I have mine on the way (yay) and am setting up my bench for it.

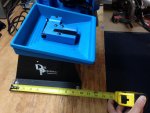

Can someone who has one tell me the dimensions of the mounting holes?

All I need is distance from front to back and side to side from center of the presses mounting holes. Not using a strong mount.

I have searched for quite a whole trying to find a mounting template, anything. I could find nothing.

This is the best place I can think to ask, thank you SH!!

FYI- I'm not drilling the holes through bench top now based off your numbers...I'll wait for the press for that. I am putting in supports under the bench top that the mounting screws will go through and I want to do that part now. Doesn't need to be exact...

Can someone who has one tell me the dimensions of the mounting holes?

All I need is distance from front to back and side to side from center of the presses mounting holes. Not using a strong mount.

I have searched for quite a whole trying to find a mounting template, anything. I could find nothing.

This is the best place I can think to ask, thank you SH!!

FYI- I'm not drilling the holes through bench top now based off your numbers...I'll wait for the press for that. I am putting in supports under the bench top that the mounting screws will go through and I want to do that part now. Doesn't need to be exact...

Last edited: