So I have been putting off getting into reloading for about 5 years and decided it was time to get going on it. I will mostly be reloading 5.56, .308 and 6.5 grendel all for ar platforms. Id still to develop accurate loads but not going to dwell on chasing them. I also plan on buying a 6.5 creedmoor bolt gun (AI) hopfully next year. Ive been looking at either the Redding t7 or a dillon 550. I have over 6k empty brass that I need to reload, and thats why I was leaning towards the dillon. Whats a realistic number that I would be able to re load with the t7 in an hour? Which press would you guys think would work best for me? Ive read that the dillon isn't ideal for precision reloading. Ive been watching elfsters reloading videos and was thinking of getting the Hornady lock n load to learn on while I watch his video, but then I started reading about the redding and Dillon.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to reloading, choosing a press

- Thread starter *AimSmall*

- Start date

Dillon. 550, 650, or 750. Great platforms that will serve you well for high volume, and precision.

I used to load on a Lee Calssic Turret and a single stage press. I recently bought an older Dillon 450, but it seriously rocks the house. I love it and should have gotten a progressive press years ago. I can do 400+ rounds an hour of 5.56, 9mm without really breaking a sweat and can do my sub-MOA 7mm RemMag, and 6.5 Creedmoor loadings just fine as well.

I used to load on a Lee Calssic Turret and a single stage press. I recently bought an older Dillon 450, but it seriously rocks the house. I love it and should have gotten a progressive press years ago. I can do 400+ rounds an hour of 5.56, 9mm without really breaking a sweat and can do my sub-MOA 7mm RemMag, and 6.5 Creedmoor loadings just fine as well.

Dillon 650 or the new 750.

Can load 700+ rounds and hour once you get familiar with it

spend the money on quality machine up front. You won’t regret it.

Can load 700+ rounds and hour once you get familiar with it

spend the money on quality machine up front. You won’t regret it.

Thankyou for the response. For some reason I was under the impression that the Dillons were more for bulk and not necessarily for precision. Good to know I can use it for precision as well.Dillon. 550, 650, or 750. Great platforms that will serve you well for high volume, and precision.

I used to load on a Lee Calssic Turret and a single stage press. I recently bought an older Dillon 450, but it seriously rocks the house. I love it and should have gotten a progressive press years ago. I can do 400+ rounds an hour of 5.56, 9mm without really breaking a sweat and can do my sub-MOA 7mm RemMag, and 6.5 Creedmoor loadings just fine as well.

four of these lol ammo all night long .

Holy crap! Maby if I wanted to start an ammo manufacturing company. Heard it is a headache

Get the Lyman book. Buy one of the cheap kits and learn on a single stage. If you enjoy it you can start upgrading your set up and think about progressives and better presses.

Yup. 3/4 moa or better 6.5 Creedmoor ammo in two different rifles.Thankyou for the response. For some reason I was under the impression that the Dillons were more for bulk and not necessarily for precision. Good to know I can use it for precision as well.

Dillon 550 for the manual advance. Just my preference. I load all my ammo from .223 through 338 LM.

For precision just remember David G Tubb and John Widden load their ammo on a Dillon 550.

For precision just remember David G Tubb and John Widden load their ammo on a Dillon 550.

I was thinking the same thing and I was telling my wife this.Your gonna want TWO presses eventually.

Forster CO-AX for precision or another quality single stage

Dillon for bulk.

If I could only have one though it would be the Dillon.

Your gonna want TWO presses eventually.

Forster CO-AX for precision or another quality single stage

Dillon for bulk.

X2.

May want to consider getting the Co-Ax first, as it is the precision choice and you may learn more up front with it (i.e., steeper learning curve possibly that way).

I used a Lee Classic Cast with Hornady Lock-N-Load bushings for the last 10 years. Have loaded plenty of MOA accurate ammunition. With a progressive there is a lot going on at once for a beginner to troubleshoot if there is a problem. As a beginner the progressive I bought left me feeling uneasy

I recently bought an RCBS Summit press and really like it for loading ammunition. I still use the Lee for sizing operations.

I believe weighing charges individually, using quality bullets and judicious brass prep is more important to making consistent ammunition than what they are loaded on. An expensive press won’t hurt but there are plenty of people who load quality ammunition on a budget.

And almost any hand loaded ammunition will be better than most store bought ammunition.

I recently bought an RCBS Summit press and really like it for loading ammunition. I still use the Lee for sizing operations.

I believe weighing charges individually, using quality bullets and judicious brass prep is more important to making consistent ammunition than what they are loaded on. An expensive press won’t hurt but there are plenty of people who load quality ammunition on a budget.

And almost any hand loaded ammunition will be better than most store bought ammunition.

I will most likely go this route. Should I get a Co-Ax instead of the T7?X2.

May want to consider getting the Co-Ax first, as it is the precision choice and you may learn more up front with it (i.e., steeper learning curve possibly that way).

I can see where there is a lot going on with a progressive for someone new to reloadingI used a Lee Classic Cast with Hornady Lock-N-Load bushings for the last 10 years. Have loaded plenty of MOA accurate ammunition. With a progressive there is a lot going on at once for a beginner to troubleshoot if there is a problem. As a beginner the progressive I bought left me feeling uneasy

I recently bought an RCBS Summit press and really like it for loading ammunition. I still use the Lee for sizing operations.

I believe weighing charges individually, using quality bullets and judicious brass prep is more important to making consistent ammunition than what they are loaded on. An expensive press won’t hurt but there are plenty of people who load quality ammunition on a budget.

And almost any hand loaded ammunition will be better than most store bought ammunition.

I will most likely go this route. Should I get a Co-Ax instead of the T7?

i personally went co-ax and I really enjoy it but all of my friends use the T7. Either will work.

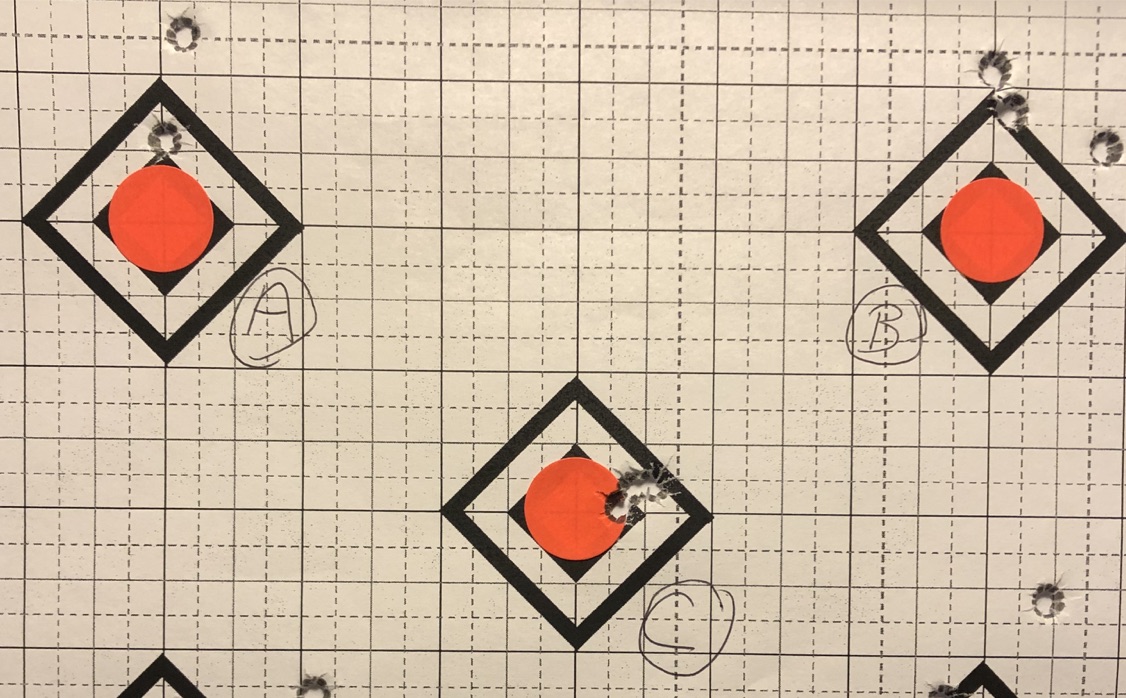

I use a Dillon 550 for bulk AND precision. For the latter, I run it more like a single-stage machine. There are a number of articles about loading precision ammo on a progressive. I guess I've about figured it out; here are today's seating depth fine-tuning results at 300 yards (yes, 300 - flat calm wind helped) based on Berger Bullets' article using 3-shot groups. Peterson 6.5CM SRP brass, CCI450 primer, Berger 140 Hybrid, 41.2gr H4350. I ran the 0.01, 0.05, 0.09, and 0.13 off the lands last week. 0.05 off was best, Per the article, I tried fine-tuning with 0.03 (B), 0.05 (A, the 2-round one), and 0.07 (C) off the lands. Grid is 1/4". Shots were round-robin (A-B-C repeat 3x except A).

All 9 shots combined went into 1.25" vertical and .75" horizontal, again at 300 yards. It will be interesting to see if group C is a fluke or if it can be replicated. If repeatable, I'll be astounded.

Point is, I don't see that it's completely necessary to have an arbor press or similar to assemble precision ammo. And I can turn out pistol or bulk .223 ammo pretty fast as well. Fwiw, I personally prefer the non-auto-indexing 550 for a better feel, especially primer seating, but that's just me.

I agree there's a lot going on with a progressive for a new handloader. Again, the press can be used in a single-stage mode: Deprime/resize/prime (or separate out the prime) for all the cases, pour powder charge (you don't have to drop from a measure!) and put charged cases in a loading block, seat bullets. It's doable if one goes slow and pays attention. Not nearly as messy as pouring shot all over the floor with a progressive shotshell loader...

Edit: It's very hard to go wrong with Dillon. Don't like it? Send it back within 30 days for a refund (I assume that's still the norm; best to check). Call for support? A human, not a machine, answers the phone (at least that was the case last time I called). If something breaks, they replace it. Forever. Mine is 23 years old. Nothing has ever broken. One piece wore out. They sent me an RMA for a replacement. It's a one-time purchase, investment for a lifetime (and no, they don't do sales or Black Friday),

All 9 shots combined went into 1.25" vertical and .75" horizontal, again at 300 yards. It will be interesting to see if group C is a fluke or if it can be replicated. If repeatable, I'll be astounded.

Point is, I don't see that it's completely necessary to have an arbor press or similar to assemble precision ammo. And I can turn out pistol or bulk .223 ammo pretty fast as well. Fwiw, I personally prefer the non-auto-indexing 550 for a better feel, especially primer seating, but that's just me.

I agree there's a lot going on with a progressive for a new handloader. Again, the press can be used in a single-stage mode: Deprime/resize/prime (or separate out the prime) for all the cases, pour powder charge (you don't have to drop from a measure!) and put charged cases in a loading block, seat bullets. It's doable if one goes slow and pays attention. Not nearly as messy as pouring shot all over the floor with a progressive shotshell loader...

Edit: It's very hard to go wrong with Dillon. Don't like it? Send it back within 30 days for a refund (I assume that's still the norm; best to check). Call for support? A human, not a machine, answers the phone (at least that was the case last time I called). If something breaks, they replace it. Forever. Mine is 23 years old. Nothing has ever broken. One piece wore out. They sent me an RMA for a replacement. It's a one-time purchase, investment for a lifetime (and no, they don't do sales or Black Friday),

Last edited:

I went with a Dillon 550 from the start - like you, I thought i wanted quality ammo (but not benchrest quality) that I could create fairly quickly, and at less cost than off the shelf rounds. Now, I'm chasing .3 to .2 loads for my .223 bolt gun... So the Dillon can do both. I also find I like reloading as it's own hobby - I think if you enjoy the process it makes a single stage option a lot more palatable.

A lot of it comes down to what is your budget, and what is your top priority?

When you budget, don't forget all the other costs as well - toolheads, dies, scale, primer tools, trimmers, chamfer tools..... etc. etc. The rabbit hole goes deep when you talk speed/comfort/accuracy chasing with reloading gadgets.

A lot of it comes down to what is your budget, and what is your top priority?

When you budget, don't forget all the other costs as well - toolheads, dies, scale, primer tools, trimmers, chamfer tools..... etc. etc. The rabbit hole goes deep when you talk speed/comfort/accuracy chasing with reloading gadgets.

I’m still a caveman using my Lee classic turret.

Someday I’d like to get a Dillon 550.

Someday I’d like to get a Dillon 550.

IMHO, get a single stage like a rockchucker or a turret to start. Even after you get a progressive, you'll still have a use for the simpler single stage press.

I was you up until 5 months ago. You'll LOVE the Dillon and kick yourself in the ass for not upgrading sooner.I’m still a caveman using my Lee classic turret.

Someday I’d like to get a Dillon 550.

I was you up until 5 months ago. You'll LOVE the Dillon and kick yourself in the ass for not upgrading sooner.

The only reason I haven’t already is I don’t shoot as much pistol as I used to and the LCT just works and makes straight ammo.

I have turrets all set up for 9mm, 40s&w, 45ACP(all with case activated powder measures) along with 223, 260, 7 saum snd 338 Norma Magnum.

DAMN. Good job! People clown on the LCT, but it does make great ammo.The only reason I haven’t already is I don’t shoot as much pistol as I used to and the LCT just works and makes straight ammo.

I have turrets all set up for 9mm, 40s&w, 45ACP(all with case activated powder measures) along with 223, 260, 7 saum snd 338 Norma Magnum.

Well said. I think your spot on.I went with a Dillon 550 from the start - like you, I thought i wanted quality ammo (but not benchrest quality) that I could create fairly quickly, and at less cost than off the shelf rounds. Now, I'm chasing .3 to .2 loads for my .223 bolt gun... So the Dillon can do both. I also find I like reloading as it's own hobby - I think if you enjoy the process it makes a single stage option a lot more palatable.

A lot of it comes down to what is your budget, and what is your top priority?

When you budget, don't forget all the other costs as well - toolheads, dies, scale, primer tools, trimmers, chamfer tools..... etc. etc. The rabbit hole goes deep when you talk speed/comfort/accuracy chasing with reloading gadgets.

My top priority would be to make sub min capable ammo without having to live in my reloading room. Another would be ease of use. And I like the idea behind the turret amd having multiple dies on one head. Something kinda minimalist with not a lot of having to change dies or have a pile of different dies and parts to go thru. I planned on spending about $1500 for my initial purchase to get going.I went with a Dillon 550 from the start - like you, I thought i wanted quality ammo (but not benchrest quality) that I could create fairly quickly, and at less cost than off the shelf rounds. Now, I'm chasing .3 to .2 loads for my .223 bolt gun... So the Dillon can do both. I also find I like reloading as it's own hobby - I think if you enjoy the process it makes a single stage option a lot more palatable.

A lot of it comes down to what is your budget, and what is your top priority?

When you budget, don't forget all the other costs as well - toolheads, dies, scale, primer tools, trimmers, chamfer tools..... etc. etc. The rabbit hole goes deep when you talk speed/comfort/accuracy chasing with reloading gadgets.

Before I started handloading, I talked with friends and was invited to visit several shops and do some reloading. It was very easy to determine who offered the best advice after doing this. The Forster COAX was highly recommended by one that had used most of them over the past 45 years. I was fortunate to find a like new used COAX and have no regrets other than a severe dislike for the built in primer. I added a Dillon 550 several years later after loading 500 pistol rounds in one day (that is an arm exerciser for sure).

I now use the single stage press for load development and precision loads. I use the Dillon for pistol and plinking/bulk rifle loads but I always size bottleneck rifle cartridges on a single stage as there are several other intermediate steps (trimming/chamfer/debur/cleaning) that makes the Dillon 550 less than optimal IMO. My experience with the Dillon is that it throws very consistent powder charges with ball and short stick powders (except the very fine Lovex powders which pretty much leaves powder everywhere). It is a bit less consistent with long stick or flake powders. There are pros and cons to both, but I would suggest starting with a single stage or turret press first and then adding a volume press later. I have no experience with the T7 but have considered adding it for bullet seating dies.

I now use the single stage press for load development and precision loads. I use the Dillon for pistol and plinking/bulk rifle loads but I always size bottleneck rifle cartridges on a single stage as there are several other intermediate steps (trimming/chamfer/debur/cleaning) that makes the Dillon 550 less than optimal IMO. My experience with the Dillon is that it throws very consistent powder charges with ball and short stick powders (except the very fine Lovex powders which pretty much leaves powder everywhere). It is a bit less consistent with long stick or flake powders. There are pros and cons to both, but I would suggest starting with a single stage or turret press first and then adding a volume press later. I have no experience with the T7 but have considered adding it for bullet seating dies.

My top priority would be to make sub min capable ammo without having to live in my reloading room. Another would be ease of use. And I like the idea behind the turret amd having multiple dies on one head. Something kinda minimalist with not a lot of having to change dies or have a pile of different dies and parts to go thru. I planned on spending about $1500 for my initial purchase to get going.

Sounds like you'd enjoy the progressive for the speed. Almost any press can produce ammo that will make that accuracy spec with a little load development and quality components, so if budget doesn't allow a progressive, there's no shame in a single stage or turret option.

I never found a 550 difficult to use- just go slow and do one step at a time at first. Think of it as a reverse turret, the case moves instead of the dies. Also, once you set a toolhead for a caliber and load, swapping back and forth takes 2 to 3 minutes, depending on if I drop an allen key on the floor and whether I'm moving from small to large primer or back. If you need to adjust seating or change a charge weight, it's a bit more involved, but once you're set up it takes very little time and is very repeatable.

I'm a huge fan of dillon, as are many others. If you go blue, go either 550 or 750, I never had any feeding issues with the slide type primer shuttle. In my mind, the decision between the two is made with the question "Do you ever want to run a case feeder and bullet feeder?"

Whatever you chose, remember to get a micrometer seater die, and a comparitor set for cartridge base to ogive and cartridge base to datum (headspace) measurements. You'll thank us later when you realize how much easier it is to setup dies and how much less time and f--ery it takes.

Thankyou all for taking the time to give info and things to think about. Are most dies universal (work with any press) or do presses have proprietary dies? What are good dies you would recommend?

Most any die you can get will be for a normal 7/8 thread.Thankyou all for taking the time to give info and things to think about. Are most dies universal (work with any press) or do presses have proprietary dies? What are good dies you would recommend?

There are dies that take a larger thread but they are more specialty and youll probably shit your pants at the cost of them before you every actually buy them.

I like forster for the better value but I like redding for the best.

Whichever route you go get a micrometer seater. Its really nice being able to dial in the seating adjustments rather than through trial and error.

Redding has a normal full length die offering and a bushing (type s) full length sizer. The difference is the bushing allows you to alter the amount of sizing done to the neck, otherwise they are the same.

Forster comes as the normal full length sizing but you can then send it into forster and they can hone the neck out to whatever diameter you want, similar to swapping the bushing in the redding only its a permanent change.

Cant go wrong with any of those though. Just dont bother buying a neck sizer.

Most dies will be a standard 7/8 thread which will work in the presses you are considering. You will get many opinions on which are the best. In rifle calibers, I have Hornady, RCBS, Dillon, Lyman, and Redding. All will get the job done however, if I knew then what I know now, I would go with the Redding full length Type S Match sets which are bushing sizing dies with the micrometer for the seating die. There is an additional cost for the bushing(s) but you can tailor the neck tension for your brass. The micrometer setting for the seating die is not required but it is much easier to get just the right seating depth for your bullet. I am sure there are other dies that may be just as good, perhaps better, I just have no experience with them.Thankyou all for taking the time to give info and things to think about. Are most dies universal (work with any press) or do presses have proprietary dies? What are good dies you would recommend?

My Dillon/Widden CNC floating lock ring tool heads sport RCBS, Forester, and Widden Custom dies. RCBS because I have several of them. Forester FL non micrometer seaters because once I set it I don’t need to adjust again. It stays in the tool head and I don’t switch bullets. Widden for all my custom chambers. No neck bushing dies for any cartridge for me.

A little update and another question. So I bought the Forster Co-AX to learn on. I got a thumbler model b, dillon super swage, lyman case prep and a Lee universal decapping die. So far I have de-primmed, tumbled the brass and swaged the primer pockets. Now I am ready to re size. I bought Redding type S bushing full die set and It does not come with a bushing. Do I need a bushing to use this? Im just following Elfsters reloading videos on youtube.

Do I need a bushing to use this?

yes, you'll need a bushing. The Redding website has instructions for selecting a bushing....or do a search here for bushings for that specific caliber you're looking at. Without the bushing the neck of the case will not be sized.

Thankyou for the reply. Before I posted the question I searched the forum for what size bushing. Its for ARs shooting 223, I ordered a .245 bushing.yes, you'll need a bushing. The Redding website has instructions for selecting a bushing....or do a search here for bushings for that specific caliber you're looking at. Without the bushing the neck of the case will not be sized.

Similar threads

- Replies

- 32

- Views

- 2K

- Replies

- 14

- Views

- 984