I just got hold of this McMillan stock , paid equivalent of $350USD for it (I’m in Australia) .

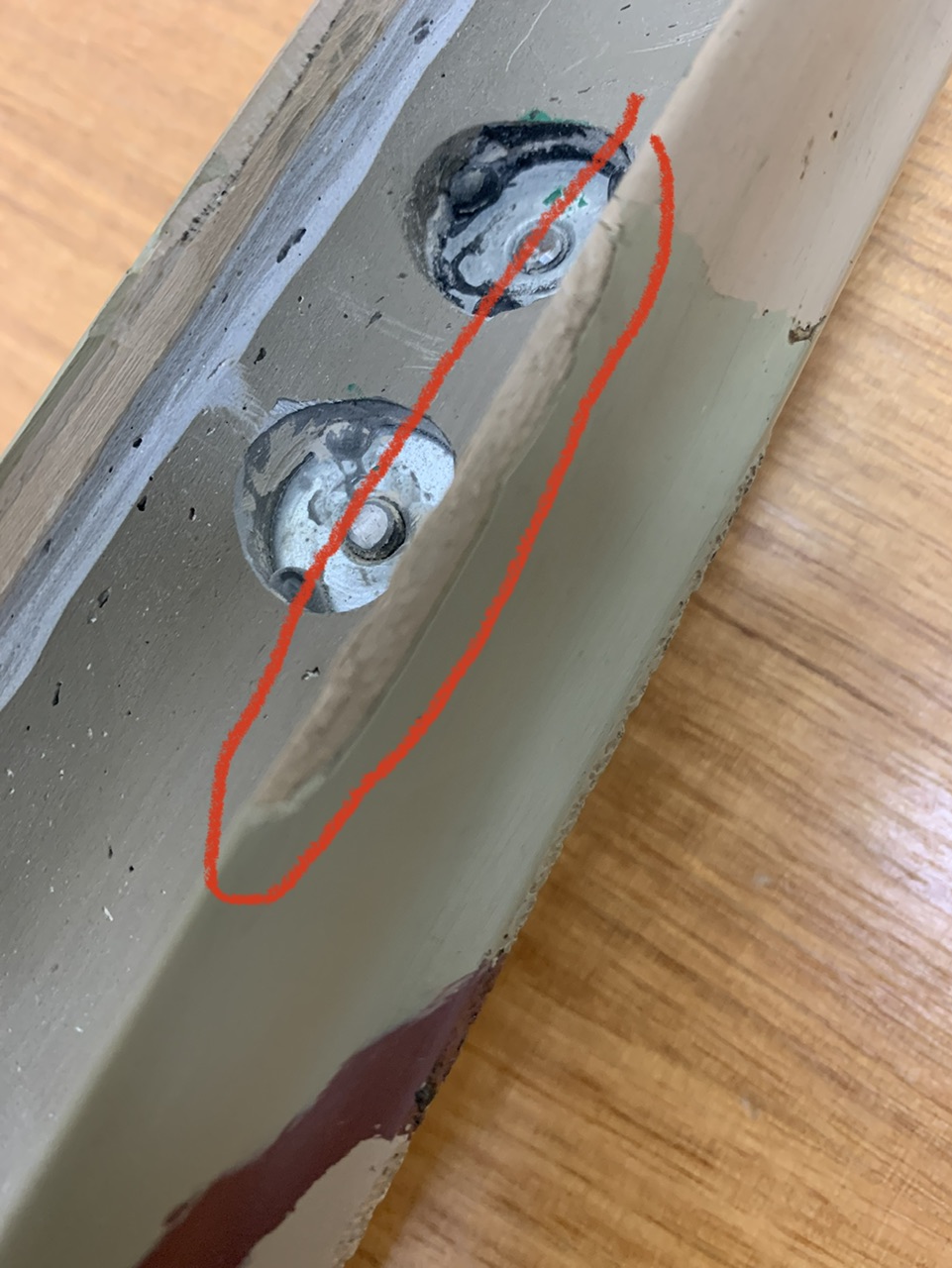

Plan was to fix it up as it was disclosed as having a chip on the forend as pictured and having been “inletted for a VTR”.

What they didn’t say was it was inletted by a blind chimp (see attached).

So the top edges of the forend are very thin and there is gouges out along the length of the forend presumably to allow for the VTR barrel , it’s also got bedding material at the tang and lug areas that is maybe arma grout?

I was confident to repair the chip however curious how others might approach this job, more so from a hobbiest perspective as I don’t have specialist tools.

Cheers

Plan was to fix it up as it was disclosed as having a chip on the forend as pictured and having been “inletted for a VTR”.

What they didn’t say was it was inletted by a blind chimp (see attached).

So the top edges of the forend are very thin and there is gouges out along the length of the forend presumably to allow for the VTR barrel , it’s also got bedding material at the tang and lug areas that is maybe arma grout?

I was confident to repair the chip however curious how others might approach this job, more so from a hobbiest perspective as I don’t have specialist tools.

Cheers