Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Suppressors Suppressor build?

- Thread starter Lrush

- Start date

Lrush, I bet if you search this or even post the same question over at silencertalk.com you might get a few more responses. I bet there are a few designs that folks will share.

I've build several , the one my 308 wears full-time was built for a 300 win mag.

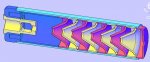

the outer tube is 1.625" OD , 1.485" ID that was bored from solid 316L SS bar. The OAL is 9.5" , the read end cap is also the blast chamber with the first baffle welded in place

followed by 9 , 60 deg cones spaced at .750".

It is heavy but it is quieter than any commercial 30 cal can I've heard , I've shot it on a 300 RUM with zero issue. Im tempted to shoot it on a 338 Lapua but the bore is to tight.

the outer tube is 1.625" OD , 1.485" ID that was bored from solid 316L SS bar. The OAL is 9.5" , the read end cap is also the blast chamber with the first baffle welded in place

followed by 9 , 60 deg cones spaced at .750".

It is heavy but it is quieter than any commercial 30 cal can I've heard , I've shot it on a 300 RUM with zero issue. Im tempted to shoot it on a 338 Lapua but the bore is to tight.

I have some plans and pics on my home computer someplace , i'll try to dig them up.

The unit is non serviceable due to being welded but the same design could be used but with threaded caps though I'd suggest adding .020" to the tube wall thickness of running 28tpi on the caps

The unit is non serviceable due to being welded but the same design could be used but with threaded caps though I'd suggest adding .020" to the tube wall thickness of running 28tpi on the caps

The color computer print is what I started with , I just adapted it to have a flat blast baffle to be a lot heavier built to cut down on erosion , the baffles on the print look to be one piece with the spacer but they are not , the con sit on top of a piece of thin wall tube as a spacer (.025" wall).

The cones are made from 316L SS and the blast baffle is made from 17-4 SS , the grooves in the frond side of the cone were made on purpose to give the surface some "texture" for the gas to deal with , I don't know if it made a difference but it coulden't have hurt.

The cones are made from 316L SS and the blast baffle is made from 17-4 SS , the grooves in the frond side of the cone were made on purpose to give the surface some "texture" for the gas to deal with , I don't know if it made a difference but it coulden't have hurt.

Attachments

I'm waiting on two more form-1's to show up (checks have been cashed) one is a for a 30 cal and one is for a 223. Both cans will be built for precision rifles and will be made from titanium.

Im going to make the 308 can threaded because I want to see what kind of buildup actually occurs. I bought some 1.625"x.070" wall grade 9 Ti tube off of ebay for $50 that's going to be the outer tube and some 1.5"x.050" that i'll turn down to make spacers out of. Probably use 316 SS for the cones again but I'm playing with the idea of just using the SS for the first 3 cones then 7068 aluminum for the last 6-7 cones , seeing how the can won't be seeing a high rate of fire and it's going to be specifically for a 308 I honestly don't see erosion being an issue.

Im going to make the 308 can threaded because I want to see what kind of buildup actually occurs. I bought some 1.625"x.070" wall grade 9 Ti tube off of ebay for $50 that's going to be the outer tube and some 1.5"x.050" that i'll turn down to make spacers out of. Probably use 316 SS for the cones again but I'm playing with the idea of just using the SS for the first 3 cones then 7068 aluminum for the last 6-7 cones , seeing how the can won't be seeing a high rate of fire and it's going to be specifically for a 308 I honestly don't see erosion being an issue.

When I tried to register with mine it said they did not accept yahoo or gmail,too many spammers

if you have a work email you can use that, otherwise create an AOL email. that's what I had to do and it worked fine. There is a ton of knowledge over there and they can definitely get you on the right track.

Similar threads

- Replies

- 14

- Views

- 1K