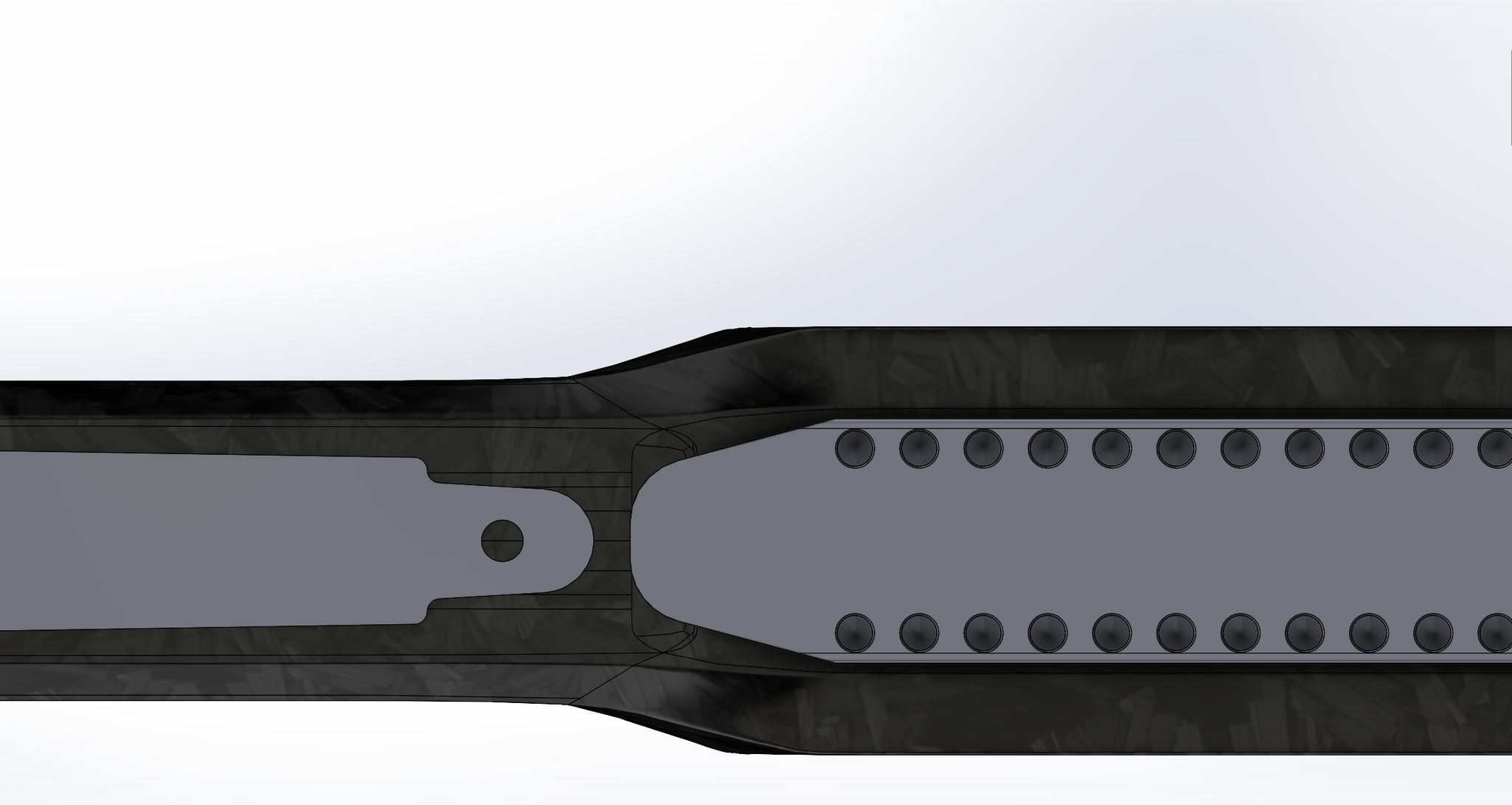

Slowly but surely developing a new carbon fiber stock design initially for rem700 clones but an small-bore version is also in the works (different tang design )that is geared toward Open PRS later other derivatives might happen as well.

Some features incorporated so far.

-low bore line

-wide forend, 66mm so as wide as 56mm optics objective

-steel RRS arca rail integrated into CF stock , both for rigidity and added weight (cca 700g of steel)

-swappable grips (can be vertical or slanted , many shapes possible)

-molded in thumb shelves

-short buttstock for possible rear weights

- 4mlock and 2 QD slots on each side

Looking for input as to what folks would like to see added to the design.

Looking at adding a forend bridge, not necessarily for NV but could also function with NV or ELR prizm

Barricade stops will of course be added but as a bolt-on add-on or part of a new bottom metal its not the part of stock itself.

Internal weights might be added to the forend .

3d printed prototype is already a bit dated as design evolved , but shows base shape well enough

Some features incorporated so far.

-low bore line

-wide forend, 66mm so as wide as 56mm optics objective

-steel RRS arca rail integrated into CF stock , both for rigidity and added weight (cca 700g of steel)

-swappable grips (can be vertical or slanted , many shapes possible)

-molded in thumb shelves

-short buttstock for possible rear weights

- 4mlock and 2 QD slots on each side

Looking for input as to what folks would like to see added to the design.

Looking at adding a forend bridge, not necessarily for NV but could also function with NV or ELR prizm

Barricade stops will of course be added but as a bolt-on add-on or part of a new bottom metal its not the part of stock itself.

Internal weights might be added to the forend .

3d printed prototype is already a bit dated as design evolved , but shows base shape well enough

Last edited: