What do you all think of this old Mitutoyo dial set? My grandfather used this for a long time in automotive, and I'm trying to save where I can as I have dropped several thousand dollars in reloading equipment already.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Quick Shot Challenge: What’s the most underrated gear you never leave home without?

Contest ends Wednesday, join now for the chance to win free Hide merch!

Join contest

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This this vintage caliper set acceptable for measuring case dimensions?

- Thread starter idkwhativebeentold

- Start date

Absolutely and with style and panache!

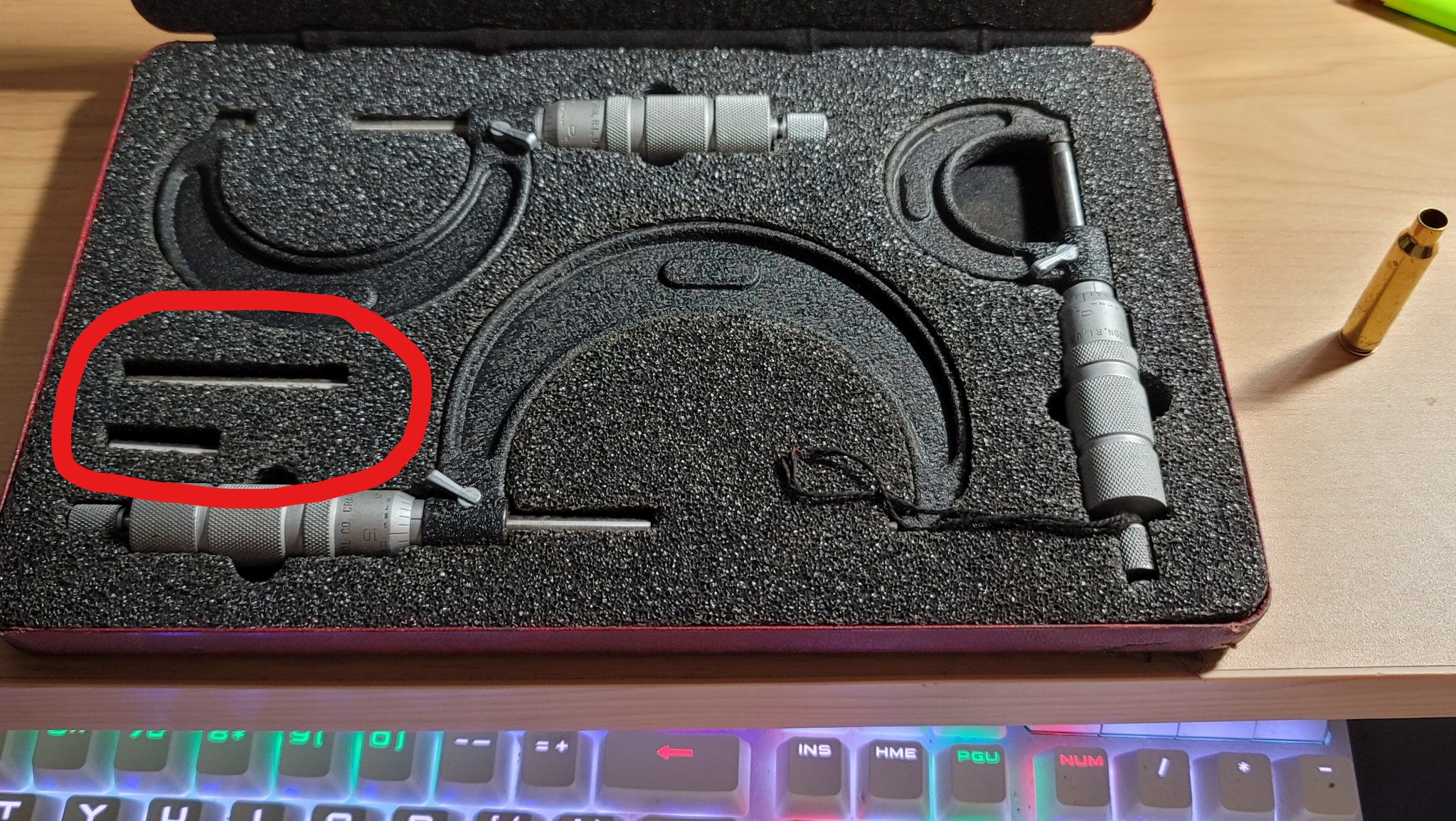

It sure is beautiful, and I'm proud to have been bestowed with all of his tools. I also have this Central Tool Co. gauge set, I was thinking I can check neck wall thickness but they aren't the ball type, what do you think?

Those OD mics will do fine for measuring neck diameter, case head diameter, bullet length, etc. You could use the 2-3" to measure case lengths.

The caliper is beautiful.

You'll be 10x ahead with the Mitutoyo over buying a cheap Harbor Freight or one of the other Chinese specials.

You'll be 10x ahead with the Mitutoyo over buying a cheap Harbor Freight or one of the other Chinese specials.

I used dial calipers at first left over from my machine shop days. . Had a nice set of mititoya 0-6. Dropped them on the floor one day. Broke. Bough a set of digital calipers, the nice thing about digital is when using the caparator you can set the 0 to the face of the insert. Becareful with them.

I use vintage Brown and Sharp calipers for my reloading. Have a bunch of them and IMO, the best calipers ever made.

I use some old mitutoyo dial calipers my grandfather had too, but they aren’t in as fancy of a case. They do have a certification sheet in Japanese though. They seem to work just fine for reloading

That is a pretty cool vintage caliper. Its almost undoubtedly better than the ones I currently use. People get wrapped around the axle with calipers for reloading. You don't really need a set that is super accurate. They just need to be repeatable.

You can do exactly the same thing with dial indicator calipers. That's what the bezel knob is for.I used dial calipers at first left over from my machine shop days...………………. the nice thing about digital is when using the caparator you can set the 0 to the face of the insert.

You worked in a machine shop and you don't know that?.

You can even insert the pin and make that new zero 12:00.You can do exactly the same thing with dial indicator calipers. That's what the bezel knob is for.

You worked in a machine shop and you don't know that?.

I dropped a cheap dial set I had and ruined them. I never used a dial set you couldn't rezero. My dad uses a vernier scale set that is probably older than those. You have to use your thinker reading them.

Last edited:

That is an awesome set of old Mitutoyo calipers. I use both dial and digital Mitutoyo's. Nothing that old, but I still prefer the dial. To me, a dial is easier to see small movements when making sure you have what your measuring flush against the jaws. Use them with pride!

Yes I do. You still have the 1 or 2 inches to subtract. I find just hitting the zero button easier , quicker.You can do exactly the same thing with dial indicator calipers. That's what the bezel knob is for.

You worked in a machine shop and you don't know that?.

I started out with vernier calipers. They are pretty much bomb proof.I dropped a cheap dial set I had and ruined them. I never used a dial set you couldn't rezero. My dad uses a veneer scale set that is probably older than those. You have to use your thinker reading them.

I like those .200 per rotation calipers. There was a reason for them....

Use with pride. I kept most of my tools when I switched fields, and have since gotten most of my dads tools when he was a tool maker.

Good stuff...

Use with pride. I kept most of my tools when I switched fields, and have since gotten most of my dads tools when he was a tool maker.

Good stuff...

You still have the 1 or 2 inches to subtract.

LOL...……….nope

I buy the older Mitys for my shop when I can because they are such higher quality tools. One thing, just to be sure I would take them somewhere like a machine shop that has a set of standards to ensure they are still calibrated. I wouldn’t send them off for the service, but look around for someone to verify that they are measuring true. One of the worst things is to trust a tool that is lying to you.

OR... just use the 1" and 2" standard that is included in the OD mics. You already have those. I bet they're even traceable. No need to spend more $$$..

Last edited:

OR... just use the 1" and 2" standard that is included in the OD mics. You already have those. I bet they're even traceable. No need to spend more $$$..

View attachment 7552594

Yep

Yea I have interapid indicators, surface gauges, full set of Starrett mics, bunch of other crap just sitting in the basement. I still get a wiff of coolant off the old tool box makes me want to vomit.I like those .200 per rotation calipers. There was a reason for them....

Use with pride. I kept most of my tools when I switched fields, and have since gotten most of my dads tools when he was a tool maker.

Good stuff...

Wait, you guys are using dials? I've just been using this. I'm out to 85 rods now.

Hell yeah! Great calipers. I'm torn on Mitutoyo or Starrett for my bougie set for reloading.What do you all think of this old Mitutoyo dial set? My grandfather used this for a long time in automotive, and I'm trying to save where I can as I have dropped several thousand dollars in reloading equipment already.

View attachment 7551612

If you're going to go nice go with the mitutoyo 500 series calipers. Available 0-6, 0-8, and 0-12.Hell yeah! Great calipers. I'm torn on Mitutoyo or Starrett for my bougie set for reloading.

View attachment 7552978

Personally have 0-6 and 0-12. Will do American and metric at the push of a button. They also don't forget where they are along the slide. Also safe to store with your guns down to 3' of water.

Use the shit out of them. I’m using my dad’s old Mit from when he went to A&P before I was born.What do you all think of this old Mitutoyo dial set? My grandfather used this for a long time in automotive, and I'm trying to save where I can as I have dropped several thousand dollars in reloading equipment already.

View attachment 7551612

If you guys like measuring tools check out this site I can read this shit for hours.

Professional repair service for test indicators, micrometers and other precision gages and small hand tools

Repair service for Interapid test indicators and other precision measuring gages by Brown & Sharpe and Mitutoyo.

I used dial calipers at first left over from my machine shop days. . Had a nice set of mititoya 0-6. Dropped them on the floor one day. Broke. Bough a set of digital calipers, the nice thing about digital is when using the caparator you can set the 0 to the face of the insert. Becareful with them.

You can zero out a dial too, C'mon man!

I run both analogue and digital measuring gear, The best part of traditional vernier and dial calipers and micrometers is that there are NO batteries to go flat in accordance with Murphy's law.What do you all think of this old Mitutoyo dial set? My grandfather used this for a long time in automotive, and I'm trying to save where I can as I have dropped several thousand dollars in reloading equipment already.

View attachment 7551612

As for "dropping" stuff: big oil-resistant rubber mats on the floor at benches and machines will save not only your expensive measuring toys but work-pieces and cutting tools as well as your feet. Standing on a concrete floor for extended time is not nice.

Last edited:

As soon as you drop a precision measuring instrument, it's not longer a precision measuring instrument. Throw it out and buy a new one, and be more careful with the next one.

Have multiple Mitys identical to yours and they perform perfectly. It is a precision instrument. It is not a hammer or pry bar. Take care of it. Treat it with care. It will serve you well.What do you all think of this old Mitutoyo dial set? My grandfather used this for a long time in automotive, and I'm trying to save where I can as I have dropped several thousand dollars in reloading equipment already.

View attachment 7551612

Early in my career. made a lot of money using Post VersaLogs like those........Wait, you guys are using dials? I've just been using this. I'm out to 85 rods now.

View attachment 7552828

Not always true. Many times they can be repaired for cheaper than a replacement. Unless you are using sub-par equipment to begin with.As soon as you drop a precision measuring instrument, it's not longer a precision measuring instrument. Throw it out and buy a new one, and be more careful with the next one.

But always re-qual if dropped to determine effect.

Stupidity should hurt. Whether it's physically, or monetarily.Not always true. Many times they can be repaired for cheaper than a replacement. Unless you are using sub-par equipment to begin with.

But always re-qual if dropped to determine effect.

Not when the gage you're using is over $900. Or when the gage has no moving parts. Or when you have a gage lab and all of the gages are serialized and almost everything is calibrated in house.As soon as you drop a precision measuring instrument, it's not longer a precision measuring instrument. Throw it out and buy a new one, and be more careful with the next one.

This. And the Average reloader should have a set of standards for this eventuality anyway. It will happen, even to the most careful users.Not when the gage you're using is over $900. Or when the gage has no moving parts. Or when you have a gage lab and all of the gages are serialized and almost everything is calibrated in house.

I recently bought a new pair of calipers from a reloading company due to an emergency. When I tested them they were off past 0.543” the rest of the way by 5 thou. Trust nothing. Verify everything. Especially when it involves controlled explosions around your face.

I would just never jack around my good calipers zero should be zero. My preference.You can zero out a dial too, C'mon man!

Precision tools require precision calibration and certification to be deemed accurate. Any old set of calipers or mic's that have not been professionally calibrated and certificated cannot be trusted for accuracy. They might be close but not dead nuts accurate. When working with stuff that goes "boom" you want to be accurate. Mitutoyo makes superb, extremely accurate, precision tools that come out of the box with an accuracy certificate, but they will all need to be periodically re-calibrated to certify accuracy. Once a year is a general requirement in engineering.

If you’re working with a caliper, you’re only ever worried about being +/-.002” accurate anyway.Precision tools require precision calibration and certification to be deemed accurate. Any old set of calipers or mic's that have not been professionally calibrated and certificated cannot be trusted for accuracy. They might be close but not dead nuts accurate. When working with stuff that goes "boom" you want to be accurate. Mitutoyo makes superb, extremely accurate, precision tools that come out of the box with an accuracy certificate, but they will all need to be periodically re-calibrated to certify accuracy. Once a year is a general requirement in engineering.

Are they any good? Hell yeah they are! They retain value too IIRC.

I thought it was funny, I clicked on this and I'll be damned if I don't use the same thing. Hard to tell whose is older. I got 'em old and well used in a pawn shop nearly thirty years ago. They've gotta be seventy years old, post WW2 stuff.

I have some shitty Frankford Arsenal ones I got some time back, cheap. They don't hold a candle to these. I dedicated those to Hornady gauges and I suppose they're good enough for that.

Do you have the little brass shim that comes with it? Or "pin" as he calls it? If not, maybe contact them for one or I can probably trace mine and mic the thickness and you could cut one from a feeler gauge. Anyway, that shim is what you use to slip the gears so you can calibrate it to zero when closed AND do that with the dial straight and not crooked. The thumbscrew is fine for little adjustments, etc., but you wanna be able to zero it properly too.

When you clean 'em, make sure to keep lint, dirt and shit out of the gears, also don't use a thick oil, it needs to be a super thin coat of a super thin oil, almost nothing at all. Just "clean" is best --there's a reason they came in that case and IMO/E that's the only part that should look well used on these. They stay in there and only come out when needed. If they were taken care of, you won't be able to tell how old they are other than "dated". Your Gramps obviously used the piss out of 'em, but obviously took great care of 'em too.

I thought it was funny, I clicked on this and I'll be damned if I don't use the same thing. Hard to tell whose is older. I got 'em old and well used in a pawn shop nearly thirty years ago. They've gotta be seventy years old, post WW2 stuff.

I have some shitty Frankford Arsenal ones I got some time back, cheap. They don't hold a candle to these. I dedicated those to Hornady gauges and I suppose they're good enough for that.

You can do exactly the same thing with dial indicator calipers. That's what the bezel knob is for.

You worked in a machine shop and you don't know that?.

You can even insert the pin and make that new zero 12:00.

Do you have the little brass shim that comes with it? Or "pin" as he calls it? If not, maybe contact them for one or I can probably trace mine and mic the thickness and you could cut one from a feeler gauge. Anyway, that shim is what you use to slip the gears so you can calibrate it to zero when closed AND do that with the dial straight and not crooked. The thumbscrew is fine for little adjustments, etc., but you wanna be able to zero it properly too.

When you clean 'em, make sure to keep lint, dirt and shit out of the gears, also don't use a thick oil, it needs to be a super thin coat of a super thin oil, almost nothing at all. Just "clean" is best --there's a reason they came in that case and IMO/E that's the only part that should look well used on these. They stay in there and only come out when needed. If they were taken care of, you won't be able to tell how old they are other than "dated". Your Gramps obviously used the piss out of 'em, but obviously took great care of 'em too.

Man, I miss my old circular slide rule.

Now as far as accuracy, most reloaders work in differences.

Precision and repeatability matters.

Many measures rely on instrument accuracy, and HUMAN FACTORS.

This neck diameter is different from this other neck diameter.

Or bump 0.002" from chamber measurement..

I trim my .223 cases to 1.760". I could be a few thousandths off (probably not).

Sameness is golden.

Relative Neck diameter before seating and after tells me a lot.

But if all are the SAME if probably don't matter none.

Sameness is golden.

A couple of check standards in your reloading lab would probably help.

Weight, length, diameter check standards NEAR your target values.

Now as far as accuracy, most reloaders work in differences.

Precision and repeatability matters.

Many measures rely on instrument accuracy, and HUMAN FACTORS.

This neck diameter is different from this other neck diameter.

Or bump 0.002" from chamber measurement..

I trim my .223 cases to 1.760". I could be a few thousandths off (probably not).

Sameness is golden.

Relative Neck diameter before seating and after tells me a lot.

But if all are the SAME if probably don't matter none.

Sameness is golden.

A couple of check standards in your reloading lab would probably help.

Weight, length, diameter check standards NEAR your target values.

Similar threads

- Replies

- 5

- Views

- 522

- Replies

- 8

- Views

- 592

- Replies

- 3

- Views

- 1K