Very much appreciatedContact Beth at the email below. She can let you know current prices and lead times.

[email protected]

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SR25 Upper Compatibility

- Thread starter POGPride

- Start date

I realize I'm responding to a year old post...You should look into and add Zev DPMS receivers in that spreadsheet. It’s all I use now to build my own gassers. No issues with am I controls and quality is superb.

Zev bought Mega and he tried a Mega, so he has tried a Zev.

Sounds strange typed out like that, but it is what it is.

I have one of the older original Mega MaTen "megalythic" monolythic upper/handguard setups.

I bought the lower from one place and the upper from another because at the time parts were very hard to find (about 6'ish years ago if I remember right).

It may as well have been a matched set, perfect fit, zero play, and the ambi controls all work perfectly.

She's a runner and has worked flawlessly since day 1.

It was my first big block build and I just ordered parts from everywhere that had them in stock....threw them together, and have never had even a slight problem with the rifle.

Ignore the rock river scope mount, I threw that thing in the trash a long while ago....just using this older pic saves me from having to get the rifle out and taking new pics.

Yeah but the mega and Zev receivers are very different. The og megalithic receivers were awesome too.I realize I'm responding to a year old post...

Zev bought Mega and he tried a Mega, so he has tried a Zev.

Sounds strange typed out like that, but it is what it is.

I have one of the older original Mega MaTen "megalythic" monolythic upper/handguard setups.

I bought the lower from one place and the upper from another because at the time parts were very hard to find (about 6'ish years ago if I remember right).

It may as well have been a matched set, perfect fit, zero play, and the ambi controls all work perfectly.

She's a runner and has worked flawlessly since day 1.

It was my first big block build and I just ordered parts from everywhere that had them in stock....threw them together, and have never had even a slight problem with the rifle.

Ignore the rock river scope mount, I threw that thing in the trash a long while ago....just using this older pic saves me from having to get the rifle out and taking new pics.

View attachment 7977504

One other question for you. Did you have to buy one of the DWilson barrel nuts with the larger ID for non KAC barrels? Or did the regular OEM barrel nut work just fine?Contact Beth at the email below. She can let you know current prices and lead times.

[email protected]

I bought a Dwilson barrel nut. Marvin Pitts (nefarious arms.) also makes these. The other option is to have the barrel and extension turned down lightly… it’s not much that needs to come off.

Hmmm, my handguard/barrel showed up and everything went on and threaded with a Criterion Barrel. I just hand tightened it as I don't have the proper wrench but it seems to work alright.I bought a Dwilson barrel nut. Marvin Pitts (nefarious arms.) also makes these. The other option is to have the barrel and extension turned down lightly… it’s not much that needs to come off.

Did your OEM barrel nut thread at all or would it just not go on at all?

Also, I've got a LMT Defender H lower on the way and a Centurion MK11 upper at home. Once that lower comes in I can get you some photos up update the thread with.

If the nut slides all the way down the barrel and up to the extension without interference, You are fine.Hmmm, my handguard/barrel showed up and everything went on and threaded with a Criterion Barrel. I just hand tightened it as I don't have the proper wrench but it seems to work alright.

Did your OEM barrel nut thread at all or would it just not go on at all?

Also, I've got a LMT Defender H lower on the way and a Centurion MK11 upper at home. Once that lower comes in I can get you some photos up update the thread with.

OP, have you considered the Armalite AR-10"A" upper for your LMT lower?

It still uses an Armalite barrel nut pitch. SLR Rifle Works solves compatibility problems by offering both Armalite and "DPMS" / KAC pitch nuts (use the "DPMS High" rail).

It still uses an Armalite barrel nut pitch. SLR Rifle Works solves compatibility problems by offering both Armalite and "DPMS" / KAC pitch nuts (use the "DPMS High" rail).

Last edited:

So, does this confuse things even further? '-)

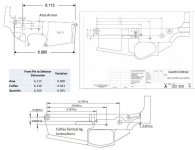

It just highlights the inconsistencies in the AR10 platform as a whole. I would be willing to bet there is less dimensional variation between the SR-25 patterned receivers mentioned in this thread than the DPMS receiver prints in your post. No way to confirm that since I don't have any SR25 prints to compare.

i’m curious if these are Sr25/LMT compatible

diamondbackfirearms.com

diamondbackfirearms.com

Upper, .308 Stripped Upper Receiver

Diamondback is pleased to offer the Upper, .308 Stripped Upper Receiver. Shop our selection to find exactly what you're looking for today! Orders over $250 ship free!

Thanks for the resurrection of this thread.

What would people suggest as an upper to build with, to make an upper to go on an Armalite AR-10TC (AR-10B) lower?

What would people suggest as an upper to build with, to make an upper to go on an Armalite AR-10TC (AR-10B) lower?

Last edited:

So, I don't know if Diamondback DB-10 is held in the same regard as lower tier like Bear creek, but they too have the slant cut. I never had an AR platform until about 2 years ago, but was always intrigued by POFs piston operation, but never could justify the cost. After my 1st 3 builds (556, 9mm & 7.62x39) I still wanted a 308, I bought a used 16" DB-10 with a Vortex strike eagle for $1100. Gun functions great and I have it set up how I like it. Scored a 6.5 BA Hansen barrel and decided to build a 2nd upper. Not knowing what was actually proprietary between manufacturers, I just bought all my parts from them. And just bought a 2nd complete 13.5" 308 upper along with one of their diamond series stripped lowers, which should be at my FFL any day now. Their uppers can be had with either 16 or 18 tpi, all they had in stock was the 18, but their handguard comes with both nuts, and is the higher height. Their prices are budget friendly; receivers & BCG are around $100 ea, handguard $75, the short upper was $500 with BCG & CH.

Had an opportunity at a match today to test compatibility between DD5V4 and Seekins SP10.

They did not fit.

You can see the differ in angles and length. The DD upper was too long from the pivot pin to the tang.

As seekins has been proven to fit with LMT, knights and several others, I think that is evidence enough to say the Daniel Defense is definitely proprietary. Did not expect that, but interesting note. I will update my original post and the excel file to confirm that this has been tried and doesn’t work.

They did not fit.

You can see the differ in angles and length. The DD upper was too long from the pivot pin to the tang.

As seekins has been proven to fit with LMT, knights and several others, I think that is evidence enough to say the Daniel Defense is definitely proprietary. Did not expect that, but interesting note. I will update my original post and the excel file to confirm that this has been tried and doesn’t work.

Attachments

Last edited:

Some photos of my finished build with a Centurion MK11 upper receiver and an LMT Defender H lower receiver. M110K1 inspired but not near clone correct. Affectionally dubbed SR-25 MOD AH (At Home)

I can provide full build details if someone wants them too, but the basics are Criterion 16" rifle gas barrel, LMT BCG, H3 buffer with a Sprinco Red spring. 4 o'clock reliable ejection, cerakote, fine tuning and assembled by Trajectory Arms.

I can provide full build details if someone wants them too, but the basics are Criterion 16" rifle gas barrel, LMT BCG, H3 buffer with a Sprinco Red spring. 4 o'clock reliable ejection, cerakote, fine tuning and assembled by Trajectory Arms.

Some photos of my finished build with a Centurion MK11 upper receiver and an LMT Defender H lower receiver. M110K1 inspired but not near clone correct. Affectionally dubbed SR-25 MOD AH (At Home)

I can provide full build details if someone wants them too, but the basics are Criterion 16" rifle gas barrel, LMT BCG, H3 buffer with a Sprinco Red spring. 4 o'clock reliable ejection, cerakote, fine tuning and assembled by Trajectory Arms.

View attachment 8155667View attachment 8155668

Looks like an allegheny arms gas block? That’s what I went with… has a really nice look.

Yup, I originally sent in a Riflespeed block to be used but upon Trajectory Arms inspecting and gauging all parts prior to Cerakote and assembly, it was found to swallow their largest gas block gauge so I was advised to not use it due to gas leakage and followed that advice. Since the TA guys also make the current Allen Engineering cans they recommended the Allegheny block so I went with that to keep the look and the superior fit. They also took the liberty to machine the front of it for me to fit an AEM4 in case I wanted to go that route in the future for a suppressor. Top notch shop and guys over there.Looks like an allegheny arms gas block? That’s what I went with… has a really nice look.

I would like to get an AEM4 or the OCM5 for mine… I though they were all 5.56 cans…Yup, I originally sent in a Riflespeed block to be used but upon Trajectory Arms inspecting and gauging all parts prior to Cerakote and assembly, it was found to swallow their largest gas block gauge so I was advised to not use it due to gas leakage and followed that advice. Since the TA guys also make the current Allen Engineering cans they recommended the Allegheny block so I went with that to keep the look and the superior fit. They also took the liberty to machine the front of it for me to fit an AEM4 in case I wanted to go that route in the future for a suppressor. Top notch shop and guys over there.

You're absolutely right, I misspoke. To quote exactly 'we shortened slightly (~0.060") and recut the taper, which means it will take an AE30 that has an AEM4 length reflex on it.'I would like to get an AEM4 or the OCM5 for mine… I though they were all 5.56 cans…

AEM4 is a 5.56 can like you said.

Some photos of my finished build with a Centurion MK11 upper receiver and an LMT Defender H lower receiver. M110K1 inspired but not near clone correct. Affectionally dubbed SR-25 MOD AH (At Home)

I can provide full build details if someone wants them too, but the basics are Criterion 16" rifle gas barrel, LMT BCG, H3 buffer with a Sprinco Red spring. 4 o'clock reliable ejection, cerakote, fine tuning and assembled by Trajectory Arms.

View attachment 8155667View attachment 8155668

Show the roll marks, for everyone that doesn’t follow you on insta.

Show the roll marks, for everyone that doesn’t follow you on insta.

Attachments

I'm letting my LMT lower and 2 sr25 cut sag uppers that fit snugly on that lower go in the px if anyone who's been following this thread is interested.

@RUBBERducky_actual, where/how did you get a Centurion Arms MK11 upper by itself? I’ve only seen Centurion Arms sell their MK11 receivers as a complete set.

Also, I was Googling SR25 uppers, and came across these:

.jpeg)

www.operationparts.com

www.operationparts.com

There is an outfit called “SR25 Cartel” that is going to make a limited run of 300 SR25 compatible upper receivers. I’m not affiliated with them at all, and I have no idea who they are. All I can find on them is a mentioned Instagram account on a random Reddit post, regarding their plans to make these uppers.

I’m interested to see how these turn out. The above listed vendors are all GTG in my opinion. I don’t think they would sell junk. I already bought a complete ZEV 308 receiver set, so I’m not in the market. However, if I could start over I’d take a chance on an LMT lower and one of these.

Also, I was Googling SR25 uppers, and came across these:

.jpeg)

SR-25 Compatible Billet Upper -SR25 Upper

www.dwilsonmfg.com

SR-25 Cartel LMT/KAC Compatible Upper (PRE-ORDER)

PRE-ORDER; WILL NOT SHIP UNTIL MID OCTOBER

www.thoroughbredarmco.com

HTX Concepts SR-25 Pattern Billet Upper Receiver

HTX Concepts SR-25 Pattern Billet Upper Receiver (SR25UPPER)

There is an outfit called “SR25 Cartel” that is going to make a limited run of 300 SR25 compatible upper receivers. I’m not affiliated with them at all, and I have no idea who they are. All I can find on them is a mentioned Instagram account on a random Reddit post, regarding their plans to make these uppers.

I’m interested to see how these turn out. The above listed vendors are all GTG in my opinion. I don’t think they would sell junk. I already bought a complete ZEV 308 receiver set, so I’m not in the market. However, if I could start over I’d take a chance on an LMT lower and one of these.

@RUBBERducky_actual, where/how did you get a Centurion Arms MK11 upper by itself? I’ve only seen Centurion Arms sell their MK11 receivers as a complete set.

Also, I was Googling SR25 uppers, and came across these:

.jpeg)

SR-25 Compatible Billet Upper -SR25 Upper

www.dwilsonmfg.com

SR-25 Cartel LMT/KAC Compatible Upper (PRE-ORDER)

PRE-ORDER; WILL NOT SHIP UNTIL MID OCTOBERwww.thoroughbredarmco.com

HTX Concepts SR-25 Pattern Billet Upper Receiver

HTX Concepts SR-25 Pattern Billet Upper Receiver (SR25UPPER)www.operationparts.com

There is an outfit called “SR25 Cartel” that is going to make a limited run of 300 SR25 compatible upper receivers. I’m not affiliated with them at all, and I have no idea who they are. All I can find on them is a mentioned Instagram account on a random Reddit post, regarding their plans to make these uppers.

I’m interested to see how these turn out. The above listed vendors are all GTG in my opinion. I don’t think they would sell junk. I already bought a complete ZEV 308 receiver set, so I’m not in the market. However, if I could start over I’d take a chance on an LMT lower and one of these.

This is interesting. Especially if DWilson is involved… likely a home run.

D Wilson is just stocking. A number of others are, including Thoroughbred: https://www.thoroughbredarmco.com/product/1380/This is interesting. Especially if DWilson is involved… likely a home run.

Hold that thought. I have a couple pics posted on page 1 here in this thread showing fitment of the JP upper with an LMT lower. I'm getting this build wrapped up but, that minor fitment issue I posted on page 1 has turned into a bigger functional issue. So, I'm currently in the process of voiding the warranty on the JP upper to make it work. I just might make a thread about it when the build is finished. If I do, I'll post a link in this thread.I may try one just to see. JP makes a side charger upper that’s supposed to be Knights/Lmt compatible also. But I have never seen anyone with one.

The SR25Cartel thing looks legit, enough that KAC got their nose bent out of shape a month or so ago on other social media/sites.@RUBBERducky_actual, where/how did you get a Centurion Arms MK11 upper by itself? I’ve only seen Centurion Arms sell their MK11 receivers as a complete set.

Also, I was Googling SR25 uppers, and came across these:

.jpeg)

SR-25 Compatible Billet Upper -SR25 Upper

www.dwilsonmfg.com

SR-25 Cartel LMT/KAC Compatible Upper (PRE-ORDER)

PRE-ORDER; WILL NOT SHIP UNTIL MID OCTOBERwww.thoroughbredarmco.com

HTX Concepts SR-25 Pattern Billet Upper Receiver

HTX Concepts SR-25 Pattern Billet Upper Receiver (SR25UPPER)www.operationparts.com

There is an outfit called “SR25 Cartel” that is going to make a limited run of 300 SR25 compatible upper receivers. I’m not affiliated with them at all, and I have no idea who they are. All I can find on them is a mentioned Instagram account on a random Reddit post, regarding their plans to make these uppers.

I’m interested to see how these turn out. The above listed vendors are all GTG in my opinion. I don’t think they would sell junk. I already bought a complete ZEV 308 receiver set, so I’m not in the market. However, if I could start over I’d take a chance on an LMT lower and one of these.

It is what it is. Nature of the beast when building large frame AR's, double-so when using two different brands on the upper and lower. I knew what I was getting into before starting, so only a little disappointing, but not unexpected.Thanks I missed that post. That sucks to hear it had to be modified. Appreciate your info.

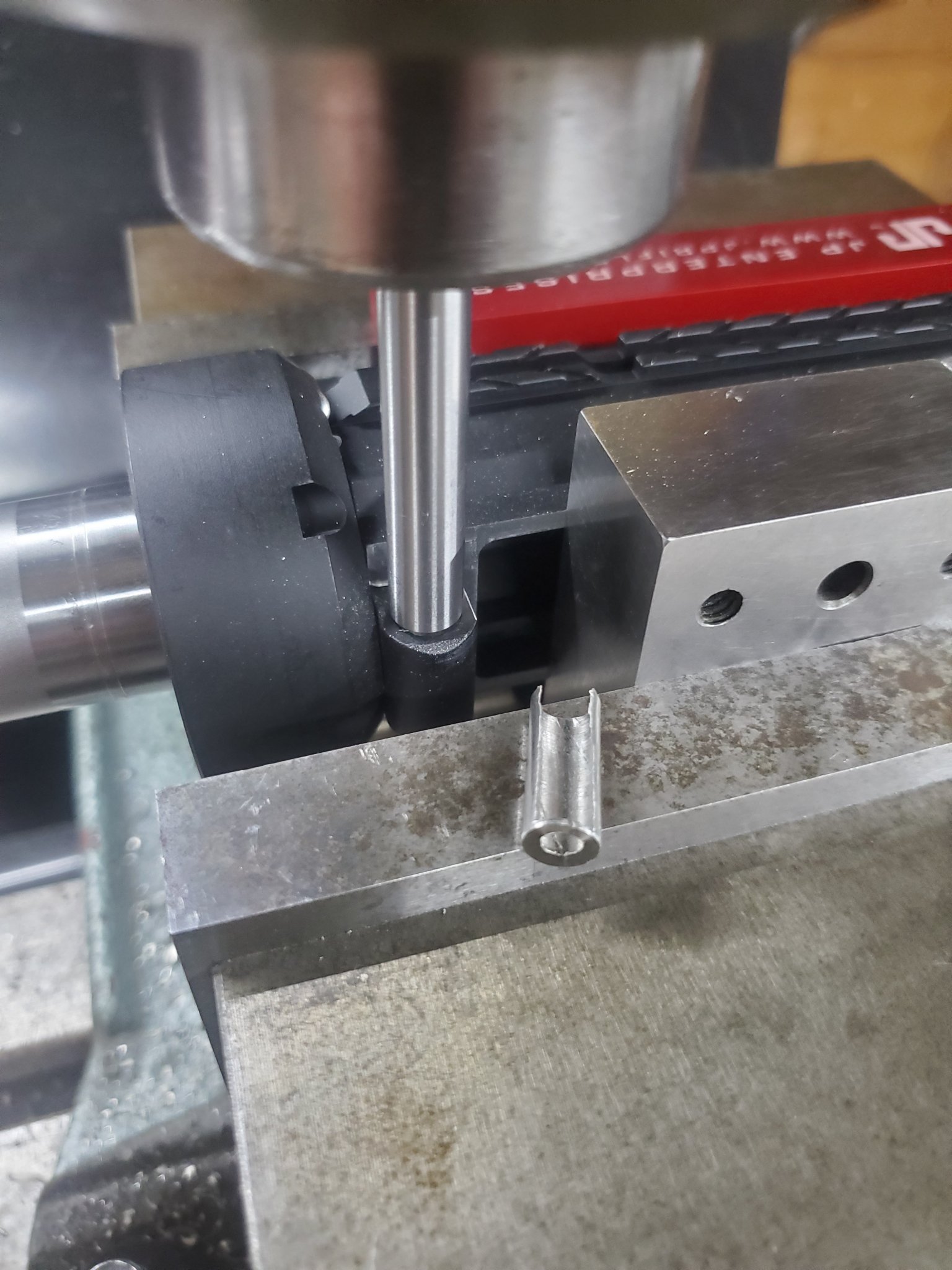

@POGPride, a little update on the JP PSC-12 upper to update the spreadsheet. I think it can be made to work, but I can't recommend the JP upper to anyone for a build. I'll go ahead and post my build here for everyone to see.

Bashing JP is not my intention here but, unless they've made programing/dimensional changes over the past (almost) 2 years since I bought the side charging upper, it's not worth the effort required to get the side charging upper to function properly. As I make this post, keep in mind that this lower has had an LMT upper mounted to it and I have also test fitted the JP upper to an LMT Defender lower and it fit just like it does on the MARS shown below.

Let's revisit this image I posted on page 1.

Notice the gap, that gap also runs along the bottom of the upper as well. It may not look like much, and there are many AR rifles both large and small frames that have little air gaps where the receivers mate. But it can also be indicative of alignment issues. In this case it was. The gap at the rear measured .015" and .025" at the slant and along bottom with feeler gages.

Would not chamber a round. Every time I pulled the charging handle, did not matter if it was a full mag, half mag or just one round in the mag. And the bolt carrier was getting stuck in the buffer tube. So, I started investigating. Bolt carrier was rubbing against the top of the buffer tube and there was a good sized step at the front of the magwell between the upper and lower. Picture below is blurry, but the dental pick is hooked onto that step.

That step measured out at .017" on the indicator. Since I bought that upper almost two years ago and I didn't feel like contacting JP for an exchange, refund or send all my parts off and have them build this rifle. I decided to give it a shot. At this point it was obvious that machine work needs to be done. After a bunch of measuring, first thing I had to decide was how to go about this, both with work holding and deciding on what to machine first. Since the LMT lower has been tested and proven to work with another upper, just about all machining will be done to the upper. I did do a minor mod to the bolt catch on the lower, but I'll get to that later.

Two choices for work holding. #1 is to make a custom set of jaws for the vise because this upper has a forward assist on one side and the rail for the side charge handle on the other making it rather difficult to clamp down on with regular vise jaws. Option #2 is to clamp it to the table and indicate in the upper. As you see I went with option #2. The first cuts I made were to eliminate the step at the magwell and close the gap at the rear of the upper. Next step was to get the bolt carrier centered with the buffer tube. (This will come back to haunt me later).

In case anyone is wondering, I decided not to remove the barrel since I had already bedded it to the upper. What you see a couple pics up is a wire feeler gage wedged between the handguard nut and the receiver to give clearance for the endmill. I still ended up nicking the handguard nut with the endmill. I took .025" off the bottom of the upper. Hindsight 20/20, I recommend just making a set of jaws to hold the upper, while this set up worked, I did have the upper try to walk away on me as I was making a cut. I had to stop, indicate the upper back in and re-clamp. On to the next step.

Take down pin holes are now out of alignment. So they got opened up, plugged, drilled and reamed. And not without issue either. The rear takedown plug worked fine. The front however.....

I underestimated the size of plug needed and the front takedown plug spun right out as I was drilling it out for the takedown pin. So, I rechecked alignment, changed the drill out for an end mill and opened that hole up some more for a larger plug. And the same thing happened again. The third plug I made on the lathe at work and just pressed it in. I couldn't do that with the first plug I made on account of the hole being offset. When I opened that hole up with the endmill, I made sure that the takedown pin hole was going to be centered in the plug.

For a brief moment there I thought I was ready to reassemble. I didn't screw up the hole locations too bad. The rear pin is very tight, needs to be tapped in and out with a punch, the front pin is a little loose in the bushing I made, but I sized the bushing so there is no side-to-side play in the lower. Between the two takedown pins being tight in perpendicular directions to each other, there is no wiggle between the upper and lower. Notice something about the above picture? That's right, JP didn't machine the feedramps. There's a couple more hours with some files and polishing stones.

It looks like I still have a step in there, but I think it's the angle the pic is taken at. Or at least that's what my dental pick tells me. Finally got to reassemble the rifle. Everything went together good. There's still a little gap between the receivers, but the bolt carrier floats in and out of the buffer tube with ease, no binding what-so-ever (Well, it did hang up on the bolt catch, so I milled the catch down a little so the carrier would clear). Loaded one round in a mag and it chambers right in. More than one round in a mag, now a real problem occurs. Double feeding now. I used a mag that has been tested on two rifles, so I know it's not the mag causing this. I know all the metal shavings have been cleaned out as well. The upper receiver is now sitting too low, the bolt carrier drags across the top of the mag, as the top round is stripped, the one below tries to ride along. As confirmation, a full mag is very hard to insert with the bolt closed. There is a fix for this. But it leaves me at this crossroad I'm standing on right now. Do I machine the bottom of the bolt carrier or just abandon this upper receiver and swap everything over and build up another upper receiver?

Anyway, here's the build specs and some final pics: Going for a fully ambidextrous and tooless build. LMT MARS-H lower, Geissele SSA-E, JP SCS, JP PSC-12 side charging upper, JP VMOS carrier with enhanced bolt, Radian charging handle, Bartlein barrel, Riflespeed adjustable gas block, PRI delta handguard with SPR rail, Dead Air flash hider. The Atlas bipod, March Highmaster 4.5-28x52, and the KAC offset irons pictured on the LMT Defender beside it were also going on this rifle.

Bashing JP is not my intention here but, unless they've made programing/dimensional changes over the past (almost) 2 years since I bought the side charging upper, it's not worth the effort required to get the side charging upper to function properly. As I make this post, keep in mind that this lower has had an LMT upper mounted to it and I have also test fitted the JP upper to an LMT Defender lower and it fit just like it does on the MARS shown below.

Let's revisit this image I posted on page 1.

Notice the gap, that gap also runs along the bottom of the upper as well. It may not look like much, and there are many AR rifles both large and small frames that have little air gaps where the receivers mate. But it can also be indicative of alignment issues. In this case it was. The gap at the rear measured .015" and .025" at the slant and along bottom with feeler gages.

Would not chamber a round. Every time I pulled the charging handle, did not matter if it was a full mag, half mag or just one round in the mag. And the bolt carrier was getting stuck in the buffer tube. So, I started investigating. Bolt carrier was rubbing against the top of the buffer tube and there was a good sized step at the front of the magwell between the upper and lower. Picture below is blurry, but the dental pick is hooked onto that step.

That step measured out at .017" on the indicator. Since I bought that upper almost two years ago and I didn't feel like contacting JP for an exchange, refund or send all my parts off and have them build this rifle. I decided to give it a shot. At this point it was obvious that machine work needs to be done. After a bunch of measuring, first thing I had to decide was how to go about this, both with work holding and deciding on what to machine first. Since the LMT lower has been tested and proven to work with another upper, just about all machining will be done to the upper. I did do a minor mod to the bolt catch on the lower, but I'll get to that later.

Two choices for work holding. #1 is to make a custom set of jaws for the vise because this upper has a forward assist on one side and the rail for the side charge handle on the other making it rather difficult to clamp down on with regular vise jaws. Option #2 is to clamp it to the table and indicate in the upper. As you see I went with option #2. The first cuts I made were to eliminate the step at the magwell and close the gap at the rear of the upper. Next step was to get the bolt carrier centered with the buffer tube. (This will come back to haunt me later).

In case anyone is wondering, I decided not to remove the barrel since I had already bedded it to the upper. What you see a couple pics up is a wire feeler gage wedged between the handguard nut and the receiver to give clearance for the endmill. I still ended up nicking the handguard nut with the endmill. I took .025" off the bottom of the upper. Hindsight 20/20, I recommend just making a set of jaws to hold the upper, while this set up worked, I did have the upper try to walk away on me as I was making a cut. I had to stop, indicate the upper back in and re-clamp. On to the next step.

Take down pin holes are now out of alignment. So they got opened up, plugged, drilled and reamed. And not without issue either. The rear takedown plug worked fine. The front however.....

I underestimated the size of plug needed and the front takedown plug spun right out as I was drilling it out for the takedown pin. So, I rechecked alignment, changed the drill out for an end mill and opened that hole up some more for a larger plug. And the same thing happened again. The third plug I made on the lathe at work and just pressed it in. I couldn't do that with the first plug I made on account of the hole being offset. When I opened that hole up with the endmill, I made sure that the takedown pin hole was going to be centered in the plug.

For a brief moment there I thought I was ready to reassemble. I didn't screw up the hole locations too bad. The rear pin is very tight, needs to be tapped in and out with a punch, the front pin is a little loose in the bushing I made, but I sized the bushing so there is no side-to-side play in the lower. Between the two takedown pins being tight in perpendicular directions to each other, there is no wiggle between the upper and lower. Notice something about the above picture? That's right, JP didn't machine the feedramps. There's a couple more hours with some files and polishing stones.

It looks like I still have a step in there, but I think it's the angle the pic is taken at. Or at least that's what my dental pick tells me. Finally got to reassemble the rifle. Everything went together good. There's still a little gap between the receivers, but the bolt carrier floats in and out of the buffer tube with ease, no binding what-so-ever (Well, it did hang up on the bolt catch, so I milled the catch down a little so the carrier would clear). Loaded one round in a mag and it chambers right in. More than one round in a mag, now a real problem occurs. Double feeding now. I used a mag that has been tested on two rifles, so I know it's not the mag causing this. I know all the metal shavings have been cleaned out as well. The upper receiver is now sitting too low, the bolt carrier drags across the top of the mag, as the top round is stripped, the one below tries to ride along. As confirmation, a full mag is very hard to insert with the bolt closed. There is a fix for this. But it leaves me at this crossroad I'm standing on right now. Do I machine the bottom of the bolt carrier or just abandon this upper receiver and swap everything over and build up another upper receiver?

Anyway, here's the build specs and some final pics: Going for a fully ambidextrous and tooless build. LMT MARS-H lower, Geissele SSA-E, JP SCS, JP PSC-12 side charging upper, JP VMOS carrier with enhanced bolt, Radian charging handle, Bartlein barrel, Riflespeed adjustable gas block, PRI delta handguard with SPR rail, Dead Air flash hider. The Atlas bipod, March Highmaster 4.5-28x52, and the KAC offset irons pictured on the LMT Defender beside it were also going on this rifle.

Last edited:

Some photos of my finished build with a Centurion MK11 upper receiver and an LMT Defender H lower receiver. M110K1 inspired but not near clone correct. Affectionally dubbed SR-25 MOD AH (At Home)

I can provide full build details if someone wants them too, but the basics are Criterion 16" rifle gas barrel, LMT BCG, H3 buffer with a Sprinco Red spring. 4 o'clock reliable ejection, cerakote, fine tuning and assembled by Trajectory Arms.

View attachment 8155667View attachment 8155668

Very Nice.

I really like the way that turned out and could see myself doing a similar build. I really like the idea behind the SR25 Cartel project, BUT, I really have reservations about getting into a project that is dependent on parts from Knights. Between the slightly larger ejection port cover, the URX 3.1 that's basically not in production. The gas block, and the price is really getting up their for a mix master.

It seems like at least with Centurian, you only need one part from Knights

@papershredder I’d say single load and see how it shoots. if its a good shooter then machine the carrier

I will take that into consideration. I was hoping I could get it to point of being able to manually cycle it without issue before going to the range, but that's not a possibility at this point. I'm not going to rush out and buy a new upper just yet. I'm taking a short break on this project to weigh my options. I might be able to get by with a partial machining of the carrier. The double feeding happens after the bolt lugs have stripped the top round out of the magazine and the next round comes up and contacts the bottom of the carrier and gets pushed forward. I hope I can get away with a partial machining because a full machining of the underside of the carrier can affect the carrier's ability to lock the hammer back. If I take too much material off the carrier and the hammer fails to lock back; that could very well lead to run away full auto or out of battery detonation in worst case scenarios. Another caveat of machining the carrier is once it's machined, then it is permanently married to this build and will have to be scrapped with the upper when/if that time comes. As of right now, if I were to just get a new upper, I won't need to buy another bolt carrier in the event I can't get this build up and running.

long as you don't touch the center or rear area of the bolt carrier underside you should be good. use a ball endmill and just take out some material to clear the tops of the cases on both sides?I will take that into consideration. I was hoping I could get it to point of being able to manually cycle it without issue before going to the range, but that's not a possibility at this point. I'm not going to rush out and buy a new upper just yet. I'm taking a short break on this project to weigh my options. I might be able to get by with a partial machining of the carrier. The double feeding happens after the bolt lugs have stripped the top round out of the magazine and the next round comes up and contacts the bottom of the carrier and gets pushed forward. I hope I can get away with a partial machining because a full machining of the underside of the carrier can affect the carrier's ability to lock the hammer back. If I take too much material off the carrier and the hammer fails to lock back; that could very well lead to run away full auto or out of battery detonation in worst case scenarios. Another caveat of machining the carrier is once it's machined, then it is permanently married to this build and will have to be scrapped with the upper when/if that time comes. As of right now, if I were to just get a new upper, I won't need to buy another bolt carrier in the event I can't get this build up and running.

long as you don't touch the center or rear area of the bolt carrier underside you should be good. use a ball endmill and just take out some material to clear the tops of the cases on both sides?

That's just it. Some material may have to come out of the center, not sure just yet. A closer look needs taken. Since the entire upper receiver has been lowered, theoretically I can get by with shaving the entire underside of the carrier and still be ok. If I do go ahead and machine the carrier, I definitely will not be taking off any more material than what I took off the bottom of the upper receiver. And I'll be doing it incrementally in .005" steps, i.e. shave .005" off, do a function test, rinse/repeat until it no longer double feeds or I hit the limit on the amount of material I'll be removing. I'll be considering all avenues of approach before making the first cut, from full machining to just machining the front half of the carrier back to the center of the magazine well to narrowing the center section kind of like what your suggesting. This is one big grey area I was hoping to avoid. It could very well have been avoided had I not tried to center the carrier with the buffer tube. Hindsight 20/20, should have shaved just enough off the bottom side of the receiver so the carrier enters buffer tube without rubbing the top side of it.

if its any consolation, if it shoots well and you machine the carrier and then give the parts a custom duracoat or cerakote job, you’ll have one heck of a unique build that will be very well tuned. (or a bottle nitride for the carrier)That's just it. Some material may have to come out of the center, not sure just yet. A closer look needs taken. Since the entire upper receiver has been lowered, theoretically I can get by with shaving the entire underside of the carrier and still be ok. If I do go ahead and machine the carrier, I definitely will not be taking off any more material than what I took off the bottom of the upper receiver. And I'll be doing it incrementally in .005" steps, i.e. shave .005" off, do a function test, rinse/repeat until it no longer double feeds or I hit the limit on the amount of material I'll be removing. I'll be considering all avenues of approach before making the first cut, from full machining to just machining the front half of the carrier back to the center of the magazine well to narrowing the center section kind of like what your suggesting. This is one big grey area I was hoping to avoid. It could very well have been avoided had I not tried to center the carrier with the buffer tube. Hindsight 20/20, should have shaved just enough off the bottom side of the receiver so the carrier enters buffer tube without rubbing the top side of it.

centering the carrier in the tube may pay dividends for accuracy because it will make the return stroke that much more repeatable, especially if using a captive buffer system like the SCS

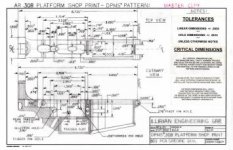

Now we just need to find a source for the extended ejection port coversd.wilson and Thoroughbred Arms are pre-ordering SR-25 Cartel's billet SR-25 uppers:

View attachment 8185927

Well, I'm scrapping the JP upper. Came across a couple more minor issues and decided it's time to put it to bed. I put in a pre-order for the Cartel upper. When the new upper arrives, I'll compare the port to the LMT. Also, If someone has an Armalite upper, post up the dimensions on it as well. As of right now, there are no KAC ejection port covers to be found.Now we just need to find a source for the extended ejection port covers. They sold out on Operation parts immediately…

I figured this much…. There are several less cumbersome options.Well, I'm scrapping the JP upper. Came across a couple more minor issues and decided it's time to put it to bed. I put in a pre-order for the Cartel upper. When the new upper arrives, I'll compare the port to the LMT. Also, If someone has an Armalite upper, post up the dimensions on it as well. As of right now, there are no KAC ejection port covers to be found.

For the ejection port cover… the parts listed below are going to be the only option for the SR-25 Cartel uppers and they are currently unobtainium

- KAC Port door cover - PN 25934

- KAC Port door rod - PN 20398-1

- KAC Poort door rod spring - PN 20397

I'll start by saying I don't know shit about large frame AR's. A coworker built one using Aero Precision upper and lower several years ago. How do they fit into this mix of different manufacturers?

Read the first postI'll start by saying I don't know shit about large frame AR's. A coworker built one using Aero Precision upper and lower several years ago. How do they fit into this mix of different manufacturers?

Not sure if he is in here but I can ping him.SR25 cartel uppers are awesome. Hope they can keep them in production.

Still need ejection port covers. I don’t think they are making any… so we will be relying on KAC.

Does anyone know if SR 25 cartel is on here?

Also he did tell me that they were planning on making their own EPC set ups for them. This was a couple months ago and I don't remember if it was a comment on a post or via DM.

I agree and am also perplexed at the lack of SR25 clone pattern uppers. Centurion Arms to the rescue ....... with their MK11 receiver set. It’s billet, and under redesign / revision at the moment. Corie confirmed it will be ambi (not sure if full ambi or what). Should be a nice solution to the SR25 pattern receivers void.I appreciate all the work you have put in on this! There is a huge hole in the market. I know Charlie's Customs was working on dimensional drawing of the SR upper but I dont know where that got left off. LMT (and KAC to some extent) lowers are readily available and I have always been confused why manufactures see the benefits of the system but then make their own proprietary sets. DD really missed an opportunity here where they could have sold their uppers to an existing user based and also to 3 letter agencies and Mil clients that dont want to get rid of their lowers.

LMT only has monolithic uppers with too short of a rail on my opinion. Larue has perfectly LMT/KAC matching uppers but they user their proprietary rail setup (although not terrible) in their ultimate uppers. From my research the SMF Tactical TAC-10 looks to be the best option but I dont understand the dimensional issues. In 2022 I dont see why this is a hard problem to solve.

If uppers were available I would buy two in a heartbeat. There is a whole M110 cloners world that have been trying to figure this out for a long time with limited success.

Last edited:

Good to hear these are coming back. Is there an eta on these?I agree and am also perplexed at the lack of SR25 clone pattern uppers. Centurion Arms to the rescue, with their MK11 receiver set. It’s billet, and under redesign / revision at the moment. Codie confirmed it will be ambi (not sure if full ambi or what).

He made a post on arf.com.Not sure if he is in here but I can ping him.

Also he did tell me that they were planning on making their own EPC set ups for them. This was a couple months ago and I don't remember if it was a comment on a post or via DM.

Fits the LMT lower like a glove! Assembly with mine went smoothly, now just waiting for a chance to get to the range.SR25 cartel uppers are awesome. Hope they can keep them in production.

........

Similar threads

- Replies

- 2

- Views

- 450

- Replies

- 3

- Views

- 470