Hello everyone,

Do you know of any quality shims I could use to get my muzzle device to sit flush? I removed my Lil B and going with Area419 hardware in order to use my suppressor and brake as needed/wanted. The APA Lil B would go in all the way. It appears my threads might be a tad bit too long and the Area419 adaptor does not make contact with the shoulder.

If someone knows of a particular product for these issues I would appreciate a link. Or is that a big No and and I should cut threads a bit?

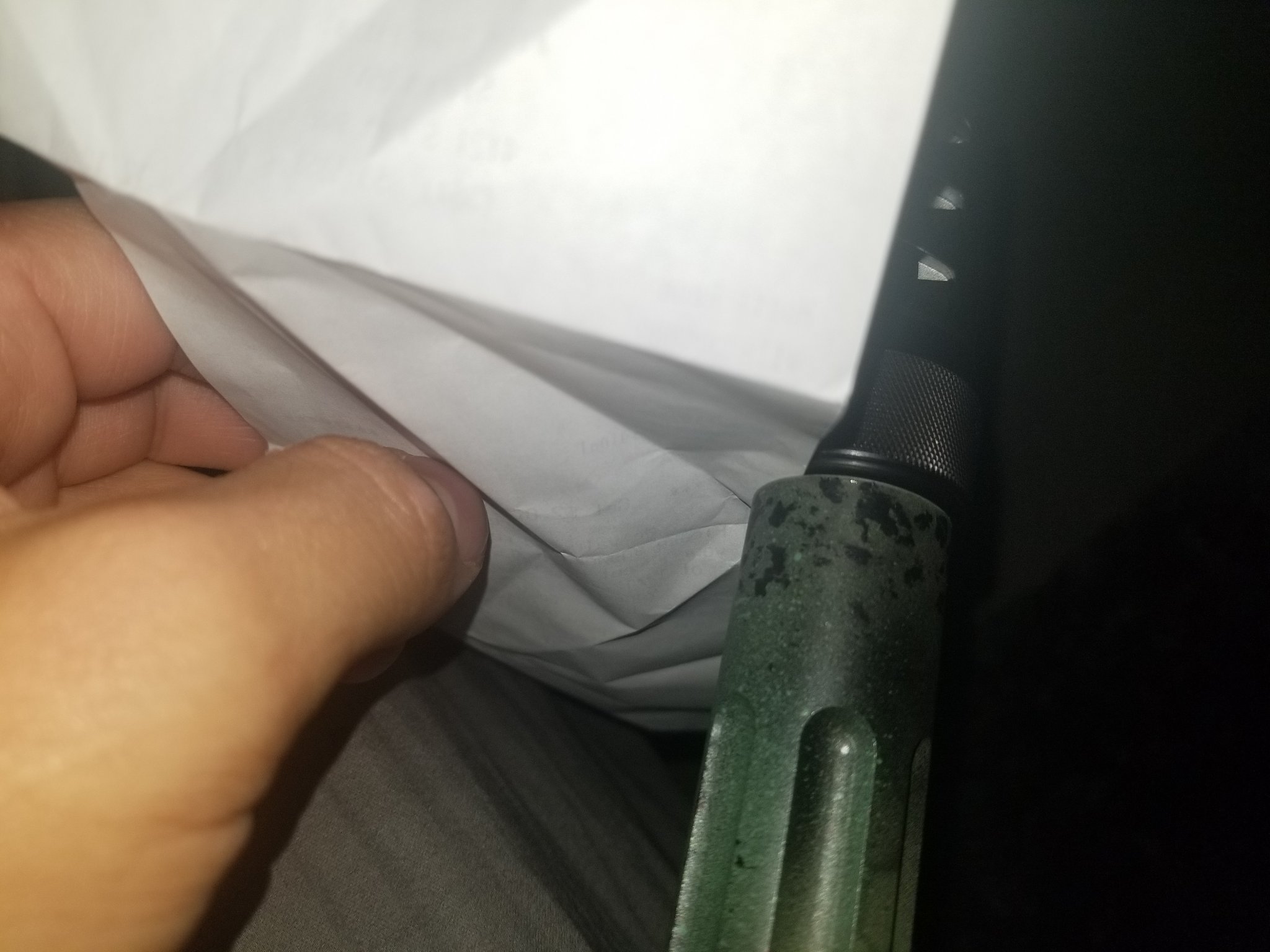

I posted a picture and as you can see I can get paper to fit between.

Thanks,

S

Do you know of any quality shims I could use to get my muzzle device to sit flush? I removed my Lil B and going with Area419 hardware in order to use my suppressor and brake as needed/wanted. The APA Lil B would go in all the way. It appears my threads might be a tad bit too long and the Area419 adaptor does not make contact with the shoulder.

If someone knows of a particular product for these issues I would appreciate a link. Or is that a big No and and I should cut threads a bit?

I posted a picture and as you can see I can get paper to fit between.

Thanks,

S