So I'm starting to switch my seating dies over to micrometer adjustable competition dies for better consistency... For the most part Forster Ultra does. However, Forster doesn't offer a 7.5 Swiss die and Redding doesn't look like they do either. I’ve noticed that RCBS does make a micrometer adjustable competition seater die. Does anyone have any experience with these does? How do they stack up in terms of consistency?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Quick Shot Challenge: What’s the most underrated gear you never leave home without?

Contest ends Wednesday, join now for the chance to win free Hide merch!

Join contest

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RCBS MatchMaster Dies?

- Thread starter Sooter76

- Start date

Anybody used one of these yet? I’m probably going to order a set of .223 to try them out unless somebody tells me they’re shit.

So the match masters are new, it sure seems people loved the gold medal match which is basically the old version of these. So I have to imagine they are great as well.

I am thinking of switching over to these because I am getting run out from my Hornady micrometer dies.

I am thinking of switching over to these because I am getting run out from my Hornady micrometer dies.

So the match masters are new, it sure seems people loved the gold medal match which is basically the old version of these. So I have to imagine they are great as well.

I am thinking of switching over to these because I am getting run out from my Hornady micrometer dies.

Have you measured run-out, then ran those cartridges through the mag and chamber, and re-measured?

My dad bought the hornaday run-out tool and we played with it in a few rifles. We couldn't find a single bit of difference from the perfect rounds to the "horrible" ones. They all shot the same groups the rifle was capable of.

It's a seating die. So long as there isn't a flaw in the die and it's trying to press sideways it would be damn hard for it to be inconsistent.

These RCBS dies work well for me. I use 223, 243, 30-06 and 6mm Creedmoor. The concentricity is really about the same as the standard dies. I do have a set of Redding dies for a 6mm AR and the seating die have about 25% less 'runout' than the RCBS dies.

These RCBS dies work well for me. I use 223, 243, 30-06 and 6mm Creedmoor. The concentricity is really about the same as the standard dies. I do have a set of Redding dies for a 6mm AR and the seating die have about 25% less 'runout' than the RCBS dies.

Perfect, thanks for the feedback!

I recently purchased a set and prefer them over Redding or Forster microseaters.

Ah interesting, thanks. Can you quantify why you prefer them please?

Ah interesting, thanks. Can you quantify why you prefer them please?

I just hated the Reddings adjuster; very skinny, and hard to read.

Forster is a great value for the price. I really have nothing against it and would use it if needed. However, I really like the bullet seating function of the RCBS MM Competition dies.

I just hated the Reddings adjuster; very skinny, and hard to read.

Forster is a great value for the price. I really have nothing against it and would use it if needed. However, I really like the bullet seating function of the RCBS MM Competition dies.

Perfect, thanks for the info!

What brand of neck bushings work in the RCBS Matchmaster sizing dies? I have zero experience with FL neck bushing dies, I only have Forster FL dies (no bushing).

Use ours. https://www.rcbs.com/reloading-dies/neck-bushings/neck-bushings/494.htmlWhat brand of neck bushings work in the RCBS Matchmaster sizing dies? I have zero experience with FL neck bushing dies, I only have Forster FL dies (no bushing).

I have a decent amount of personal experience with the Matchmaster dies now. I came from using the Hornady dies for years and their micrometer adjustment. I prefer the Matchmaster now by far, and the concentricity is better than I have experienced with the Hornady dies. The loading window makes seating a total breeze. There's an internal floating sleeve that the bullet drops into and a C clip catches it from falling through. The sleeve aligns the bullet with the case before they ever meet so they go very straight. I've only ran the seater on the Summit press so far, and I've only done sizing on a Rock Chucker Supreme so far, and those were with the FL sizing MM die.

The first time setting one up took some trial & error to get the seating stem in the right place as it can be put into a few different height positions, and the depth of the seater die took some playing around, but the next 2 I set up went really fast from the experience gained on the first one.

Putting the bushings in is fairly straight forward and they fit great.

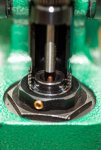

We're working on jazzing up the Matchmaster die product pages right now, but I can give you all some sneak peak images we're looking to put up to show these dies off and how they work.

If you have other questions on them give a shout. I'll try to dig up more pictures.

WM

Attachments

More Matchmaster die pics - My loading bench has seen some things . . .

Attachments

Thanks for the great info! I just ordered a set of dies and bushing for my soon to be built 6GT. Can’t wait!

can I use the FL die with out the bushing and still size brass? or do you offer a similar set without the bushing systemUse ours. https://www.rcbs.com/reloading-dies/neck-bushings/neck-bushings/494.html

I have a decent amount of personal experience with the Matchmaster dies now. I came from using the Hornady dies for years and their micrometer adjustment. I prefer the Matchmaster now by far, and the concentricity is better than I have experienced with the Hornady dies. The loading window makes seating a total breeze. There's an internal floating sleeve that the bullet drops into and a C clip catches it from falling through. The sleeve aligns the bullet with the case before they ever meet so they go very straight. I've only ran the seater on the Summit press so far, and I've only done sizing on a Rock Chucker Supreme so far, and those were with the FL sizing MM die.

The first time setting one up took some trial & error to get the seating stem in the right place as it can be put into a few different height positions, and the depth of the seater die took some playing around, but the next 2 I set up went really fast from the experience gained on the first one.

Putting the bushings in is fairly straight forward and they fit great.

We're working on jazzing up the Matchmaster die product pages right now, but I can give you all some sneak peak images we're looking to put up to show these dies off and how they work.

If you have other questions on them give a shout. I'll try to dig up more pictures.

WM

can I use the FL die with out the bushing and still size brass? or do you offer a similar set without the bushing system

If you don't have a bushing, the neck will not get sized.

Anyone know if you can use Redding bushings in these dies? The RCBS ones are all out of stock or backordered. I bought the Redding ones to get started.

Anyone know if you can use Redding bushings in these dies? The RCBS ones are all out of stock or backordered. I bought the Redding ones to get started.

Should fit just fine. I've got 3 different brands of bushing now, and I am 99% sure they are all the same size/outer diameter.

i'm brand new to reloading, and got the rcbs matchmaster seater die for .223. so far so good, i like the ease of dropping the bullet in the window vs sitting it atop the case for my handgun calibers. nothing else to compare it to regarding quality, accuracy, consistency, etc.

The Matchmaster sizing dies are only bushing dies. If you don't want to use bushings then you'd want to just grab a regular FLS die, then a Matchmaster seater die, which we do sell by itself.can I use the FL die with out the bushing and still size brass? or do you offer a similar set without the bushing system

Are these seater dies short enough to fit in a Forster coaxial press? I like the design, just trying to determine if they'll fit (6.5 CM specifically) under the yoke of the Forster. Some of the Hornady micrometer seaters just barely fit (like less than an 1/8" clearance).The Matchmaster sizing dies are only bushing dies. If you don't want to use bushings then you'd want to just grab a regular FLS die, then a Matchmaster seater die, which we do sell by itself.

I don't have a Coax myself, but I just measured the seater for my 6CM and it could be as long as 5.5" depending on seating depth and how you have it set up. The dial diameter is 1.025". With how I have my 6CM setup in my Summit, it's measuring right around 5" from the top of the dial to the bottom of the die body.Are these seater dies short enough to fit in a Forster coaxial press? I like the design, just trying to determine if they'll fit (6.5 CM specifically) under the yoke of the Forster. Some of the Hornady micrometer seaters just barely fit (like less than an 1/8" clearance).

Hmmm...Yeah, that sounds a bit long for the Forster, as they tend to have the die sit higher up. I wonder if a shorter micrometer seating stem would work?...just thinking out loud here. I know Hornady had to mod some of their early New Dimension seater dies, because they were too long for Forster presses (and we know how popular they are with the precision crowd).

Anyone else running these on a Forster Co-Ax?

Anyone else running these on a Forster Co-Ax?

I am using one for loading 300 prc on my Forster with no problem at all for clearance. I did have RCBS make a custom seater stem to load the 230gr A-tip. My oal is 3.755 so it should be fine.Hmmm...Yeah, that sounds a bit long for the Forster, as they tend to have the die sit higher up. I wonder if a shorter micrometer seating stem would work?...just thinking out loud here. I know Hornady had to mod some of their early New Dimension seater dies, because they were too long for Forster presses (and we know how popular they are with the precision crowd).

Anyone else running these on a Forster Co-Ax?

I have Gold Medal in 221 fireball and it's best thing ever! I bought 223 also only to discover it's identical die. I want to buy one for 6.5 Grendel and 6 ARC. It's the same shoulder, is it possible to buy a different guide and stem and use the same die by swapping internals? Also is it possible to use 6.5 Creedmoor seating die for 6.5 Grendel? I know it's different parent case but I got one universal die in 30 cal that works with all 30 cartridges.Use ours. https://www.rcbs.com/reloading-dies/neck-bushings/neck-bushings/494.html

I have a decent amount of personal experience with the Matchmaster dies now. I came from using the Hornady dies for years and their micrometer adjustment. I prefer the Matchmaster now by far, and the concentricity is better than I have experienced with the Hornady dies. The loading window makes seating a total breeze. There's an internal floating sleeve that the bullet drops into and a C clip catches it from falling through. The sleeve aligns the bullet with the case before they ever meet so they go very straight. I've only ran the seater on the Summit press so far, and I've only done sizing on a Rock Chucker Supreme so far, and those were with the FL sizing MM die.

The first time setting one up took some trial & error to get the seating stem in the right place as it can be put into a few different height positions, and the depth of the seater die took some playing around, but the next 2 I set up went really fast from the experience gained on the first one.

Putting the bushings in is fairly straight forward and they fit great.

We're working on jazzing up the Matchmaster die product pages right now, but I can give you all some sneak peak images we're looking to put up to show these dies off and how they work.

If you have other questions on them give a shout. I'll try to dig up more pictures.

WM

The guides and stems are oftentimes different between cartridges of same size, e.g. 6mm. The stems and guides are all made to be as tight as possible to reduce runout and produce the straightest ammo, so they're actually accounting for those size differences. So in this example the 6.5CM has a neck spec of .295" while the 6.5 Grendel has a spec of .292". Also, the ARC/Grendel/PPC/Russian cases are much shorter than the short action cartridge like the 6.5CM, and so that MM die comes with a special shell holder that raises the body up into the die body further to actually seat the bullet. So, while you could possibly put some parts from 6.5CM into a 6 ARC die and possibly get it to work, I can't advocate for it or promise it'll work, and it certainly won't product the best concentricity with things having .003" extra slop in the system between 6.5CM and 6.5G.I have Gold Medal in 221 fireball and it's best thing ever! I bought 223 also only to discover it's identical die. I want to buy one for 6.5 Grendel and 6 ARC. It's the same shoulder, is it possible to buy a different guide and stem and use the same die by swapping internals? Also is it possible to use 6.5 Creedmoor seating die for 6.5 Grendel? I know it's different parent case but I got one universal die in 30 cal that works with all 30 cartridges.

I personally would really like to see a 6.5 Grendel MM die, so I'll hit up the product team and see if we can get it rolling.

Hope this helps!

I know what you mean about tolerances, but there can't be zero tolerance it's just not practical. The gun chamber has a "slop" in the neck to accommodate for expanding neck, it has to. Also you have to allow for variances in brass thickness. Also in case of my 223 GM die I am expanding my 223 necks beyond normal size to seat .225 lead cast bullets and it works. I haven't measured the tollerances but I know that in my 30 cal die I could use up to .310 bullets. The thing is because of the angled shoulders the case will try to auto center itself and in the end, it worked really well.

I don't know if RCBS sell the extra parts or how do I go about ordering but I think it's worth a try.

I don't know if RCBS sell the extra parts or how do I go about ordering but I think it's worth a try.

I love these Matchmaster seaters for Dillons, but last night, for the first time, I had a bullet not fully settle into the die. I didn’t notice it happened, and when I pulled the handle, the stem jammed into the side of the bullet, and it bent the stem. Probably my own fault for not watching the bullet fully settle into the dye every time, I guess I take that for granted how well it works 99.9% of the time.The guides and stems are oftentimes different between cartridges of same size, e.g. 6mm…

I called technical support to get a replacement part, and they were great about offering me that part - its in the mail now. But now I’m concerned that I might bend another stem the night before a match and put myself in a tough place. I asked if I could purchase an extra stem or two, and I was told no I could not. Apparently, they are so concerned with people swapping these dies to convert them from one caliber to another, that they will no longer sell parts. That just seems crazy to me. But my real question is, is there any way to get spare seating stems? Now that I’ve had this failure once, if it comes back and bites me, then I will have no one to blame but myself for not preparing for this possibilty!

Because having a $10 spare part and changing it in 2 minutes without swapping out the die is a lot easier and more convenient than spending $50-$150 on another die, that then needs to be swapped in, readjusted, and may or may not act the same after taking significantly more time, then needing to presumably swap it back after the replacement part arrives.

Just say you broke it again and get a second. Moral hazard is always a concern with shitty business practices.

That sir, is between you and RCBS. If you like to get spare parts for possible future user error by choosing a match master die and they aren’t willing to sell them, there isn’t anything I can help with other than above suggestions.

Similar threads

- Replies

- 6

- Views

- 446

Reloading Equipment

Redding Dies 6x47, 6.5x47, 6XC, Wilson 6x47 Forster 22 CM

- Replies

- 10

- Views

- 644