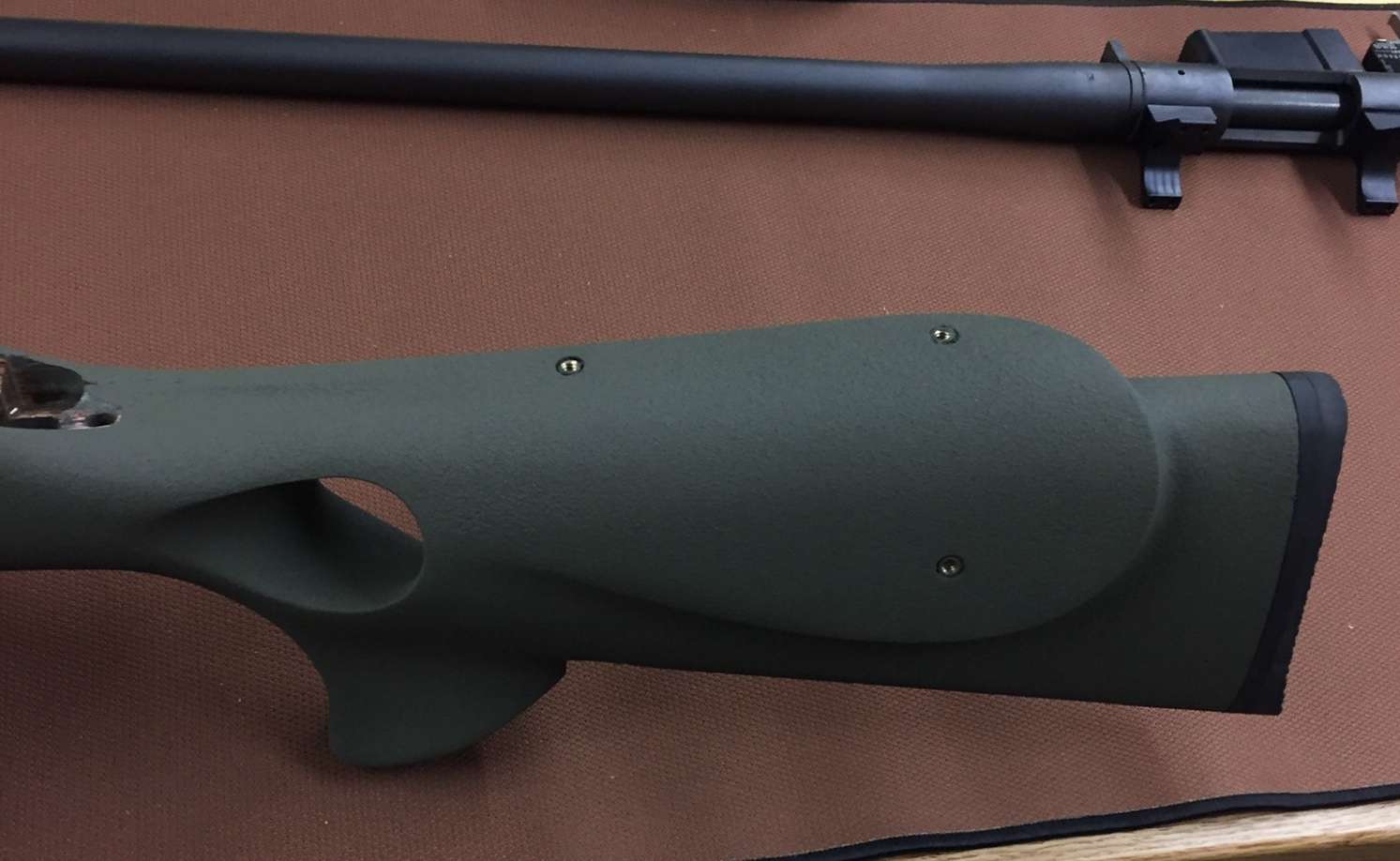

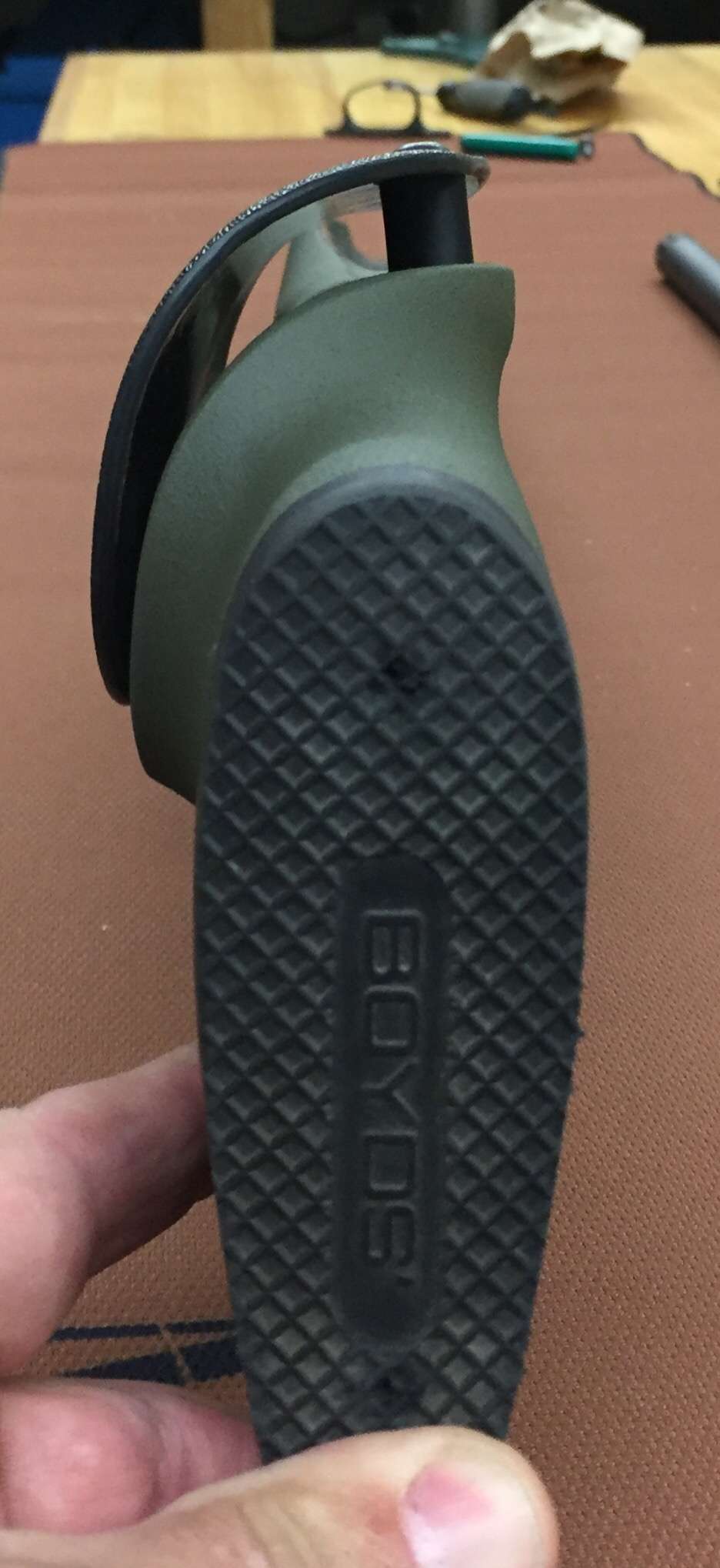

Had a buddy stop by wanting to know if I could fit a Boyds stock to his newly acquired Rem 223 Tactical. Stock was previously used on a Rem 700ML so there were a couple things that needed attention.

Had to fill the ramrod slot and the notch for the bolt retention screw.

There were no provisions for a sling swivel in the stock so I epoxied in an aluminum bar that was then drilled and tapped for a stud.

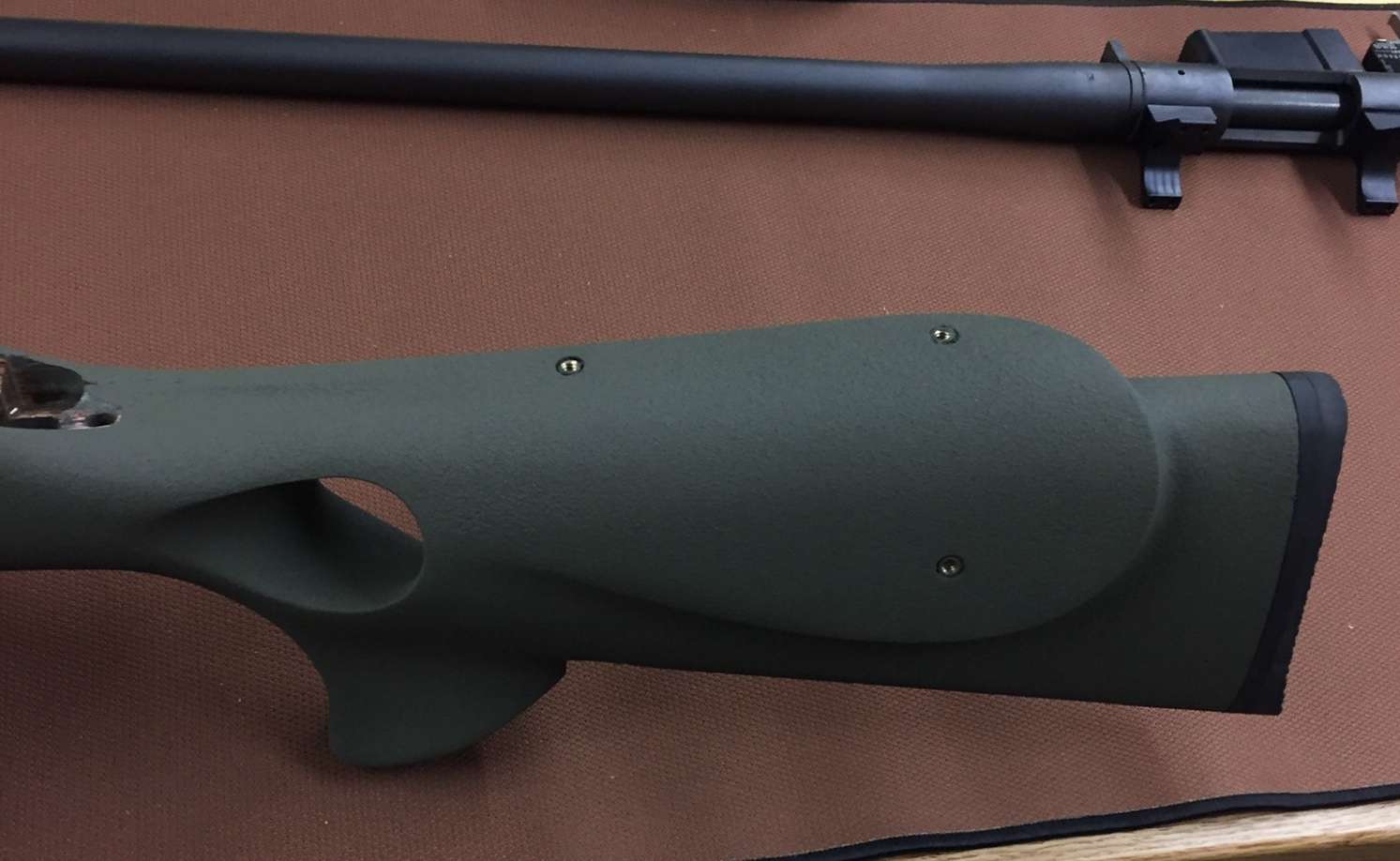

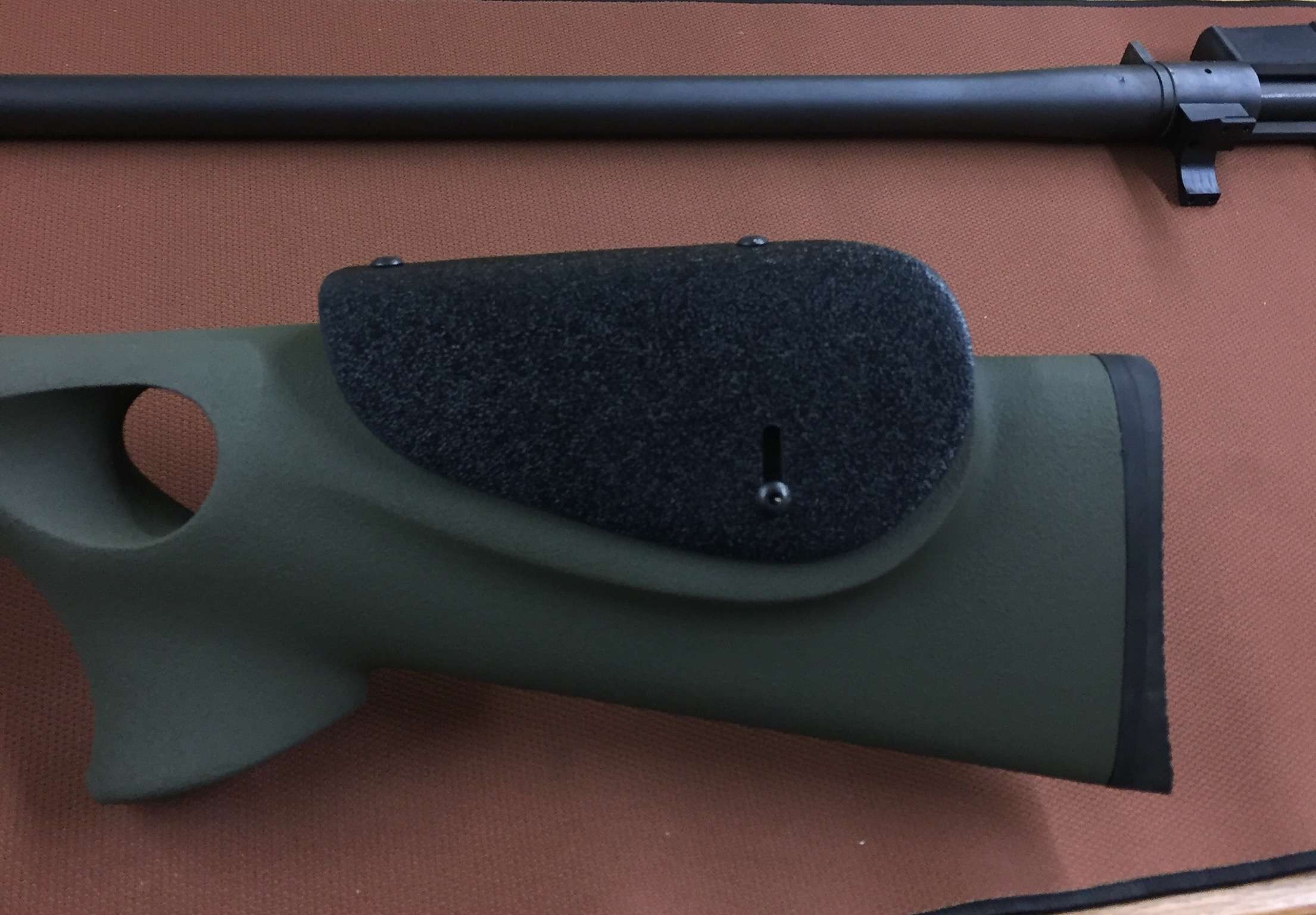

After some texture and color.

Turned out nice for what it is....

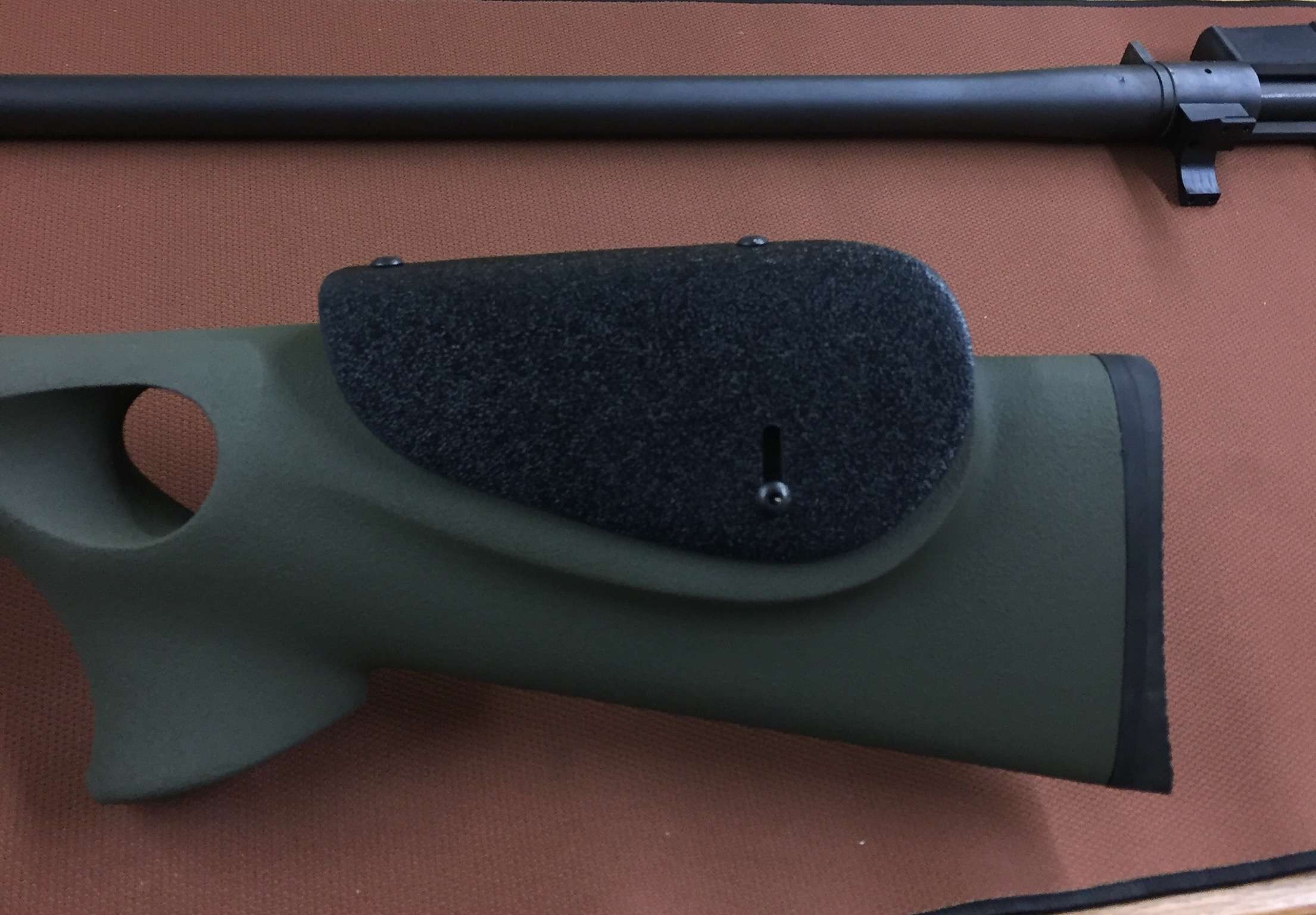

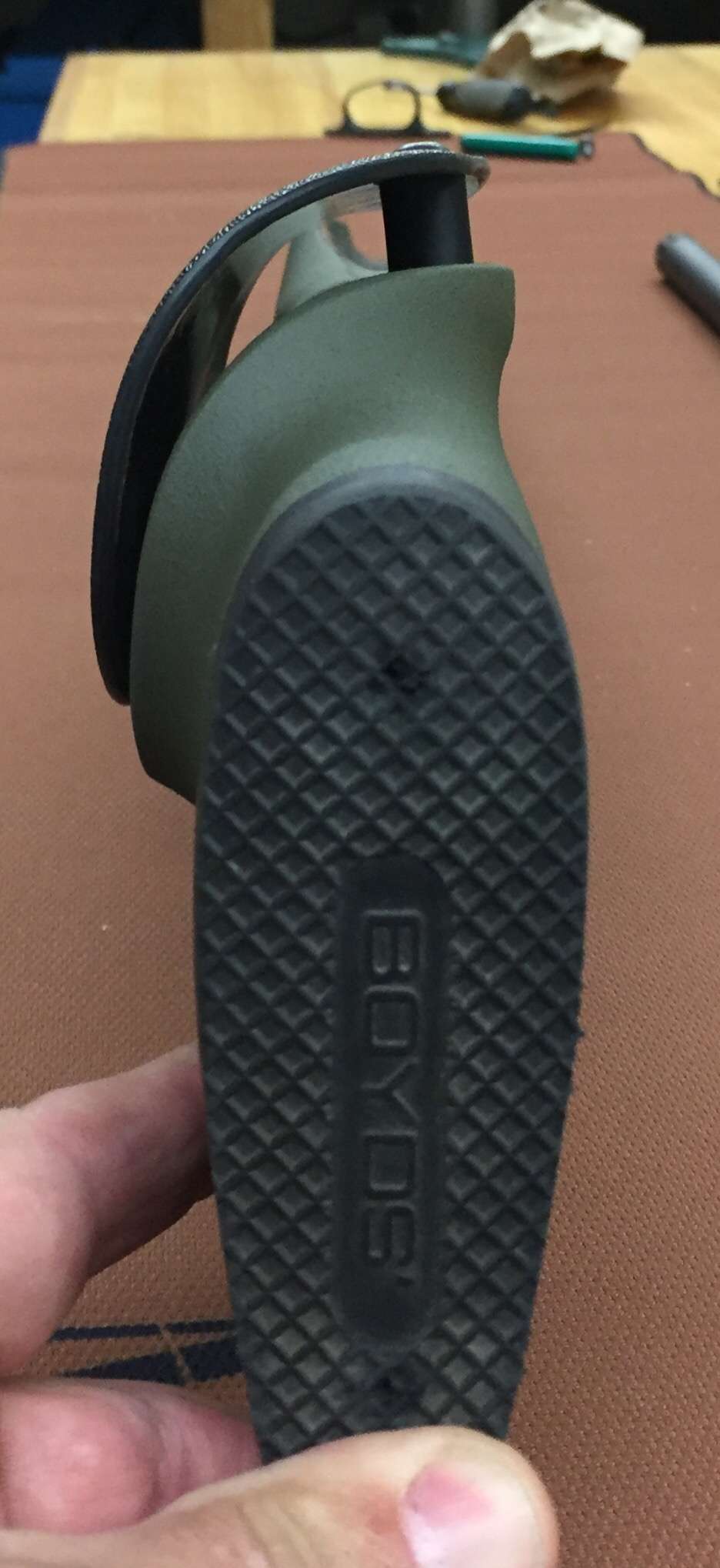

Wasn’t but a couple days and he was back wanting to know what could be done for better cheek weld. The thumbhole rollover cheek piece had me scratching my head.

Had never tried making anything out of Kydex before but that seemed like the way to handle this.

Threaded brass inserts were installed.

I molded a piece of .125” Kydex to the shape of the cheek piece.

Height is adjustable by changing the black delrin spacers. He wanted 5/8 rise as a starting point.

All in all it turned out pretty well.

Had to fill the ramrod slot and the notch for the bolt retention screw.

There were no provisions for a sling swivel in the stock so I epoxied in an aluminum bar that was then drilled and tapped for a stud.

After some texture and color.

Turned out nice for what it is....

Wasn’t but a couple days and he was back wanting to know what could be done for better cheek weld. The thumbhole rollover cheek piece had me scratching my head.

Had never tried making anything out of Kydex before but that seemed like the way to handle this.

Threaded brass inserts were installed.

I molded a piece of .125” Kydex to the shape of the cheek piece.

Height is adjustable by changing the black delrin spacers. He wanted 5/8 rise as a starting point.

All in all it turned out pretty well.