i'm cheap and have a relatively basic setup than most but this is what i've learned over the years

GOOD

besides the usual basic stuff like press, primer pocket cleaning brushes, calipers digital, lubing pad, a tumbler, trimmer, chamfer tool and so on...

a dedicated reloading area away from the missus - bench / desk / whatever to mount the press(s), trimmers, etc. with an electrical receptacle or two close by. i use a L shaped office desk, a 90deg turn gets me from my brass processing only area to charging area.

good lighting

cleaning up (small brush and dust pan) & putting everything back in place when finished, every time. getting residue out the press, keeping it lubed. rags and paper towels.

using an apron instead of pant legs to wipe hands

drawers, filing cabinets, cupboards to organize "stuff" like dies, stuck shell removers, lube, etc.

masking tape to label stuff and times shot brass using ink, not pencil, to write the label with.

a notebook

squirreling away and using small containers - aspirin bottles, small rubbermaid containers, .22LR plastic slide top boxes, etc for putting attachments, loose bullets, etc in. ammo cans - get as many as you can. i love coffee cans.

a comfortable swivel chair, with some sort of adjustability for height and lumbar support.

a mat for the floor

chronograph, even a cheap one is a fantastic tool.

dedicated reloading tool kits kept at the bench - wrenches, allen wrenches, pliers, files, socket set, screwdrivers, etc. even a dedicated cheap electric drill or rotary tool.

a decent digital scale for mass producing short range plinking rifle and pistol ammo, i still rather a balance beam for more the more serious stuff.

making my own dippers out of a spent shell that equals my load to get me close on those scales, then trickle in.

never dull - works great on brass

bullet puller. for impact pullers, a wad of papertowel or cotton in the tip to not destroy the bullet tip

carbide dies for pistol ammo

clock radio - easy to lose track of time when loading, radio covers up the missus' mumbling about it

saving tossed 50 hole plastic pistol factory ammo holders from the range to hold brass while processing and loading

making dummy shells for OAL, case trimming, etc for resetting dies.

using 2 old colanders to sift brass from tumbler media

using a decapping rod and pin to clean brass flashholes

hand priming tool

making sure to check twice that all brass is primed before charging, and all brass is charged before seating heads.

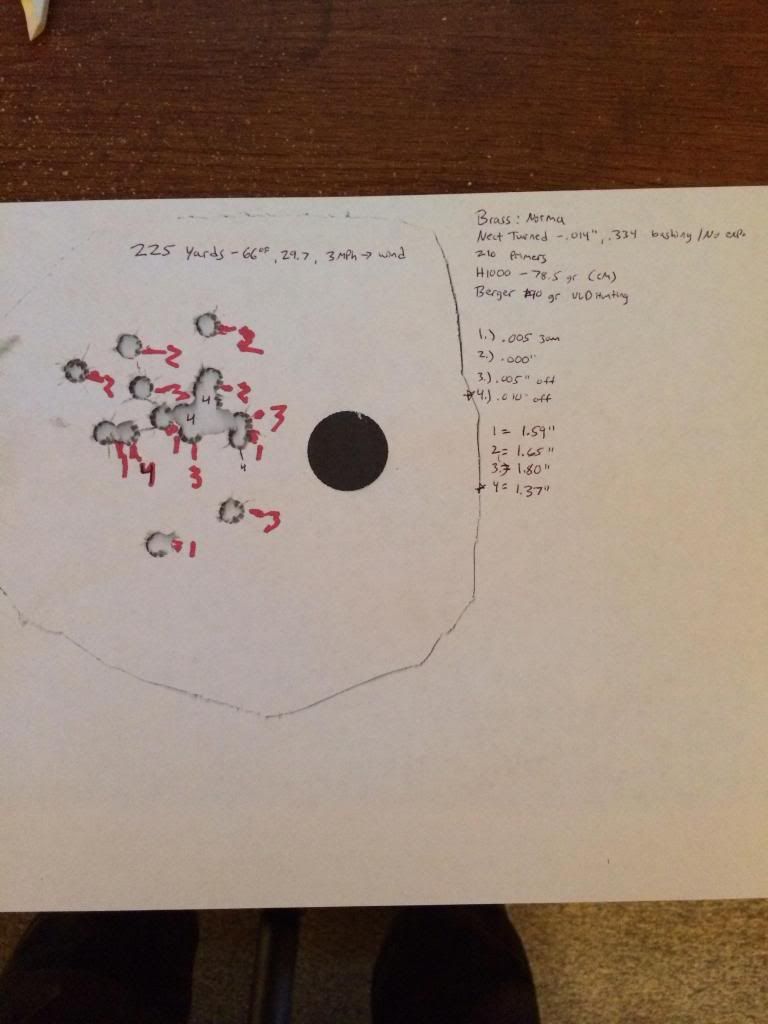

make your own targets, measurements and sizes that gets yo the data you want.

manila folders - keep your test targets and all previous test data that "you know you'll never need to refer to again"

load 1 caliber at a time

loading up in .3 or .5 grain increments, sometimes the sweet spot is in those little graduations

keeping a bad or too used brass bucket, taking it for scrap $ a few times a year.

keeping what you know you will not use in a milk bottle crate - easy to quickly take it all to swop with someone for something you need.

using forums like this to gain info, compile it using Excel, and see what works best over a group of folks comparing similar bullet weight and design, cases, primers, and powder charge

getting to get familiar with powder burn rates vs. barrel length and / or bullet weight.

BC comparisons to judge a bullet against another is only as good as the FPS the bullet is traveling

keeping a picture of my ol' man on the bench reminding me to do all of the above.

BAD (some just a pain in the butt or a DOOH!)

drinking more than 2 beers and continuing to load

hurrying

reloading while tired

having your mind on something else when reloading

thinking hot loads are always better than tame ones

not checking everything at least twice

pushing how many times you load an under $1.00 piece of brass than just tossing it. makes no sense to take a chance of messing up your rifle over this. like driving a corvette fast in the rain on bald tires.

loading up an excessive amount of ammo vs anticipated next few months usage. you never know when the next best bullet comes out, you chop your barrel or sell the rifle having all that ammo to pull apart sucks.

not give a fair shake trying other safe powder, bullet, OAL or trim length combinations just to see if you can come up with a more accurate load for your rifle.

trusting just 1 source of load data, cross reference many books.

not realizing that bullet "A" does not work well with powder "B" at "C" FPS through barrel length "D" with an "E" rate of twist

thinking you know everything without trying something different, as long trying something new is generally considered safe

handling freshly molyed bullets before realizing i should have worn surgical gloves.

putting too much liquid or gell brass cleaning additives to tumbler media making it too gummy caking inside the case and primer pocket.

using brass that is a different manufacturer for working up a load vs. the brass you are actually going to use - case capacity varies per manufacturer!

STILL EXPLORING

neck sizing

HBN coating