Hey guys, just checking in. I need to carve out more time to hop on Snipers Hide to help answer questions. I will give you guys the rundown on what we have going on regarding dies.

We first started using Newlon die blanks in 12L14. They are a pretty good product, but we were running into supply issues and it always bugged me that the bullet seating stems would mark some bullets up. In addition, I hated the fact that people need to buy so many different bullet seating dies for cartridges that were extremely similar.

So we started designing "The" Seating Die with the goal of being able to offer one die that could seat bullets in a very straight, concentric fashion on a variety of cartridges. Furthermore, we wanted to solve the seating stem problem that most dies have.

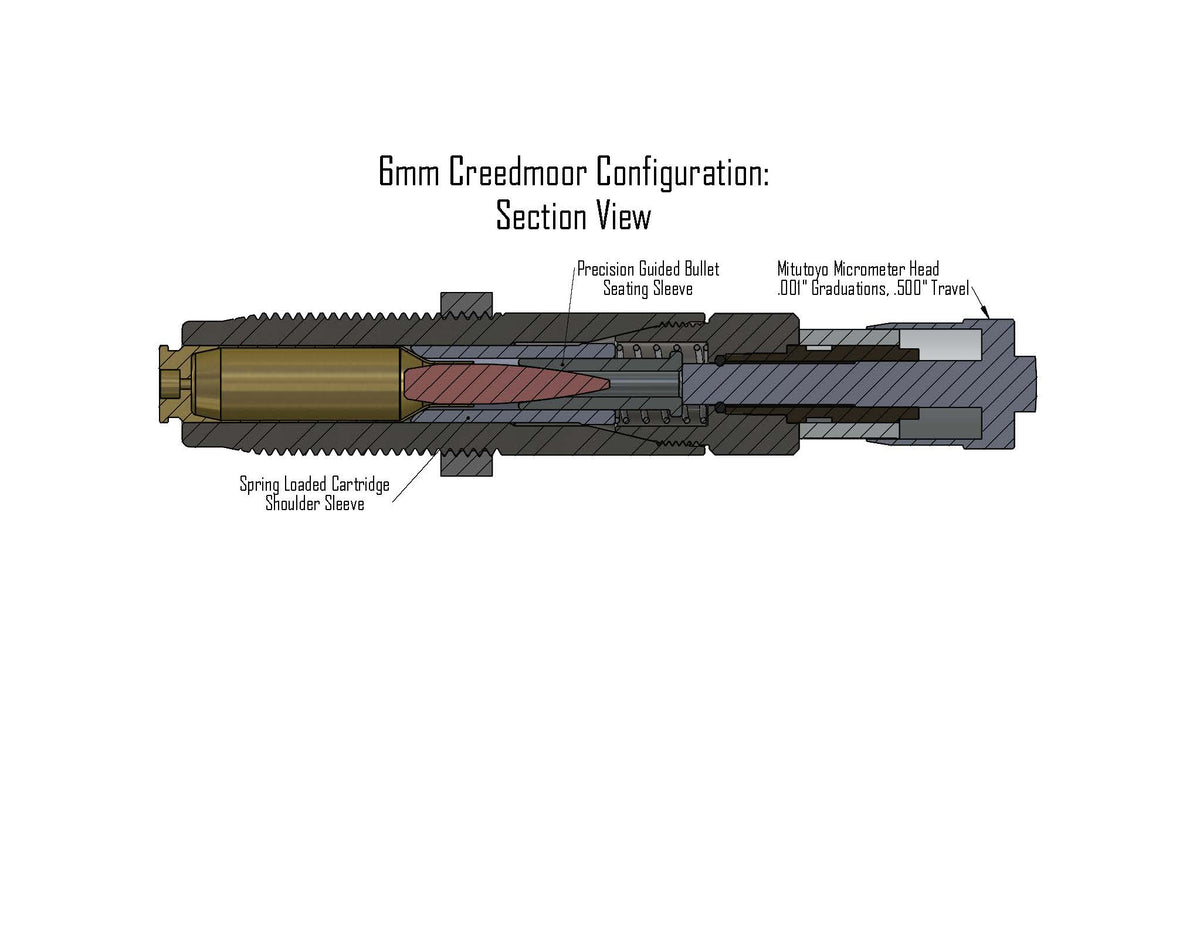

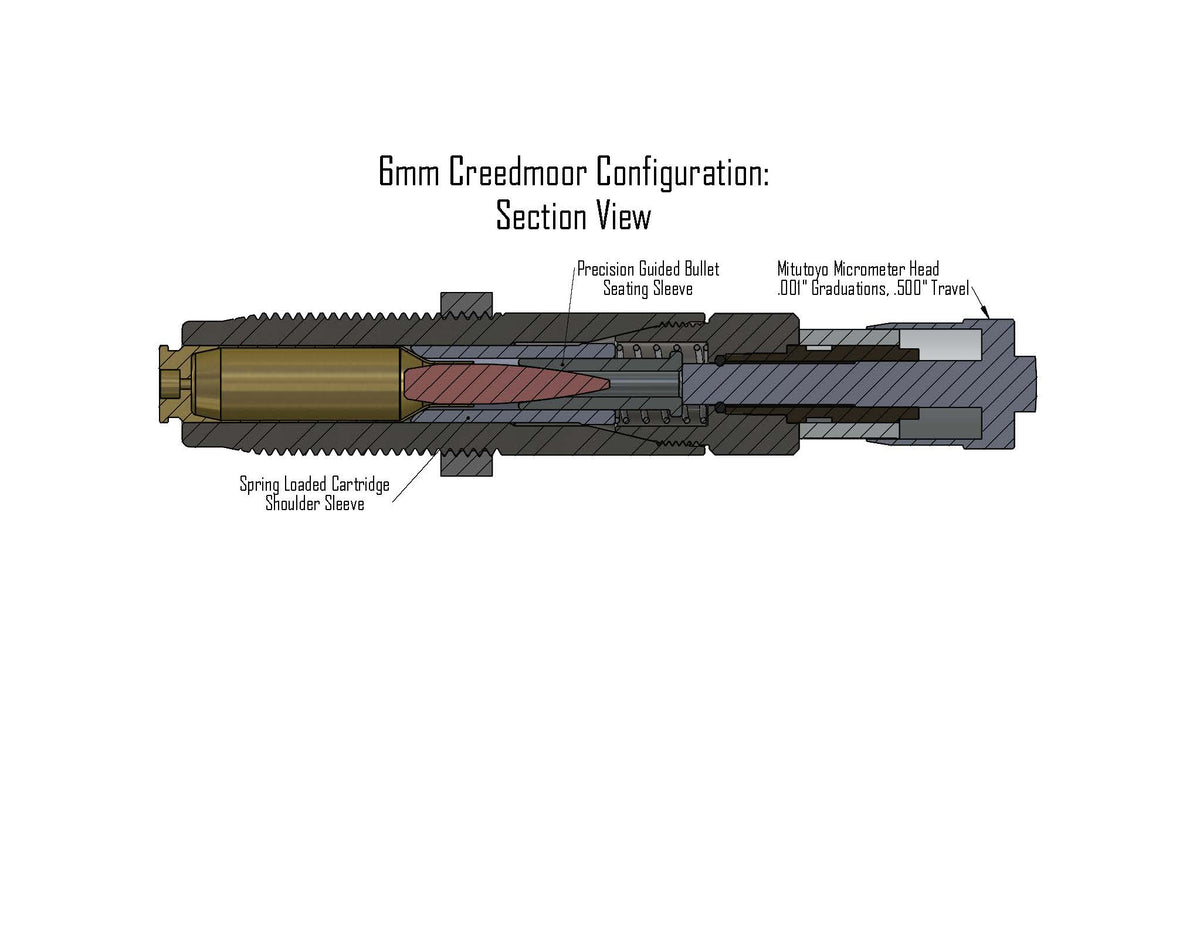

So we developed our seating with these features in mind. The heart of the system is the die body which we make from 12L14 then Black Nitride it. We chose this material because the "breakthrough" with our die body is making a hole through the center of the die body which about as perfectly straight as possible, but also has the inside diameter held to a +/- .0002 diameter tolerance (each one we measure is actually exactly the same size) and has as close to a mirror like finish on the inside. We use a special inside diameter burnishing tool which controls the surface finish and diameter. This is why we chose 12L14 is because it is ductile enough to allow this process to work. We made some prototypes in 17-4 Stainless, but the I.D. Burnishing process didn't work as well. Lastly, the diameter is a little over .4730" which offers a .001"-.002" clearance for the base of most short action cartridges to center up. Again, that is only .0005"-.001" per side of clearance. I grabbed my (Brand X) sliding chamber sleeve from the bullet seating die and measured the body diameter and it was .005" larger than the cartridge body.....so are most bullet seating dies ACTUALLY supporting the case??

Next, we designed the "Cartridge Shoulder Centering Sleeve" to only have a .001" fit inside the die body, which keeps the two very straight and concentric. The Cartridge Shoulder Centering Sleeve has a radius on the bottom which interfaces with any shoulder angle of the cartridge and centers up the shoulder with the die body. Now we have the cartridge base and shoulder held considerably straight.

Then we made an oversized bullet seating stem with a .3145" outside diameter. We did this so prevent the bullet contact geometry from swelling and bulging over time like my (Brand Y) bullet seating stem does.Next we made the stem with a through hole to 1). Prevent suction on the bullet 2). prevent any bullet tips from contacting the stem 3). Ease the manufacturing process, chip clearance when precision boring.

We also tried a bunch of angles for the bullet seating stem and created an angle that fits the bullet a little lower on the bullet nose which prevents bullet damage and creates more contact with the bullet which increases the bullet concentricity. Lastly, it also pushes the bullet down closer to the center of gravity instead of at the top of the bullet which increases runout.

View attachment 7413348

Each seating die will ship with a 10mm polished ball which serves as a spacer which increases the travel of the Mitutoyo Micrometer head. The 10mm ball is not needed for some 6GT, 6x47L, 243 Win, and 6mm Creedmoor cartridges, but is likely needed for the 6 BR, 6BRA, 6Dasher and other shorter 6mm cartridges.

View attachment 7413350

View attachment 7413351

Right now, "The" Seating Die ships as a 6mm seating die configuration. We have found that the bullet seating stem we use actually works really well with other bullets such as some 22 cal bullets as well as 25 cal and 6.5mm bullets. We plan on making some caliber dedicated seating stems very shortly.

Lastly, the current configuration that is shipping cannot handle the 308 Winchester cartridges just yet. This is because the "Cartridge Shoulder Sleeve) has a 8mm (.315") inside diameter and a neck will not make it in. We intend on making multiple configurations shortly.

Let us know if you have any questions. We will get our other Precision Resizing Dies on the website today!!!

Mark.

shop.shortactioncustoms.com

shop.shortactioncustoms.com

shop.shortactioncustoms.com

shop.shortactioncustoms.com