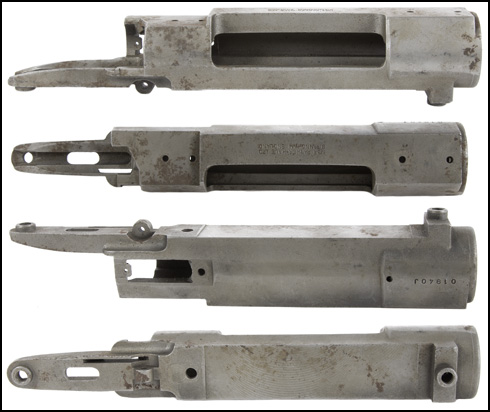

A while back I got the bug to build a C3A1 clone from one of the PH M84 single shot receivers floating around out there.

Well, that's when the search for parts started to get real interesting. At this point, all I had was the receiver in the condition you see above. After many months, I was able to locate a few parts from the US, UK, and Canada. The big challenge has been the bottom metal. I was only able to find a trigger bow, mag catch, and screw. Finally I got a big break on Ebay with finding 2 magazines that were unfinished. Basically the main mag body was formed and welded, 2 spacers, and the bottom metal. No springs or followers.

Well, that's when the search for parts started to get real interesting. At this point, all I had was the receiver in the condition you see above. After many months, I was able to locate a few parts from the US, UK, and Canada. The big challenge has been the bottom metal. I was only able to find a trigger bow, mag catch, and screw. Finally I got a big break on Ebay with finding 2 magazines that were unfinished. Basically the main mag body was formed and welded, 2 spacers, and the bottom metal. No springs or followers.