Personally I run McMillan A6-7 stocks. Typically when I think of carbon fiber, I think of light weight stocks/chassis. Can carbon fiber be made in a heavy fill configuration. Pardon my ignorance on thisCheck post 9 above .

Like said , on paper Chassis should be the way to go by a country mile , still top PRS/NRL shots at the moment are running Foundation stocks instead, oh the horror , crude shapes, non modular ,short forends not even an arca but an Anschutz/UIT rail on it. and there are reasons for it ,

Chassis are way more modular and easy to kit up with all sorts of doodads you can't easily add to a stock,

But if you take an honest look once stock is set up and balanced the way you want /need it you do not need any more modularity than that arca rail on the bottom is offering

Stocks feel and shoot differently,this might sound hyperbolic but stocks especially when they do not need to be light (wooden, composite,micarta)will with near 100% certainty outshot any metal chassis you can buy, period.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

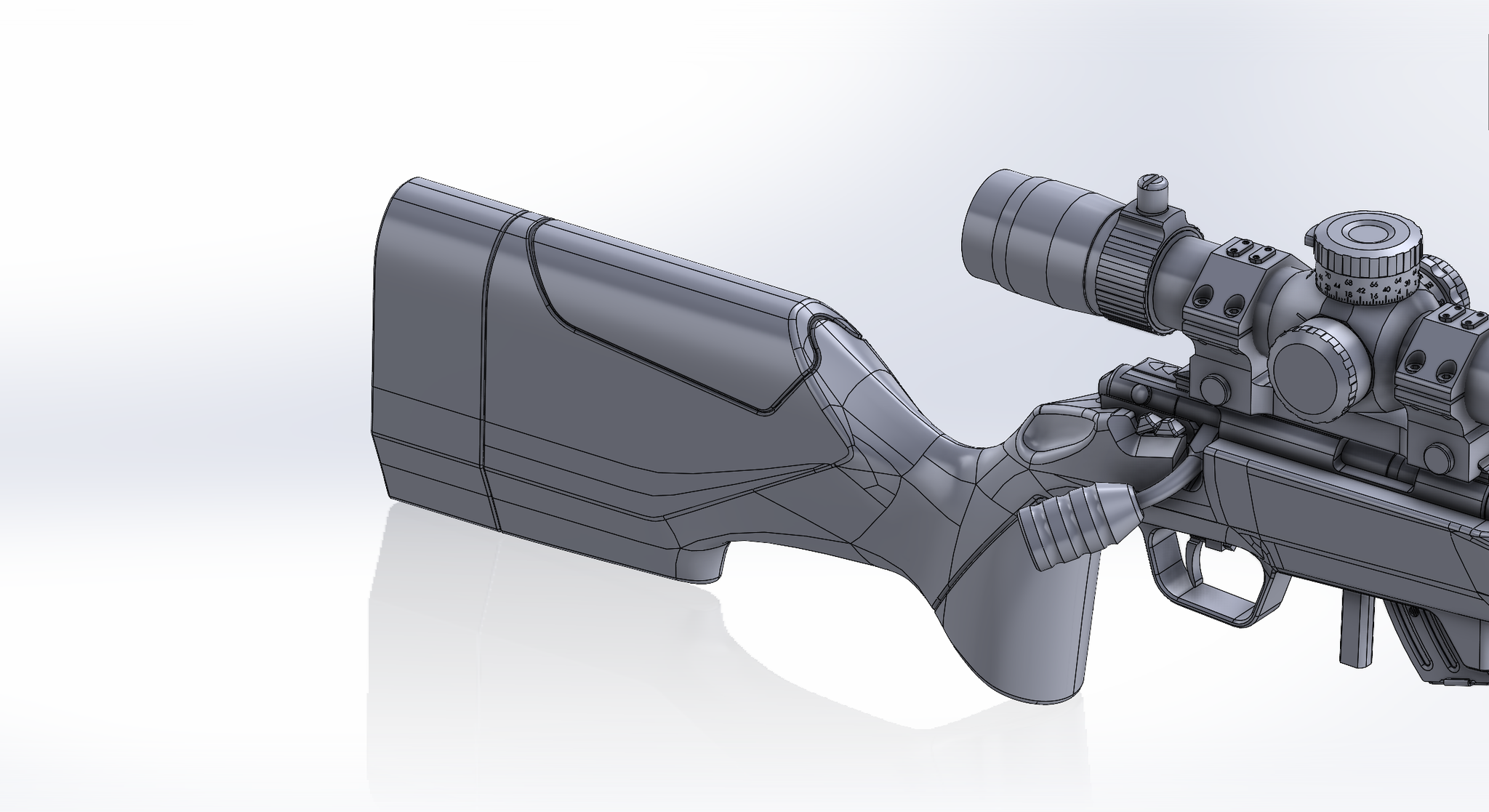

PRS oriented stock design

- Thread starter Mr.BR

- Start date

yes stock can be heavy fill ,depending on purpose the fill can even be heavier than aluminum ,but more importantly can be made with variable density fill, so rear volume can be lighter than front volume

Genuine question, but why is that? Say something like a manners TCS, the action interfaces with an aluminum mini chassis so wouldn’t it be the same as a full blown chassis like a KRG/MPA etc. ?Stocks feel and shoot differently,this might sound hyperbolic but stocks especially when they do not need to be light (wooden, composite,micarta)will with near 100% certainty outshot any metal chassis you can buy, period.

Are you saying something like a foundation with no mini chassis would in theory be more accurate?

Not trying to derail too much just genuinely curious.

That's my biggest gripe with Manners TCS stocks.......too tail heavy.yes stock can be heavy fill ,depending on purpose the fill can even be heavier than aluminum ,but more importantly can be made with variable density fill, so rear volume can be lighter than front volume

Even mini chassis is then fixed into a stock so its interacting with the stock material that has many times the vibration-dampening properties of aluminum .In most chassis you can feel them vibrating on every shot ,very few stocks give you that feeling .Genuine question, but why is that? Say something like a manners TCS, the action interfaces with an aluminum mini chassis so wouldn’t it be the same as a full blown chassis like a KRG/MPA etc. ?

Are you saying something like a foundation with no mini chassis would in theory be more accurate?

Not trying to derail too much just genuinely curious.

Ideal mini chassis for a stock is a forged carbon unit that can be bonded in place , this is a nearly inert material compared to aluminum

This is a bedding block in Bix'n'Andy hunting rifle

Brass. Make the entire chassis out of brass. Longer foreend, maybe add 12".. no 14". That will maybe be long enough. More mloks. Sides of magazine well, butt stock, one on each side of cheek piece.. more mloks i say !. Telescoptic cheek rest. I can never get enough adjustment for my big brain bucket, so need 12" of adjustment.

Make a stock FOR YOU. Ignore everyone else. You even said you dont like the new design. Take feed back, thats important. But i can see this devolving into the homer.

IVe had customers with buyers remorse on guns ive built. They built it for their mates. Suggested colour theme, cartridge, barrel profile, even scope. If you build a gun for your mates, it wont ever be good enough. They sell the gun, build another, the way THEY want, and enjoy it.

Feed back yes, but build it your way.

Make a stock FOR YOU. Ignore everyone else. You even said you dont like the new design. Take feed back, thats important. But i can see this devolving into the homer.

IVe had customers with buyers remorse on guns ive built. They built it for their mates. Suggested colour theme, cartridge, barrel profile, even scope. If you build a gun for your mates, it wont ever be good enough. They sell the gun, build another, the way THEY want, and enjoy it.

Feed back yes, but build it your way.

Attachments

Nice looking stock. Interested to see its development.

Some recommendations:

- Definitely agree with the above sentiment. Do what you want first and foremost. Consider the feedback, make changes you see as benefitting the overall design, but above all else make sure it’s what you envision it to be at its core.

- Definitely don't go TOO far towards extremes. For example the small hands crowd... they love to clamor for shorter grip/trigger guard distance. I will tell you that there are plenty of us with man hands that prefer the longer distance as well. If 90* OTC is achievable for the average hand, you’re good to go. Understanding that adjustment is only feasible in so many aspects, it is definitely feasible to strike a middle ground and accompany both extremes (similar to your idea with the interchangeable grip panels, palm swell thickness, and thumb location).

- Modularity is your friend. Having an integral ability to tune weight/balance would be a big benefit to a lot of guys, especially if it meant not having to run 5 sets of external weights, a heavy ass barrel profile, and suppressor to get it to balance where they want it.

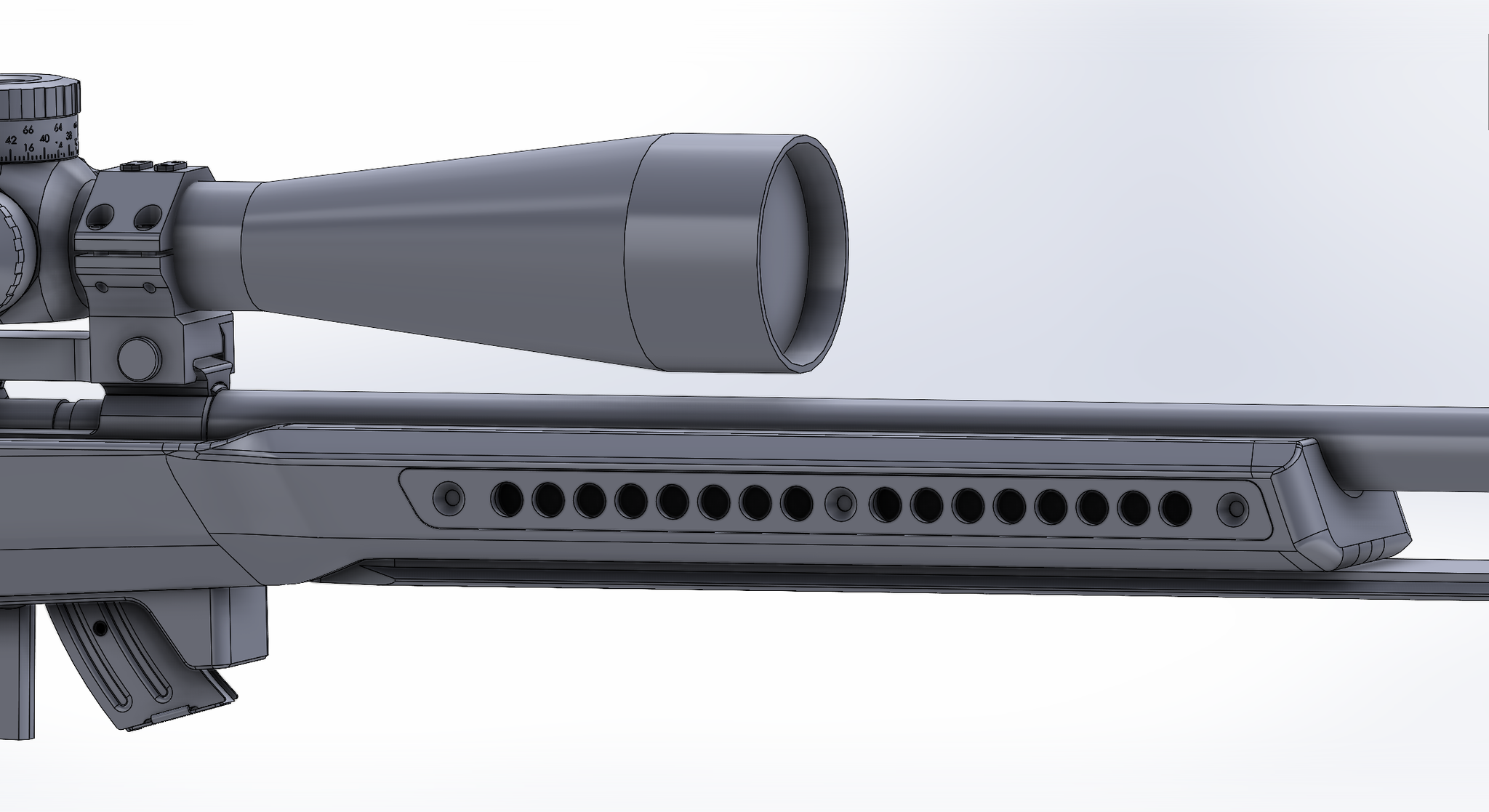

- Ensure the forend is ERECT. RIDGID. Incorporated steel Arca rail is a good start. MLOK slots down the fore end would satisfy the dudes who feel like they need to run 40lb BRs, though it sounds like you’re already planning to make the forend wide enough to not need those god forsaken wings. Good on ya.

- Finally I’d say that a bridge of sorts would be a necessity. Especially with modern positional support hand techniques. Having the ability to place a hand on the forend without touching the barrel is pretty much a requirement at this point. Also another reason why the last point of forend rigidity is so important.

Otherwise, keep up the great work and keep the renditions coming! Will be excited to start seeing some prototypes and hopefully, eventually, a PV!

Some recommendations:

- Definitely agree with the above sentiment. Do what you want first and foremost. Consider the feedback, make changes you see as benefitting the overall design, but above all else make sure it’s what you envision it to be at its core.

- Definitely don't go TOO far towards extremes. For example the small hands crowd... they love to clamor for shorter grip/trigger guard distance. I will tell you that there are plenty of us with man hands that prefer the longer distance as well. If 90* OTC is achievable for the average hand, you’re good to go. Understanding that adjustment is only feasible in so many aspects, it is definitely feasible to strike a middle ground and accompany both extremes (similar to your idea with the interchangeable grip panels, palm swell thickness, and thumb location).

- Modularity is your friend. Having an integral ability to tune weight/balance would be a big benefit to a lot of guys, especially if it meant not having to run 5 sets of external weights, a heavy ass barrel profile, and suppressor to get it to balance where they want it.

- Ensure the forend is ERECT. RIDGID. Incorporated steel Arca rail is a good start. MLOK slots down the fore end would satisfy the dudes who feel like they need to run 40lb BRs, though it sounds like you’re already planning to make the forend wide enough to not need those god forsaken wings. Good on ya.

- Finally I’d say that a bridge of sorts would be a necessity. Especially with modern positional support hand techniques. Having the ability to place a hand on the forend without touching the barrel is pretty much a requirement at this point. Also another reason why the last point of forend rigidity is so important.

Otherwise, keep up the great work and keep the renditions coming! Will be excited to start seeing some prototypes and hopefully, eventually, a PV!

Stock was always meant to be race-ready out of the box only minimal balancing needed ,preferably without external bolt on stuff.

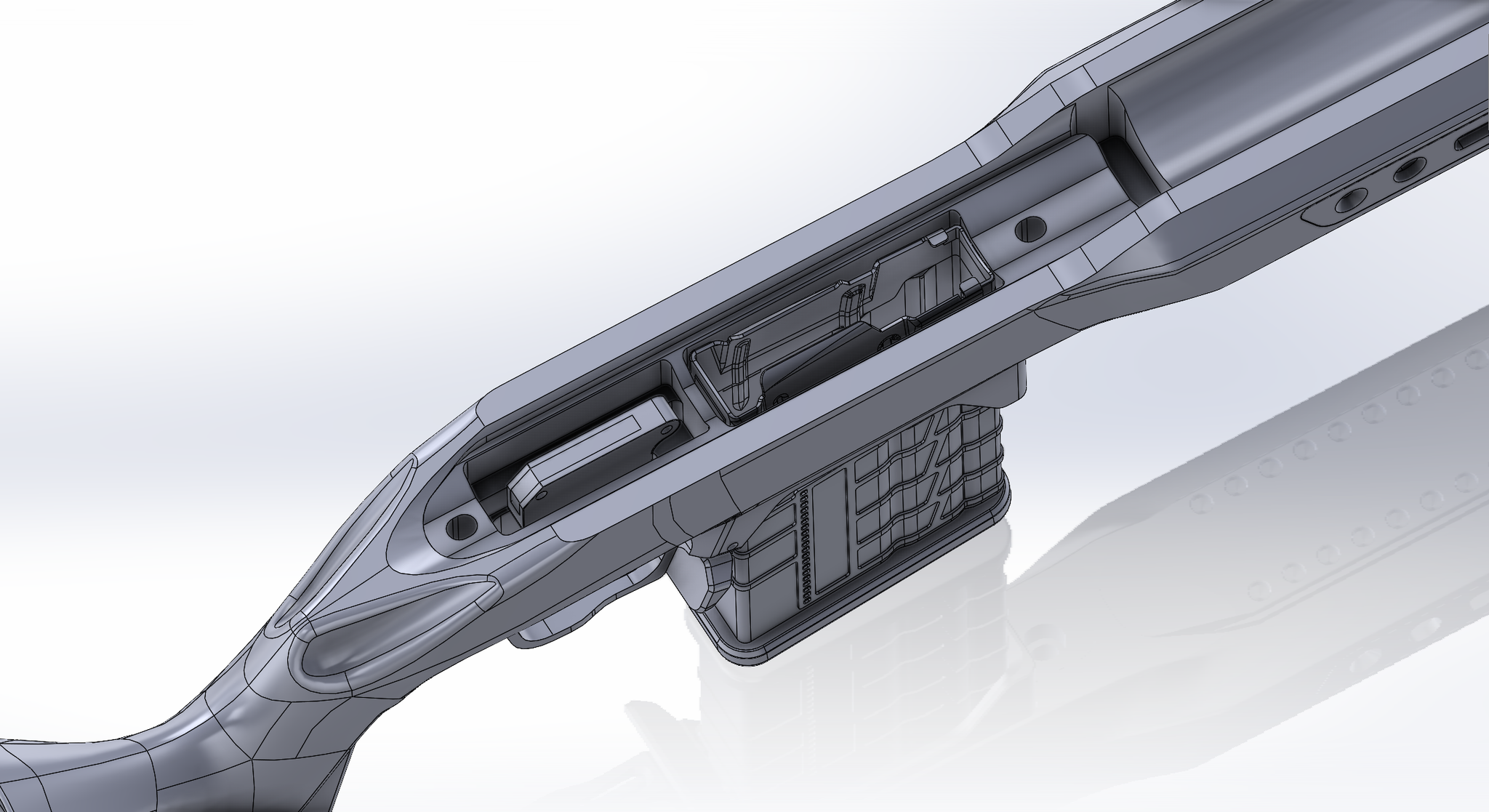

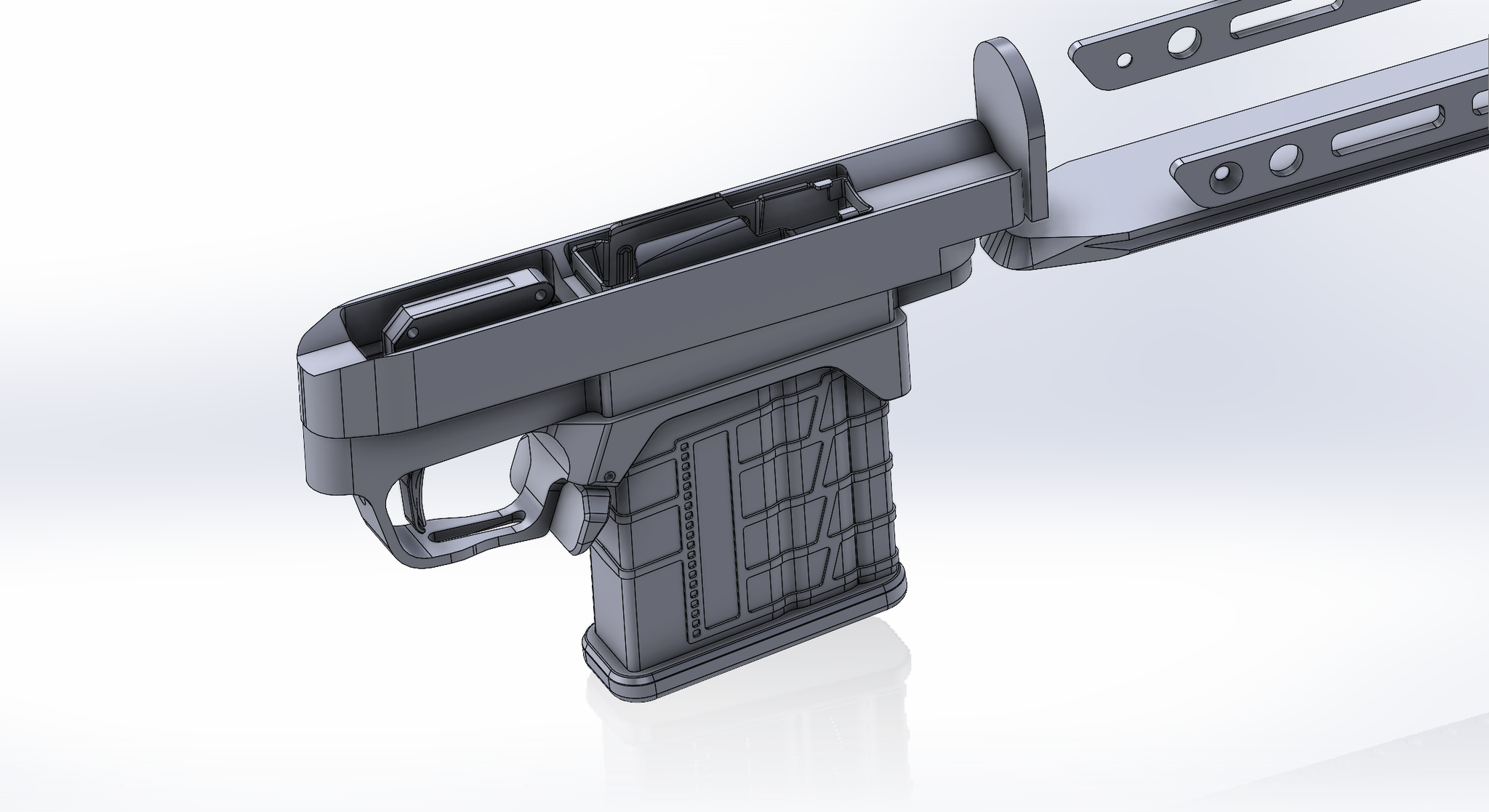

As you can imagine with such projects things tend to snowball, new bottom metal is in the works

Bottom metals haven't even remotely kept up with the chassis, ordered half a dozen different mags to try out both AW and AICS to do the bottom metal .

3d printed this version and except for some minor details only thing realy wrong is the molded NVO bridge platform,it seems it would be much better to just go the old-fashioned 2-part aluminum base . Definitely this is a bit of a challenge to make look good vs just bolting some fugly parts together.

As you can imagine with such projects things tend to snowball, new bottom metal is in the works

Bottom metals haven't even remotely kept up with the chassis, ordered half a dozen different mags to try out both AW and AICS to do the bottom metal .

3d printed this version and except for some minor details only thing realy wrong is the molded NVO bridge platform,it seems it would be much better to just go the old-fashioned 2-part aluminum base . Definitely this is a bit of a challenge to make look good vs just bolting some fugly parts together.

Last edited:

It's pretty rare to see almost anyone using the standard manners or Mcmillan grip and performing a properly 90 deg trigger press (meaning only one knuckle bent) without having to get up on their fingertips or have some space between their fingers and palm on the grip.

Cycle through old Rifles Only videos and you'll see Jacob showing how he has to alter his grip and he has average sized hands at a minimum. Walk around any PRS match looking for fundamental mistakes and the biggest one will always be a jointed trigger press followed by not being straight behind the rifle.

A2 grip interfaces are much closer along with grips like AI plastic grips and KMW.

Cycle through old Rifles Only videos and you'll see Jacob showing how he has to alter his grip and he has average sized hands at a minimum. Walk around any PRS match looking for fundamental mistakes and the biggest one will always be a jointed trigger press followed by not being straight behind the rifle.

A2 grip interfaces are much closer along with grips like AI plastic grips and KMW.

With your other fingers fully on the grip? No gap?I got no problem getting a 90 degree trigger finger on my Manners stocks and I have about average hands. I hear people complain about it but never had a problem.

Huh. I’ve only fondled a manners long ago (CZ 455 special version). Can’t remember the grip. What size gloves do you wear?Yeah around the grip and thumb up top. Tried to blow up a pic from a couple weeks back so not really clear but gives the idea.

View attachment 8246836

I wear med or large, depending on the brand and individual sewing (usually on the leather gloves).

You can see just how close the custom MKM grip I have on my W3 is to the trigger on this post:

PRS oriented stock design

Slowly but surely developing a new carbon fiber stock design initially for rem700 clones but an small-bore version is also in the works (different tang design )that is geared toward Open PRS later other derivatives might happen as well. Some features incorporated so far. -low bore line -wide...

Huh. I’ve only fondled a manners long ago (CZ 455 special version). Can’t remember the grip. What size gloves do you wear?

I wear med or large, depending on the brand and individual sewing (usually on the leather gloves).

You can see just how close the custom MKM grip I have on my W3 is to the trigger on this post:

PRS oriented stock design

Slowly but surely developing a new carbon fiber stock design initially for rem700 clones but an small-bore version is also in the works (different tang design )that is geared toward Open PRS later other derivatives might happen as well. Some features incorporated so far. -low bore line -wide...www.snipershide.com

Yeah the Manners are pretty good for me. That is a TCS in the pic and I also used T2A, T3, PRS-2 and one of their folders over the years. I’ll have to look of I have a pic of just the stock to compare to the pic of yours you posted. Yours does look closer to the trigger guard.

My hands aren’t overly large. I use large gloves usually.

Yeah, just eyeballing the pic your hands look bigger than mine.My hands aren’t overly large. I use large gloves usually.

I think stock makers’ thoughts about man hands are a bit like how chick’s estimation of how tall the “average” US man is. Women say something like 6ft or 6’1”.

The average dude in the US is actually 5’9”. Wikipedia says for white guys = 5’10”.

Also reminds me of the big handgun reviewers on YT. Usually they have giant octopus hands and naturally always like sorta awkward pistols for medium-handed guys, and hate little CCW pistols that women like.

Having huge hands seems to help control pistols (unsurprisingly).

(This is not a critique of you)

Last edited:

@Rob01 you got a pic from the other side, because frankly, that doesn’t look like a 90* trigger finger from here. First pad in the light, second pad in shadow, third pad on the trigger…jointed all the way around.

Will have to look but it is 90 degrees. Been doing it a long time. It’s a straight pull back on the trigger.

I’m all for having the front strap closer to the back of the trigger guard. I can palm a basketball, wear size large gloves, and have yet to find a stock or chassis with a grip that doesn’t have me up on my fingertips. Closest I’ve been is the various aftermarket grips on the matrix (think 5x5 precision). Foundation? Nope. Manners? Nope. XLR? Nope. KRG? Nope. Matrix with largest grip? Nope.

Must be finger to hand bone geometry thing cause that looks pretty good from the right side, @Rob01

Must be finger to hand bone geometry thing cause that looks pretty good from the right side, @Rob01

Mine is very much the same on a TCS and an MG2, both of which people often complain about being too long.

On the contrary I would almost say that my AT-X is a little too close depending on the grip I use. It took some trial and error to get it where I wanted.

All that said I wear XL-XXL gloves so I wouldn’t say I have average size hands.

On the contrary I would almost say that my AT-X is a little too close depending on the grip I use. It took some trial and error to get it where I wanted.

All that said I wear XL-XXL gloves so I wouldn’t say I have average size hands.

You gotta call MKM and have them make the grip I had them make for a KRG W3. The grip is at least 3/8” closer to the trigger (maybe more). It is the most relaxing grip, even more natural (to me) than my AIAX with the Anarchy thumb shelf (which itself is pretty good).I’m all for having the front strap closer to the back of the trigger guard. I can palm a basketball, wear size large gloves, and have yet to find a stock or chassis with a grip that doesn’t have me up on my fingertips. Closest I’ve been is the various aftermarket grips on the matrix (think 5x5 precision). Foundation? Nope. Manners? Nope. XLR? Nope. KRG? Nope. Matrix with largest grip? Nope.

Must be finger to hand bone geometry thing cause that looks pretty good from the right side, @Rob01

Don’t worry, I get nothing. No agenda. I paid for it via shipping my whole chassis in for them to scan.

We've got some cool stuff in the works that'll... Compliment(?) Our bottom metalsGet @MDT_Josh to give you a bottom metal to use and .... advertise ? Or buy one. Im not his supervisor.

- Josh

The new PBM is definitely a big step up.We've got some cool stuff in the works that'll... Compliment(?) Our bottom metals

- Josh

I

Im picking up what your putting down.We've got some cool stuff in the works that'll... Compliment(?) Our bottom metals

- Josh

Postman dropped off a bottom metal and a bunch of mags so hope to do the next version of the stock design soon, will see how things go.The bottom metal is just meant as a placeholder till a new one is developed.

Many things in worx right now not just the stock.

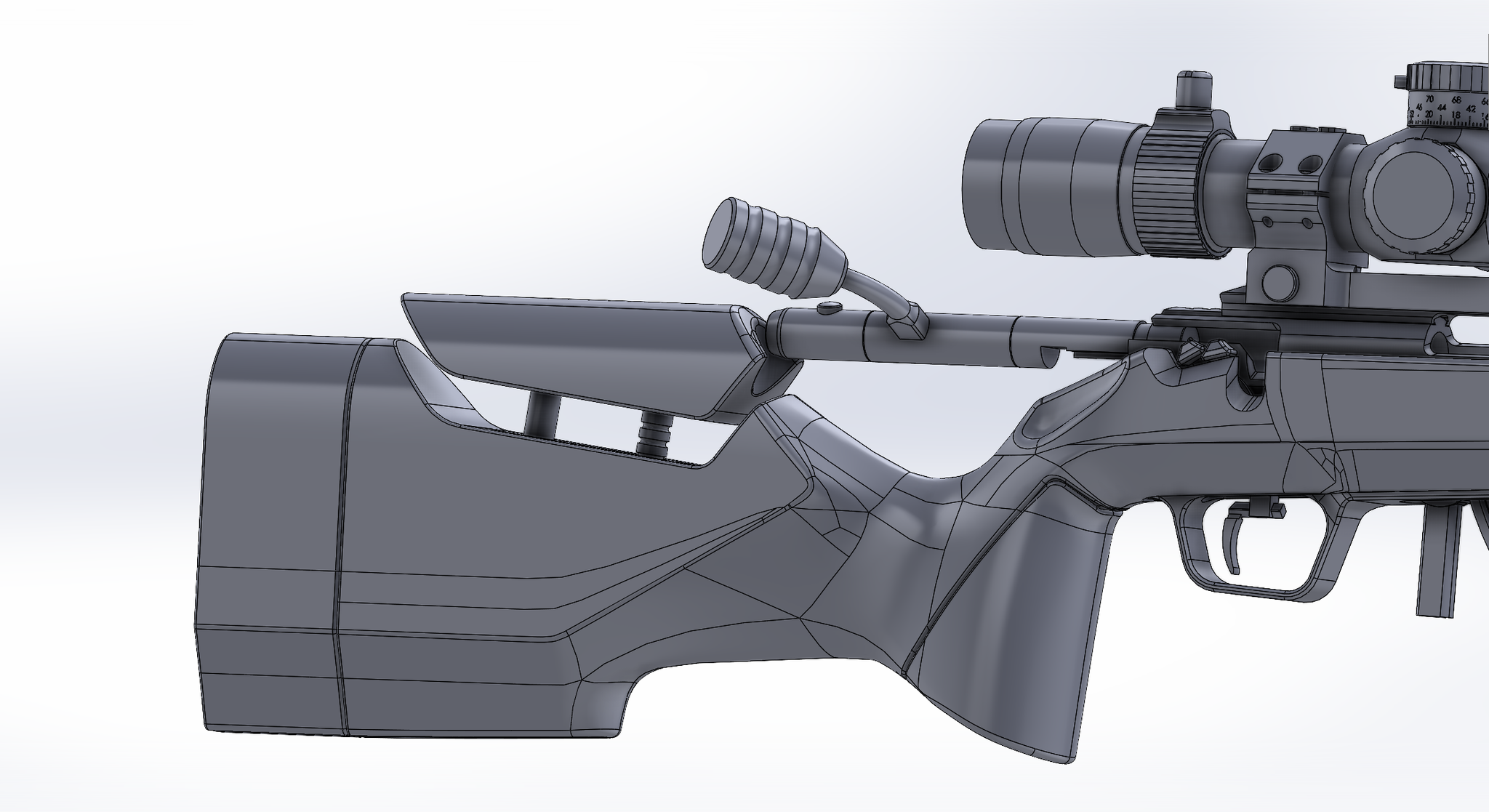

Finishing up a new integrally suppressed bolt action carbine of my own design that has been in the works for a while now one piece receiver center chassis, design and engineering are all finished now few more parts need to be machined and CNC shops seem to be beyond busy.

Top , abandoned switch barrel .338LM tube chassis and stout rear locking action project.

Bottom the 300BLK carbine , middle same gun just unsuppressed variant

Many things in worx right now not just the stock.

Finishing up a new integrally suppressed bolt action carbine of my own design that has been in the works for a while now one piece receiver center chassis, design and engineering are all finished now few more parts need to be machined and CNC shops seem to be beyond busy.

Top , abandoned switch barrel .338LM tube chassis and stout rear locking action project.

Bottom the 300BLK carbine , middle same gun just unsuppressed variant

Last edited:

Well , slowly but surely bottom metal is in the works.

Stock design can and should be somewhat complimentary to bottom metal design so before finalizing the stock , the bottom metal should be completed.

Stock is already at the 10th or 11th design iteration, the bottom metal is just starting to take shape. For now M5 footprint ,will likely change as there is no DBM compatibility sought or available anyway once you are using some sort of a mini chassis, sticking with M5 i would only be limiting the design options

Stock design can and should be somewhat complimentary to bottom metal design so before finalizing the stock , the bottom metal should be completed.

Stock is already at the 10th or 11th design iteration, the bottom metal is just starting to take shape. For now M5 footprint ,will likely change as there is no DBM compatibility sought or available anyway once you are using some sort of a mini chassis, sticking with M5 i would only be limiting the design options

Last edited:

Progress is a bit slow on getting together components for a mule, first will be a Bergara and Anschutz rimfires

Slowly drawing up mini chassis and bottom metal ,next up is the forend weight system and 3way butt with weight options

*detailing for trigger safety still missing

Slowly drawing up mini chassis and bottom metal ,next up is the forend weight system and 3way butt with weight options

*detailing for trigger safety still missing

Last edited:

Yes its a model of MDT poly metal mag ,one of many magazines we have drawn up in detail as i collected all sorts of AICS and AW mags to see the dimensional differences among them.Did you model the MDT magazine or whats the deal with that ?

Looks more detailed that anything else ive seen.

One thing in the firearms business, there are few if any ''standard specs'' so better safe than sorry.

Takes lots of work and time to build up a database of parts but then at least some is usable on various projects. Although it seems the next project will take another round of drawing up new mags as LM mag collection is even less '' standardized'' manufacturers went full diversity hire and gender fluid on those, fully embracing ''look at me i am special'' .

Last edited:

I will shortly be drawing up a fully adjustable and weighable buttstock mechanism similar to that used on PRS-TCS , still trying to figure out how far i should go on that in terms of adjustment axes lop, height, cant.Loopy mk5hd ? Nice. How are yoi gonna do the recoil pad and LOP setup ?

Last edited:

I didn't read all of your thread but it looks well thought out!

One aspect I like a lot about my Bolthorn chassis is adjustable length of the grip to the trigger because of my short fingers. It's the only one I found that did this back when I bought it.

Also the grip that comes with this chassis is thin and superb feeling.

Yeah just me but I love the looks too.

One aspect I like a lot about my Bolthorn chassis is adjustable length of the grip to the trigger because of my short fingers. It's the only one I found that did this back when I bought it.

Also the grip that comes with this chassis is thin and superb feeling.

Yeah just me but I love the looks too.

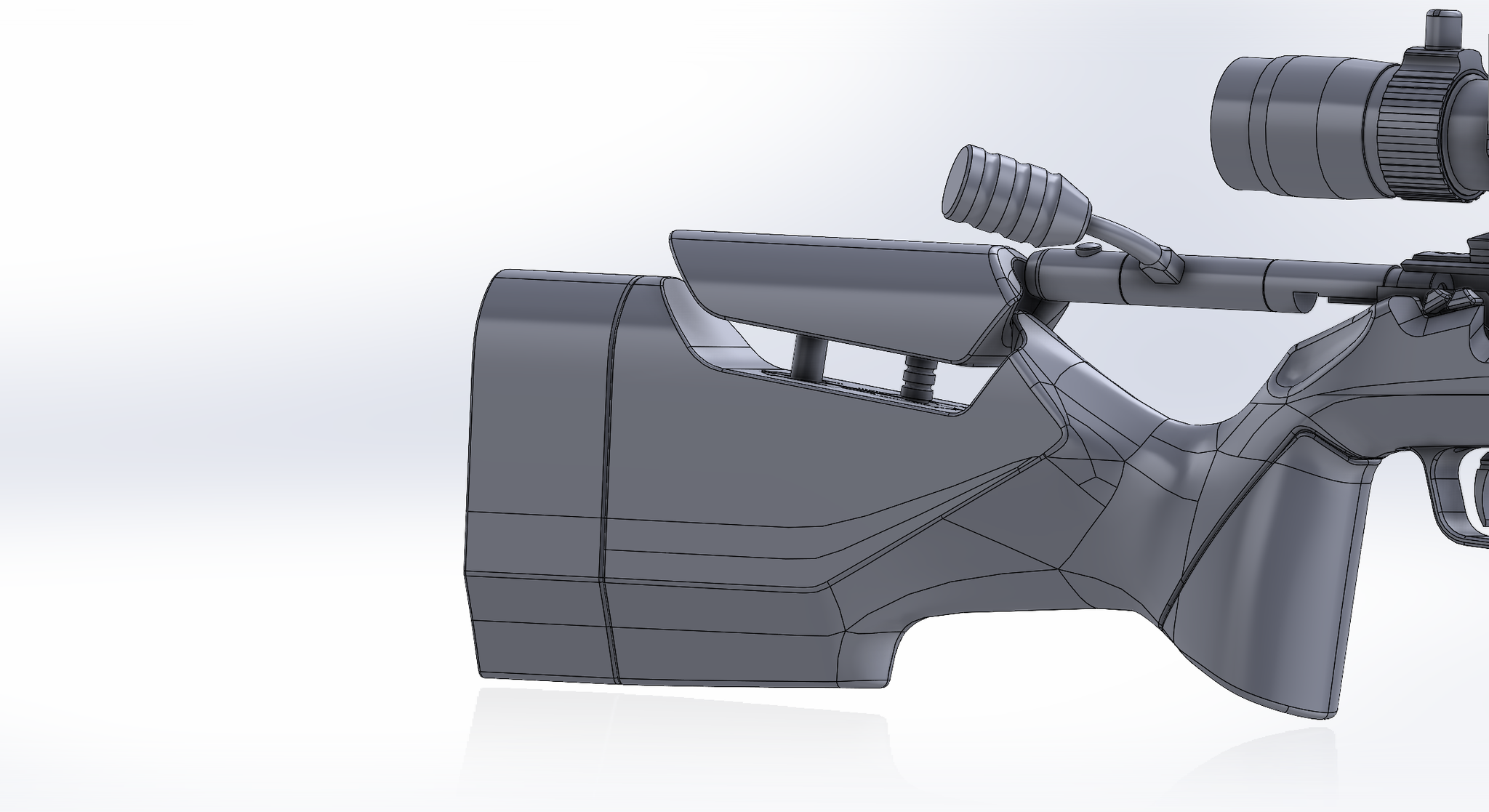

The Anschutz64 variant is now nearly finished, practically only missing the buttplate bits and QD cups ,. Over barrel hood will be bolted from the top on this one but not on Rem700 model

An all QD side plate option for those that would like to use Sikes Clutch

Forend is lower as on the Rem700 compatible model as the action is much smaller and can be sunk deeper into the stock

An all QD side plate option for those that would like to use Sikes Clutch

Forend is lower as on the Rem700 compatible model as the action is much smaller and can be sunk deeper into the stock

Last edited:

Some mods on the cheek rest , dealing with the bolt clearance ,Anschutz has a similar clearance lenght to a rem 700SA even tough its a very short stroke action.

Getting a bit adventurous in design

Angled cheek and simple cut

More elaborate solution

Getting a bit adventurous in design

Angled cheek and simple cut

More elaborate solution

Attachments

Last edited:

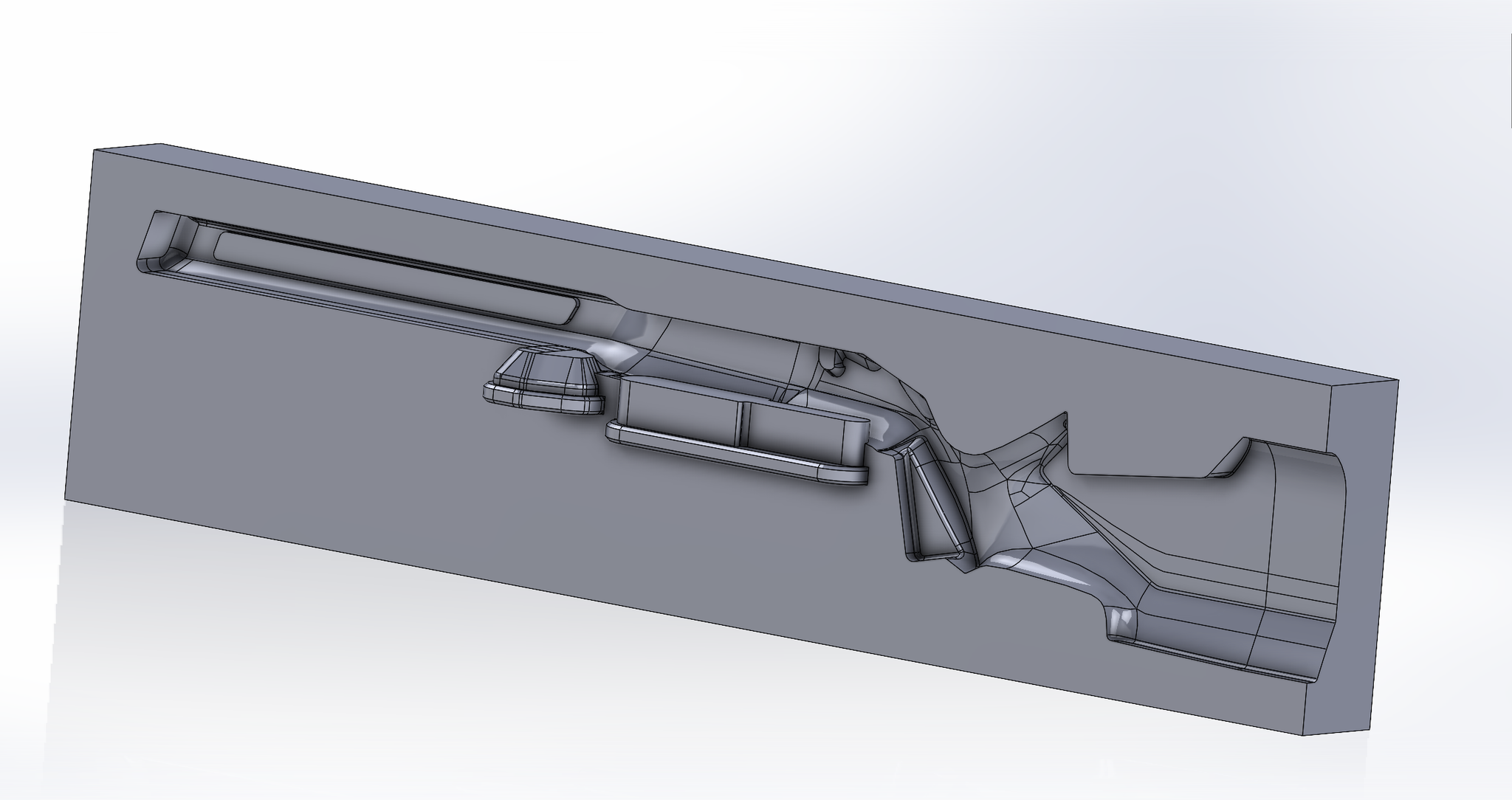

Finished Anschutz variant (has slightly lower forend top line than the rem700), ready to machine the tooling , forend grew a bit longer (will grow even longer on the Rem700 variant)

Hopefully, prototype tooling will get done before the new year , for both Anschutz and Rem700

Mold half

Hopefully, prototype tooling will get done before the new year , for both Anschutz and Rem700

Mold half

Attachments

Something that I don't think exists that would be cool is a stock/chassis that's designed for a medium length action and the MDT XM magazines, but has a spacer or adjustable mag well that you can run standard length 223/308 magazines.Yes its a model of MDT poly metal mag ,one of many magazines we have drawn up in detail as i collected all sorts of AICS and AW mags to see the dimensional differences among them.

One thing in the firearms business, there are few if any ''standard specs'' so better safe than sorry.

Takes lots of work and time to build up a database of parts but then at least some is usable on various projects. Although it seems the next project will take another round of drawing up new mags as LM mag collection is even less '' standardized'' manufacturers went full diversity hire and gender fluid on those, fully embracing ''look at me i am special'' .

That way you could realistically have a switch barrel set up that'll run 223, 6BR, 6.5cm/308 and short mag length cartridges.

What CAD program do you use? Solid works?

Those drawings are beautiful.

For now, it will be Rem700 ,will see once we get some production stocks doneSomething that I don't think exists that would be cool is a stock/chassis that's designed for a medium length action and the MDT XM magazines, but has a spacer or adjustable mag well that you can run standard length 223/308 magazines.

That way you could realistically have a switch barrel set up that'll run 223, 6BR, 6.5cm/308 and short mag length cartridges.

What CAD program do you use? Solid works?

Those drawings are beautiful.

* i might be stuffing in my long-action Tikka clone in .284 Shehane. but that will be more of a Dremel project if it happens, its just something i might do so i have a rifle for the April European PRS series comp , before i get a proper gun built otherwise tactical big rig will have to do .

Making carbon fiber extended capacity LA mags as well as the proprietary mags are only 5rd

Last edited:

3d printed mockup for the Anschutz64

Still some changes coming mostly to the tang thumb shelf , dialing in the thumb ledge design

Still some changes coming mostly to the tang thumb shelf , dialing in the thumb ledge design

Similar threads

- Replies

- 46

- Views

- 6K

- Replies

- 1

- Views

- 1K

- Replies

- 6

- Views

- 975