Food for thought for those who are interested.

I chronoed some more rounds once again while lot testing with the bench.

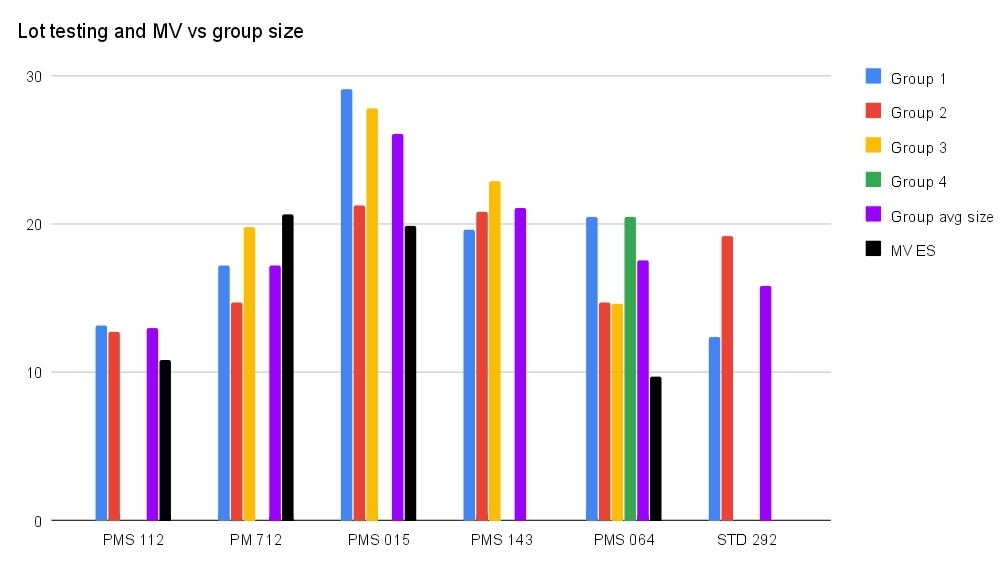

I compared average group sizes against muzzle velocity extreme spread to see how well they correlate and the result was 0.6, which is quite strong correlation! Seen here as purple and black columns. Unfortunally I did not get the MV for STD+ 292 recorded due to guests there.

I then compared individual group sizes against their corresponding muzzle velocity extreme spreads and the correlation lowered to 0.22.

After thinking about this I came to a conclusion that not all MV variances are caused by a single reason, there is variance within the variance.

The causes for changing MV could be things like bullet crimp, bullet width, offset, chamber conditions and of course powder amount.

And as always, correlation does not imply causation.

This leads to the fact that individual cartridge has so many different small variables that making conclusions based on one variable alone is impossible as long the as all of the variables cannot be identified and measured.

With rimfire, a string of 10 is not data, just 10 random occurances.

I chronoed some more rounds once again while lot testing with the bench.

I compared average group sizes against muzzle velocity extreme spread to see how well they correlate and the result was 0.6, which is quite strong correlation! Seen here as purple and black columns. Unfortunally I did not get the MV for STD+ 292 recorded due to guests there.

I then compared individual group sizes against their corresponding muzzle velocity extreme spreads and the correlation lowered to 0.22.

After thinking about this I came to a conclusion that not all MV variances are caused by a single reason, there is variance within the variance.

The causes for changing MV could be things like bullet crimp, bullet width, offset, chamber conditions and of course powder amount.

And as always, correlation does not imply causation.

This leads to the fact that individual cartridge has so many different small variables that making conclusions based on one variable alone is impossible as long the as all of the variables cannot be identified and measured.

With rimfire, a string of 10 is not data, just 10 random occurances.