Part I

Hello,

I was playing around with some different lubes today. I came up with this:

Yes, it's "evil black".

It works very well - no matter how bad I mess up a bullet - undersize, oversize, whatnot - I still cannot get any leading, just a bit of powder fouling that comes out easily with a bore snake.

It's made from copper and graphite and used in a tumble lube process that keeps the graphite trapped and everything clean.

Here's how it's done:

1. Visit your local auto parts store.

2. Buy Copper Coat. It's used to coat head gaskets and contains copper in an excellent carrier base which dries quickly.

3. Buy ultra fine powdered graphite.

4. Put the bullets to be lubed into a pan and spray the copper coat onto them, and shake the pan for even coating. I am using disposable aluminum bread pans.

5. Immediately dump them into a container that can be shaken. I have a largish yogurt container I'm using.

6. Sprinkle a bit of graphite onto them.

7. Shake.

8. Check to see if coating is complete; add if needed. Don't go overboard.

9. Pour back into pan to let dry for 30 minutes.

10. Pour into another pan lined with paper towels. Shake back and forth. This removes any excess graphite; there should not be a lot at all.

If anyone else wishes to experiment with this, I'd love to hear feedback. I'm having accuracy issues with these cast boolits; it's a new mould and accuracy drops off beyond 15 yards or so. If someone has an established load they can try this on and report back, I'd love to hear about it.

Part II

Use less. That was the original application, and I added too much graphite. It should be just a light dusting.

<span style="font-style: italic">Best application as compared to a .22LR bullet, which also uses a graphite suspension.</span>

Makes it prettier and cuts down on bore ash even more.

Remember folks, smokeless powder has graphite for flowing properties. I wouldn't really worry about it hurting the bore (there have been some questions here and on some other boards, PMed and posted). J.S

Part III

Ok, improved the loads so the groups are now improved.

1. Got consistency going with the alloy. The bullets weigh 230gn +/- 1gn (best I could do) and I rejected <span style="font-style: italic">everything</span> that wasn't as perfect as I could make it.

2. Reduced the powder charge to 4.9gn +/- .1gn.

3. Switched to Fed 155 primers.

4. And I believe this is the biggie - I did away with the Lee FCD. No crimp is on this these things, and it looks like it was taking the bullets down from my preferred .452" to .451" or so. I didn't feel contact but examined the cases very closely - there was a bit of a spot where it contacted.

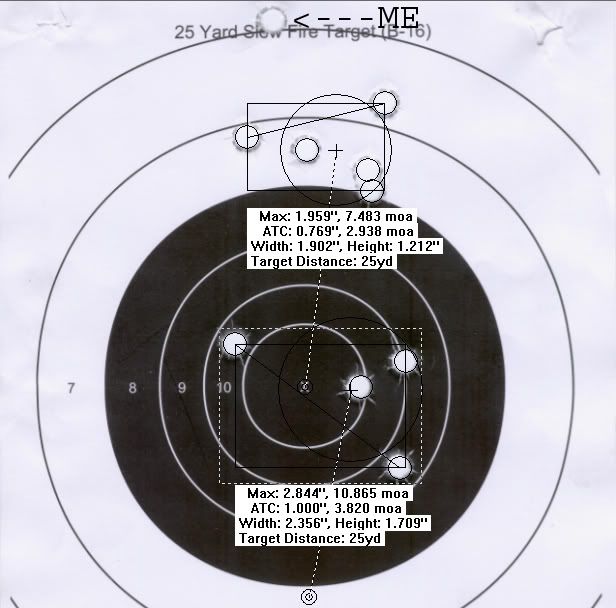

Baseline accuracy with this pistol (my own, built on an RIA frame and slide) is 1.5" at 25 yards with Speer Gold Dot, 230gn.

Here are the results of the bullets coated with Alox:

<span style="font-weight: bold">One, 10 shot group was fired. I had two fliers: one was me and marked as such, and the other, I don't know. There are nine shots on target.</span>

Here are the results of the JS Lube (I'm calling it that for lack of a better name):

<span style="font-weight: bold">Two, five shot groups were fired simply because I <span style="font-style: italic">could</span> get actual groups. One flier, and that was called. I shot while coming out of recoil.</span>

I should be able to reduce these groups even more once I get the alloy just right, and more importantly, consistent from lot to lot. These groups were fired from the same lot of bullets.

I'd like to see if others have the same results, as well as the reduced leading.

Thanks,

Josh

Hello,

I was playing around with some different lubes today. I came up with this:

Yes, it's "evil black".

It works very well - no matter how bad I mess up a bullet - undersize, oversize, whatnot - I still cannot get any leading, just a bit of powder fouling that comes out easily with a bore snake.

It's made from copper and graphite and used in a tumble lube process that keeps the graphite trapped and everything clean.

Here's how it's done:

1. Visit your local auto parts store.

2. Buy Copper Coat. It's used to coat head gaskets and contains copper in an excellent carrier base which dries quickly.

3. Buy ultra fine powdered graphite.

4. Put the bullets to be lubed into a pan and spray the copper coat onto them, and shake the pan for even coating. I am using disposable aluminum bread pans.

5. Immediately dump them into a container that can be shaken. I have a largish yogurt container I'm using.

6. Sprinkle a bit of graphite onto them.

7. Shake.

8. Check to see if coating is complete; add if needed. Don't go overboard.

9. Pour back into pan to let dry for 30 minutes.

10. Pour into another pan lined with paper towels. Shake back and forth. This removes any excess graphite; there should not be a lot at all.

If anyone else wishes to experiment with this, I'd love to hear feedback. I'm having accuracy issues with these cast boolits; it's a new mould and accuracy drops off beyond 15 yards or so. If someone has an established load they can try this on and report back, I'd love to hear about it.

Part II

Use less. That was the original application, and I added too much graphite. It should be just a light dusting.

<span style="font-style: italic">Best application as compared to a .22LR bullet, which also uses a graphite suspension.</span>

Makes it prettier and cuts down on bore ash even more.

Remember folks, smokeless powder has graphite for flowing properties. I wouldn't really worry about it hurting the bore (there have been some questions here and on some other boards, PMed and posted). J.S

Part III

Ok, improved the loads so the groups are now improved.

1. Got consistency going with the alloy. The bullets weigh 230gn +/- 1gn (best I could do) and I rejected <span style="font-style: italic">everything</span> that wasn't as perfect as I could make it.

2. Reduced the powder charge to 4.9gn +/- .1gn.

3. Switched to Fed 155 primers.

4. And I believe this is the biggie - I did away with the Lee FCD. No crimp is on this these things, and it looks like it was taking the bullets down from my preferred .452" to .451" or so. I didn't feel contact but examined the cases very closely - there was a bit of a spot where it contacted.

Baseline accuracy with this pistol (my own, built on an RIA frame and slide) is 1.5" at 25 yards with Speer Gold Dot, 230gn.

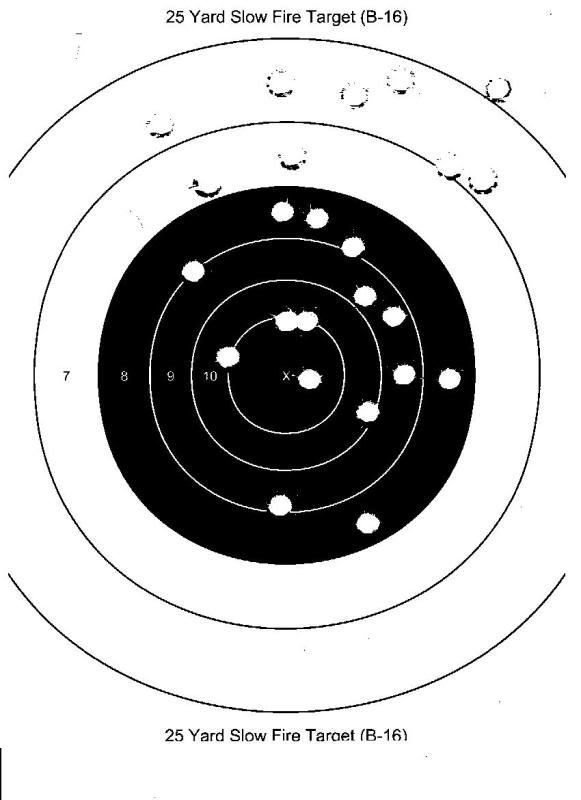

Here are the results of the bullets coated with Alox:

<span style="font-weight: bold">One, 10 shot group was fired. I had two fliers: one was me and marked as such, and the other, I don't know. There are nine shots on target.</span>

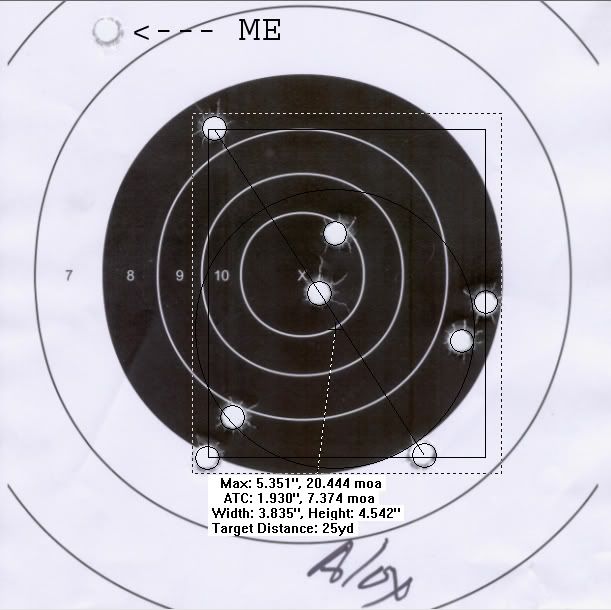

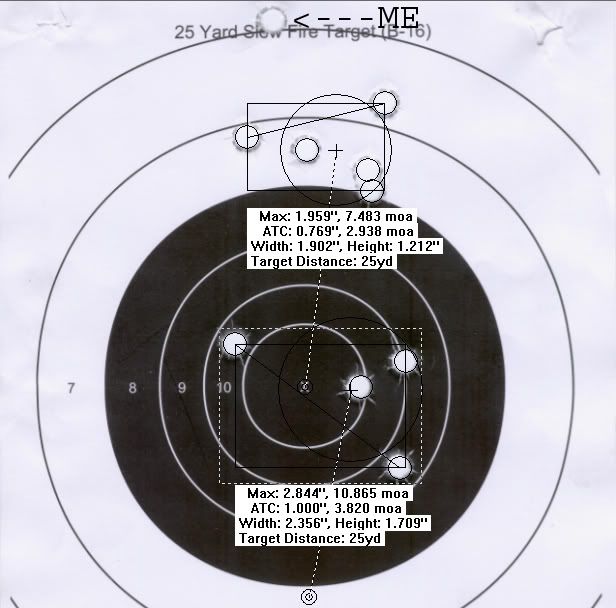

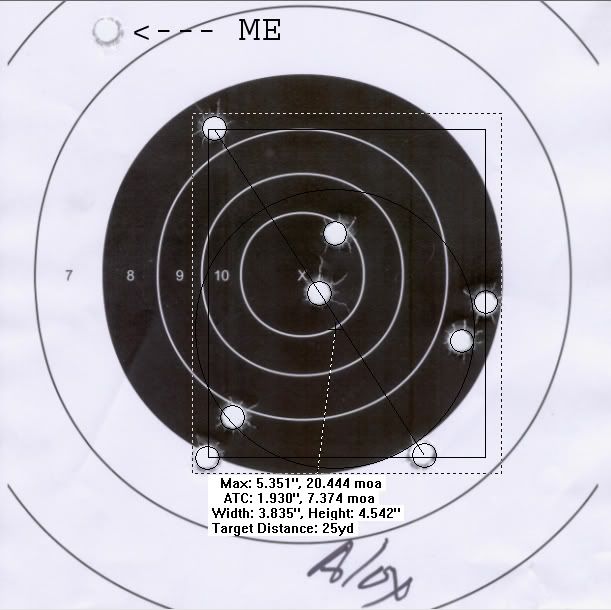

Here are the results of the JS Lube (I'm calling it that for lack of a better name):

<span style="font-weight: bold">Two, five shot groups were fired simply because I <span style="font-style: italic">could</span> get actual groups. One flier, and that was called. I shot while coming out of recoil.</span>

I should be able to reduce these groups even more once I get the alloy just right, and more importantly, consistent from lot to lot. These groups were fired from the same lot of bullets.

I'd like to see if others have the same results, as well as the reduced leading.

Thanks,

Josh