I am attaching a paper reporting where we now stand in development and testing of a new monolithic copper ULD bullet design for ELR rifle shooting. I now see that practical accuracy is a limitation on how fast these bullets should be spinning out of the muzzle. I am changing my rifling twist recommendation from 20 to 24 calibers per turn; i.e., from 6.6 to 8.0 inches per turn for 338-caliber rifles for firing (any) copper bullets. That should reduce 5-shot group sizes from 0.75 to 0.50 MOA, which is probably good enough for most ELR shooting, without reducing bullet speed at extreme range too much. Initial gyroscopic stability (Sg) should be in the 2.0 to 2.5 range, instead of 2.5 to 3.0, for long copper ULD bullets. David Tubb has been kindly testing our 338-caliber prototypes at 1,000 yards.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress in Developing Copper ULD Bullets

- Thread starter Jim Boatright

- Start date

1. Half-hard, cold-rolled copper rod stock (40,000 psi minimum yield strength) was recommended by Dan Warner for this ULD bullet prototyping.

2. The specific gravity of this nearly pure copper alloy is 8.84, versus about 8.36 for free-machining brass.

3. Brass is typically softer, weaker, much more brittle, and has worse shear friction (fouling) characteristics.

2. The specific gravity of this nearly pure copper alloy is 8.84, versus about 8.36 for free-machining brass.

3. Brass is typically softer, weaker, much more brittle, and has worse shear friction (fouling) characteristics.

I am attaching a paper reporting where we now stand in development and testing of a new monolithic copper ULD bullet design for ELR rifle shooting. I now see that practical accuracy is a limitation on how fast these bullets should be spinning out of the muzzle. I am changing my rifling twist recommendation from 20 to 24 calibers per turn; i.e., from 6.6 to 8.0 inches per turn for 338-caliber rifles for firing (any) copper bullets. That should reduce 5-shot group sizes from 0.75 to 0.50 MOA, which is probably good enough for most ELR shooting, without reducing bullet speed at extreme range too much. Initial gyroscopic stability (Sg) should be in the 2.0 to 2.5 range, instead of 2.5 to 3.0, for long copper ULD bullets. David Tubb has been kindly testing our 338-caliber prototypes at 1,000 yards.

I love your papers...thanks for sharing

Yes, if there was ever an application for a silver bullet, this would be it. With a density of 10.5 grams/cc, a 350-gr monolithic silver (Ag) 338-caliber bullet might just be feasible. However, the market price for 0.999-fine silver bullion is currently a bargain at US$16.60/Troy Ounce (480 grains). Made in 99.6-percent copper (0.996 Cu) at 8.84 gm/cc, my 265-gr ULD bullet design would have to be 7.5 calibers long to weigh 350-grains. This is based on lengthening its bore-riding shank by 85-gr worth of copper, which would not increase bore friction losses.

I am attaching a revised paper on ULD copper bullet development which presents a better explanation of the trade-off between lowest possible air-drag and target accuracy made necessary by destabilization of the bullets' yaw attitude in the muzzle-blast zone. Firing rifle bullets with minimum initial yaw is really a rifle building problem and not strictly a bullet design issue.

Attachments

I missed this thread last month, so am glad that I caught your update today.

I find it interesting that your recommendation for barrel twist rate, revised now through further study and down range verification, now correlates exactly to what Dan Warner recommended to me back a few years ago when I was buying his 255.5g Flatlines for .338. He told me then that my 9 twist button barrel was marginal for the copper solids and that I would be better served with an 8 twist cut barrel, based upon his exoerience

I did not change my barrel at that time and my own experiences with that barrel seem to bear out much of what I’ve read in your papers, though that surely could be just confirmation bias on my part. The copper solids in my barrel did not give me the one hole groups at 100 yards that my 285 gr Hornady BTHPs did, but out to and past 1800 yards, they performed admirably. Admirably meaning less than 1 moa at ELR distances. This was before you started publishing your papers here.

At some point, I will likely get a gain twist barrel that ends up at the 24 times caliber now recommended and see how that works for me.

Thanks again for all of your work on this subject and for publishing it for us here to read and digest.

I find it interesting that your recommendation for barrel twist rate, revised now through further study and down range verification, now correlates exactly to what Dan Warner recommended to me back a few years ago when I was buying his 255.5g Flatlines for .338. He told me then that my 9 twist button barrel was marginal for the copper solids and that I would be better served with an 8 twist cut barrel, based upon his exoerience

I did not change my barrel at that time and my own experiences with that barrel seem to bear out much of what I’ve read in your papers, though that surely could be just confirmation bias on my part. The copper solids in my barrel did not give me the one hole groups at 100 yards that my 285 gr Hornady BTHPs did, but out to and past 1800 yards, they performed admirably. Admirably meaning less than 1 moa at ELR distances. This was before you started publishing your papers here.

At some point, I will likely get a gain twist barrel that ends up at the 24 times caliber now recommended and see how that works for me.

Thanks again for all of your work on this subject and for publishing it for us here to read and digest.

Engineers have to push things until they break in development testing to know where to back off to. I did not really expect to see so much aerodynamic jump induced accuracy degradation and shot-to-shot yaw-drag variation because I had no idea just how much initial yaw we were seeing. As a bullet designer, I am not really in control of how they are going to be fired. The new slower recommended twist rate of 24 calibers per turn is a compromise trading off a little of the bullet's dynamic stability for smaller group sizes. This compromise would not be necessary if we can figure out how to prevent destabilizing the rifle bullets in yaw attitude between exiting the muzzle crown and the beginning of ballistic flight 10 or 15 feet downrange. Porting the barrel comes to mind as does using an integral suppressor. Perhaps a T-style artillery type muzzle brake or clam-shell brake might be less destabilizing than our muzzle-attached, milled tubular designs.

Last edited:

I emailed many in the shooting community with this information earlier this evening, and wanted to share it here as well. I now have the formulations in hand to back-up what I have been saying here for some time. We need rifling twist-rates of 20 calibers per turn for lowest air-drag, but we need 2 to 3 times longer per turn for best accuracy.

Yaw destabilization of the bullets in passing through the muzzle-blast zone before commencing ballistic flight is now the largest remaining accuracy and air-drag limitation. We and David Tubb are seeing the effects of around 2.5 to 5 degrees of initial yaw in firing our very good copper bullets from very good 338-caliber rifles. We need to find ways to launch these bullets straighter.

EDIT: I am attaching another note explaining this new formulation of the slow-mode damping factor and why it is important to riflemen. I am attempting to make this explanation as straightforward as possible.

Yaw destabilization of the bullets in passing through the muzzle-blast zone before commencing ballistic flight is now the largest remaining accuracy and air-drag limitation. We and David Tubb are seeing the effects of around 2.5 to 5 degrees of initial yaw in firing our very good copper bullets from very good 338-caliber rifles. We need to find ways to launch these bullets straighter.

EDIT: I am attaching another note explaining this new formulation of the slow-mode damping factor and why it is important to riflemen. I am attempting to make this explanation as straightforward as possible.

Attachments

Last edited:

I do not know an awful lot about the destabilizing mechanisms which can occur while the bullet transits the muzzle-blast zone. However, I think there would be two beneficial effects from redistributing the bullet mass as described. First, by moving the CG "forward" nearer the CP during reversed aerodynamic flight, the overturning moment should be reduced in several yaw-destabilizing scenarios. Also, the second moment of inertia about a cross-axis through the CG (Iy) would be reduced some which would speed up the coning rate--reducing the accuracy robbing aerodynamic jump caused by any initial yaw angle.

EDIT: Modern match-type jacketed rifle bullets usually have open tips and hollow nose cavities filled (due to dynamic pressure in flight) with air at about 40-percent increased density over ambient. The resulting speeding-up of the initial coning rate is a real accuracy advantage.

EDIT: Modern match-type jacketed rifle bullets usually have open tips and hollow nose cavities filled (due to dynamic pressure in flight) with air at about 40-percent increased density over ambient. The resulting speeding-up of the initial coning rate is a real accuracy advantage.

Last edited:

I have completed a comprehensive study of the exterior ballistics effects of selecting various different rifling twist rates. I discovered that random yaw destabilization occurring while the fired rifle bullet is transiting the muzzle-blast zone between the crown of the muzzle and exiting the blast envelope a few yards ahead is a serious accuracy and yaw-drag issue. I also found that slow twists promote best accuracy while fast twists reduce air-drag, both in the presence of random initial yaw destabilization. My recommendation is first to reduce the yaw destabilization by proper choice of muzzle brakes and then to go ahead with very fast-twist barrels for shooting copper bullets. I am planning to test a Barrett 98B/MRAD muzzle brake in 338 caliber to evaluate its yaw destabilization effects. The large side ports promise higher evacuation rates for the high-pressure gasses. We have been using a really good tubular-style multi-ported muzzle brake, but it has been destabilizing our test bullets fired from barrels made with 19 to 23 calibers per turn rifling twist-rates.

The attached paper supersedes and replaces the earlier ones posted here.

The attached paper supersedes and replaces the earlier ones posted here.

Attachments

Great Googlie Mooglie that's a bunch of scientific hocus pocus! So with all that, what about the degradation of barrel life with the increased rifle twist rate? Surely radials/lands and groves will take the brunt of the damage with the increased friction of a closer twist rate. Any thoughts on reduction of barrel life and how that will destabilize the round with that damage?

Great Googlie Mooglie that's a bunch of scientific hocus pocus! So with all that, what about the degradation of barrel life with the increased rifle twist rate? Surely radials/lands and groves will take the brunt of the damage with the increased friction of a closer twist rate. Any thoughts on reduction of barrel life and how that will destabilize the round with that damage?

I see no mechanical reason to expect significantly more barrel friction or shorter barrel life due simply to increasing the twist-rate for firing copper bullets. However, switching to copper bullets does affect lots of things. You want a narrow land rifling pattern designed for improved gas sealing like Gary Schneider's P5 or Boots Obermeyer's 5R patterns. A pre-stressed button-rifled barrel will seal the powder gasses better with non-expanding copper bullets than will a stress-free cut-rifled barrel (due to less internal barrel expansion). You want a throat angle no greater than 1.5 degrees per side to minimize shot-start pressures with copper bullets.

I mentioned above the likelihood that a high evacuation-rate muzzle brake will be required for best accuracy and lower variation in air-drag with very fast-twist barrels. The yaw destabilization in tubular brakes is a killer with fast-twist barrels, probably caused by high-rate gas flow through an annular ring-shaped aperture around the bullet.

What are your thoughts on a suppressor and it’s affects compared to a good brake?I see no mechanical reason to expect significantly more barrel friction or shorter barrel life due simply to increasing the twist-rate for firing copper bullets. However, switching to copper bullets does affect lots of things. You want a narrow land rifling pattern designed for improved gas sealing like Gary Schneider's P5 or Boots Obermeyer's 5R patterns. A pre-stressed button-rifled barrel will seal the powder gasses better with non-expanding copper bullets than will a stress-free cut-rifled barrel (due to less internal barrel expansion). You want a throat angle no greater than 1.5 degrees per side to minimize shot-start pressures with copper bullets.

I mentioned above the likelihood that a high evacuation-rate muzzle brake will be required for best accuracy and lower variation in air-drag with very fast-twist barrels. The yaw destabilization in tubular brakes is a killer with fast-twist barrels, probably caused by high-rate gas flow through an annular ring-shaped aperture around the bullet.

Great Googlie Mooglie that's a bunch of scientific hocus pocus! So with all that, what about the degradation of barrel life with the increased rifle twist rate? Surely radials/lands and groves will take the brunt of the damage with the increased friction of a closer twist rate. Any thoughts on reduction of barrel life and how that will destabilize the round with that damage?

Hi,

Monolithic solids have substantially less engraving area than traditional jacketed projectiles so the barrel life is "normally" improved even with faster twist rates.

I say "normally" because I can make either/or eat a barrel faster no matter what the twist rate is......

Barrels "wear" at the throat from heat way way way more than lands/grooves wear from friction.

Sincerely,

Theis

Hi,

Now onto the muzzle brakes

Decades ago Fisher and Ken Johnson (K&P Barrels) did crazy amounts of testing of muzzle brake types, ports and patterns back when the only people using monolithics were the "extreme" BMG guys.

Both Fisher and Ken come to the same conclusion/results..that clam style muzzle brakes provided the best accuracy in grouping for those guys in the FCSA 1k yard game.

Same reason the big artillery pieces use the clam style/shark style......

I was not smart enough to grasp the insight and forward thinking back in 2009 when I got about 10 different brakes from Fisher to test out but I think I have a better understanding of it now that Jim has taken all the time to narrow it down and explain it in a more science driven method.

Sincerely,

Theis

Now onto the muzzle brakes

Decades ago Fisher and Ken Johnson (K&P Barrels) did crazy amounts of testing of muzzle brake types, ports and patterns back when the only people using monolithics were the "extreme" BMG guys.

Both Fisher and Ken come to the same conclusion/results..that clam style muzzle brakes provided the best accuracy in grouping for those guys in the FCSA 1k yard game.

Same reason the big artillery pieces use the clam style/shark style......

I was not smart enough to grasp the insight and forward thinking back in 2009 when I got about 10 different brakes from Fisher to test out but I think I have a better understanding of it now that Jim has taken all the time to narrow it down and explain it in a more science driven method.

Sincerely,

Theis

What are your thoughts on a suppressor and it’s affects compared to a good brake?

An integral suppressor which maintains the perforated barrel all the way through its length would be best, by far, at launching the bullets reliably nose forward with no appreciable yaw-rate. But, to whatever extent the rifled barrel is shortened inside the integral suppressor, bullet guidance at the muzzle would suffer more yaw destabilization.

Dr. Michael Courtney's paper (a resource paper here IIRC) addresses the effects of various suppressor design types on bullet stability. He seemed to favor a muzzle-attached 2-stage design such as made by Predator as their TSS (Two-Stage Suppressor?). We now know that decreasing the number n of calibers per turn for a faster twist-rate barrel will inversely increase group sizes due to initial yaw instability and resulting aerodynamic jump. Using faster twist-rate barrels would have made Michael's study easier by amplifying the effects he was trying to measure.

My guess would be that any well designed muzzle-attached suppressor (not using mechanical wipes) would be better at launching bullets straight than even a high evacuation-rate brake, or even no brake at all (plain muzzle).

Last edited:

An integral suppressor which maintains the perforated barrel all the way through its length would be best, by far, at launching the bullets reliably nose forward with no appreciable yaw-rate. But, to whatever extent the rifled barrel is shortened inside the integral suppressor, bullet guidance at the muzzle would suffer more yaw destabilization.

Dr. Michael Courtney's paper (a resource paper here IIRC) addresses the effects of various suppressor design types on bullet stability. He seemed to favor a muzzle-attached 2-stage design such as made by Predator as their TSS (Two-Stage Suppressor?). We now know that decreasing the number n of calibers per turn for a faster twist-rate barrel will inversely increase group sizes due to initial yaw instability and resulting aerodynamic jump. Using faster twist-rate barrels would have made Michael's study easier by amplifying the effects he was trying to measure.

My guess would be that any well designed muzzle-attached suppressor (not using mechanical wipes) would be better at launching bullets straight than even a high evacuation-rate brake, or even no brake at all (plain muzzle).

I hope you’re right because my 375 rifle is a 7twist shooting CE 377 MTACs and 400 lazers. I should be getting my suppressor stamp approved soon.

I hope you’re right because my 375 rifle is a 7twist shooting CE 377 MTACs and 400 lazers. I should be getting my suppressor stamp approved soon.

Hi,

I would suggest reading that paper by Dr. Courtney...the suppressor design he refers to is rather unique in a lot of ways.

Sincerely,

Theis

Hi,

I would suggest reading that paper by Dr. Courtney...the suppressor design he refers to is rather unique in a lot of ways.

Sincerely,

Theis

I've read it. I actually think you suggested it to me back when I was asking you questions about Crux suppressors; way before their current fiasco.

that being said, my brain can’t handle to much concussion so I’ll be using it regardless.

So from @RAVAGE88 responses in this thread

It seems to me to be concerning the same issue of muzzle pressure effecting group size in faster twist barrels. Except in the .22lr example, a longer barrel is actually leading to lower muzzle pressure due to a tiny powder charge and increased volume.

Would it be too far off to compare both threads together?

It seems to me to be concerning the same issue of muzzle pressure effecting group size in faster twist barrels. Except in the .22lr example, a longer barrel is actually leading to lower muzzle pressure due to a tiny powder charge and increased volume.

Would it be too far off to compare both threads together?

I hope you’re right because my 375 rifle is a 7twist shooting CE 377 MTACs and 400 lazers. I should be getting my suppressor stamp approved soon.

The good news is you will see higher average BC's than others shooting those copper bullets from slower-twist barrels. Crosswind sensitivity will be amazingly low and maximum supersonic ranges will be greatly extended.

The bad news is that you are going to be really stressing your rifle system's ability to launch these bullets straight. Almost any yaw disturbance in the transition zone will create less-that-great accuracy results, even at short ranges, and larger-than-expected VARIANCES in the measured air-drag.

You will have to become a champion at minimizing yaw disturbances occurring in the first several feet in front of the crown of the muzzle. Let us know what you experience.

The good news is you will see higher average BC's than others shooting those copper bullets from slower-twist barrels. Crosswind sensitivity will be amazingly low and maximum supersonic ranges will be greatly extended.

The bad news is that you are going to be really stressing your rifle system's ability to launch these bullets straight. Almost any yaw disturbance in the transition zone will create less-that-great accuracy results, even at short ranges, and larger-than-expected VARIANCES in the measured air-drag.

You will have to become a champion at minimizing yaw disturbances occurring in the first several feet in front of the crown of the muzzle. Let us know what you experience.

that last paragraph makes me wish I got an 8 twist instead lol. I’m no champion unfortunately.

I wonder if a stacked-shim type muzzle brake with spacing comparable to the length of the caliber-diameter shank of the bullet might prove a good middle ground between annular overrun and gas evacuation.

I wonder if a stacked-shim type muzzle brake with spacing comparable to the length of the caliber-diameter shank of the bullet might prove a good middle ground between annular overrun and gas evacuation.

I think that could work, gnochi, but why bother? The really high evacuation rate brakes are loud as hell, but they do work well at producing counter-recoil force. I am thinking that a simple horizontal-firing T-style single chamber brake (like a glorified pipe Tee) might be best for launching bullets straight. The more rearward exhaust of some of the clamshell designs produces some more forward thrust, but they are not fun to be behind.

Well it's late & I'm tired, but Jim's post got me thinking. They always do!

I'm starting to wonder if the "node" everyone try's to find during load development has more to do with timing when the bullet passes through the muzzle in relation to pressure wave reversal vs. barrel harmonics???

The barrel whip you see on slow mo video never visibly starts before the bullet leaves the barrel. That's when the positive blast wave behind the bullet instantly changes sign to negative and races back down the barrel.

There are also + & - waves happening in front of the bullet Edit: While still in the bore. I'm sure there is barrel flex before bullet exit & it doesn't take much to shift POI, but the majority of barrel whip appears to occur after bullet exit.

It's counter intuitive, but the negative pressure wave after a blast is actually more powerful and destructive. I've seen this on high speed film during live blast testing for bomb resistant building facade's

Accuracy node may have a lot to do with the timing of bullet exit vs shock wave amplitude induced yaw.

Someone should shoot high speed video of supersonic bullet exit tuned to accuracy node contrasted with inaccuracy node. I've never seen that done.

I'd like to see what would happen if David Tubb screwed a 7 degree tapered cone (no ports) on the muzzle about 4-8" in length?

If I remember correctly 7 degree is the steepest angle the high pressure gasses will follow, thus creating a uniform blast wave disbursal both ahead off, and behind the bullet exit.

Edit: I hope the above is a terrible idea. It would look awefull!

I'm starting to wonder if the "node" everyone try's to find during load development has more to do with timing when the bullet passes through the muzzle in relation to pressure wave reversal vs. barrel harmonics???

The barrel whip you see on slow mo video never visibly starts before the bullet leaves the barrel. That's when the positive blast wave behind the bullet instantly changes sign to negative and races back down the barrel.

There are also + & - waves happening in front of the bullet Edit: While still in the bore. I'm sure there is barrel flex before bullet exit & it doesn't take much to shift POI, but the majority of barrel whip appears to occur after bullet exit.

It's counter intuitive, but the negative pressure wave after a blast is actually more powerful and destructive. I've seen this on high speed film during live blast testing for bomb resistant building facade's

Accuracy node may have a lot to do with the timing of bullet exit vs shock wave amplitude induced yaw.

Someone should shoot high speed video of supersonic bullet exit tuned to accuracy node contrasted with inaccuracy node. I've never seen that done.

I'd like to see what would happen if David Tubb screwed a 7 degree tapered cone (no ports) on the muzzle about 4-8" in length?

If I remember correctly 7 degree is the steepest angle the high pressure gasses will follow, thus creating a uniform blast wave disbursal both ahead off, and behind the bullet exit.

Edit: I hope the above is a terrible idea. It would look awefull!

Last edited:

I think that could work, gnochi, but why bother? The really high evacuation rate brakes are loud as hell, but they do work well at producing counter-recoil force. I am thinking that a simple horizontal-firing T-style single chamber brake (like a glorified pipe Tee) might be best for launching bullets straight. The more rearward exhaust of some of the clamshell designs produces some more forward thrust, but they are not fun to be behind.

My though was that if the T unsupported length and the bullet length are comparable, you could get a substantial moment on the front of the bullet (and corresponding yaw), but it really depends on the exact particulars of the supersonic flow.

On the other hand, since the pressure would be lower towards the front of the bullet, there may very well be an optimal unsupported length that balances the higher pressure at the back of the bullet decreasing towards the CG, then decreasing further but extending further towards the bullet tip.

Have you had the chance to test a bare muzzle yet?

Well it's late & I'm tired, but Jim's post got me thinking. They always do!

I'm starting to wonder if the "node" everyone try's to find during load development has more to do with timing when the bullet passes through the muzzle in relation to pressure wave reversal vs. barrel harmonics???

The barrel whip you see on slow mo video never visibly starts before the bullet leaves the barrel. That's when the positive blast wave behind the bullet instantly changes sign to negative and races back down the barrel.

There are also + & - waves happening in front of the bullet Edit: While still in the bore. I'm sure there is barrel flex before bullet exit & it doesn't take much to shift POI, but the majority of barrel whip appears to occur after bullet exit.

It's counter intuitive, but the negative pressure wave after a blast is actually more powerful and destructive. I've seen this on high speed film during live blast testing for bomb resistant building facade's

Accuracy node may have a lot to do with the timing of bullet exit vs shock wave amplitude induced yaw.

Someone should shoot high speed video of supersonic bullet exit tuned to accuracy node contrasted with inaccuracy node. I've never seen that done.

I'd like to see what would happen if David Tubb screwed a 7 degree tapered cone (no ports) on the muzzle about 4-8" in length?

If I remember correctly 7 degree is the steepest angle the high pressure gasses will follow, thus creating a uniform blast wave disbursal both ahead off, and behind the bullet exit.

Edit: I hope the above is a terrible idea. It would look awefull!

Good thinking, except for the rocket nozzle attachment idea. I am not so concerned about any destabilization happening to the bullets beyond the frontmost metal parts attached to the muzzle. I believe the main destabilization problems to solve first are due to (1) high speed gas flow through any annular ring-shaped aperture around the bullet, and (2) high pressure waves reflecting back against the bullet within any muzzle attachment. The bare muzzle is the standard for minimizing both of these problems.

Big bore shooters do need recoil moderation via the delayed counter-recoil force provided by a muzzle brake. That is why I keep mentioning brakes with very high gas evacuation rates. Any tubular brake is designed for controlled (sequentially staged) gas releases over the transit time of the bullet.

Last edited:

Well it's late & I'm tired, but Jim's post got me thinking. They always do!

I'm starting to wonder if the "node" everyone try's to find during load development has more to do with timing when the bullet passes through the muzzle in relation to pressure wave reversal vs. barrel harmonics???

The barrel whip you see on slow mo video never visibly starts before the bullet leaves the barrel. That's when the positive blast wave behind the bullet instantly changes sign to negative and races back down the barrel.

There are also + & - waves happening in front of the bullet Edit: While still in the bore. I'm sure there is barrel flex before bullet exit & it doesn't take much to shift POI, but the majority of barrel whip appears to occur after bullet exit.

It's counter intuitive, but the negative pressure wave after a blast is actually more powerful and destructive. I've seen this on high speed film during live blast testing for bomb resistant building facade's

Accuracy node may have a lot to do with the timing of bullet exit vs shock wave amplitude induced yaw.

Someone should shoot high speed video of supersonic bullet exit tuned to accuracy node contrasted with inaccuracy node. I've never seen that done.

I'd like to see what would happen if David Tubb screwed a 7 degree tapered cone (no ports) on the muzzle about 4-8" in length?

If I remember correctly 7 degree is the steepest angle the high pressure gasses will follow, thus creating a uniform blast wave disbursal both ahead off, and behind the bullet exit.

Edit: I hope the above is a terrible idea. It would look awefull!

You are correct, Max, that the harmonic standing wave transverse vibrations of a center-fire rifle barrel occur after the bullet has departed, unlike with long 22LR rifle barrels. These transverse barrel distortions are primarily driven by the rifle's recoil reaction forces which are eccentric to the bore axis. When the bullet exits, the barrel begins to vibrate harmonically. However, the barrel "knows" its vibration modes even while being distorted by the recoil forces, and begins to assume those mode shapes while being forcibly distorted.

There are many different types and modes of barrel vibrations, but they are mostly all shear wave vibrations with particle motion transverse to the direction of wave propagation. They propagate at about 10,500 FPS up and down the barrel. The gross vertical plane transverse waves we first think of as barrel vibrations (in several different modes) are all shear waves, as are the bore ID enlarging/contracting pressure waves discussed by the Optimum Barrel Time guys. Different transverse vibration modes can be excited by striking the bare barrel sides at suitable anti-node points. The ends of the barrel are always anti-nodes for all transverse modes.

These shear waves reflect back and forth off of the impedance changes at each end of the barrel, with 180-degree phase reversal upon each reflection. At each reflection, some other vibration modes may also be excited. There are also torsional shear vibration modes which probably do not affect accuracy.

Longitudinal acoustic pressure waves are the non-shear-wave exception. They depend primarily upon the density and elasticity of the barrel steel and travel very rapidly through steel at about 19,500 FPS. In fact, they are used to measure Young's Modulus of Elasticity for a steel material in slender rods (like our rifle barrels) or the bulk modulus of elasticity in bulk steel. Striking endwise on the tip of a suspended bare barrel causes a very high-pitched acoustic ringing.

I have completed a comprehensive study of the exterior ballistics effects of selecting various different rifling twist rates. I discovered that random yaw destabilization occurring while the fired rifle bullet is transiting the muzzle-blast zone between the crown of the muzzle and exiting the blast envelope a few yards ahead is a serious accuracy and yaw-drag issue. I also found that slow twists promote best accuracy while fast twists reduce air-drag, both in the presence of random initial yaw destabilization. My recommendation is first to reduce the yaw destabilization by proper choice of muzzle brakes and then to go ahead with very fast-twist barrels for shooting copper bullets. I am planning to test a Barrett 98B/MRAD muzzle brake in 338 caliber to evaluate its yaw destabilization effects. The large side ports promise higher evacuation rates for the high-pressure gasses. We have been using a really good tubular-style multi-ported muzzle brake, but it has been destabilizing our test bullets fired from barrels made with 19 to 23 calibers per turn rifling twist-rates.

The attached paper supersedes and replaces the earlier ones posted here.

This is a very interesting topic to me as I have always wondered what various brake/port designs have adversely affected accuracy. What's surprising is there are countless tests comparing different brakes and how effective they are at reducing recoil and muzzle rise but I have not found a single test done to compare their affects on accuracy.

I began to question this several years ago when it was no longer legal to own a semi-auto firearm in NY with any type of muzzle brake/flash suppressor. I was forced to remove the standard GI flash hider and install a dummy flash hider which is noting more than a piece of steel that is milled to look like a GI flash hider and maintain all the necessary dimensions but does not have the slots cut out to reduce flash signature. I have always questioned what was happening to the bullet as it traveled through this smooth bore tube after it exits the barrel and what effect the blast waves were having on it as it leaves the rifling. The rifle does shoot well but I wonder if it could shoot better in its original form.

As far as the Barrett MRAD brake, do you feel the size of the 2 very large ports works better to evacuate the gases faster than say a 4 port Terminator or APA Fat Bastard? Interested to hear how your testing goes.

Last edited:

This is a very interesting topic to me as I have always wondered what various brake/port designs have adversely affected accuracy. What's surprising is there are countless tests comparing different brakes and how effective they are at reducing recoil and muzzle rise but I have not found a single test done to compare their affects on accuracy.

I began to question this several years ago when it was no longer legal to own a semi-auto firearm in NY with any type of muzzle brake/flash suppressor. I was forced to remove the standard GI flash hider and install a dummy flash hider which is noting more than a piece of steel that is milled to look like a GI flash hider and maintain all the necessary dimensions but does not have the slots cut out to reduce flash signature. I have always questioned what was happening to the bullet as it traveled through this smooth bore tube after it exits the barrel and what effect the blast waves were having on it as it leaves the rifling. The rifle does shoot well but I wonder if it could shoot better in its original form.

As far as the Barrett MRAD brake, do you feel the size of the 2 very large ports works better to evacuate the gases faster than say a 4 port Terminator or APA Fat Bastard? Interested to hear how your testing goes.

I looked up the Terminator and APA brakes mentioned, and yes the ports on the Barrett MRAD brake are much larger, which was what I wanted for testing. In fact, it is hard for me to see why the outer (front) pair of ports are even needed for the MRAD brake. I will probably cut them off after testing it as supplied.

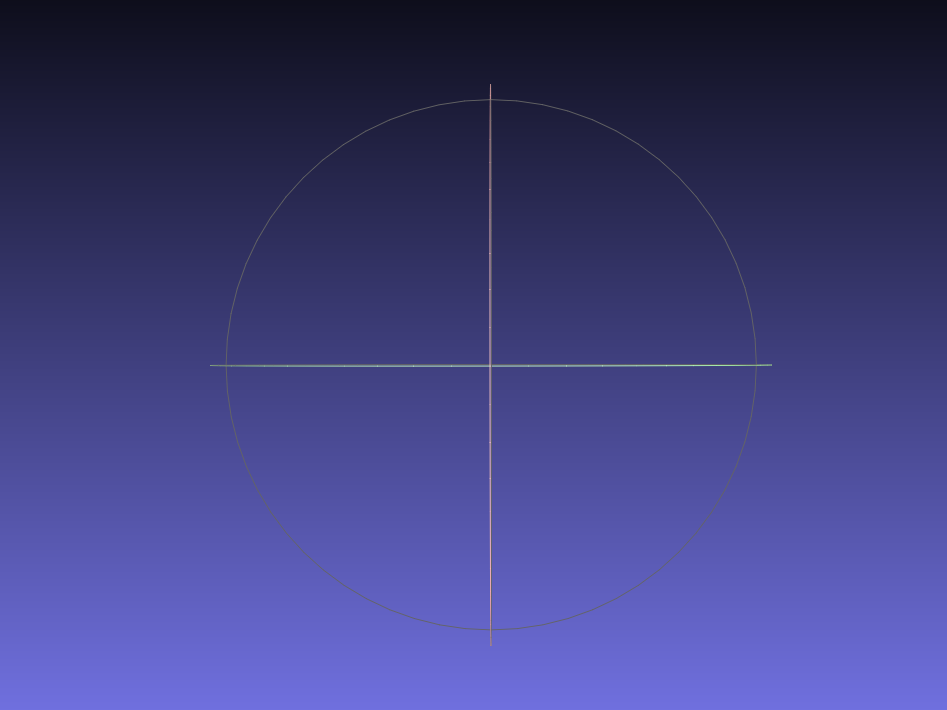

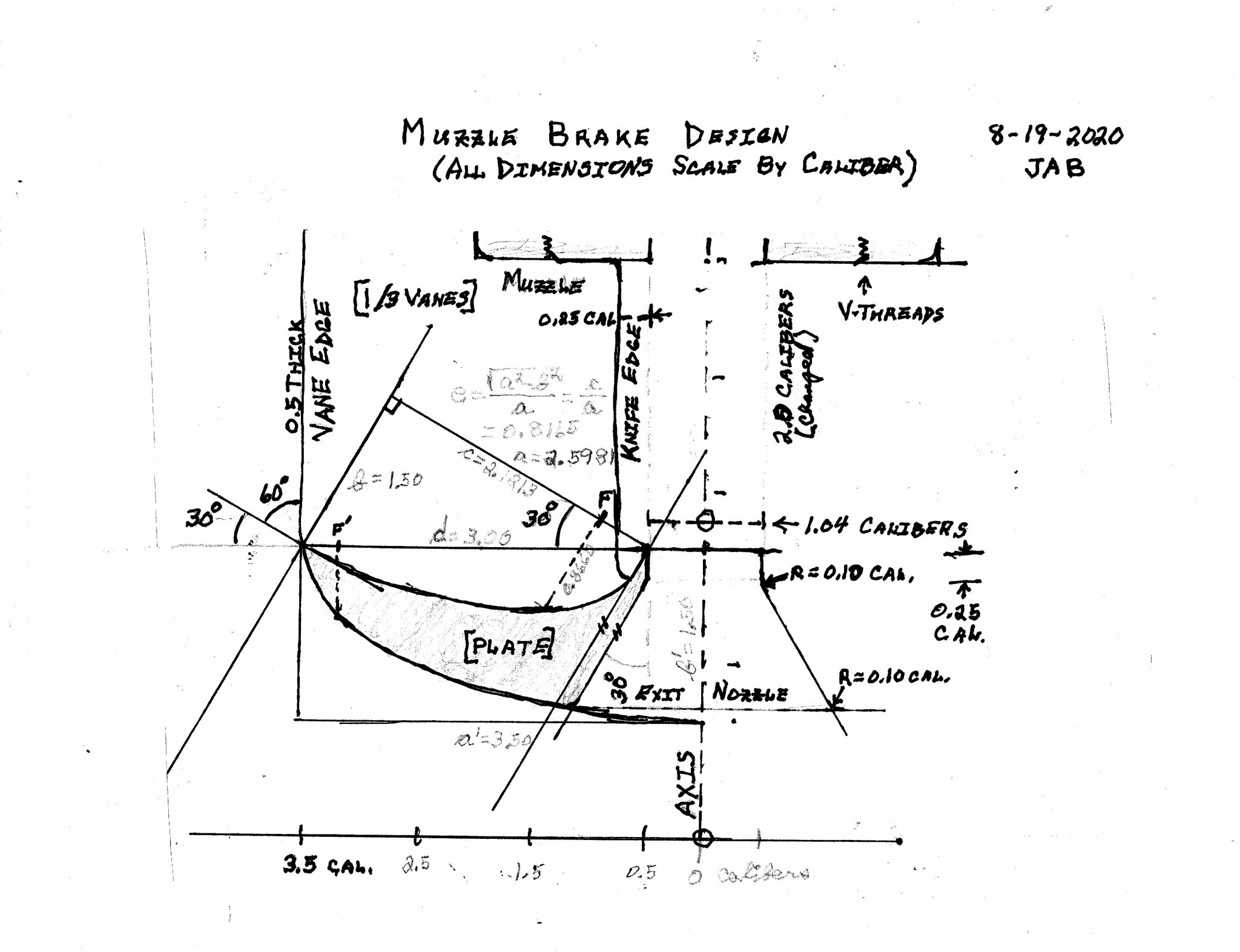

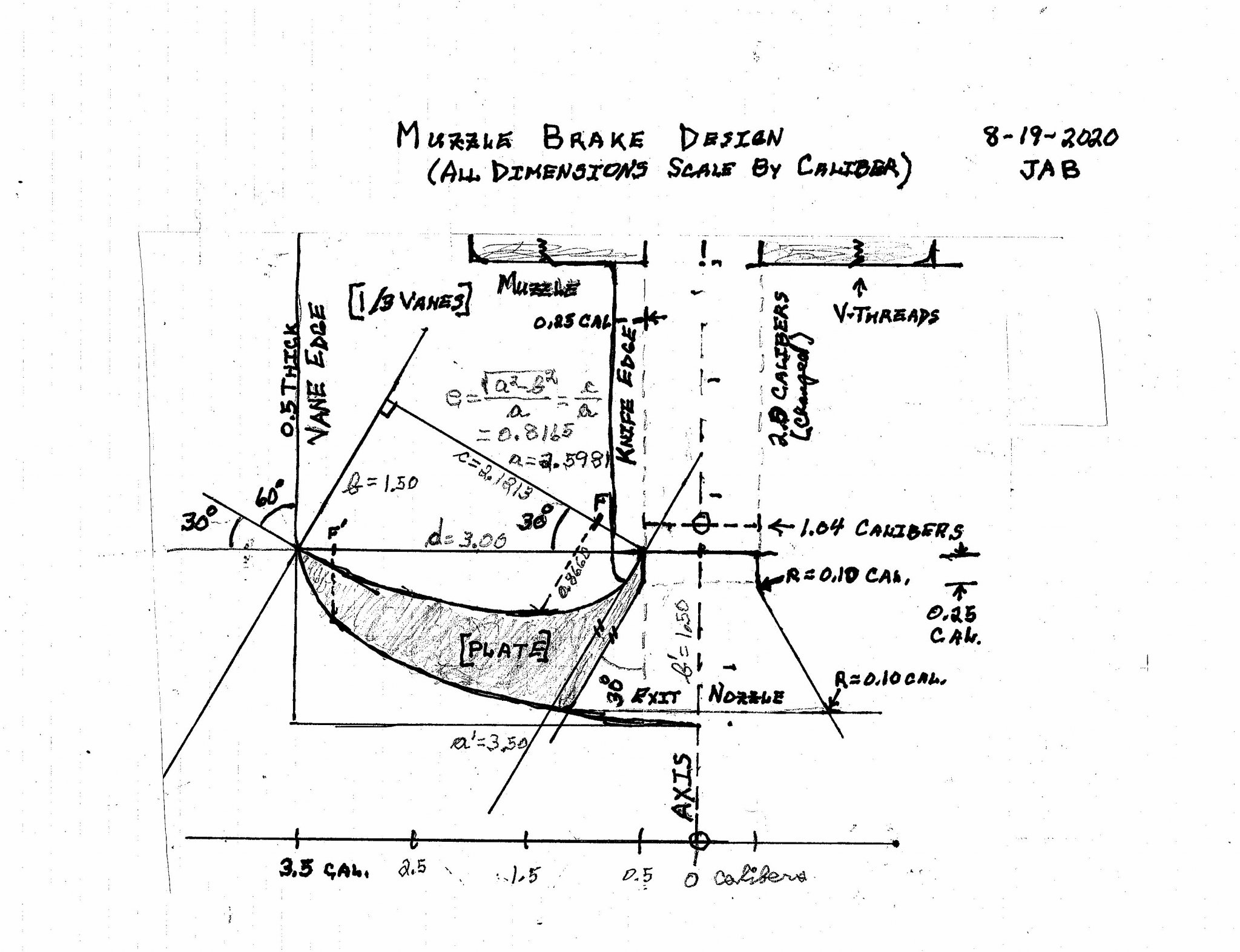

I envision the ideal MB for minimum bullet disturbance being about a 1.5-inch diameter flat plate with central 0.350-inch hole supported at about 0.6-inch in front of the crown of the muzzle for 338-caliber. The plate could be supported via three or four narrow knife-edged vanes with the vanes pointed toward the axis of the bore. The axial length of the "ports" should allow the full-diameter shank of a 338-caliber bullet to enter the hole through the gas deflecting plate just before the gas seal in the bore is broken by the boat-tail of the bullet starting to exit the muzzle crown.

I might make this MB from aluminum round stock just for grins. It would be loud as hell, but might be reasonably effective in generating counter-recoil force.

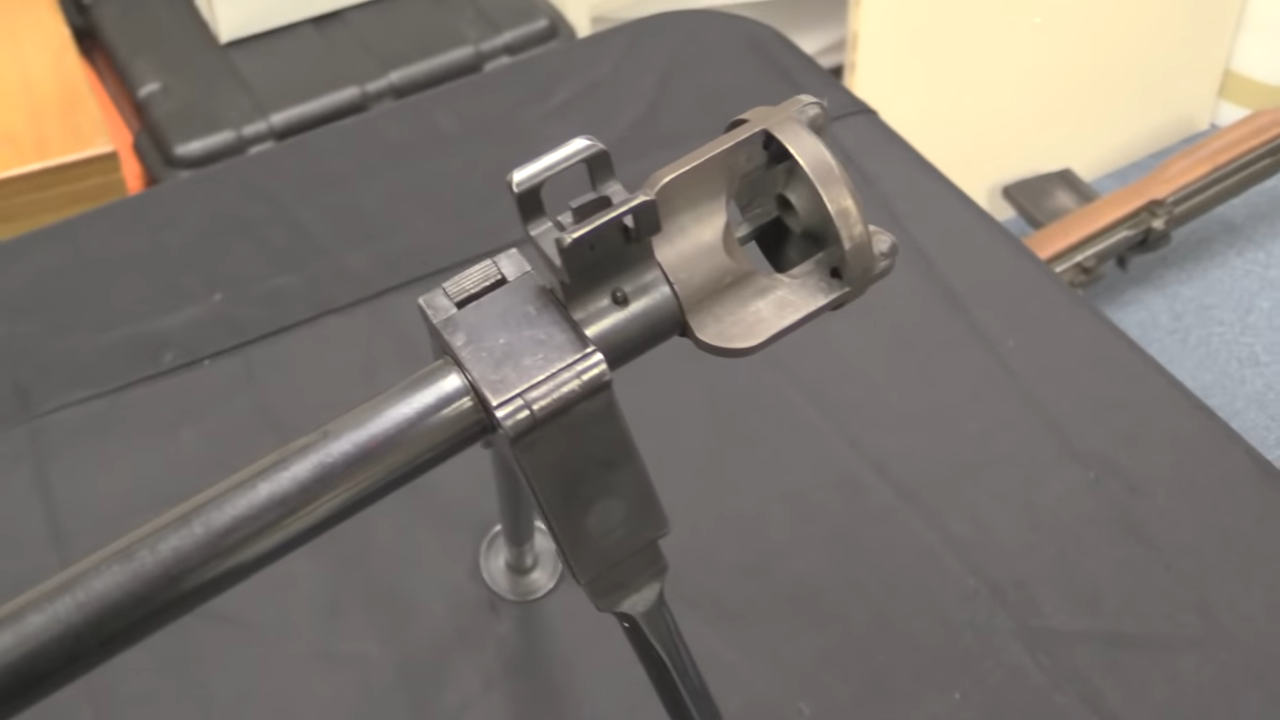

I have found the muzzle brake which I had been mentally designing to provide an adequate counter-recoil impulse without destabilizing the bullet in yaw. It was shown by Ian McCollum (ForgottenWeapons.com) in his August 1, 2016, program on the Winchester Automatic Rifle, a late WWII replacement for the BAR requested by the US Army. The original prototype rifle in .30-'06 was marked "EXP" (having this muzzle brake) and was successfully demonstrated to the Army in December, 1944. Ten more "production models" were ordered for testing at that time. The program was abruptly cancelled by the ending of the war in August, 1945. The two surviving specimens of the WAR are in the Cody Firearms Museum in Wyoming.

The MB seems to be a machined steel casting, possibly as two joined parts. The only change I would make to it would be to cone the bullet outlet port at about 30 degrees (almost back to the flow separator) to minimize any possible yaw destabilization caused by internal acoustic reflections. I could find no patent filed on this MB, and all records are lost (at least for now). Here are a couple of screenshots from Ian's Youtube video:

EDIT: Sorry about doubling up on the two screenshots. Couldn't see them all together while posting.

The MB seems to be a machined steel casting, possibly as two joined parts. The only change I would make to it would be to cone the bullet outlet port at about 30 degrees (almost back to the flow separator) to minimize any possible yaw destabilization caused by internal acoustic reflections. I could find no patent filed on this MB, and all records are lost (at least for now). Here are a couple of screenshots from Ian's Youtube video:

EDIT: Sorry about doubling up on the two screenshots. Couldn't see them all together while posting.

Last edited:

Hi,

@Jim Boatright

Purely because of my OCD, lol.....and that our level of manufacturing has greatly increased since that one was designed and made.

Would it be as effective if it was built with 4 "openings" instead of what looks like 3 in above pictures.

Sincerely,

Theis

@Jim Boatright

Purely because of my OCD, lol.....and that our level of manufacturing has greatly increased since that one was designed and made.

Would it be as effective if it was built with 4 "openings" instead of what looks like 3 in above pictures.

Sincerely,

Theis

Going to make an assumption purely based on nothing other than what pops in my head, but yes. If you use 4 supporting points they could be thinner than the 3 and as long as the surface area that’s presented to the gas is the same or less, it should be just as effective and has as little influence on the bullet as the 3 supports

I remember That design from Ian’s channel.I have found the muzzle brake which I had been mentally designing to provide an adequate counter-recoil impulse without destabilizing the bullet in yaw. It was shown by Ian McCollum (ForgottenWeapons.com) in his August 1, 2016, program on the Winchester Automatic Rifle, a late WWII replacement for the BAR requested by the US Army. The original prototype rifle in .30-'06 was marked "EXP" (having this muzzle brake) and was successfully demonstrated to the Army in December, 1944. Ten more "production models" were ordered for testing at that time. The program was abruptly cancelled by the ending of the war in August, 1945. The two surviving specimens of the WAR are in the Cody Firearms Museum in Wyoming.

The MB seems to be a machined steel casting, possibly as two joined parts. The only change I would make to it would be to cone the bullet outlet port at about 30 degrees (almost back to the flow separator) to minimize any possible yaw destabilization caused by internal acoustic reflections. I could find no patent filed on this MB, and all records are lost (at least for now). Here are a couple of screenshots from Ian's Youtube video:

View attachment 7401626View attachment 7401627

View attachment 7401626View attachment 7401627

EDIT: Sorry about doubling up on the two screenshots. Couldn't see them all together while posting.

Sure, Theis, you could use four struts instead of three just as long as each strut has a knife edge pointing toward the axis of the bore. Keep in mind the tremendous strength needed to withstand the repeated muzzle blast forces. The gap between the crown of the muzzle and the aperture of the gas flow separator should just exceed the expected length of the bullet shanks (say about 2.5 calibers). The gas deflector plate should be a solid of revolution with a carefully considered inside surface profile and with only the flow separator aperture coming near to the bullet (about 1.04 calibers ID). My initial design for the deflector profile would be one quarter of an ellipse with the major axis angled back 30 degrees from the normal to the bore axis. The inner end of the major axis would be at the outside edge of the flow separator aperture, and the end of the minor axis would be on the outer circumference of the deflector disc. The bullet exit cone would be a right circular cone with a 30-degree apex half-angle. The axial depth of the deflector plate should be about 2.5 calibers, and its OD should be about 5 to 6 calibers. EDIT: Here is a preliminary design sketch of a monolithic MB which should not destabilize the rifle bullets after they exit the muzzle. The design scales with caliber, so each caliber is different. The flow separation aperture is just 4-percent larger than the diameter of the exiting bullet. The bulk of the powder gasses exit against the deflector plate which recovers their momentum and deflects the gasses away from the bullet. The exit nozzle is intended to reduce the velocity, pressure, density, and temperature of the gasses which follow the bullet so that they do not follow it very far. We may decide that the 7.0-caliber OD of the deflector plate is too large for long-range scope sighting equipment.

Last edited:

I am pretty sure I can fix your problem in the form of a suppressor. If you would like to talk about it I would be glad to help.I have completed a comprehensive study of the exterior ballistics effects of selecting various different rifling twist rates. I discovered that random yaw destabilization occurring while the fired rifle bullet is transiting the muzzle-blast zone between the crown of the muzzle and exiting the blast envelope a few yards ahead is a serious accuracy and yaw-drag issue. I also found that slow twists promote best accuracy while fast twists reduce air-drag, both in the presence of random initial yaw destabilization. My recommendation is first to reduce the yaw destabilization by proper choice of muzzle brakes and then to go ahead with very fast-twist barrels for shooting copper bullets. I am planning to test a Barrett 98B/MRAD muzzle brake in 338 caliber to evaluate its yaw destabilization effects. The large side ports promise higher evacuation rates for the high-pressure gasses. We have been using a really good tubular-style multi-ported muzzle brake, but it has been destabilizing our test bullets fired from barrels made with 19 to 23 calibers per turn rifling twist-rates.

The attached paper supersedes and replaces the earlier ones posted here.

Tim Sellars.

I suspect I'm going to live up to my name here... Have you stopped to consider that low drag is not really desired over intrinsic stability? Sure you can fiddle with twist rates to make up the difference to a certain extent but certain shapes are simply prone to dynamic instability downrange. An easy example is the radius boat tail. It has lower tail drag which looks good on paper but tail drag is inherently stabilizing and every radius boat tail bullet has shot badly. The best performing ELR bullet is not the one with the highest BC. Don't redouble your effort while loosing sight of your goal.

-Alex

-Alex

A really good point, Alex. I do seek a higher BC bullet design which retains its dynamic stability throughout its flight. To that end, one of my earliest bullet design criteria was to maintain a sharp angle at the rear corner of the 7.5-degree boattail of 0.7-calibers in length. I reasoned that the typical radiused rear corner would encourage airflow to try to follow the surface around that rear corner and create more wake turbulence by alternately shedding vortices. I believe that both Bob McCoy and Bryan Litz would agree on this point.

I did, however, settle on convex radiusing the (otherwise machined flat) 0.842-caliber base of my copper bullet design to minimize yaw destabilization in the muzzle-blast zone, which I have discovered to be a serious accuracy and drag variation issue. After the more dynamic aspects of the muzzle blast have resolved into a spherical shock wave travelling at Mach 1.0 in air, the bullet remains "flying backward," still being propelled through a turbulent jet of muzzle gasses. This process finally ends about 5 to 20 feet downrange when the bullet moving at an airspeed of Mach 2.0 plus penetrates that blast shock wave and commences ballistic flight through the undisturbed air. I reasoned that the original design's machined square flat base would cause the location of its reversed aerodynamic stagnation point to be unstable, thus inducing random yaw destabilization, so I convex radiused that base at 0.7-calibers, keeping the rear corner angle (now at about 50-degrees) machined sharp.

I am now looking at a muzzle-attached brake design which will separate and redirect the main muzzle blast gasses from the flying bullet about 2 calibers from the muzzle crown. The bullet passes through a flow separation aperture (of 1.04 calibers ID) through the dished-in gas deflector plate as sketched below. After the 0.1-caliber (axial distance) of the aperture ring, that aperture flares out into a 30-degree (half-angle) exit nozzle intended to minimize any acoustic reflections disturbing the bullet while spreading out the turbulent gas jet following the bullet.

I did, however, settle on convex radiusing the (otherwise machined flat) 0.842-caliber base of my copper bullet design to minimize yaw destabilization in the muzzle-blast zone, which I have discovered to be a serious accuracy and drag variation issue. After the more dynamic aspects of the muzzle blast have resolved into a spherical shock wave travelling at Mach 1.0 in air, the bullet remains "flying backward," still being propelled through a turbulent jet of muzzle gasses. This process finally ends about 5 to 20 feet downrange when the bullet moving at an airspeed of Mach 2.0 plus penetrates that blast shock wave and commences ballistic flight through the undisturbed air. I reasoned that the original design's machined square flat base would cause the location of its reversed aerodynamic stagnation point to be unstable, thus inducing random yaw destabilization, so I convex radiused that base at 0.7-calibers, keeping the rear corner angle (now at about 50-degrees) machined sharp.

I am now looking at a muzzle-attached brake design which will separate and redirect the main muzzle blast gasses from the flying bullet about 2 calibers from the muzzle crown. The bullet passes through a flow separation aperture (of 1.04 calibers ID) through the dished-in gas deflector plate as sketched below. After the 0.1-caliber (axial distance) of the aperture ring, that aperture flares out into a 30-degree (half-angle) exit nozzle intended to minimize any acoustic reflections disturbing the bullet while spreading out the turbulent gas jet following the bullet.

Last edited:

I know complex geometry is easy now and it is attractive to play with it. Certainly the von karman nose cones I played with fell into that category but boat tails are much more influential on stability in the end and in unintuitive ways. There are a lot of things that influence stability in the boat tail from exhaust mechanics to disruptions in air density in the flight path all the way down to the great big kick in the ass that is the transition back to subsonic. If you dive old literature, there are some great articles about this stuff often from eons ago (1970s). Here is a relevant example that addresses a number of the tradeoffs:

www.dropbox.com

www.dropbox.com

-Alex

Dropbox - Error - Simplify your life

-Alex

Thanks for the reference, Alex. Somehow I missed that report on DTIC.

Figure 10 seems to support my rather conservative choices of a 7.5-degree BT of 0.70-calibers in length. Ten thousand calibers of travel would be 85.6 yards for a 30-caliber bullet. The critical slow-mode (gyroscopic precession or "coning" rate) exponential damping factor indicated would be about +3.0 per 10,000 calibers travel (ie, damping to 5-percent amplitude in 85.6 yards of travel for 30-caliber bullets), while the fast-mode (nutation) damping would be still positive at about +0.9 per 10,000 calibers travel (damping to 40-percent nutation ). Fast-mode damping is never a problem limiting the dynamic stability of rifle bullets at extreme ranges, but slow-mode damping normally is limiting.

My copper bullet design shifts the CG forward, not only by boat-tailing, but also by base drilling at about 0.5-caliber ID to about half way under the rear driving band (just ahead of the BT) for gas sealing (obturation) reasons. The CG-to-CP lever arm converting aerodynamic lift into overturning moment is reduced accordingly. [I can only hope this doesn't cause weird Magnus effects in the transonic flight regime.] Interestingly, according to Coning Theory, the product of the CG-to-Cone Apex distance and the CG-to-CP distance (each in calibers) is always equal to (R + 1)*(ky)^2, where R is the ratio of the fast/slow gyroscopic rates of the bullet and ky is the transverse radius of gyration of that bullet (in calibers). Specifying R is entirely equivalent to specifying gyroscopic stability [Sg = ((R + 1)^2)/(4*R)]. R increases monotonically during flat-firing flights.

I selected a 3.5-caliber LD-Haack headshape truncated with a 0.12-caliber meplat for ease of CNC turning. It is one of those parametric headshapes optimized for lowest drag for length (L) and diameter (D). While it derives from subsonic flow theory, it works well in the supersonic regime as well (but not so much in hypersonic flight). I think the F-16 nose is of this shape.

Figure 10 seems to support my rather conservative choices of a 7.5-degree BT of 0.70-calibers in length. Ten thousand calibers of travel would be 85.6 yards for a 30-caliber bullet. The critical slow-mode (gyroscopic precession or "coning" rate) exponential damping factor indicated would be about +3.0 per 10,000 calibers travel (ie, damping to 5-percent amplitude in 85.6 yards of travel for 30-caliber bullets), while the fast-mode (nutation) damping would be still positive at about +0.9 per 10,000 calibers travel (damping to 40-percent nutation ). Fast-mode damping is never a problem limiting the dynamic stability of rifle bullets at extreme ranges, but slow-mode damping normally is limiting.

My copper bullet design shifts the CG forward, not only by boat-tailing, but also by base drilling at about 0.5-caliber ID to about half way under the rear driving band (just ahead of the BT) for gas sealing (obturation) reasons. The CG-to-CP lever arm converting aerodynamic lift into overturning moment is reduced accordingly. [I can only hope this doesn't cause weird Magnus effects in the transonic flight regime.] Interestingly, according to Coning Theory, the product of the CG-to-Cone Apex distance and the CG-to-CP distance (each in calibers) is always equal to (R + 1)*(ky)^2, where R is the ratio of the fast/slow gyroscopic rates of the bullet and ky is the transverse radius of gyration of that bullet (in calibers). Specifying R is entirely equivalent to specifying gyroscopic stability [Sg = ((R + 1)^2)/(4*R)]. R increases monotonically during flat-firing flights.

I selected a 3.5-caliber LD-Haack headshape truncated with a 0.12-caliber meplat for ease of CNC turning. It is one of those parametric headshapes optimized for lowest drag for length (L) and diameter (D). While it derives from subsonic flow theory, it works well in the supersonic regime as well (but not so much in hypersonic flight). I think the F-16 nose is of this shape.

Similar threads

- Replies

- 6

- Views

- 603

- Replies

- 51

- Views

- 6K

- Replies

- 31

- Views

- 6K