Hey everybody, I have been reloading since 2006, I still consider myself new and reltively inexpierenced. I have never had any issues with safety or erratic results until I started loading for my GAP barreled 300WM.

This is a Win M70 action with a 24" Shilen 1:10 installed by Moon (Tim?) at GA. I have 400 hundred rounds of factory match ammunition from Hornady (178), Southwest and Corbon (both 190SMK) with no pressure issues and started loading 220 SMKs in once fired Winchester Brass. They are FL sized, trimmed, and set up with Fed 215M, IMR 7828 SSC set at mag length of 3.390 OAL.

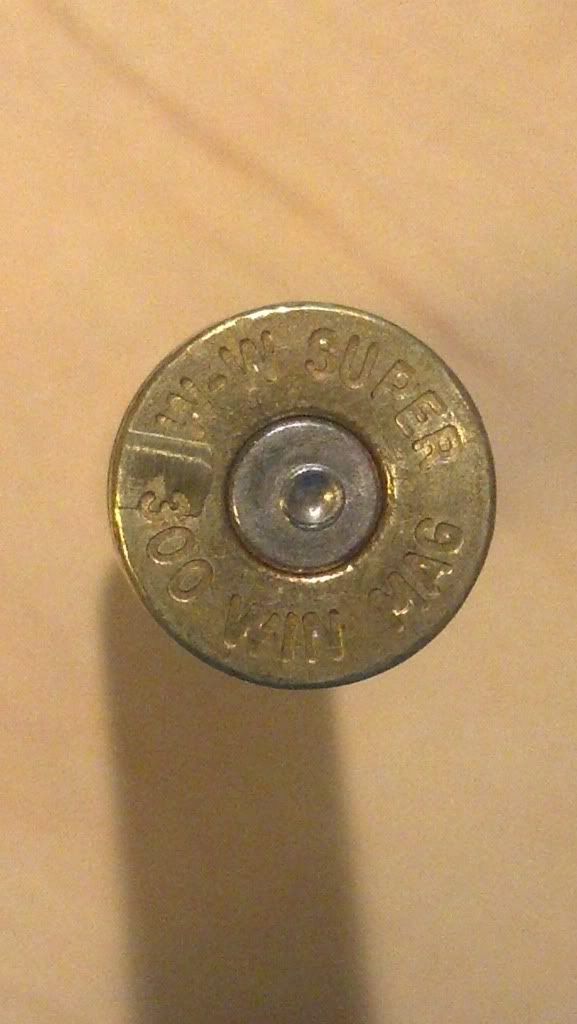

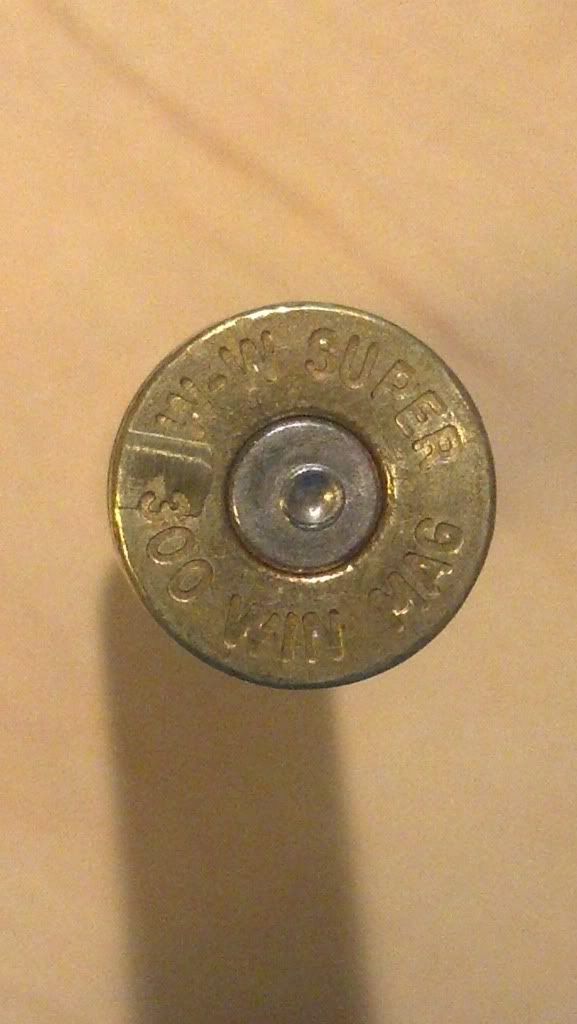

At 72gr (3 grains under max from IMR) I got this on my case head with slightly hard bolt lift:

To me, this seems a bit early to be seeing what I assume is significant pressure, I stopped immediatley and and didnt go any further in my higher charged loads. Can this be a result of a match chamber being tighter than factory cut and I'm seeing early pressure? I need to chrono the 70-71.5 to see if my velocity is adequite for shooting 1000+, and if so I'll leave well enough alone.

Anyone else have rifles that hit pressure signs this early in development? Any advice is more than welcome!

Thanks

C_K

This is a Win M70 action with a 24" Shilen 1:10 installed by Moon (Tim?) at GA. I have 400 hundred rounds of factory match ammunition from Hornady (178), Southwest and Corbon (both 190SMK) with no pressure issues and started loading 220 SMKs in once fired Winchester Brass. They are FL sized, trimmed, and set up with Fed 215M, IMR 7828 SSC set at mag length of 3.390 OAL.

At 72gr (3 grains under max from IMR) I got this on my case head with slightly hard bolt lift:

To me, this seems a bit early to be seeing what I assume is significant pressure, I stopped immediatley and and didnt go any further in my higher charged loads. Can this be a result of a match chamber being tighter than factory cut and I'm seeing early pressure? I need to chrono the 70-71.5 to see if my velocity is adequite for shooting 1000+, and if so I'll leave well enough alone.

Anyone else have rifles that hit pressure signs this early in development? Any advice is more than welcome!

Thanks

C_K