Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Seating Hornady 135 atip

- Thread starter DEWD_STUFF

- Start date

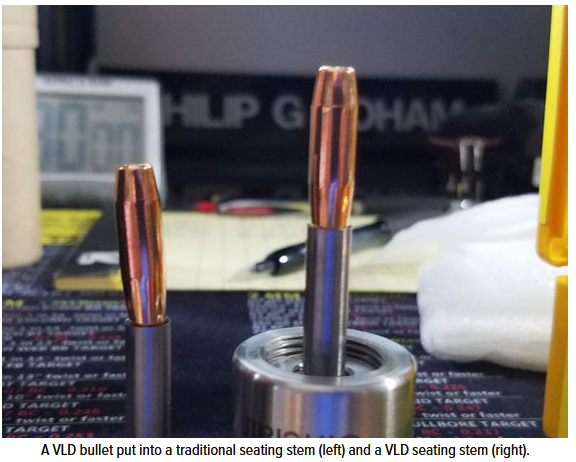

The cost of the new stem is trivial compared to the A-tip bullets themselves, why not just get it?

All you need to do is pull the stem from your die and check the fit.

More than likely my money is on the tip bottoming out in the stem.

I was reluctant but knew better when I ordered a box of the 150smk and was hoping the standard stem in my Redding die would be GTG but now own the vld stem as well.

More than likely my money is on the tip bottoming out in the stem.

I was reluctant but knew better when I ordered a box of the 150smk and was hoping the standard stem in my Redding die would be GTG but now own the vld stem as well.

Bec

because I don’t have Hornady comp dies, I have Redding. And Hornady website states you need to use their dies for the stem and the stem is needed in order to correct seat. So in a nut shell if I want to use a tips I have to buy their dies with their stem?The cost of the new stem is trivial compared to the A-tip bullets themselves, why not just get it?

Bec

because I don’t have Hornady comp dies, I have Redding. And Hornady website states you need to use their dies for the stem and the stem is needed in order to correct seat. So in a nut shell if I want to use a tips I have to buy their dies with their stem?

Since you allready own the Redding dies it couldn't hurt to reach out to them with the question.

More than likely the vld stem would be a good match to the A-Tip and it might eliminate the need for another die floating around your bench just to match one type of bullet.

I am using the standard stem in the Whidden dies without issue, 6 and 6.5. I would just pull the stem and check it, they are real long and depending on stem might bottom out on tip.

Last edited:

That is really a good point. I kind of wish I’d read their website so closely myself before I bought the stem, since my 6.5 dies are also Redding. I assumed the stems were interchange. Oopsie.Bec

because I don’t have Hornady comp dies, I have Redding. And Hornady website states you need to use their dies for the stem and the stem is needed in order to correct seat. So in a nut shell if I want to use a tips I have to buy their dies with their stem?

Im using the Redding micrometer seater the VLD stem fits the 135 A tip really well. Very low runnout. Almost none, maybe 0.0005. The standard stem that comes with the die didnt fit them well. So no, get the VLD stem and youll be good.

Im using the Redding micrometer seater the VLD stem fits the 135 A tip really well. Very low runnout. Almost none, maybe 0.0005. The standard stem that comes with the die didnt fit them well. So no, get the VLD stem and youll be good.

Sorry if this is a stupid question but how do you determine whether they fit well or not. I also have the Redding competition dies and haven’t noticed any problems with the 147 eld-m

Im using the Redding micrometer seater the VLD stem fits the 135 A tip really well. Very low runnout. Almost none, maybe 0.0005. The standard stem that comes with the die didnt fit them well. So no, get the VLD stem and youll be good.

Same for 153 A-Tip.

Initial test for me is nothing scientific. Take the stem out of the die, put a bullet into it, see how much movement there is side to side. Rinse and repeat with a couple different makes/models of bullets and youll feel a difference. Also can check a circular mark on the top part of the bullet after loading. Relative to neck tension but usually means the stem is contacting the ogive mostly or competely with the outer rim of the stem, not the bearing surface. Measuring with a concentricity gauge after loading would give you a more quantitative answer. How much all that matters is still up for debate.

I'm running the Redding with the VLD stem. I have no issues with the 135 A-tip. I did chuck up on bullet in the drill and used a little polish compound to clean the edge. I was seeing a slight ring on them but not on the 140 ELDM. That took care of the ring issue. It seemed to have a slight sharp edge. I have virtually no runout either.

TIP: Polish Seating Stems to Eliminate Ring Marks on Bullets « Daily Bulletin

Here's a helpful hint for hand-loaders from Sierra Bullets. While this article focuses on Sierra's new Tipped Match-King bullets, the recommended solutions apply to other bullet types as well.

Might be of interest:

Tray 1, measured as it was packed:

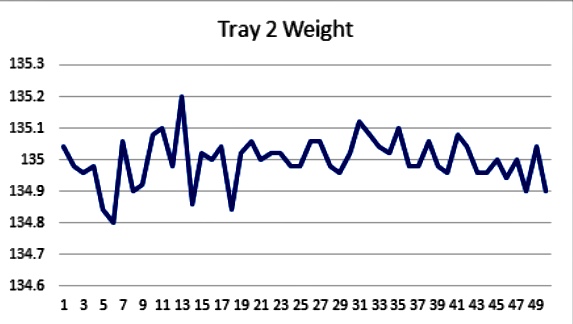

Tray 2:

Tray 2, assuming bullets are packed in rows of 5, left to right, total of 10 rows per tray.

Weight is pretty consistent. Combined data set (100 bullets) have ES of 0.40 gn and SD of 0.07 gn. Good SD but less than ideal ES makes it worth sorting them, i think.

Tray 1, measured as it was packed:

Tray 2:

Tray 2, assuming bullets are packed in rows of 5, left to right, total of 10 rows per tray.

Weight is pretty consistent. Combined data set (100 bullets) have ES of 0.40 gn and SD of 0.07 gn. Good SD but less than ideal ES makes it worth sorting them, i think.

Last edited:

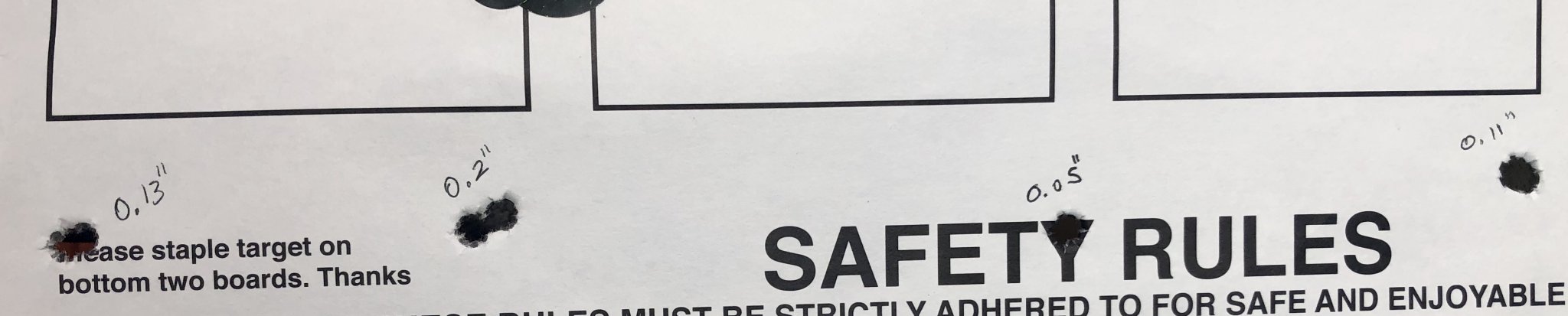

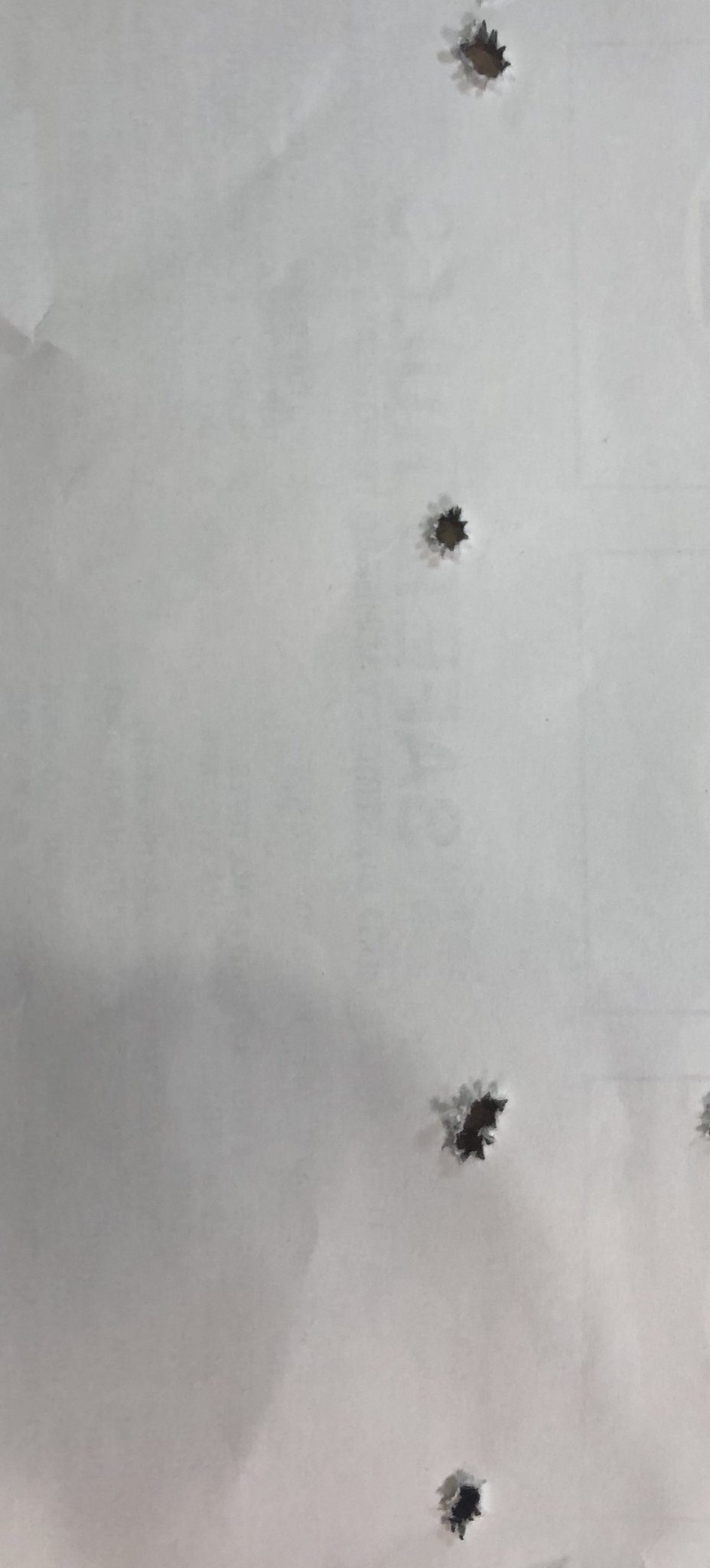

Rushed to the range after work, and could only shoot 4 “groups” with the 135 Atips (weight sorted) before the range closed. Results were frankly astonishing. Just doing a rough ladder/pressure test in increments of 0.3 gn of RL-16 at book COAL to see where the ES is low and the MV curve is flat, using two rounds per powder charge. The “group” size measurement was a bonus and these results may not repeat in future:

One “group” was 0.4” (not shown) with an ES of 56 fps.... me thinks me did not trickle it up. User error, as the tech support guy would say.

I realize that two shot groups are meaningless, so will repeat for a narrow range where the speed curve goes flat. Hope to find a nice wide node slightly over 2800 fps. Not chasing high speed.

Will complete tomorrow, MV is still slow, and of course zero pressure signs so far.

What speed are you guys getting?

BTW : The back of the target shows the two shot ovals better:

Interesting to see the orientation of the oval change with powder charge. Sometimes you see a trend there during load development. [Btw: Tuner was not adjusted yet. Might not be needed this time. Same setting as i got with 144 Bergers.]

One “group” was 0.4” (not shown) with an ES of 56 fps.... me thinks me did not trickle it up. User error, as the tech support guy would say.

I realize that two shot groups are meaningless, so will repeat for a narrow range where the speed curve goes flat. Hope to find a nice wide node slightly over 2800 fps. Not chasing high speed.

Will complete tomorrow, MV is still slow, and of course zero pressure signs so far.

What speed are you guys getting?

BTW : The back of the target shows the two shot ovals better:

Interesting to see the orientation of the oval change with powder charge. Sometimes you see a trend there during load development. [Btw: Tuner was not adjusted yet. Might not be needed this time. Same setting as i got with 144 Bergers.]

Last edited:

Im about to load some with some sta ball to see what happens. I can't get my hands on any rl 16.

how far are you guys jumping them. I measured and at mag length ill be at .110 thou.

how far are you guys jumping them. I measured and at mag length ill be at .110 thou.

Im about to load some with some sta ball to see what happens. I can't get my hands on any rl 16.

how far are you guys jumping them. I measured and at mag length ill be at .110 thou.

I managed to develop two 135 Atip loads that worked well: One with a small jump with a COAL of 2.950” that is strictly single feed, so way longer than the AW mag i use.

The second load is almost as accurate with a very long jump, and a COAL of 2.810 which fits in my magazine. [Don’t have my notebook close by, so can’t check exact numbers.]

Don’t be scared of jumping these bullets, they still shoot well with massive jump.

I know people hate weight sorting bullets, same for me. So just saying: Best group size for me prior to weight sorting was around 0.35”. Post weight sorting it was at about 0.1” to 0.15. At least on that particular day. [Maybe i had a less than perfect batch of bullets that benefited from sorting. Maybe your batch is better.]

And i have to add: I have no guarantees that my 0.15” groups will repeat. Have not been able to get more of these bullets because of the shortage. Might have been a fluke, but i hope not!]

Last edited:

Th

Thanks I’m trying to get some rl 16 but I’m going to try sta ball to see if it will be a good alternative.I managed to develop two loads that worked well: One with a small jump measuring around 2.950” that is strictly single feed, as it is way longer than the AW mag i use. The second load is almost as accurate with a very long jump, and a COAL of 2.810 which fits in my magazine. [Don’t have my notebook close by, so can’t check exact numbers.]

Don’t be scared of jumping these bullets, they still shoot well with massive jump.

I know people hate weight sorting bullets, same for me. Best group size prior to weight sorting was around 0.35”. Post weight sorting it was at or below 0.1”. At least on that particular day. Maybe i had a less than perfect batch. [No guarantees that the 0.1” groups will repeat. Have not been able to get more of these bullets because of the shortage.]

need to work on your breathing a little... {insert serious sarcasm pic here}This is 41.5 grains of H4350, with the 135 A-Tip seated 2.171 at the ogive, using the Redding competition seating die with standard stem.

5 rounds at 100

what's your OAL?

couple things:

brownells and midsouth both have 135 and 153 a-tips in stock.

factory hornady 6.5 prc eldx just BARELY fits in my 300wsm accurate mag. longest round in the box measured is 2.947 (shortest 2.940).

brownells and midsouth both have 135 and 153 a-tips in stock.

factory hornady 6.5 prc eldx just BARELY fits in my 300wsm accurate mag. longest round in the box measured is 2.947 (shortest 2.940).

Haha - yeah I pulled a couple. I believe the OAL was 2.82, and still had plenty of room in the AICS mag.need to work on your breathing a little... {insert serious sarcasm pic here}

what's your OAL?

Also used CCI #250 large rifle magnum primers in Hornady brass

I'm about half the thickness of a business card from front of my magwell and my bto is 2.2685 if that helps

What do you run for a polishing compound? I'm getting ready to get started with both the 135 and 153 A-tips.I'm running the Redding with the VLD stem. I have no issues with the 135 A-tip. I did chuck up on bullet in the drill and used a little polish compound to clean the edge. I was seeing a slight ring on them but not on the 140 ELDM. That took care of the ring issue. It seemed to have a slight sharp edge. I have virtually no runout either.

I know this is an older thread, but just in case this is from Berger's site as to when a VLD stem is needed...just in response to that question above about how to determine if needed

bergerbullets.com

bergerbullets.com

Good luck finding a Redding VLD seating stem for .264 in the USA...at least a few weeks ago I couldn't find one anywhere in the USA to buy one.

I did end up getting it from ReloadingUK for a not too terrible price...with currency fee, etc I believe it came to $28

They have them if looking for one

www.reloading.co.uk

www.reloading.co.uk

Do I need VLD Seating Stems?

When loading a Very Low Drag (VLD) bullet or a hybrid bullet, we recommend that you use a VLD seating stem to ensure load consistency.

Good luck finding a Redding VLD seating stem for .264 in the USA...at least a few weeks ago I couldn't find one anywhere in the USA to buy one.

I did end up getting it from ReloadingUK for a not too terrible price...with currency fee, etc I believe it came to $28

They have them if looking for one

Redding Competition Bullet Seating Stem VLD 6.5 CREEDMOOR (55746) - Premier Distributors

Redding makes these VLD seat stems for use with many popular VLD style bullets

I use the long vld stem. The short one didn't work for me. I expand with a mandrel to get the neck tension down I haven't had any issues. but I haven't been playing with the 135s long.

I wanted to bring this old thread up again. Wanted to know if anyone who contributed has any further results since it’s been a year.

Anyone getting random flyers?

Anyone think that since they say minimum of 1:8.5 twist that really matters if you have an 1:8?

I wanted to try these to start with in my ATX and found the 135s for 65$ per hundred. Ordered 600 from Brunos

That’s the cheapest I’ve seen them and it makes me think something may be wrong with the batch they have b/c most want 78-84$.

65$ is even cheaper than I’ve seen bulk l of 1000 or 2500 bullets go for

Most of what’s in this thread is good info for me to try them. I just wanted to see if anyone has further views on this year old thread

Anyone getting random flyers?

Anyone think that since they say minimum of 1:8.5 twist that really matters if you have an 1:8?

I wanted to try these to start with in my ATX and found the 135s for 65$ per hundred. Ordered 600 from Brunos

That’s the cheapest I’ve seen them and it makes me think something may be wrong with the batch they have b/c most want 78-84$.

65$ is even cheaper than I’ve seen bulk l of 1000 or 2500 bullets go for

Most of what’s in this thread is good info for me to try them. I just wanted to see if anyone has further views on this year old thread

I wanted to bring this old thread up again. Wanted to know if anyone who contributed has any further results since it’s been a year.

Anyone getting random flyers?

Anyone think that since they say minimum of 1:8.5 twist that really matters if you have an 1:8?

I wanted to try these to start with in my ATX and found the 135s for 65$ per hundred. Ordered 600 from Brunos

That’s the cheapest I’ve seen them and it makes me think something may be wrong with the batch they have b/c most want 78-84$.

65$ is even cheaper than I’ve seen bulk l of 1000 or 2500 bullets go for

Most of what’s in this thread is good info for me to try them. I just wanted to see if anyone has further views on this year old thread

I got the best groups ever from my MPA bolt action rifle with this bullet and RL-16 (which is now impossible to find). It has an 8 twist Spencer/MPA barrel. Have only about 30 bullets left over, but powder is running low. Once i locate an 8 lbs can of RL-16 again, i will shoot it once more and post results.

The “minimum of 8.5 twist rate” just means don’t expect stability in a 9 or 10 twist rifle. Almost everybody shoots an 8 twist (same for me), and that just means you will get a stability factor of 1.68 (very good) instead of 1.49 (barely acceptable) in an 8.5 twist barrel. Theoretically your groups will be 4% bigger from an identical rifle with the only difference being the slightly faster barrel twist rate. If you were competing for the short range BR ten shot group size record, then yes you would worry about that extra 0.5, but if your groups are 0.15” or bigger, it really is a non-issue.

Fliers are often a sign of a rifle with either a) a mechanical issue (loose action screw, barrel is not properly free floated, scope does not hold zero), or b) more likely the load has not yet been perfectly tuned. Or the lands have moved and a small tweak is needed. Either SD is too large (could benefit from trying different primers while adjusting powder load to keep the speed the same), or further seating depth optimization needs to be done. [Or the powder/bullet/chamber combo is an unhappy marriage. Then try other well known combos that others have success with.]

Consider getting Eric Cortina’s superb brake/barrel tuner combo, and close up the group size (quick and easy). Very likely that will do the trick.

Edge case: I would not usually sort premium bullets, but it may be worth doing a quick spot check: check 20 bullets for base to ogive measurement. If they vary by 3 thou or more, that could be a bad batch. Might need to measure twice, calipers are not that accurate. Have seen one bad batch that had 7-9 thou ES for thr 147 ELDM. Two distinct groups post sorting, looks like they were made on two different production lines. Rare - but it happens.

Thanks. At least someone replied. Appreciate the talk. A few things I pulled from your reply that I will do when these atips arrive.I got the best groups ever from my MPA bolt action rifle with this bullet and RL-16 (which is now impossible to find). It has an 8 twist Spencer/MPA barrel. Have only about 30 bullets left over, but powder is running low. Once i locate an 8 lbs can of RL-16 again, i will shoot it once more and post results.

The “minimum of 8.5 twist rate” just means don’t expect stability in a 9 or 10 twist rifle. Almost everybody shoots an 8 twist (same for me), and that just means you will get a stability factor of 1.68 (very good) instead of 1.49 (barely acceptable) in an 8.5 twist barrel. Theoretically your groups will be 4% bigger from an identical rifle with the only difference being the slightly faster barrel twist rate. If you were competing for the short range BR ten shot group size record, then yes you would worry about that extra 0.5, but if your groups are 0.15” or bigger, it really is a non-issue.

Fliers are often a sign of a rifle with either a) a mechanical issue (loose action screw, barrel is not properly free floated, scope does not hold zero), or b) more likely the load has not yet been perfectly tuned. Or the lands have moved and a small tweak is needed. Either SD is too large (could benefit from trying different primers while adjusting powder load to keep the speed the same), or further seating depth optimization needs to be done. [Or the powder/bullet/chamber combo is an unhappy marriage. Then try other well known combos that others have success with.]

Consider getting Eric Cortina’s superb brake/barrel tuner combo, and close up the group size (quick and easy). Very likely that will do the trick.

Edge case: I would not usually sort premium bullets, but it may be worth doing a quick spot check: check 20 bullets for base to ogive measurement. If they vary by 3 thou or more, that could be a bad batch. Might need to measure twice, calipers are not that accurate. Have seen one bad batch that had 7-9 thou ES for thr 147 ELDM. Two distinct groups post sorting, looks like they were made on two different production lines. Rare - but it happens.

I do have 5lbs of re16,but I’m gonna start with h4350 or v555…gonna save my re16.

The AI-ATX factory barrel should shoot…I’m gonna get a 6mm cm PVA barrel for it also,but not right away

But yeah can’t wait to try these

Thanks. At least someone replied. Appreciate the talk. A few things I pulled from your reply that I will do when these atips arrive.

I do have 5lbs of re16,but I’m gonna start with h4350 or v555…gonna save my re16.

The AI-ATX factory barrel should shoot…I’m gonna get a 6mm cm PVA barrel for it also,but not right away

But yeah can’t wait to try these

H4350 has the right burn rate for this load, and should do really well. Not familiar with N555, will go read up about it.

Enjoy that superb rifle!

Similar threads

- Replies

- 26

- Views

- 853

- Replies

- 25

- Views

- 997

- Replies

- 22

- Views

- 610