their lawyers busy so maybe spell it backwards, 'Ivel' or 'iveL' finish? lolLooks really nice. Maybe too nice. Maybe a custom option of tossing it in the dryer inside a bag of rocks? Gain that realistic look. Lol.

Just kidding. Really just waiting for a release date. Patience is a virtue I’m told.

Looks like one telling feature, even when mounted, is going to be the slightly added material around the screw heads. It looks like it will completely encircle/enclose the heads when torqued down making them not be visible from the side like the originals are. The kind of anal detail only an obsessed cloner would mind, or perhaps even notice. Those are looking good.As requested. A legacy piece next to our stuff.

You be the judge.

I assume those are 0 MOA? That could be a new tougher test of your skills. Unertl clone mount with 20 MOA. Might be more of a help to the redfields than the Unertls but if it can give them a bit more reach.

The holes for the mount screws also appear to have more material around them or more clearance between them and the rings in certain cases. In addition, either the mount base is a little wider than the original or the base of the rings are slightly smaller than the original?As requested. A legacy piece next to our stuff.

You be the judge.

Looks like one telling feature, even when mounted, is going to be the slightly added material around the screw heads. It looks like it will completely encircle/enclose the heads when torqued down making them not be visible from the side like the originals are. The kind of anal detail only an obsessed cloner would mind, or perhaps even notice. Those are looking good.

I assume those are 0 MOA? That could be a new tougher test of your skills. Unertl clone mount with 20 MOA. Might be more of a help to the redfields than the Unertls but if it can give them a bit more reach.

The holes for the mount screws also appear to have more material around them or more clearance between them and the rings in certain cases. In addition, either the mount base is a little wider than the original or the base of the rings are slightly smaller than the original?

You've got some sharp eyes! Chad and I are aware of a few things that need to be tweaked, even a few things that aren't in either of your posts. When these mounts are complete, they will be 100% correct replicas. So, you don't have to worry about wider or narrower bases, or screw hole locations, or etc. We know exactly what needs to be worked on, and we're going to get everything cleaned up this week.

I deally appreciate your 2 posts because it shows exactly how sharp-eyed cloners are, and how we can notice the smallest of details. I teamed up with Chad for this project (and a few other projects) because I have complete trust and confidence in his abilities to perfectly replicate these Unertl mounts. If I had any doubts, I wouldn't have driven out to South Dakota to give a total stranger that I've never met before (and had only talked to one time on the phone) $70,000+ in original rifles and extremely rare firearm parts. Please keep in mind that we're still in the prototype phase, so there's still more work to be done.

The only way I knew anything was different was because you had the original mount right with it in the pics to closely look at the details. It seemed to me that the slight differences could easily make it a better mount.You've got some sharp eyes! Chad and I are aware of a few things that need to be tweaked, even a few things that aren't in either of your posts. When these mounts are complete, they will be 100% correct replicas. So, you don't have to worry about wider or narrower bases, or screw hole locations, or etc. We know exactly what needs to be worked on, and we're going to get everything cleaned up this week.

I deally appreciate your 2 posts because it shows exactly how sharp-eyed cloners are, and how we can notice the smallest of details. I teamed up with Chad for this project (and a few other projects) because I have complete trust and confidence in his abilities to perfectly replicate these Unertl mounts. If I had any doubts, I wouldn't have driven out to South Dakota to give a total stranger that I've never met before (and had only talked to one time on the phone) $70,000+ in original rifles and extremely rare firearm parts. Please keep in mind that we're still in the prototype phase, so there's still more work to be done.

I was not intending my posts to be a dig in any way. I thought of the pictures and LRI's "You be the judge" as one of those old "can you find the discrepancies" games. Gave it a shot to see if I could pick out any differences.

These are definitely old school in style and construction, with an elegance the pic rails and comparatively massive rings of modern mounts can't match.

The only other thing I see is on the front lug, when looking at the bottom, the semicircle doesn't go all the way around and the front of the lug. There is a straight side on the left side of the lug.The holes for the mount screws also appear to have more material around them or more clearance between them and the rings in certain cases. In addition, either the mount base is a little wider than the original or the base of the rings are slightly smaller than the original?

Attachments

The new mount looks slightly off vertical to me in that picture compared to the original so it could be throwing my perception off. It might be a combo of camera and lighting placement. The finish differences alsoThe only other thing I see is on the front lug, when looking at the bottom, the semicircle doesn't go all the way around and the front of the lug. There is a straight side on the left side of the lug.

make things look different so I'm not absolutely sure of myself, but here's how I see it.

I'll look at the 3 different photos of the bottoms since they all have different orientations and hope I can notice things properly. I won't count the fourth photo since it catches the original in the process of falling over and no comparison can be made from it.

The area of the lug your looking at is the result of several differences it appears. I'll just refer to things in the picture's orientation for simplicity.

Starting with the main flat angled surface, it looks to be at a different pitch than the original. First resulting difference is the larger size of the semicircular ledge. Or the ledge was cut slightly short which also would result in a slightly bigger semicircle.

It also appears to have a step left at main angle's base from needing another pass with the bit I think. I never got play with the machine tools in shop class back in the day. I only got to sand cast aluminum.

The original looks to have a cliff, for lack of a better word, in that location from maybe milling the main flat base surface?

The right side vertical cut appears cleaner on the new one.

The original, maybe due to surface wear highlighting, appears to have a sharper point where the vertical and angle cuts meet on that right side of the lug than the new.

The left side has a much bigger cut off it than the original. It also appears to have a more rounded cut for the exit of the ejection port area. Doing that could have resulted in the bigger cut off.

The rear port opening appears more rounded than the original too.

The main circular cut, resuting in the rounded side of the lug, appear to be slightly deeper on the new one.

The screw holes appear to me now to be inset inward more on the new than the original. Which would result in the extra material surounding the screwhead I noticed before. Or the rings are slightly thicker than the original requiring the clearance cut. But that would also mean the overal width of the ring was a bit wider too. AAAAAAaaaaaaaaa

I'm feeling more like that dog now. LOL Someone bring in a 3D laser scanner so we can end this guessing game. Or schematics.

Come on guys they said it was a prototype and they had some tweaks that needed done.

I was just seeing how much detail I could notice. Just an enthusiastic student type viewpoint watching the pro do his thing. Not as a put down in any way. I'm a bit fascinated by the machine work. Both milling and lathing. If PRI or USMCSGT0331 have taken offense I apologize to them.Come on guys they said it was a prototype and they had some tweaks that needed done.

I have definitely got to get some machines and start creating things. But there is so many brands, many chinese made from what I can tell and no telling which are the names to stick with for lasting quality. Anytime I've tried asking about brands in the past, the answers were usually some chinese made hobby or north tool type. I don't think they wanted competition in buying the better big old machines.

I never said it was a put down. Just stating facts that they said it wasn’t the end product.I was just seeing how much detail I could notice. Just an enthusiastic student type viewpoint watching the pro do his thing. Not as a put down in any way. I'm a bit fascinated by the machine work. Both milling and lathing. If PRI or USMCSGT0331 have taken offense I apologize to them.

I have definitely got to get some machines and start creating things. But there is so many brands, many chinese made from what I can tell and no telling which are the names to stick with for lasting quality. Anytime I've tried asking about brands in the past, the answers were usually some chinese made hobby or north tool type. I don't think they wanted competition in buying the better big old machines.

I’m sure Chad knows how to make parts.

These look amazing! Have you thought of a pricepoint range, or when you might actually start to sell them? I will definitely take one!

Chad could you make a Metal M70 Trigger guard for the new McMillian release stocks? I'm thinking get one off of Ryan already modified and just make a run of those?

With these 50 stocks being released I think a lot of will be looking for them, and it appears these parts are hard to find in metal.

With these 50 stocks being released I think a lot of will be looking for them, and it appears these parts are hard to find in metal.

Chad could you make a Metal M70 Trigger guard for the new McMillian release stocks?

Well specifically steel if you want it to be accurate, there are plenty of aluminum post 64 trigger guards and even stainless that pop up for sale often, steel is the one thats hard to find.

It is also worth noting that smear stocks being early in the M40A1 production, would have most likely had (and many return stocks that had bottom metal did) the pre-64 trigger guard, which are easy to find.

A note here would be they should be produced as the Winchester part would have with the metal extended, as cutting them to size is custom to individual stocks, not everyone might need the part for the new blueprinted smear in other words.

I have one of the new made Smears and it is cut for the wider post 64 trigger guard. I put a pre 64 up to it last night and there is definitely a lot of slop. I don't know if you can just bed them in, but I think I would rather have one that actually fits it.

You can (and should) bed the action and bottom metal, I just wanted to include all the info there for anyone else reading through because with the m40forum gone its going to be hard for new people to find detailed info like that. The post 64 looks better regardless.

Another bit of info to add, there is also pre-64 and post-64 floor plates as well. They will all need fitted by a gunsmith but the pre-64 is thinner and when used with a post 64 trigger guard there is a gap with some movement, yes there are verified issued ones set up like this. And if you want to go all in there were even pre-64 and post-64 floor plates marked - SUPERGRADE -, they still have the different thickness and are marked with slightly different fonts. And yes, the supergrade floor plates were also seen on issued weapons.

Another bit of info to add, there is also pre-64 and post-64 floor plates as well. They will all need fitted by a gunsmith but the pre-64 is thinner and when used with a post 64 trigger guard there is a gap with some movement, yes there are verified issued ones set up like this. And if you want to go all in there were even pre-64 and post-64 floor plates marked - SUPERGRADE -, they still have the different thickness and are marked with slightly different fonts. And yes, the supergrade floor plates were also seen on issued weapons.

We have a resident wizard on M40A1 bottom Metal modifications in house. @Raven 6

Methinks that at the time a floorplate was a floorplate was a floorplate.You can (and should) bed the action and bottom metal, I just wanted to include all the info there for anyone else reading through because with the m40forum gone its going to be hard for new people to find detailed info like that. The post 64 looks better regardless.

Another bit of info to add, there is also pre-64 and post-64 floor plates as well. They will all need fitted by a gunsmith but the pre-64 is thinner and when used with a post 64 trigger guard there is a gap with some movement, yes there are verified issued ones set up like this. And if you want to go all in there were even pre-64 and post-64 floor plates marked - SUPERGRADE -, they still have the different thickness and are marked with slightly different fonts. And yes, the supergrade floor plates were also seen on issued weapons.

Never knew there was all that variation. I was wondering about new made guards and floorplates as well. All the new buyers and even some of the return owners could want them. Hope USMSSGT0331 has pics for the book of those differences.You can (and should) bed the action and bottom metal, I just wanted to include all the info there for anyone else reading through because with the m40forum gone its going to be hard for new people to find detailed info like that. The post 64 looks better regardless.

Another bit of info to add, there is also pre-64 and post-64 floor plates as well. They will all need fitted by a gunsmith but the pre-64 is thinner and when used with a post 64 trigger guard there is a gap with some movement, yes there are verified issued ones set up like this. And if you want to go all in there were even pre-64 and post-64 floor plates marked - SUPERGRADE -, they still have the different thickness and are marked with slightly different fonts. And yes, the supergrade floor plates were also seen on issued weapons.

Slightly off topic but still M40 related, He said about posting all the new stock pics as released so there would be records for future generations. That, and as many return pics he could gather from owners would make a good section for the book. Either McMillan or Quantico records could let him a list wood, smear, semi smear, woodland, destroyed/replaced if either location kept those details. I guess any return woodland would by an indication of a deceased smear at some point? Then there is the A3 return and later stocks that also would have shared holding the same action number though with detachable mag bottom metal.

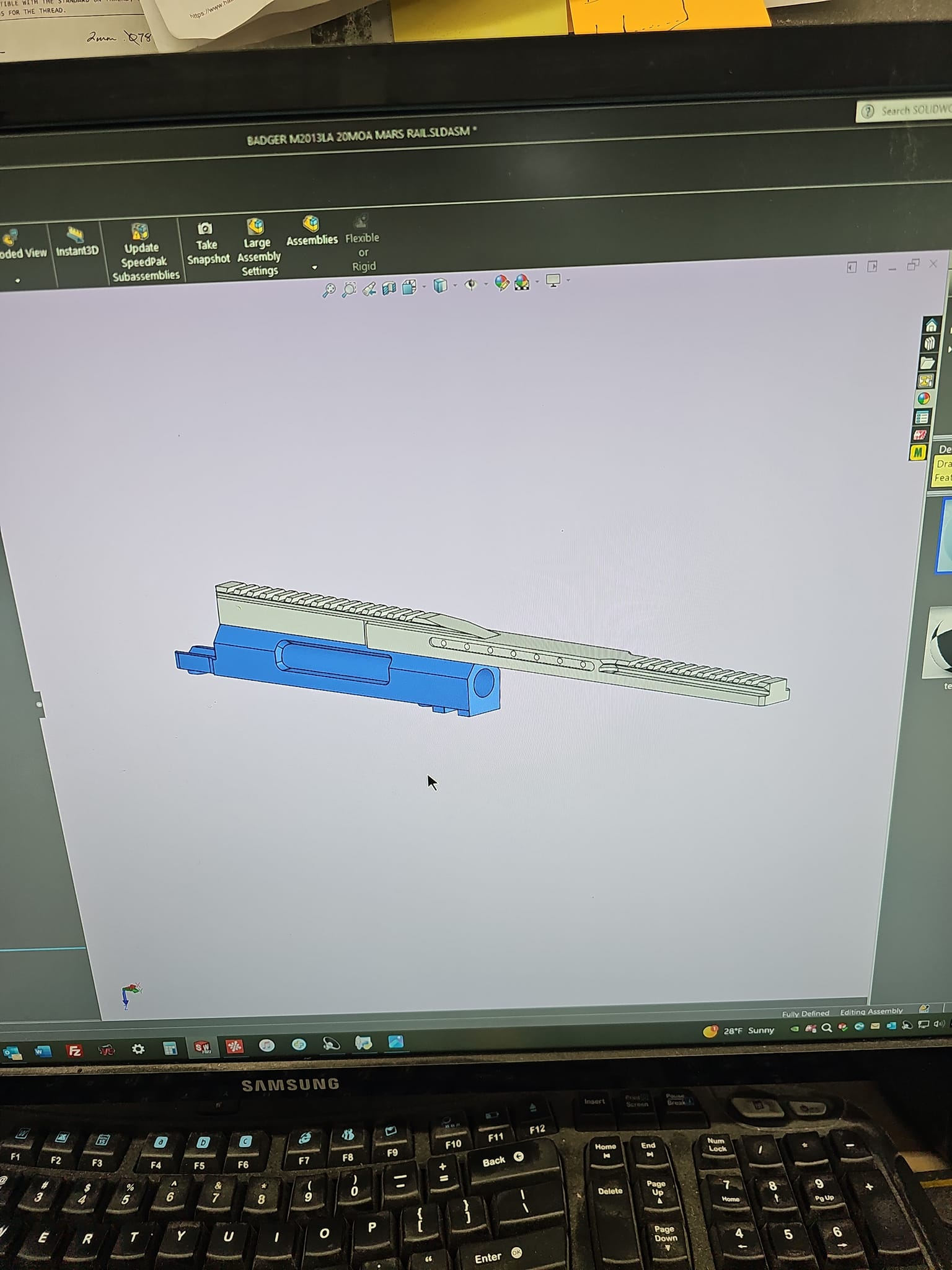

I had a rush order on some belt fed stuff and I had to get this thing made as well. -A MARS rail for a Badger 2013 action. Wierd, but kinda cool at the same time. (I guess, lol)

My saw blades finally arrived. Soon as I'm able to set this back up, I'll post up some progress photos.

My saw blades finally arrived. Soon as I'm able to set this back up, I'll post up some progress photos.

White fuzz? Aluminum oxidation?The white fuzz is starting to creep out from under my rings on my crappy TMA mount

MIM part returning to it's powdered form? lol

If you own one of his piece of shit mounts you know.White fuzz? Aluminum oxidation?

MIM part returning to it's powdered form? lol

I have no clue what it is.

So true!If you own one of his piece of shit mounts you know.

I have no clue what it is.

OddBall: no aluminum was used on them, so it’s not aluminum oxide. Plus, aluminum oxide on aluminum doesn’t creep. Even on his POS mounts. Some claim magnets inside. I’ve intentionally twisted off several of his rings and mine all had a steel dowel pin in them.

Very strange, maybe it is bluing salts? I have a hard time thinking of the dull black finishes of todays firearms as bluing. I picture the old polished guns of yesteryear with a beautiful blue finish.So true!If they were hot blued, it would be the leftover bluing salts creeping out. I’m 99% sure he cold blued them. Probably some solution weeping out from under the rings.

OddBall: no aluminum was used on them, so it’s not aluminum oxide. Plus, aluminum oxide on aluminum doesn’t creep. Even on his POS mounts. Some claim magnets inside. I’ve intentionally twisted off several of his rings and mine all had a steel dowel pin in them.

He's waiting on a pic-a-nic basket full of fresh finished mounts. Bear-ly containing himself.

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 41

- Views

- 2K

- Replies

- 8

- Views

- 2K

- Replies

- 0

- Views

- 565