So a fun little woodworking project today... I'll finish it up tomorrow with the metal work and stain, etc.

This is a cigar cutter in the form of a French Revolution Guillotine! All made out of oak with the blade made of spring steel weighted with .175" thick copper plates/guides. Stands about 24" tall including the keystone at the top. Pretty sure it would lop a finger off without too much trouble!

View attachment 8259337

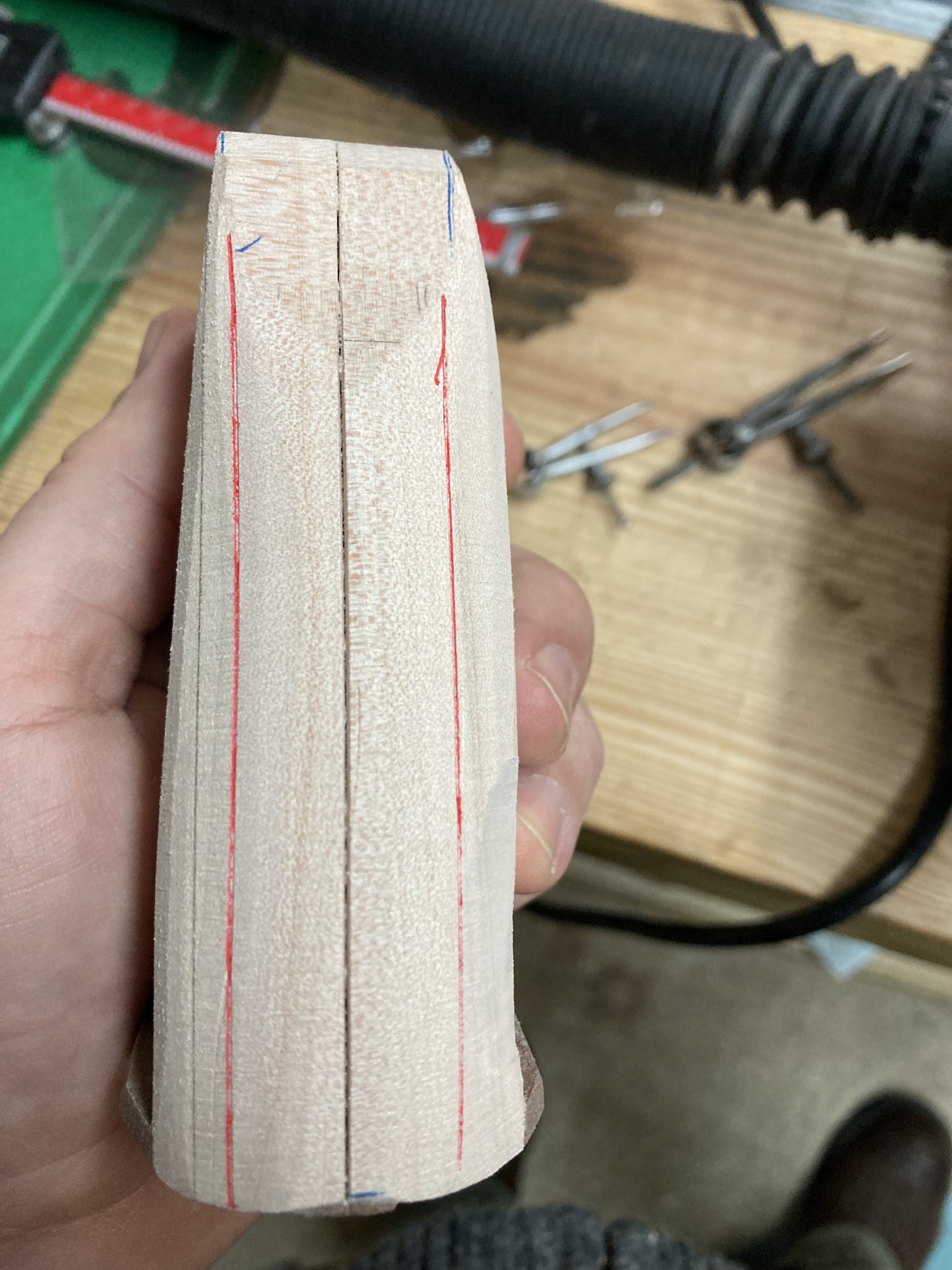

3/4" oak plank sliced into beams. Sort of like a Lincoln Logs project!

View attachment 8259338

Blade is flat spring steel bolted to copper weights/guides. It weighs enough that it comes down with a 'thunk!'

View attachment 8259340

Cheated and did most of the woodwork on a milling machine. But, hey, whatever works! Bolted and glued the beams together. Those are 8BA steel bolts.

This is sort of inspiring me to pursue my dreams of building a real one. It's not that daunting a project, in reality. Though the joining would be some serious work with a chainsaw and chisels. But I think every neighborhood needs one these days...

Well, I'll finish it up tomorrow and post 'After' pix. Hopefully while enjoying a nice cleved-stogie!

Sirhr

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s The Wood Shop

- Thread starter TxWelder35

- Start date

And if anyone tries to teabag my ciger cutter... They get what they deserve!

Sirhr

Your ho will love the hope chest you make of it.

Last edited:

I wonder how long it took this dude to turn off commenting on his post….

Sirhr

Sirhr

Pics of some cabinets I built for the little kitchen in my bachelor pad before I retired. I downsized my house years ago so I could age in place without having a lot to maintain and clean. Preparing and painting the entire inside of my house took me the better part of two weeks. Cabinets all have removeable toe kicks, so I'll replace the floor next summer. Cancer kicked my butt (colon cancer two years ago, bladder cancer last year) and my age is really showing, but I still plug along at a snail's pace. All that remains is to stab the new fridge into the corner, hang the door that goes into the laundry space, and scrub the filthy floor.

Nice joinery! Old-school shaper or router table?Pics of some cabinets I built for the little kitchen in my bachelor pad before I retired. I downsized my house years ago so I could age in place without having a lot to maintain and clean. Preparing and painting the entire inside of my house took me the better part of two weeks. Cabinets all have removeable toe kicks, so I'll replace the floor next summer. Cancer kicked my butt (colon cancer two years ago, bladder cancer last year) and my age is really showing, but I still plug along at a snail's pace. All that remains is to stab the new fridge into the corner, hang the door that goes into the laundry space, and scrub the filthy floor.

View attachment 8261435

View attachment 8261436

View attachment 8261437

View attachment 8261438

View attachment 8261439View attachment 8261441

This is great. I have zero reason to have one, but want to build it all the same. Nice job.Got to move a couple of screws (the problem with not working off any real plans or blueprints... occasional oopsie. And clean up the stain and add the ropes. But it's done. Came out pretty cool!

View attachment 8259915

Table with groove that lines up right with the head hole! Table is removable. I may or may not add some leather straps and buckles, just to make it creepy! I mean, why not? I have the footman loops and buckles in 1/6 scale. Hummmmm. I may have to do that!

View attachment 8259916

Messed up on the engraving. I have to relocate three screw holes and it will be visible. 1789. La Republique. Seems fitting. Three new holes and my engraving will be properly revealed.

View attachment 8259917

Pulley is ebony with machined brass yoke. Spins great. The rest of the bits are brass or German silver scrap. The whole thing was built from one 4' leftover piece of 3/4" oak. And scrap from other projects. The best kind of build! Just a weekend well spent in bad weather!

@Bigfatcock if you want detailed photos... let me know! I don't really have plans except the Interwebz 'plans' that I loosely followed. But really everything was just done ad hoc. The best way to build stuff! Just wing it!

Cheers,

Sirhr

Precisely why I built it! A week ago, I didn't even know these existed. Then last Thursday night, I saw an antique guillotine cigar cutter for sale on an aucton site and I knew I had to have one. But not for $1,000 plus shipping! Screw that. I wanted it and with one scrap oak board, a bit of scrap metal, some small hardware and cord... and I've got one. I don't need one. But I needed to make one!This is great. I have zero reason to have one, but want to build it all the same. Nice job.

Love making things!

Cheers,

Sirhr

Damn!

For my infrequent wood project this was my place!

For my infrequent wood project this was my place!

Go in and clear out their exotic wood section.

You want that stuff, go here...Go in and clear out their exotic wood section.

Exotic Lumber

One of Southern California largest selections including: Bastongne Walnut Figured Bubinga Goncalo Alves Ebony Gaboon Jatoba Koa Lacewood Mappa Burl Mesquite Monkey Pod Padauk Pau Ferro Peruvian Walnut Purple HeartRed Zebrawood ( Ebiara)Santos Rosewood Shedua Thuya Burl Wenge Quarter Sawn...

I was thinking maybe their Japanese sharpening stones.Go in and clear out their exotic wood section.

Look for any "Three Cherries" tools like chisels and japanese handsaws.I was thinking maybe their Japanese sharpening stones.

They are very exceptional and usually cost to match.

If it's a true clearance you might be able to make some good money turning them on fleabay or whatever.

Get you some good rasps. Auriou or Liogier. Hirsch gouges and former chisels. Dyes and dye powders.I was thinking maybe their Japanese sharpening stones.

First attempt at a live edge bowl. It is 12” at the widest point and a little over 6” tall.

The most used chisels in my shop are Henry Taylor socket bevel edged and cranked neck paring chisels along with L-N socket chisels. I bought them nearly 40 years ago when most of the good English woodworking tools were still available. Have a bunch of Sorby mortise and swan neck chisels but only use them if mortises can't be chopped on the Powermatic mortiser. Hand mortising hardwoods is a PITA. If I was going to invest in chisels today, I would look no further than L-N. Only sharpen plane blades and chisels on Japanese water stones with grits running from 250 to 12000. For the backside of blades initially flattten them with a diamond lapping plate. 69 is just around the corner and God willing I'll have a several more years to put them to good use.Get you some good rasps. Auriou or Liogier. Hirsch gouges and former chisels. Dyes and dye powders.

I finally caved and bought a Robert Sorby pro-edge for my chisels. Been sharpening chisels and plane blades on stones for close to 20 years, and just got tired of it.The most used chisels in my shop are Henry Taylor socket bevel edged and cranked neck paring chisels along with L-N socket chisels. I bought them nearly 40 years ago when most of the good English woodworking tools were still available. Have a bunch of Sorby mortise and swan neck chisels but only use them if mortises can't be chopped on the Powermatic mortiser. Hand mortising hardwoods is a PITA. If I was going to invest in chisels today, I would look no further than L-N. Only sharpen plane blades and chisels on Japanese water stones with grits running from 250 to 12000. For the backside of blades initially flattten them with a diamond lapping plate. 69 is just around the corner and God willing I'll have a several more years to put them to good use.

Love the pro-edge. Worth every penny. The time savings are enormous.

That's nice. I just resharpened my plane blade with my Veritas mk2 on some water stones after roughing it in on a harbor freight diamond lap plate. Realized how long I've had the mk2 and felt old. 2006ish.I finally caved and bought a Robert Sorby pro-edge for my chisels. Been sharpening chisels and plane blades on stones for close to 20 years, and just got tired of it.

Love the pro-edge. Worth every penny. The time savings are enormous.

Been working on crazy house project. Not sure if it fits here. Does fixing sub floor, widening a sliding glass door opening, and fitting pergo on floor and stairs count?

Time flies! I’ve easily got over $1,000 worth of diamond stones, Arkansas stones, and Shapton stones in my sharpening plus my sharpening jigs. That’s not even considering what has worn out over the years. No more for me! Besides as I get older holding and working the jigs starts to hurt my hands.That's nice. I just resharpened my plane blade with my Veritas mk2 on some water stones after roughing it in on a harbor freight diamond lap plate. Realized how long I've had the mk2 and felt old. 2006ish.

Been working on crazy house project. Not sure if it fits here. Does fixing sub floor, widening a sliding glass door opening, and fitting pergo on floor and stairs count?

I finished on the pro edge in about 30 minutes what would have taken me hours on the stones. No stone flattening, no water mess, no repetitive movement. Worth every penny. Chisels and plane irons come off the 3000 grit belt ready to work.

I’m sadly getting to the point where I’m going to have to swap to the machines for my wood work. Maybe about 5 more years or so of being able to break down and mill boards to readiness with all hand tools.

Alright guys, I have been asked the eternal question: what do you want for Christmas. Aside from more cigars, I need a quality hand saw. Like a plain design hand saw. But it needs to be good. The wood I use around here is typically oak, mesquite and pine. What do you recommend? I hate cheap quality hand tools so give me what you would get for yourself if the money was a secondary consideration.

Panel or backsaw?Alright guys, I have been asked the eternal question: what do you want for Christmas. Aside from more cigars, I need a quality hand saw. Like a plain design hand saw. But it needs to be good. The wood I use around here is typically oak, mesquite and pine. What do you recommend? I hate cheap quality hand tools so give me what you would get for yourself if the money was a secondary consideration.

What are you using it for? Ripping or cross cutting? Is it for breaking down lumber or cutting joinery?

Panel. For rough cuts mainly. Cross cutting will be most of what it will be used for.Panel or backsaw?

What are you using it for? Ripping or cross cutting? Is it for breaking down lumber or cutting joinery?

If breaking down rough lumber than a panel saw is what I would choose.

Sadly there are no good low level new made saws.

I’d source a good vintage panel saw that has been restored, sharpened, and set.

Midgrade would be the Pax or lynx. Sometimes the are really good out the box, and sometimes they need to be resharpened and set out of the box.

Top of the heap is bad axe.

8-11 TPI is what you’re looking for.

This is my Arsenal for breaking down lumber. 4 TPI rip to 11 TPI cross cut on the panel saws. The tenon saw is 14 TPI.

Sadly there are no good low level new made saws.

I’d source a good vintage panel saw that has been restored, sharpened, and set.

Midgrade would be the Pax or lynx. Sometimes the are really good out the box, and sometimes they need to be resharpened and set out of the box.

Top of the heap is bad axe.

8-11 TPI is what you’re looking for.

This is my Arsenal for breaking down lumber. 4 TPI rip to 11 TPI cross cut on the panel saws. The tenon saw is 14 TPI.

Last edited:

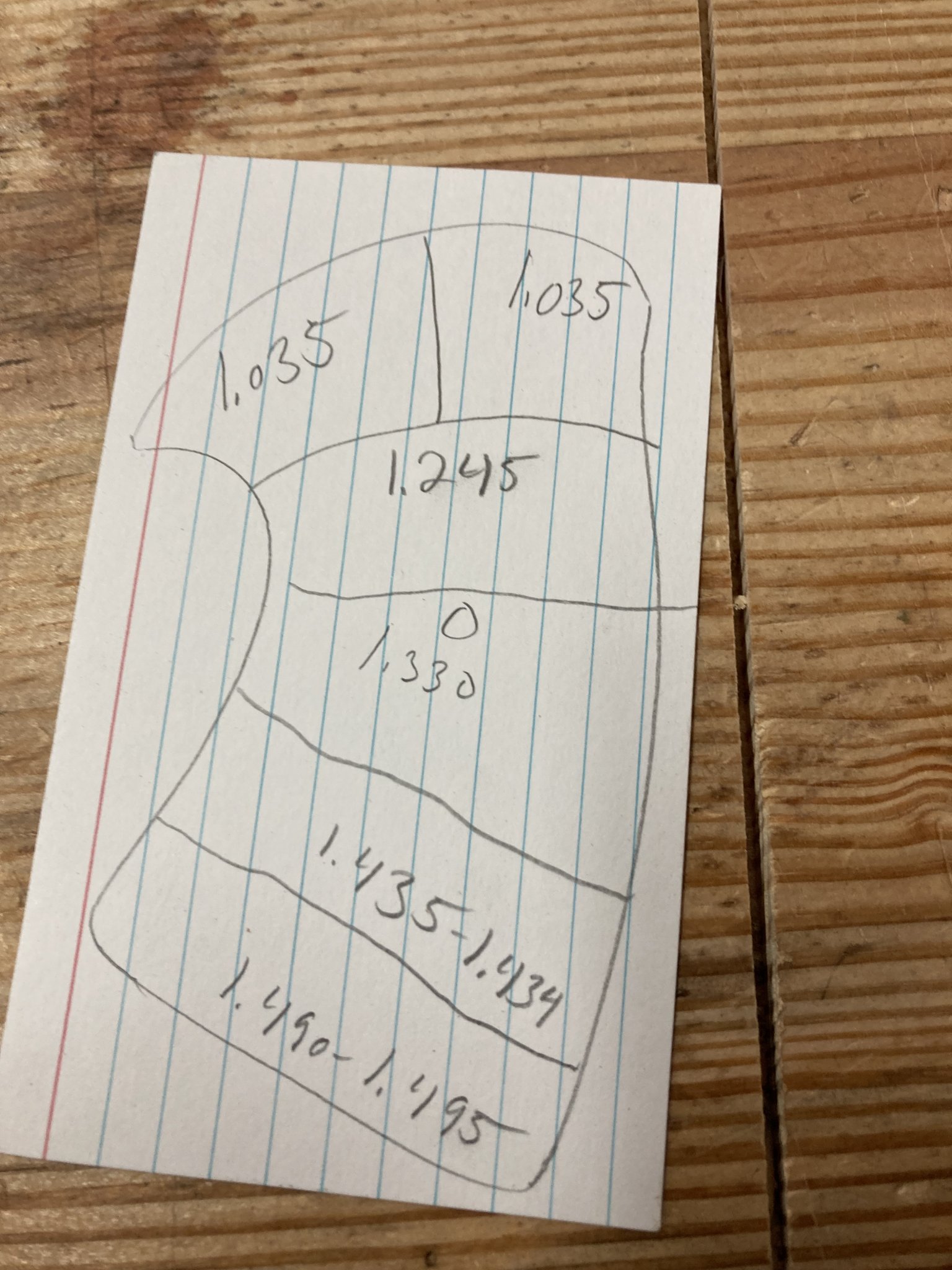

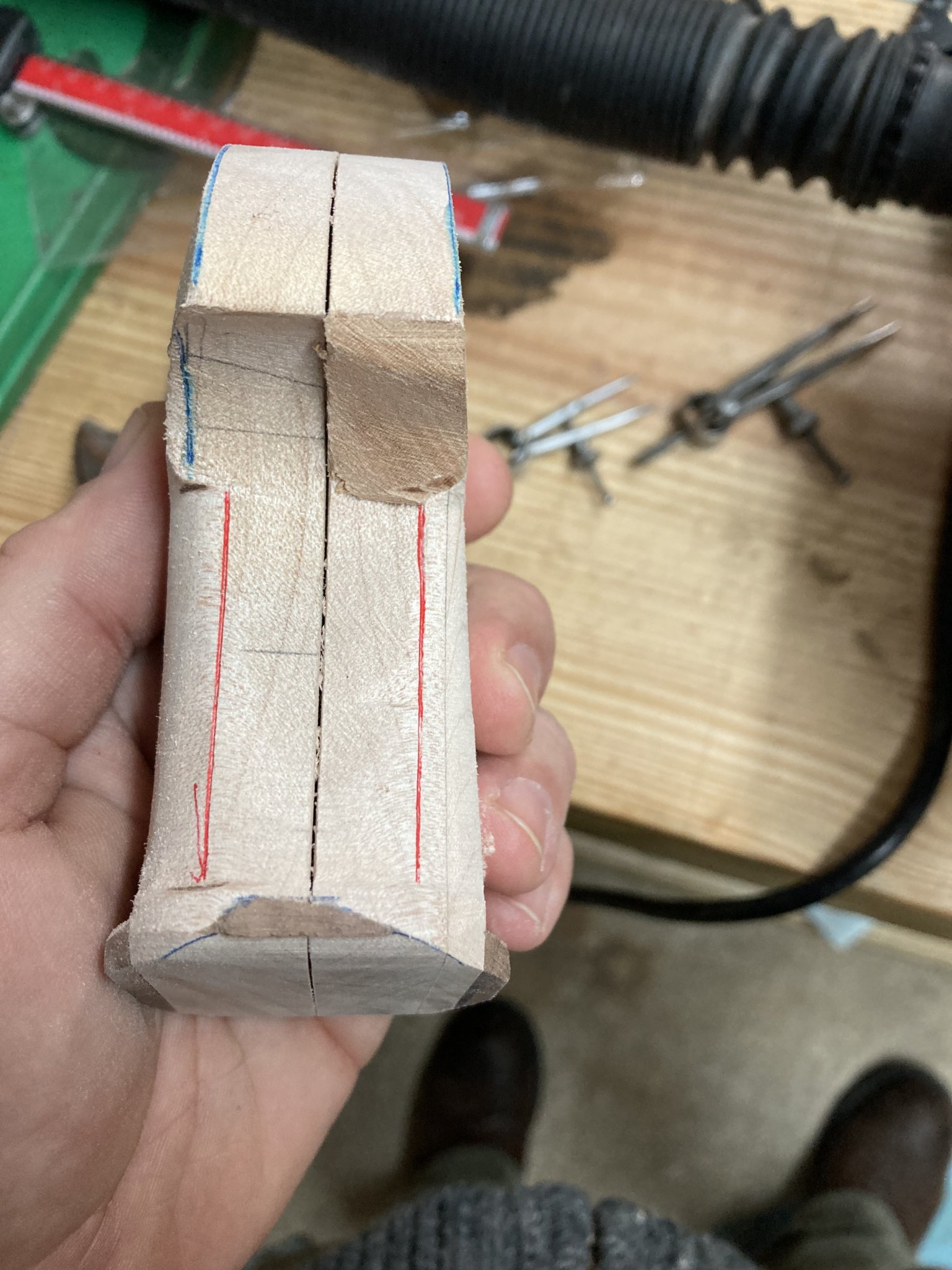

Working on a set of grips for a 6 foot double ended dildo.

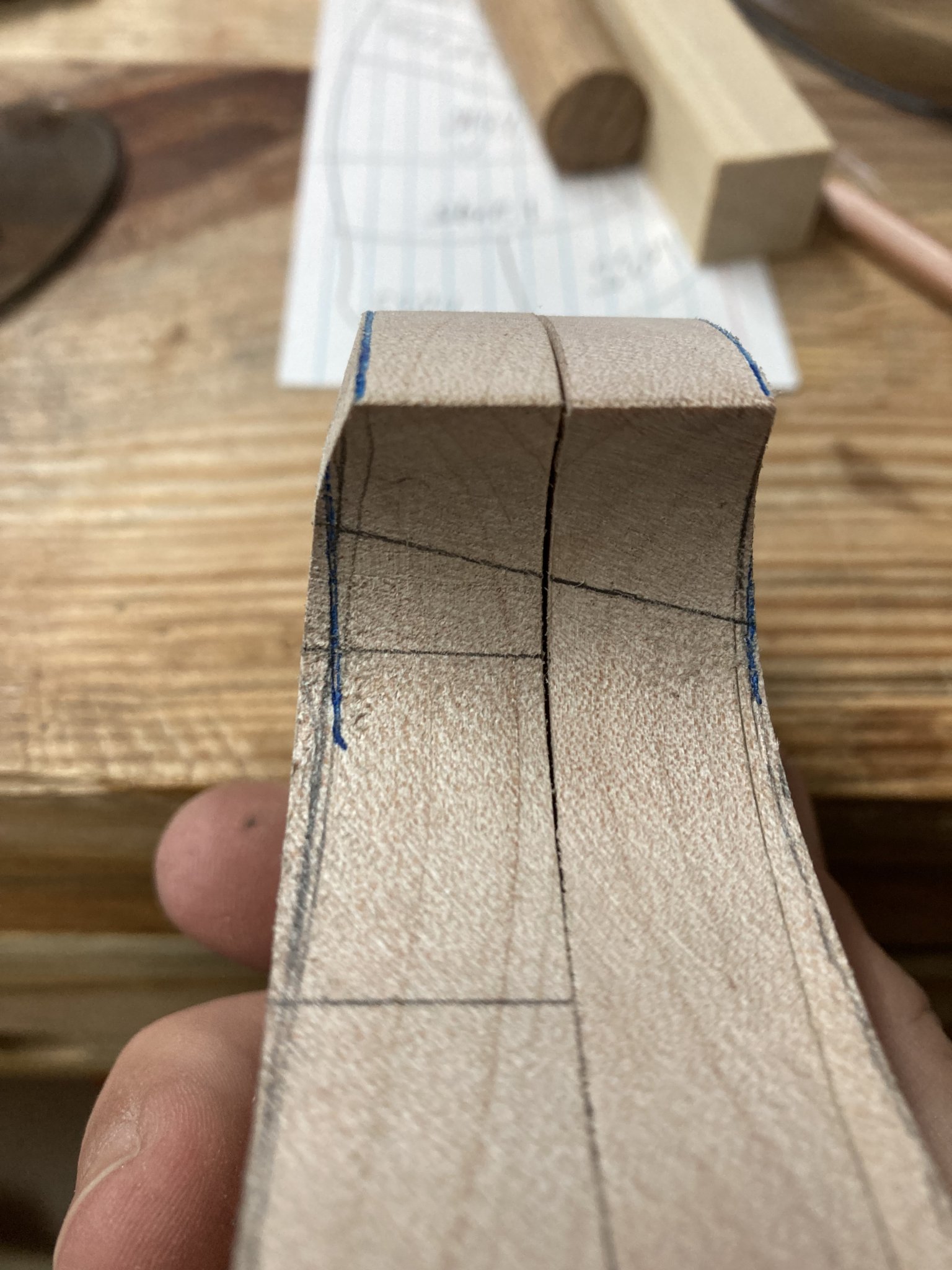

Damn taper. These are the thicknesses I have to hit as I taper the grips. Then I have to figure out a flare on the bottom which probably won’t be possible without adding some pieces to the bottom. Good thing these are the practice set!

Damn taper. These are the thicknesses I have to hit as I taper the grips. Then I have to figure out a flare on the bottom which probably won’t be possible without adding some pieces to the bottom. Good thing these are the practice set!

Last edited:

Alright guys, I have been asked the eternal question: what do you want for Christmas. Aside from more cigars, I need a quality hand saw. Like a plain design hand saw. But it needs to be good. The wood I use around here is typically oak, mesquite and pine. What do you recommend? I hate cheap quality hand tools so give me what you would get for yourself if the money was a secondary consideration.

I had some extra OT money so I ordered a couple re-makes of the classic Disston panel saws from Bad Axe Tool Works. Very nice. There are a couple places like Highland Woodworking that carry a limited selection in stock.

That said, I've always kind of wanted one of these 'hardware store saws' from Tools For Working Wood.

Ohhh my!Working on a set of grips for 6 foot double ended dildo.

View attachment 8271971

Damn taper. These are the thicknesses I have to hit as I taper the grips. Then I have to figure out a flare on the bottom which probably won’t be possible without adding some pieces to the bottom. Good thing these are the practice set!

View attachment 8271974

Those will be sweet when done.

These will look like pure unadulterated ass. Practice set 2 will look better, lol.Ohhh my!

Those will be sweet when done.

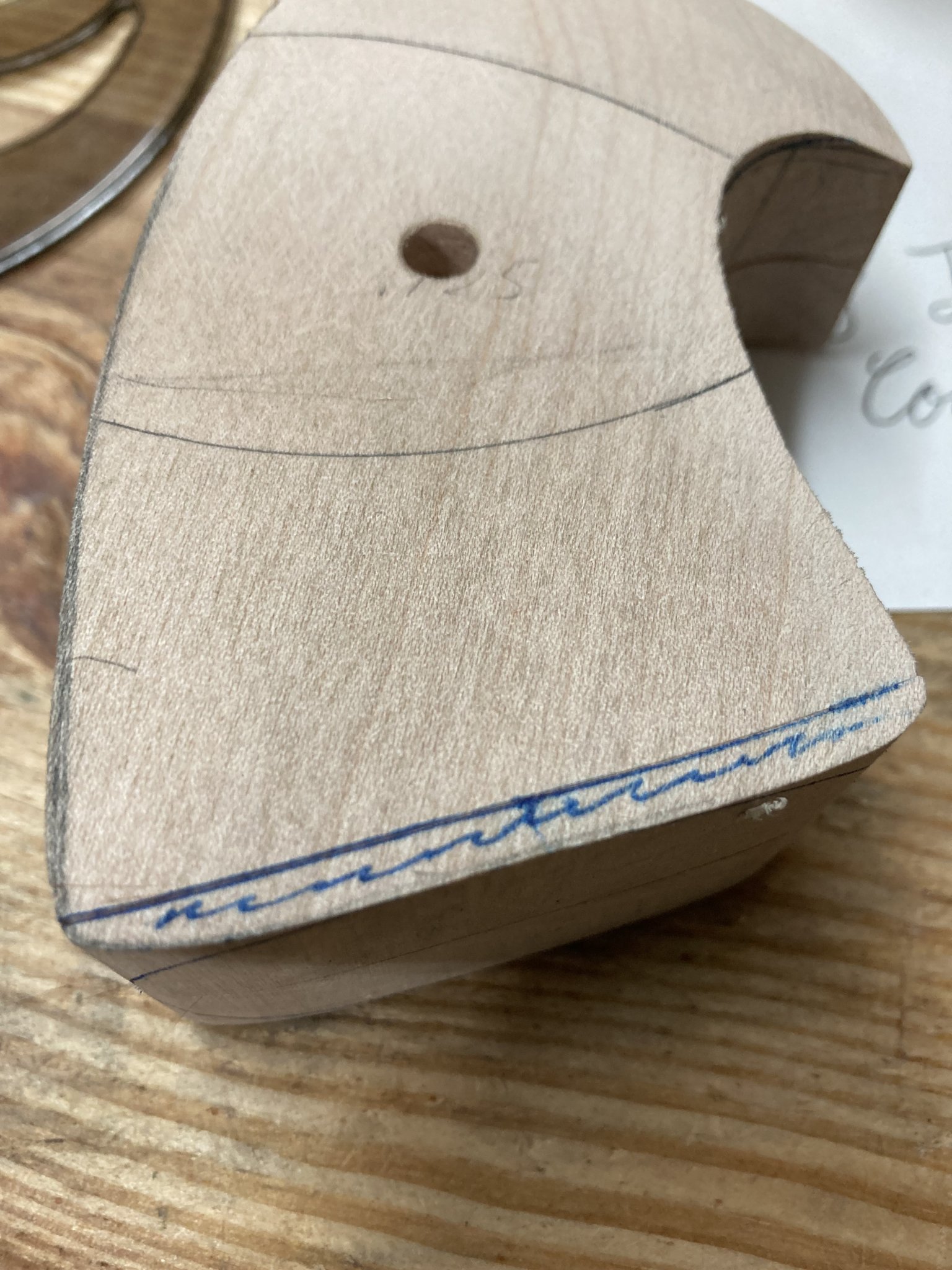

The big goof on these was not leaving enough meat on them to have a flare/palm shelf around the bottom while still hitting the other parameters. I might be able to pull it off on the these, but will probably have to glue some pieces on the bottom and blend them for the flare.

Fed as I much of the grip blanks to the belt sander as I could, and now it’s back to the rasps.

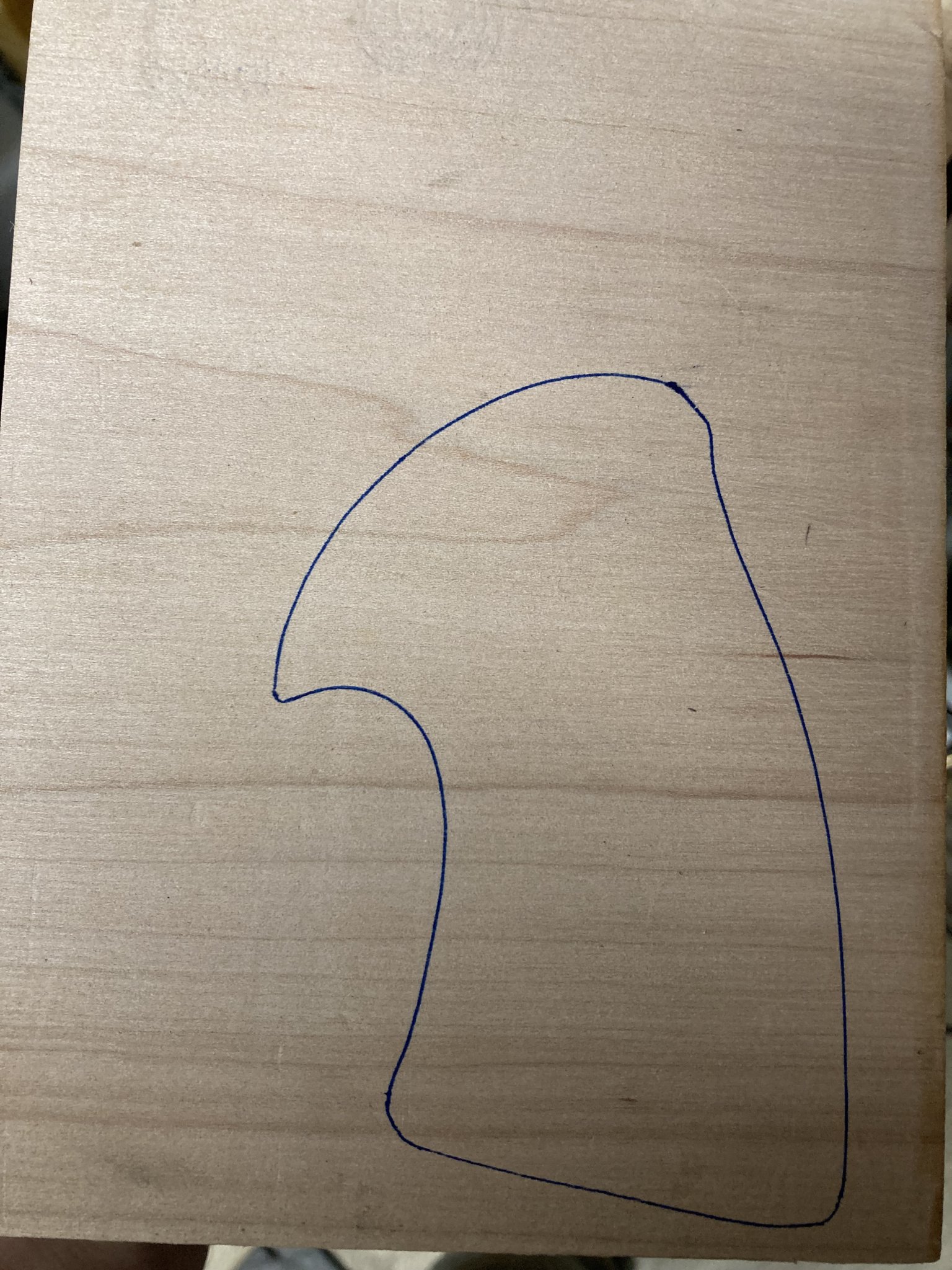

A fuck up below. The filler should slope downward from right to left to rest on the shooter’s middle finger I didn’t do that on this practice set because I’m an idiot. Might fill it in on one side with some epoxy wood filler or glue a wood spacer in there:

As you can see, the shelf is not resting on the middle finger at its natural slope. Now the shooter will have to adjust their grip to an unnatural grip:

This part is correct since it’s the right fit to the middle finger:

Another fuck up is I didn’t leave enough meat at the bottom for a palm shelf all around. I’ll glue some pieces on to add enough and shape them in. The blue scribble is where the shelf should be. You can also see where I outlined where the palm swell will be:

Rear profile of the palm swell for a right handed shooter. The left grip panel is really one straight taper from the top to the bottom of the grips. The right grip panel will have a palm swell:

Details matter, lol. Good thing these are a practice set.

A fuck up below. The filler should slope downward from right to left to rest on the shooter’s middle finger I didn’t do that on this practice set because I’m an idiot. Might fill it in on one side with some epoxy wood filler or glue a wood spacer in there:

As you can see, the shelf is not resting on the middle finger at its natural slope. Now the shooter will have to adjust their grip to an unnatural grip:

This part is correct since it’s the right fit to the middle finger:

Another fuck up is I didn’t leave enough meat at the bottom for a palm shelf all around. I’ll glue some pieces on to add enough and shape them in. The blue scribble is where the shelf should be. You can also see where I outlined where the palm swell will be:

Rear profile of the palm swell for a right handed shooter. The left grip panel is really one straight taper from the top to the bottom of the grips. The right grip panel will have a palm swell:

Details matter, lol. Good thing these are a practice set.

Attachments

Last edited:

Added some wood back and you can’t even tell I made a mistake @sirhrmechanic !

After a little rasp work:

Filler resting on the middle finger like it’s supposed to:

But now I see I needed to leave more wood on the right grip panel!

I’m going to move onto contouring the grips before I mess with the filler on the right grip panel.

Yippee prototypes!

After a little rasp work:

Filler resting on the middle finger like it’s supposed to:

But now I see I needed to leave more wood on the right grip panel!

I’m going to move onto contouring the grips before I mess with the filler on the right grip panel.

Yippee prototypes!

Last edited:

I see no mistakes... I just see awesome!Added some wood back and you can’t even tell I made a mistake @sirhrmechanic !

View attachment 8272738

After a little rasp work:

View attachment 8272739

Filler resting on the middle finger like it’s supposed to:

View attachment 8272740

But now I see I needed to leave more wood on the right grip panel! View attachment 8272741

I’m going to move onto contouring the grips before I mess with the filler on the right grip panel.

Yippee prototypes!

Cheers,

Sirhr

My humble addition. Love the pictures guys. Threw together a quick set of cornhole boards for camping.

Last edited:

More adventures in grip making.

Marking out contours:

Off the belt sander and now comes the rasp and file work:

Starting to look a lot like gripmas!

A little 180 grit:

Palm swell and front filler:

Next practice set:

Marking out contours:

Off the belt sander and now comes the rasp and file work:

Starting to look a lot like gripmas!

A little 180 grit:

Palm swell and front filler:

Next practice set:

Looks like you're getting there...

Looks a hell of a lot better than a grip that a top-name stock maker shipped me years ago.

Looks a hell of a lot better than a grip that a top-name stock maker shipped me years ago.

Nice guillotine, and yes I agree that every neighborhood needs one. As does a trebuchet. Actually, I believe every HOUSE needs a trebuchet.

Nice guillotine, and yes I agree that every neighborhood needs one. As does a trebuchet. Actually, I believe every HOUSE needs a trebuchet.

I was going to joke and say “What does it come with a Gateway for programming?”View attachment 8292309

My CNC has arrived and magically assembled itself... I think gnomes or elfs helped.

No I just have to figure out the small details like how to make it run.

Than I blew it up and saw the monitor is a Gateway.

This belongs in Vintage.

That shit is running windows 1!I was going to joke and say “What does it come with a Gateway for programming?”

Than I blew it up and saw the monitor is a Gateway.

This belongs in Vintage.

What drawing program will you use? What do you plan to make with it?Its an old standy-by monitor (cira 2001 on the back)

My new laptop arrives next weekend...

Bet he does dial up porn……

lol. Took over an hour to download a picture of a titty.

The brand is Carbide 3D and comes with their own software called Carbide Create and Carbide Motion.What drawing program will you use? What do you plan to make with it?

My goal is to make something like this pic but all wood.

For the love of big tits, please don’t use burnt hardware store lumber. Buy some nice wood…no homo.The brand is Carbide 3D and comes with their own software called Carbide Create and Carbide Motion.

My goal is to make something like this pic but all wood.

View attachment 8292507

Homo wood will only be for early trial and error... lots and lots of errors I suspect...

Then it'll be time to break out the good stuff...

And... I LIKE BOOBIES... big or little...

Then it'll be time to break out the good stuff...

And... I LIKE BOOBIES... big or little...

Keep us updated! Doesn’t look that difficult. A rectangle with foam inside, som drawer slides, and a rectangle attached on top.Homo wood will only be for early trial and error... lots and lots of errors I suspect...

Then it'll be time to break out the good stuff...

And... I LIKE BOOBIES... big or little...

Holly if you can find large enough pieces, and blood wood for the stripes. Not sure what to use for the blue part.

Could use cherry sapwood or lighter maple for the white stripes too.

Or curly maple dyed to the correct colors.

Damn it, now the wheels are turning.

When I was MSG in Liberia the country was just going to shit and we were on the eve of Sharp Edge.lol. Took over an hour to download a picture of a titty.

We were in the Marine House and we had some dude from the MEU staying with us that was the MIS guy for the MEU ops people. Dude was a computer POG.

We were in the Marine House one day and the Wackenfuck Guard showed up and told us there was a man at the gate with a brain.

We all ran out to check this out a dude had a brain figuring it was in a jar.

Dude had a computer.

We all ended up buying IBMs, I think they were 350SX or something like that.

I remember the computer POG at the house telling us we should have bought Gateways like we would have that option on back gate sales.

That IBM was the BOM in college.

Similar threads

Precision Rifle Gear

Can you use a Badger Ordnance Diving Board w/ Leupold MK4 rings?

- Replies

- 0

- Views

- 173