Tonight I was ready to prime my first set of prepped brass. Once fired from my REM 700 5r and Ruger RPR in 6.5 CM. I totally forgot to separate at the range, but for all intensive purposes I just want to load my 1st reload (does that make sense lol)...

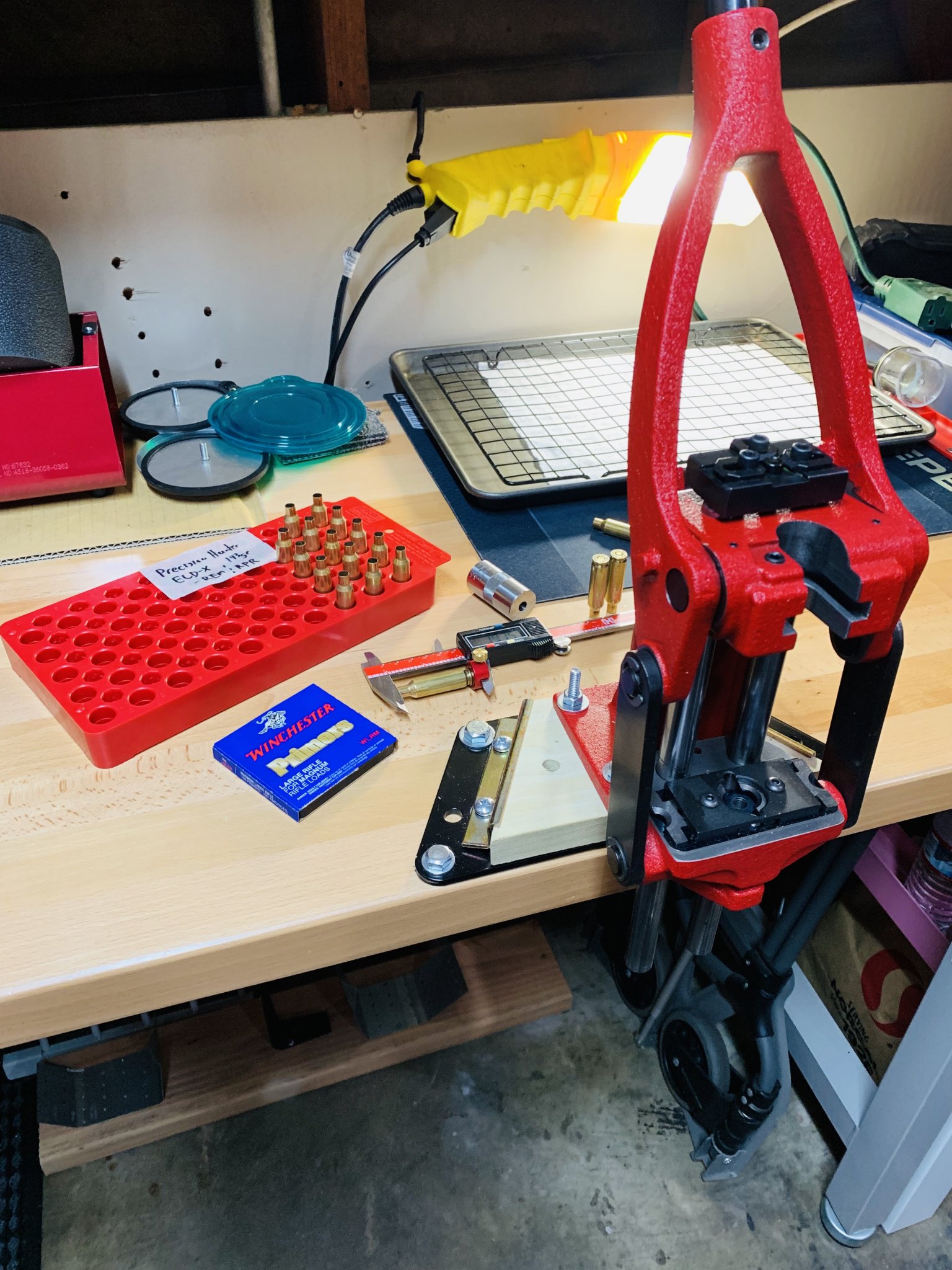

Gathering my tools and consumables has taken about two months. Still changing things as I go. I’ve already changed out my hornady LnL for a Co-Ax, and I haven’t even finished my first reload! I’m pretty sure there will be a ton of changes to come. Still waiting on my Chargemaster, GemPro 250, and Dandy Auto trickler.

I’m going to keep this thread live as a history of how much freaking money and time I’ve spent on this journey/new found hobby. I’ll be posting my full list of everything I’ve bought, how much I spent (new/used) and what I’ve changed out and why. Hopefully this will help out any one else crazy enough to go down this rabbit hole. J/K, it’s been a great learning experience thus far.

I actually think I like reloading better then actually shooting... crazy! So addicting learning something that was totally foreign to me a couple months ago. I’ve never reloaded and not even sure why I started to be honest, but I’m so glad I did...

Here goes...

- decapped w/Lee universal decapper die

- annealed - DIY annealer

- sized w/Hornady custom die (waiting on my Forester die set)

- trimmed to 1.915 w/Crow Gunworks tool

- reamed/cleaned out primer pockets

- reamed/cleaned out flash holes

- chamfered/deburred the case mouths

- wet tumbled in my Harbor Freight tumbler w/Lemi shine & dawn

- air dried overnight and heated up with a heat gun for a couple of seconds to make sure all moisture was gone from the inside of the case

- Prime with Co-Ax

- Check primer seating visually and with Wilson gauge

- Check overall length again 1.915 (my target)

Now to impressions and questions.

- Co-Ax for priming, setting it up was key. The pocket had to be aligned with the three plates and ensure it pushes the plunger high enough to seat the primer. I had 3 / 6 that wouldn’t seat right. After I adjusted the travel (screw by the jaw plates), the 3 set screws, and oiled the plunger spring, it was mush better ‘feel’. I’ve never done this before, so it was definitely a learning experience.

Questions.

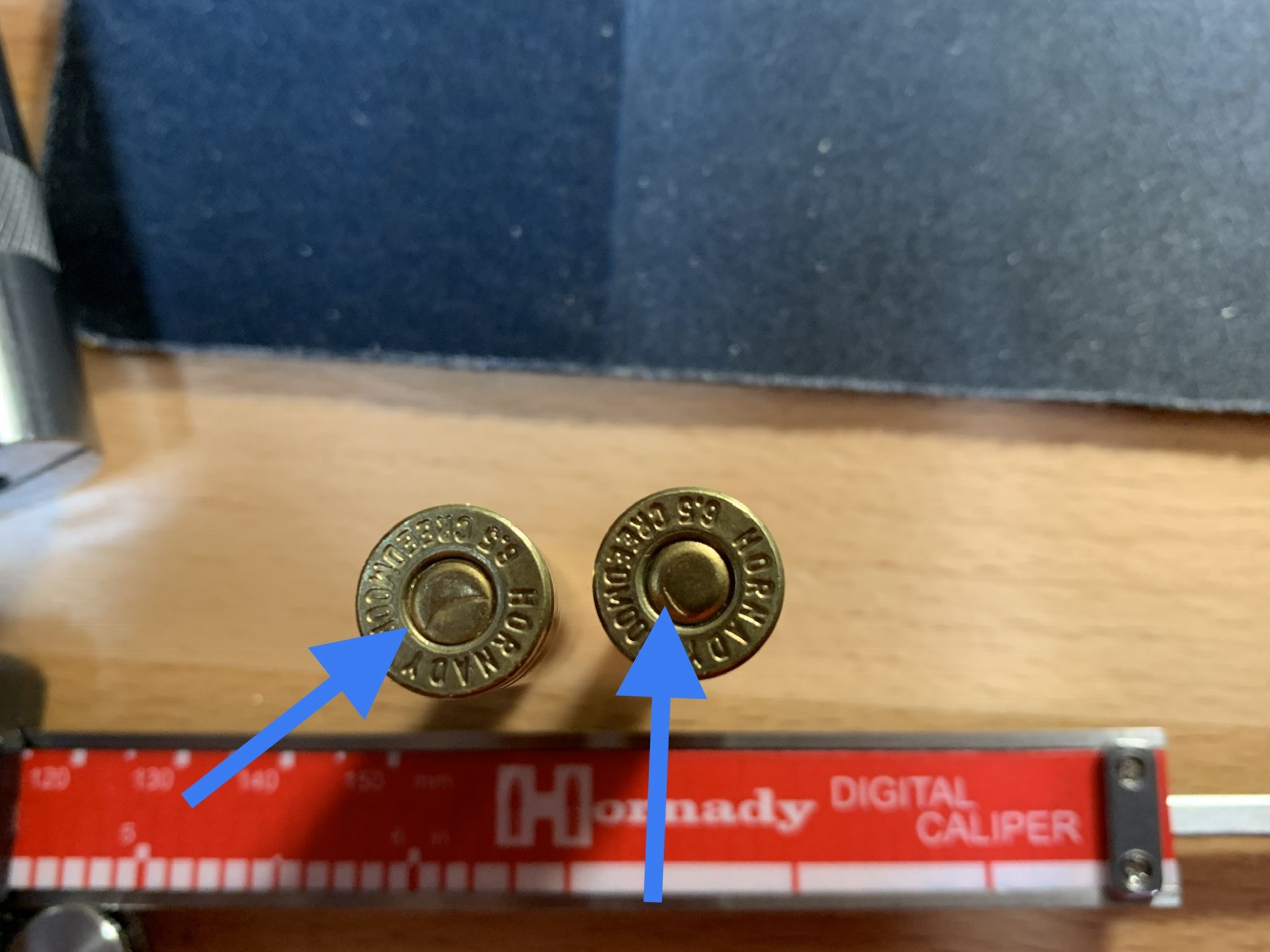

1. So 2 of the 14 I primed seemed to have primer flash between the plunger and the primer, so when I seated the primer.. the primers were damaged. See pic,

How does this happen? Is this common in general?

2. One case was significany longer than 1.915 target see pic. It’s passed the max end of 1.920. My question is... if I wanted to trim a case that is already primed is it a bad idea since the shaving will definitely get caught in the case body. Do you guys de-prime first and then trim, or is it ok to trim a primed case and just clean out. I’m assuming NO.

Gathering my tools and consumables has taken about two months. Still changing things as I go. I’ve already changed out my hornady LnL for a Co-Ax, and I haven’t even finished my first reload! I’m pretty sure there will be a ton of changes to come. Still waiting on my Chargemaster, GemPro 250, and Dandy Auto trickler.

I’m going to keep this thread live as a history of how much freaking money and time I’ve spent on this journey/new found hobby. I’ll be posting my full list of everything I’ve bought, how much I spent (new/used) and what I’ve changed out and why. Hopefully this will help out any one else crazy enough to go down this rabbit hole. J/K, it’s been a great learning experience thus far.

I actually think I like reloading better then actually shooting... crazy! So addicting learning something that was totally foreign to me a couple months ago. I’ve never reloaded and not even sure why I started to be honest, but I’m so glad I did...

Here goes...

- decapped w/Lee universal decapper die

- annealed - DIY annealer

- sized w/Hornady custom die (waiting on my Forester die set)

- trimmed to 1.915 w/Crow Gunworks tool

- reamed/cleaned out primer pockets

- reamed/cleaned out flash holes

- chamfered/deburred the case mouths

- wet tumbled in my Harbor Freight tumbler w/Lemi shine & dawn

- air dried overnight and heated up with a heat gun for a couple of seconds to make sure all moisture was gone from the inside of the case

- Prime with Co-Ax

- Check primer seating visually and with Wilson gauge

- Check overall length again 1.915 (my target)

Now to impressions and questions.

- Co-Ax for priming, setting it up was key. The pocket had to be aligned with the three plates and ensure it pushes the plunger high enough to seat the primer. I had 3 / 6 that wouldn’t seat right. After I adjusted the travel (screw by the jaw plates), the 3 set screws, and oiled the plunger spring, it was mush better ‘feel’. I’ve never done this before, so it was definitely a learning experience.

Questions.

1. So 2 of the 14 I primed seemed to have primer flash between the plunger and the primer, so when I seated the primer.. the primers were damaged. See pic,

How does this happen? Is this common in general?

2. One case was significany longer than 1.915 target see pic. It’s passed the max end of 1.920. My question is... if I wanted to trim a case that is already primed is it a bad idea since the shaving will definitely get caught in the case body. Do you guys de-prime first and then trim, or is it ok to trim a primed case and just clean out. I’m assuming NO.

Last edited: