Hi, I'm in the middle of bedding my Remington 700 SPS to a Bell & Carlson Medalist Tactical stock. When I set the barreled action into the stock The tang is raised slightly (1/8"). When I push down on to the tang as if tightening it down, the end of the barrel raises. My question is should I wrap enough tape at the end of the barrel to where it makes the Tang sit flush to begin with? It appears that the metal bedding area behind the recoil lug is the area causing the action/Tang to rock. That area had 100% wear marks from the barrel. Should I try to take out some of that aluminum bedding or just put tape on the end of the barrel and in front of the recoil lug to where it makes the Tang sit flush? Also should I put bedding material at the Tang as well? I was mainly bedding it because the recoil lug area has way to much play. Thanks for any help. This is my first bedding attempt.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Newbie Bedding questions

- Thread starter shadowsk

- Start date

I don't know enough about that stock. It has Aluminum bedding? The tang can touch Aluminum if you push down? That would be good. I would tape the barrel to get into that position.

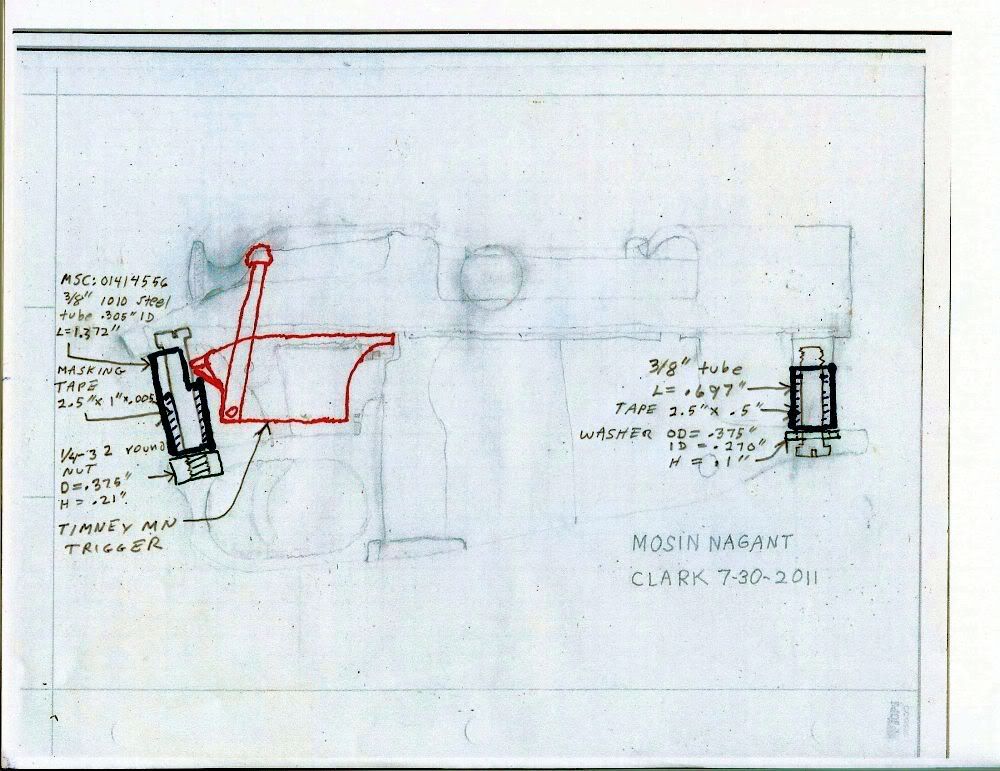

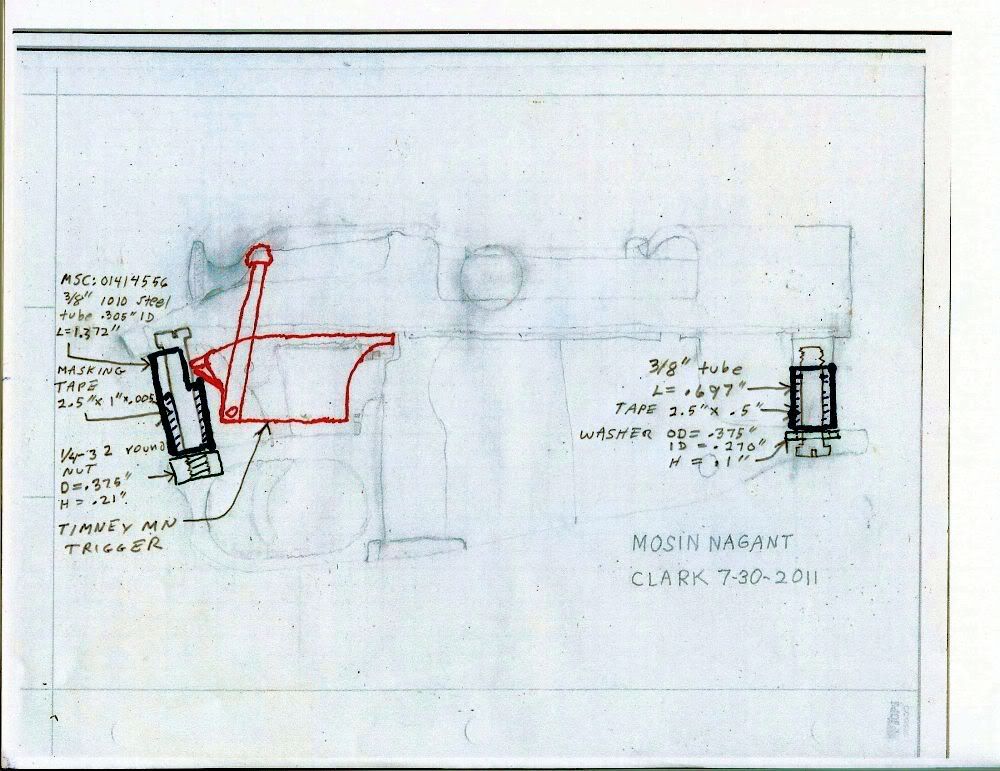

This is a drawing I made of a different rifle, but it shows my plan to have only the rear of the recoil lug touch the stock and only the top of the compressed pillars touch the action. Making a drawing helps me make the pillars.

This is a drawing I made of a different rifle, but it shows my plan to have only the rear of the recoil lug touch the stock and only the top of the compressed pillars touch the action. Making a drawing helps me make the pillars.

I believe the Medalist stock have a full length aluminum bedding block, ala H.S. I would do just enough tape around the barrel, forward where the stock stops, to make the action parallel to the bedding block and mask off the front, bottom, and sides of the recoil lug.

There are a lot of great posts on SH about the process used by the best gunsmiths working today. I'd review some of them and learn all you can. I learned from a guy who taught me a ton about doing the job right. I still messed up a couple times. Take your time and don't be hard on yourself if you mess up. Just learn from those "happy accidents".

There are a lot of great posts on SH about the process used by the best gunsmiths working today. I'd review some of them and learn all you can. I learned from a guy who taught me a ton about doing the job right. I still messed up a couple times. Take your time and don't be hard on yourself if you mess up. Just learn from those "happy accidents".

Ok, I have some pics. Putting a level on the action shows that it's closer to level without pressing down on the Tang. It's basically see-sawing on the Factory metal bedding that I have circled. You can see where the barrel has wear marks there. So to get perfectly level and stress free off the Tang the Tang area definitely needs some bedding material, correct? So if I bed the lug and area in front and the Tang area, everything should be good right? Any other suggestions? Thanks again.

Tang not pressed, action just laying naturally

Tang pressed down

Lug area (pressure area circled)

Tang not pressed, action just laying naturally

Tang pressed down

Lug area (pressure area circled)

I took material away from my bedding block to get the position I wanted. Just remember most epoxies like Devcon call for a critical minimum thickness (about 1/8" if I remember correctly; check that).

Anyway, I did remove material bedded the entire action. Turned out great.

Others may have different recommendations and reasons....

Anyway, I did remove material bedded the entire action. Turned out great.

Others may have different recommendations and reasons....

I have no special knowledge of what is best..... but it looks like if you follow Special_KG's work and cut the bedding block down for 1/8" clearance everywhere, put tape on the barrel, get the tang to make solid contact, fill over the bedding block with epoxy, then you will get the best result. Do the bottom metal and action screws like that too?

It's "see-sawing" on that area because the barrel is heavier than the action. The barrel touching the stock at the tip is all that is stopping it from tipping right out. You will have some tension in the action, it is all that keeps the barrel off the stock. What you are trying to achieve is good contact between action block and action, with no twist or bind, like two blued and lapped surfaces. Heck, the rifles shooting really small groups in the BR world, are glued into the stock, no action screws at all. You are not trying to go that far.

Tape the front of the barrel to get flush with the tang. Before bedding, check the entire length of the barrel to make sure there is no contact with the stock.

Tape the lug, as was mentioned before - you need clearance on the front bottom and sides, lug touches bedding only on aft side.

Also as was mentioned - there are several good videos of bedding on here, look at them all, several times. I don't believe you need 1/8" material either, if so, use something different. I use Devcon Ti, others like Marine-Tex, which comes in handy bedding project sized doses. Use plenty, it's easier to get it off when curing, that it is to add more to fill in voids after it cures.

Tape the front of the barrel to get flush with the tang. Before bedding, check the entire length of the barrel to make sure there is no contact with the stock.

Tape the lug, as was mentioned before - you need clearance on the front bottom and sides, lug touches bedding only on aft side.

Also as was mentioned - there are several good videos of bedding on here, look at them all, several times. I don't believe you need 1/8" material either, if so, use something different. I use Devcon Ti, others like Marine-Tex, which comes in handy bedding project sized doses. Use plenty, it's easier to get it off when curing, that it is to add more to fill in voids after it cures.

Correction: Devcon steel putty 10110 recommended thickness is 3-5 mils per their technical data. Not sure why I remembered 1/8"; must have been for something else.

Your good to go with the devcon in a thin application. I have had it flake from a scope base after removal with thin clearances filled been roughed to 320 grit, but it's not relevant when mounted and in use.

As mentioned, you may be experiencing see-sawing lifting the rear tang if the barrel is not supported with tape.

I still removed some aluminum bedding block and skimmed with the Devcon to avoid the pressure points from the v-block. If bedded stress free (not using action screws to secure during curing) the epoxy will be a uniform thickness above the aluminum bedding block. This means you will have uniform support with little to no pressure points as the v-block is designed to have.

Whether it's actually makes a meaningful difference, who knows. It's what I thought was best at the time. Worked great for me.

Your good to go with the devcon in a thin application. I have had it flake from a scope base after removal with thin clearances filled been roughed to 320 grit, but it's not relevant when mounted and in use.

As mentioned, you may be experiencing see-sawing lifting the rear tang if the barrel is not supported with tape.

I still removed some aluminum bedding block and skimmed with the Devcon to avoid the pressure points from the v-block. If bedded stress free (not using action screws to secure during curing) the epoxy will be a uniform thickness above the aluminum bedding block. This means you will have uniform support with little to no pressure points as the v-block is designed to have.

Whether it's actually makes a meaningful difference, who knows. It's what I thought was best at the time. Worked great for me.

Last edited:

It's "see-sawing" on that area because the barrel is heavier than the action.

Is the action sitting flat on the forward bedding when the tang is touching in the rear?

Thanks for the advice guys. Just wanted to update. I ended up putting to much bedding in both areas. It had raised the action up about 3/32 above the ejection port. My Wyatts DBM mags would not feed. So away I went to sanding the Devcon with 80grit sandpaper wrapped around a socket. I dremeled out the lug area and rebedded that. I must have spent 3 or 4 hours sanding and testfitting. I eventually got the action down to about 1/16 above the ejection port. It feeds reliably now. I'd like to get out down to level with the port but I got down pretty thin in the bedding so I was just gonna shoot it and see first.

In hindsight... I should have made absolutely sure the action was level with the port. I probably should have just done the lug area and been done with it. But you learn as you go. IL know what to look out for on the next one.

In hindsight... I should have made absolutely sure the action was level with the port. I probably should have just done the lug area and been done with it. But you learn as you go. IL know what to look out for on the next one.

By sanding out the bedding to get the action lower and feed reliably, you've lost any benefits that your supposed to gain from bedding in the first place. My advice would be to remove all the material and start over again, making sure you have proper alignment before it cures.

By sanding out the bedding to get the action lower and feed reliably, you've lost any benefits that your supposed to gain from bedding in the first place. My advice would be to remove all the material and start over again, making sure you have proper alignment before it cures.

+1

I made a similar mistake on my first. It's stress free bedding, but you have to ensure the action is in proper position. Too much bedding material and/or not enough relief area for the bedding to go can cause hydraulic lock. Basically the action won't go down into the stock all the way if it can't "ooze" out somewhere.

I would start again...

Similar threads

- Replies

- 1

- Views

- 287