Re: Reworking my Howa, Remington and Mauser

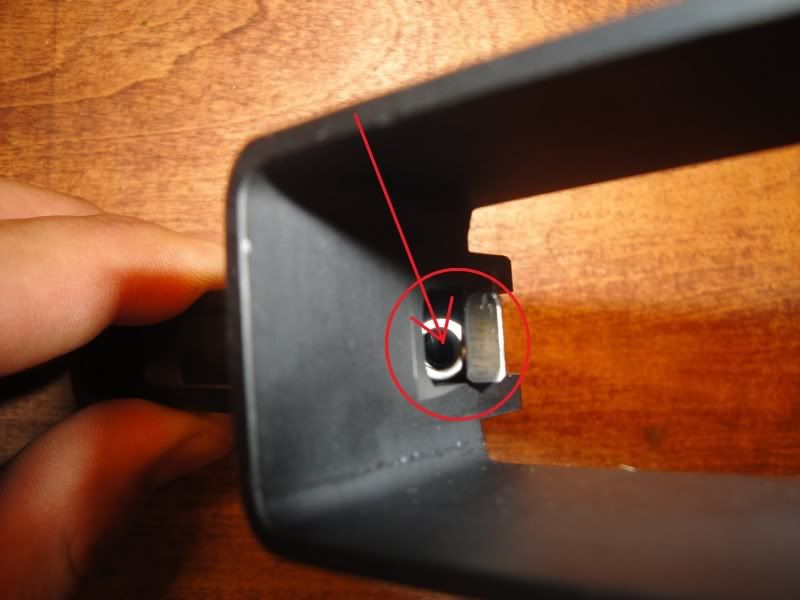

Mike post a picture of that. It needs to be inletted deeper. But then its going to sit/look weird.

That is the Howa, inletted by Mcmillan. Mike had to mill out one small part so it would even drop in at all. Not CDI or mcmillans fault, just poor communication maybe.

After doing that so it would drop in to stock line front and back, the trigger area was too bulky and comes down too far. Feels terrible when griping it. We can fix it with inletting and maybe some stock line changes though. Or we might need to mill some of the trigger guard opening out to bring it up to stock line.

Mike post a picture of that. It needs to be inletted deeper. But then its going to sit/look weird.

That is the Howa, inletted by Mcmillan. Mike had to mill out one small part so it would even drop in at all. Not CDI or mcmillans fault, just poor communication maybe.

After doing that so it would drop in to stock line front and back, the trigger area was too bulky and comes down too far. Feels terrible when griping it. We can fix it with inletting and maybe some stock line changes though. Or we might need to mill some of the trigger guard opening out to bring it up to stock line.