Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Winner! Quick Shot Challenge: What’s the dumbest shooting myth you’ve heard?

View thread

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing my "off time" project

- Thread starter LRI

- Start date

Re: my "off time" project

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JACQ</div><div class="ubbcode-body">Is there anything you DONT do?</div></div>

I bet he doesn't break dance!

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JACQ</div><div class="ubbcode-body">Is there anything you DONT do?</div></div>

I bet he doesn't break dance!

Re: my "off time" project

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Oddball-Six</div><div class="ubbcode-body">

I bet he doesn't break dance! </div></div>

Came through Sturgis last Thursday afternoon and it was nice and sunny. Some bleached out looking dude wearing funny clothes in the Industrial Park on west side of town with a mic(the measuring kind) in his hand back sliding across the parking lot.....soooooo.........uh,.......we uh,......probably shouldn't rule that out just yet,......just sayin!!!

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Oddball-Six</div><div class="ubbcode-body">

I bet he doesn't break dance! </div></div>

Came through Sturgis last Thursday afternoon and it was nice and sunny. Some bleached out looking dude wearing funny clothes in the Industrial Park on west side of town with a mic(the measuring kind) in his hand back sliding across the parking lot.....soooooo.........uh,.......we uh,......probably shouldn't rule that out just yet,......just sayin!!!

Re: my "off time" project

I like your choice of hobbies man!

I dabbled in a slightly slower sport of RC Sailboats a while back; looking to graduate to flying machines soon.

I like your choice of hobbies man!

I dabbled in a slightly slower sport of RC Sailboats a while back; looking to graduate to flying machines soon.

Re: my "off time" project

This engine, if it even runs when I'm finished, is for an all composite Formula One airplane known as a Kelly.

The Unlimited Scale Racing Association (USRA) is the sanctioning body for this stuff. The #69 plane IS NOT mine. It's a stock photo I pulled off the web just to show one assembled. These are 42% of scale models.

In the Formula One class your required to use an "untouched" 80cc engine made by Zenoah. Pump gasoline and a spec prop are required. I'm hoping to run in the Formula One Pro class which only has an 80cc displacment restriction. You can run any fuel/any prop.

This engine of mine will be running between 30-60 percent nitromethane/methanol for fuel.

Ignition systems are ditched in favor of glow plugs. Simpler and more reliable.

Speeds vary with class. The Formula One planes run around 130mph. The F1 Pro are close to 200mph. The Unlimited class hovers around 240mph and the experimental aircraft run closer to 260+.

http://usraracing.net/

I have a friend down in Flagstaff who's pretty much the smartest guy on the planet when it comes to this stuff. He's helped me ALOT with this project. He has a new engine for the Unlimited class that should put his plane over 300mph. These are actual speeds, not scale.

The aircraft typically use a one piece wing made from a honeycomb/composite material and they see G loads in excess of 40+ when cornering.

12 is generally lethal for a human being.

The track is two pylons spaced 1600 feet apart. Go fast turn left for six laps. If you do it right your plane shouldn't be in the air more than 2 minutes.

Seems contradictory, the faster you go the less time you get to actually do it. Maybe that's why I love drag racing too.

I'm hoping to gin up either a mechanical or maybe even an electronic fuel injection setup for this bugger. Three injectors. One in each transfer port and one in the crankcase to ensure the bottom end sees oil. (two strokes are lubricated by oil mixed with the fuel)

We'll see. I have the crank/rods done already. I'm frankensteining pistons from a different engine, although I did contact JE race pistons and they sent me unmachined forged slugs in case I want to do my own.

debating on the material for the liners. I have a stick of Durabar centrifugally spun, graphite impregnated, normalized, micro grain cast iron that I may use for liners. I can also just buy a finished liner from the same company I got the pistons finished pistons from. I may go that route because it'll be a drop in fit that way. Far less work.

Fun stuff!

This engine, if it even runs when I'm finished, is for an all composite Formula One airplane known as a Kelly.

The Unlimited Scale Racing Association (USRA) is the sanctioning body for this stuff. The #69 plane IS NOT mine. It's a stock photo I pulled off the web just to show one assembled. These are 42% of scale models.

In the Formula One class your required to use an "untouched" 80cc engine made by Zenoah. Pump gasoline and a spec prop are required. I'm hoping to run in the Formula One Pro class which only has an 80cc displacment restriction. You can run any fuel/any prop.

This engine of mine will be running between 30-60 percent nitromethane/methanol for fuel.

Ignition systems are ditched in favor of glow plugs. Simpler and more reliable.

Speeds vary with class. The Formula One planes run around 130mph. The F1 Pro are close to 200mph. The Unlimited class hovers around 240mph and the experimental aircraft run closer to 260+.

http://usraracing.net/

I have a friend down in Flagstaff who's pretty much the smartest guy on the planet when it comes to this stuff. He's helped me ALOT with this project. He has a new engine for the Unlimited class that should put his plane over 300mph. These are actual speeds, not scale.

The aircraft typically use a one piece wing made from a honeycomb/composite material and they see G loads in excess of 40+ when cornering.

12 is generally lethal for a human being.

The track is two pylons spaced 1600 feet apart. Go fast turn left for six laps. If you do it right your plane shouldn't be in the air more than 2 minutes.

Seems contradictory, the faster you go the less time you get to actually do it. Maybe that's why I love drag racing too.

I'm hoping to gin up either a mechanical or maybe even an electronic fuel injection setup for this bugger. Three injectors. One in each transfer port and one in the crankcase to ensure the bottom end sees oil. (two strokes are lubricated by oil mixed with the fuel)

We'll see. I have the crank/rods done already. I'm frankensteining pistons from a different engine, although I did contact JE race pistons and they sent me unmachined forged slugs in case I want to do my own.

debating on the material for the liners. I have a stick of Durabar centrifugally spun, graphite impregnated, normalized, micro grain cast iron that I may use for liners. I can also just buy a finished liner from the same company I got the pistons finished pistons from. I may go that route because it'll be a drop in fit that way. Far less work.

Fun stuff!

Re: my "off time" project

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: C. Dixon</div><div class="ubbcode-body"> I have a stick of Durabar centrifugally spun, graphite impregnated, normalized, micro grain cast iron that I may use for liners. </div></div>

You just made me feel stoopid

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: C. Dixon</div><div class="ubbcode-body"> I have a stick of Durabar centrifugally spun, graphite impregnated, normalized, micro grain cast iron that I may use for liners. </div></div>

You just made me feel stoopid

Re: my "off time" project

When you finally do ask that beautiful girlfriend of yours to marry you I bet you'll CNC her a ring won't you? Too much cool stuff.

When you finally do ask that beautiful girlfriend of yours to marry you I bet you'll CNC her a ring won't you? Too much cool stuff.

Re: my "off time" project

<div class="ubbcode-block"><div class="ubbcode-header">Quote:</div><div class="ubbcode-body">Maybe that's why I love drag racing too.</div></div>

Amen to that, brother... the Nitro classes are an awesome sight to behold, but Pro stock & Pro Mod is where it's at for me as far as the professionals go. Then there's the Outlaw 10.5 stuff too.... I used to dabble in the RC drag scene many moons ago as well.

Anyway, your RC engine sounds like it'll be a killer. Best of luck with it!

<div class="ubbcode-block"><div class="ubbcode-header">Quote:</div><div class="ubbcode-body">Maybe that's why I love drag racing too.</div></div>

Amen to that, brother... the Nitro classes are an awesome sight to behold, but Pro stock & Pro Mod is where it's at for me as far as the professionals go. Then there's the Outlaw 10.5 stuff too.... I used to dabble in the RC drag scene many moons ago as well.

Anyway, your RC engine sounds like it'll be a killer. Best of luck with it!

Re: my "off time" project

NICE Plane. I flew RC planes about 15 years ago, but mine were all .60 class. Built a new plane over the winter, then flew it most of the summer. Evemtually it was so patched up with epoxy it would not get off the ground.

I was mentored by an older gentleman that flew for 30+ years; always remember what he said..."if you fly em..eventually you crash em".

He was right! I crashed quite a few.

My gun hobby is much cheaper...and WAY less stressful!

NICE Plane. I flew RC planes about 15 years ago, but mine were all .60 class. Built a new plane over the winter, then flew it most of the summer. Evemtually it was so patched up with epoxy it would not get off the ground.

I was mentored by an older gentleman that flew for 30+ years; always remember what he said..."if you fly em..eventually you crash em".

He was right! I crashed quite a few.

My gun hobby is much cheaper...and WAY less stressful!

Re: my "off time" project

Chad,

Have you considered Nikasil or Alusil for cylinders?

Would be very lite and piston to bore expansion ratio would be more stable through the heat range. Not sure who all does the forging or plating but I bet you could figure out how to machine it. I worked with both style blocks when I was with BMW. Good stuff....

Heres a link with some info: http://www.lnengineering.com/whynickies.html

Chad,

Have you considered Nikasil or Alusil for cylinders?

Would be very lite and piston to bore expansion ratio would be more stable through the heat range. Not sure who all does the forging or plating but I bet you could figure out how to machine it. I worked with both style blocks when I was with BMW. Good stuff....

Heres a link with some info: http://www.lnengineering.com/whynickies.html

Re: my "off time" project

Nikasail sounds viable. May have to look at it further. Still piddling with the programming. Its a bit complicated as the entire model is a series of surfaces stitched together. Really wears on my graphics card. (Upgrade coming!) I've got90% of the tool paths done for the snout/front case cover portion. Ordered some tooling, should be here by tomorrow maybe. Won't have any time to fuss over the weekend. Lots of gun stuff to catch up on. Planning on proofing the code with machinable wax. Great stuff for these kinds of things. Hope to have it running by summer. Next winter ill finish the plane. I have a 42%, all composit sukkoi (124" wing) to build yet too.

Need more hours in the day!

Nikasail sounds viable. May have to look at it further. Still piddling with the programming. Its a bit complicated as the entire model is a series of surfaces stitched together. Really wears on my graphics card. (Upgrade coming!) I've got90% of the tool paths done for the snout/front case cover portion. Ordered some tooling, should be here by tomorrow maybe. Won't have any time to fuss over the weekend. Lots of gun stuff to catch up on. Planning on proofing the code with machinable wax. Great stuff for these kinds of things. Hope to have it running by summer. Next winter ill finish the plane. I have a 42%, all composit sukkoi (124" wing) to build yet too.

Need more hours in the day!

Re: my "off time" project

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Oddball-Six</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JACQ</div><div class="ubbcode-body">Is there anything you DONT do?</div></div>

I bet he doesn't break dance!</div></div>

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/Vr_R9EKs1uI"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/Vr_R9EKs1uI" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Oddball-Six</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JACQ</div><div class="ubbcode-body">Is there anything you DONT do?</div></div>

I bet he doesn't break dance!</div></div>

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/Vr_R9EKs1uI"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/Vr_R9EKs1uI" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

Re: my "off time" project

Not sure if Chad can break dance, but you can bet that he can write a CNC program that can...

Not sure if Chad can break dance, but you can bet that he can write a CNC program that can...

Re: my "off time" project

Chad, that is one trick engine! Want to CNC me a custom radically finger ported chainsaw engine? I think your design will be a winner! How many revs will this thing be turning?

Chad, that is one trick engine! Want to CNC me a custom radically finger ported chainsaw engine? I think your design will be a winner! How many revs will this thing be turning?

Re: my "off time" project

That is very nice, I had a kit like that that was given to me about 35 years ago, it had 2 fox engines, but I never got around to building it. I have no idea what happened to it either, I think I gave it to this old man I used to know.... Those sucker hall ass in the right persons hands......

Thanks for sharing.....

That is very nice, I had a kit like that that was given to me about 35 years ago, it had 2 fox engines, but I never got around to building it. I have no idea what happened to it either, I think I gave it to this old man I used to know.... Those sucker hall ass in the right persons hands......

Thanks for sharing.....

Re: my "off time" project

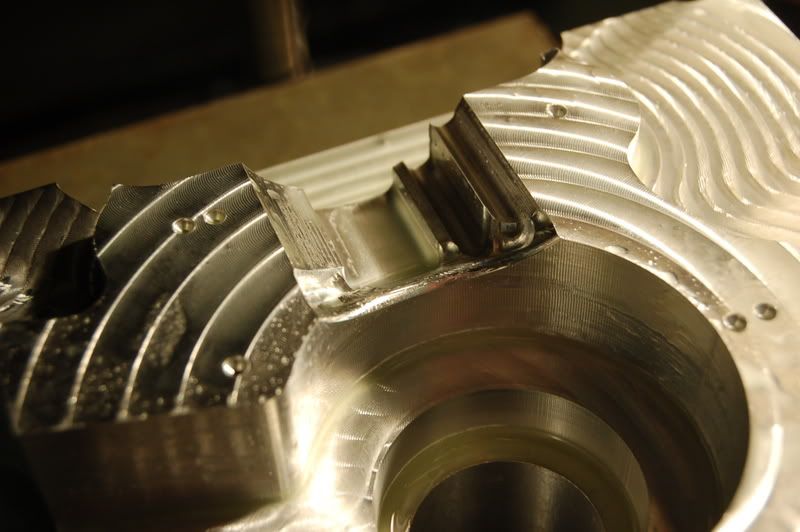

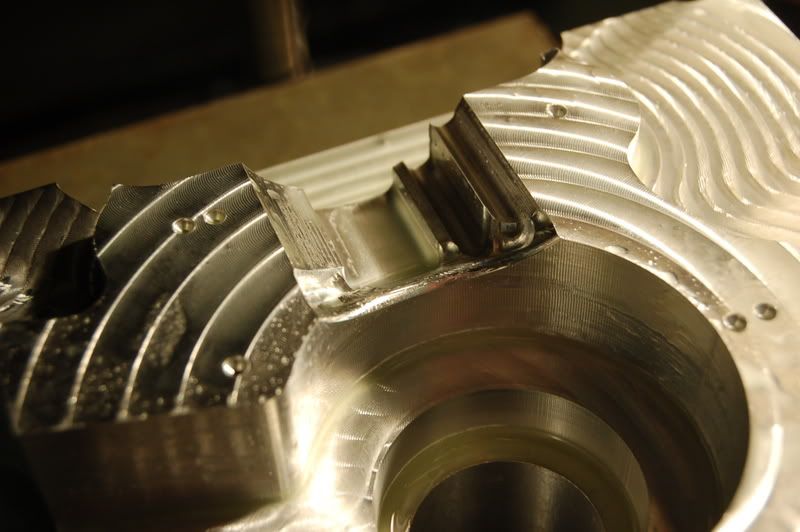

Well I got some time to work on this last night.

Here's where I'm at so far. The right bank is pretty close to done. The surfacing programming for the transfer ports was fun! I have the left to do yet and I'm roughing the outside contour right now. (lot of material to make go away so this will take a little while.)

The center bores for the bearings and crankshaft are done. I have to chamfer the edges yet, but everything is qualified and looks pretty good.

Will work on it today till I get the bolt/dowel holes done, then it's back to work!

Enjoy,

C

Well I got some time to work on this last night.

Here's where I'm at so far. The right bank is pretty close to done. The surfacing programming for the transfer ports was fun! I have the left to do yet and I'm roughing the outside contour right now. (lot of material to make go away so this will take a little while.)

The center bores for the bearings and crankshaft are done. I have to chamfer the edges yet, but everything is qualified and looks pretty good.

Will work on it today till I get the bolt/dowel holes done, then it's back to work!

Enjoy,

C

Re: my "off time" project

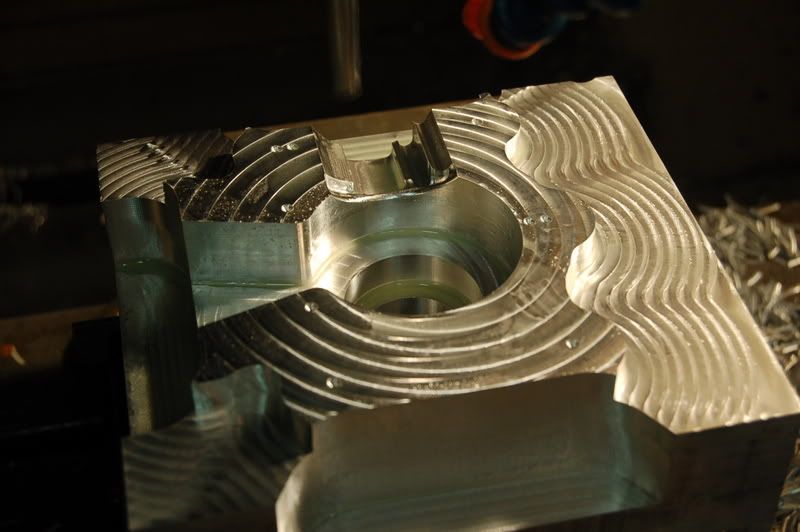

MORE progress!! Woo Hoo, I'm gettin a fatty!

I wished I'd done both sets of transfer ports like this. Nitromethane doesn't atomize for chit. It likes to cling and form a big ol glob that goes bang. I'm hoping the stepped finish in the transfer ports helps to break it up a little. I left some material on the opposite bank so I may go back and revise my tool path to see if I can replicate the left one.

Fun stuff.

For all purposes its ready now to come out of the machine. I checked my deck dimensions. I'm within .003" for overall width. That's plenty close. I can make up the difference by altering the length of the cylinders a bit. Motor won't know a thing. Just need to cut my boost ports now and she's ready to pop out of the vise and be flipped over.

There's quite a bit of tool chatter on the outside finish. I plowed around this thing as fast as I dared. 95% of it will come off during the final surfacing/contouring with a little 3/16" ball/ and .03 radius bull mill so I'm not worried about it much. I left .1" on the outside for plenty of meat to hopefully leave a nice clean finish. I'm shooting for a .100" wall thickness on the case. This will likely induce some chatter as the part will want to ring like a church bell while machining. My plan is to fill the inner cavity with cerosafe to make it a solid piece again. The heavy metal should deaden things up quite a bit. Then when I'm done I'll just cook the stuff out of it and we'll be done.

But I have to get back to "real" work (dern it!) so it'll have to sit for a day or two.

Laters!

C

MORE progress!! Woo Hoo, I'm gettin a fatty!

I wished I'd done both sets of transfer ports like this. Nitromethane doesn't atomize for chit. It likes to cling and form a big ol glob that goes bang. I'm hoping the stepped finish in the transfer ports helps to break it up a little. I left some material on the opposite bank so I may go back and revise my tool path to see if I can replicate the left one.

Fun stuff.

For all purposes its ready now to come out of the machine. I checked my deck dimensions. I'm within .003" for overall width. That's plenty close. I can make up the difference by altering the length of the cylinders a bit. Motor won't know a thing. Just need to cut my boost ports now and she's ready to pop out of the vise and be flipped over.

There's quite a bit of tool chatter on the outside finish. I plowed around this thing as fast as I dared. 95% of it will come off during the final surfacing/contouring with a little 3/16" ball/ and .03 radius bull mill so I'm not worried about it much. I left .1" on the outside for plenty of meat to hopefully leave a nice clean finish. I'm shooting for a .100" wall thickness on the case. This will likely induce some chatter as the part will want to ring like a church bell while machining. My plan is to fill the inner cavity with cerosafe to make it a solid piece again. The heavy metal should deaden things up quite a bit. Then when I'm done I'll just cook the stuff out of it and we'll be done.

But I have to get back to "real" work (dern it!) so it'll have to sit for a day or two.

Laters!

C

Re: my "off time" project

I am going to have to check this out tomorrow when we stop over. I am starting to think that you live there at the shop.

I am going to have to check this out tomorrow when we stop over. I am starting to think that you live there at the shop.

Re: my "off time" project

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: LWILLIAMS</div><div class="ubbcode-body">I am going to have to check this out tomorrow when we stop over. I am starting to think that you live there at the shop. </div></div>

He does live there. The back of the shop should have a sign hanging that says "Chad Cave".

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: LWILLIAMS</div><div class="ubbcode-body">I am going to have to check this out tomorrow when we stop over. I am starting to think that you live there at the shop. </div></div>

He does live there. The back of the shop should have a sign hanging that says "Chad Cave".

Re: my "off time" project

If I had his shop there is no way I would be able to have a gf/wife, luckily that HAAS mill can probably cook dinner too with the right programming!

If I had his shop there is no way I would be able to have a gf/wife, luckily that HAAS mill can probably cook dinner too with the right programming!

Re: my "off time" project

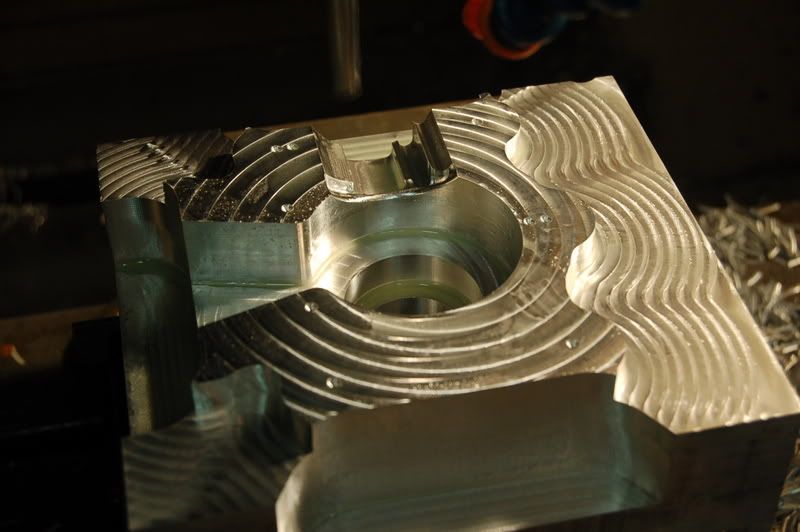

Few more updates.

Bearing registers are all set now. Crank sits in the case really well. Nice and fluid on the rotation with minimal clearances everywhere. I was off a bit on the rod clearance so I'll have to widen that a bit (UNLESS!(idea!) I time up my boost ports with each of the rods. Then I'll have the clearance I need without over-sizing the crankcase too much. One of the keys to making a 2S haul the mail is what's known as "stuffing the crankcase". The tighter the volume you make down low the higher the static primary compression is. This sends the "signal" (intake charge) squirting up the boost/transfer ports with some snort and helps fill the cylinder more.

I'm debating on just turning this thing into a monster biche and violating all the rules by using a pair of tuned stinger exhaust cans. That will really wake this thing up. Getting the motor "on the pipe" then becomes a function of fuel, plug selection, and choice of prop. The sanctioning body won't allow anything other than a 4" long open header (bummer) so I wouldn't be legal to compete, but MAN would it wake this bugger up.

The case is still quite ugly, but the critical stuff is over. Now the fun starts. Surfacing the exterior to put it on a diet and make it look American Made instead of Soviet.

Fun stuff.

Off to go do V. Day stuff with girly.

Laters,

C

Few more updates.

Bearing registers are all set now. Crank sits in the case really well. Nice and fluid on the rotation with minimal clearances everywhere. I was off a bit on the rod clearance so I'll have to widen that a bit (UNLESS!(idea!) I time up my boost ports with each of the rods. Then I'll have the clearance I need without over-sizing the crankcase too much. One of the keys to making a 2S haul the mail is what's known as "stuffing the crankcase". The tighter the volume you make down low the higher the static primary compression is. This sends the "signal" (intake charge) squirting up the boost/transfer ports with some snort and helps fill the cylinder more.

I'm debating on just turning this thing into a monster biche and violating all the rules by using a pair of tuned stinger exhaust cans. That will really wake this thing up. Getting the motor "on the pipe" then becomes a function of fuel, plug selection, and choice of prop. The sanctioning body won't allow anything other than a 4" long open header (bummer) so I wouldn't be legal to compete, but MAN would it wake this bugger up.

The case is still quite ugly, but the critical stuff is over. Now the fun starts. Surfacing the exterior to put it on a diet and make it look American Made instead of Soviet.

Fun stuff.

Off to go do V. Day stuff with girly.

Laters,

C

Re: my "off time" project

That thing would sound bitchin with a set of tuned pipes on it. I built a tuned pipe for my gas blender... yeah over kill but it sure sounds wild and makes a wicked adult party beverage. Built another pipe for my moped, should be fun this spring. Both pipes I hydro-formed with a pressure washer after the two flats got gas welded together, real slick process. The nitro engine is looking real cool, cant wait to see it all together and running!

That thing would sound bitchin with a set of tuned pipes on it. I built a tuned pipe for my gas blender... yeah over kill but it sure sounds wild and makes a wicked adult party beverage. Built another pipe for my moped, should be fun this spring. Both pipes I hydro-formed with a pressure washer after the two flats got gas welded together, real slick process. The nitro engine is looking real cool, cant wait to see it all together and running!

Re: my "off time" project

Awesome! Would be such a good feeling to build something like that yourself.

Kudos to you Chad

Awesome! Would be such a good feeling to build something like that yourself.

Kudos to you Chad

Similar threads

- Replies

- 3

- Views

- 667

- Replies

- 27

- Views

- 1K