Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Quick Shot Challenge: What’s the most underrated gear you never leave home without?

Contest ends Wednesday, join now for the chance to win free Hide merch!

Join contest

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Threading and chambering

- Thread starter jcmullis2

- Start date

You can't ream between centers thats why you have to indicate the bore for a prefect reamer cut.

I'll separate turning the breach tenon/threading from chambering.Is it better to work between centers when threading and chambering a barrel? If the reamer follows the bore does indicating really change anything?

You want the tenon to be concentric with the bore at the breech end. If you work between centers, the tenon you turn will be concentric to the imaginary line between the center of the bore of the muzzle and of the bore at the breech. If you work with a 4 jaw chuck and indicate from two points (usually referred to as the radial and axial alignment) via a long stylus DTI or range/grizzly rod - the tenon you turn will be concentric to the imaginary line between those two points (usually 1"-3" apart). Under the theory that best accuracy is achieved by closest alignment of the chamber to the throat of the barrel, then indicating from the bore at the breech end will result in better alignment.

As for chambering, if you use a floating reamer holder, then within the limitations of radial and axial "float" of the holder, the reamer will follow the bore. I would say though that far less chance of reamer chatter if the reamer doesn't have to wobble in the floating reamer holder in order to follow the bore. So, the more concentric the bore is to the lathe spindle, the better.

Mark Gordon of SAC does some of the best chambering using solid reaming.

So you use a 4 jaw with the stylus and indicate off it to cut your tenon. Are you using a floating reamer holder or a collet? Are you working through your head stock?I'll separate turning the breach tenon/threading from chambering.

You want the tenon to be concentric with the bore at the breech end. If you work between centers, the tenon you turn will be concentric to the imaginary line between the center of the bore of the muzzle and of the bore at the breech. If you work with a 4 jaw chuck and indicate from two points (usually referred to as the radial and axial alignment) via a long stylus DTI or range/grizzly rod - the tenon you turn will be concentric to the imaginary line between those two points (usually 1"-3" apart). Under the theory that best accuracy is achieved by closest alignment of the chamber to the throat of the barrel, then indicating from the bore at the breech end will result in better alignment.

As for chambering, if you use a floating reamer holder, then within the limitations of radial and axial "float" of the holder, the reamer will follow the bore. I would say though that far less chance of reamer chatter if the reamer doesn't have to wobble in the floating reamer holder in order to follow the bore. So, the more concentric the bore is to the lathe spindle, the better.

I was taught, in general, that between centers gives you the most concentricity. However a bunch of guys are using the stylus method and I didn’t know if it was because their lathe was too short or what the reason was. I can certainly see why people charge what they do for that with what they have to go through.

Every time I remove the stylus and put it back in its different. Not much but it changes. I’ll give it another try like you suggested and see what happens. Thanks buddy

Yep you’re right but it would be darn exciting while it lasted. I forgot to mention my steady rest. LolYou can't ream between centers thats why you have to indicate the bore for a prefect reamer cut.

PDF of chambering methods from accurate shooter

A worthwhile read if you’re getting started

I’ve watched a few videos of guys using the grizzly/ range rods, and another guy used a Dti on the inside of the bore. I’ve not had anything resembling success with repeatability using the range rod technique.

I thought I understood this concentricity thing. I was taught to work between centers when concentricity was critical. It seems like concentricity would be paramount threading and chambering so why use a technique that can only be as concentric if done perfectly each time. I might do a barrel or two a year so perfecting a more difficult technique isn’t likely.

Like you said, I’ll figure out the way that works best for me. It’s not like I’m trying to get into the barrel chambering business. I wasn’t satisfied with the through the head stock setup and my 4 jaw again. I’ll go ahead between centers on this one and maybe someone can explain how a 4 jaw and range rod consistently give better results over between centers. It just seems like a “work around solution” to a short bed or a short cut of some sort. It’ll be my barrels that’ll end up in the trash if things go south. I waited months for this barrel so I sure hope I don’t muck it up. Lol

I thought I understood this concentricity thing. I was taught to work between centers when concentricity was critical. It seems like concentricity would be paramount threading and chambering so why use a technique that can only be as concentric if done perfectly each time. I might do a barrel or two a year so perfecting a more difficult technique isn’t likely.

Like you said, I’ll figure out the way that works best for me. It’s not like I’m trying to get into the barrel chambering business. I wasn’t satisfied with the through the head stock setup and my 4 jaw again. I’ll go ahead between centers on this one and maybe someone can explain how a 4 jaw and range rod consistently give better results over between centers. It just seems like a “work around solution” to a short bed or a short cut of some sort. It’ll be my barrels that’ll end up in the trash if things go south. I waited months for this barrel so I sure hope I don’t muck it up. Lol

Pro tip. You only want the chamber concentric. You don't want the muzzle and chamber to be "concentric" in the way you think.

Get an old barrel, put 2 bricks on the ground, and place the barrel on it so one brick is under the muzzle, and one under the chamber. The barrel should be supported at each end.

Hit the middle of the barrel with a big hammer, or stand on it so you can put a bend in the barrel. If you were to lay the barrel on a flat surface and roll it, it should have a noticeable wobble or "lump" in it.

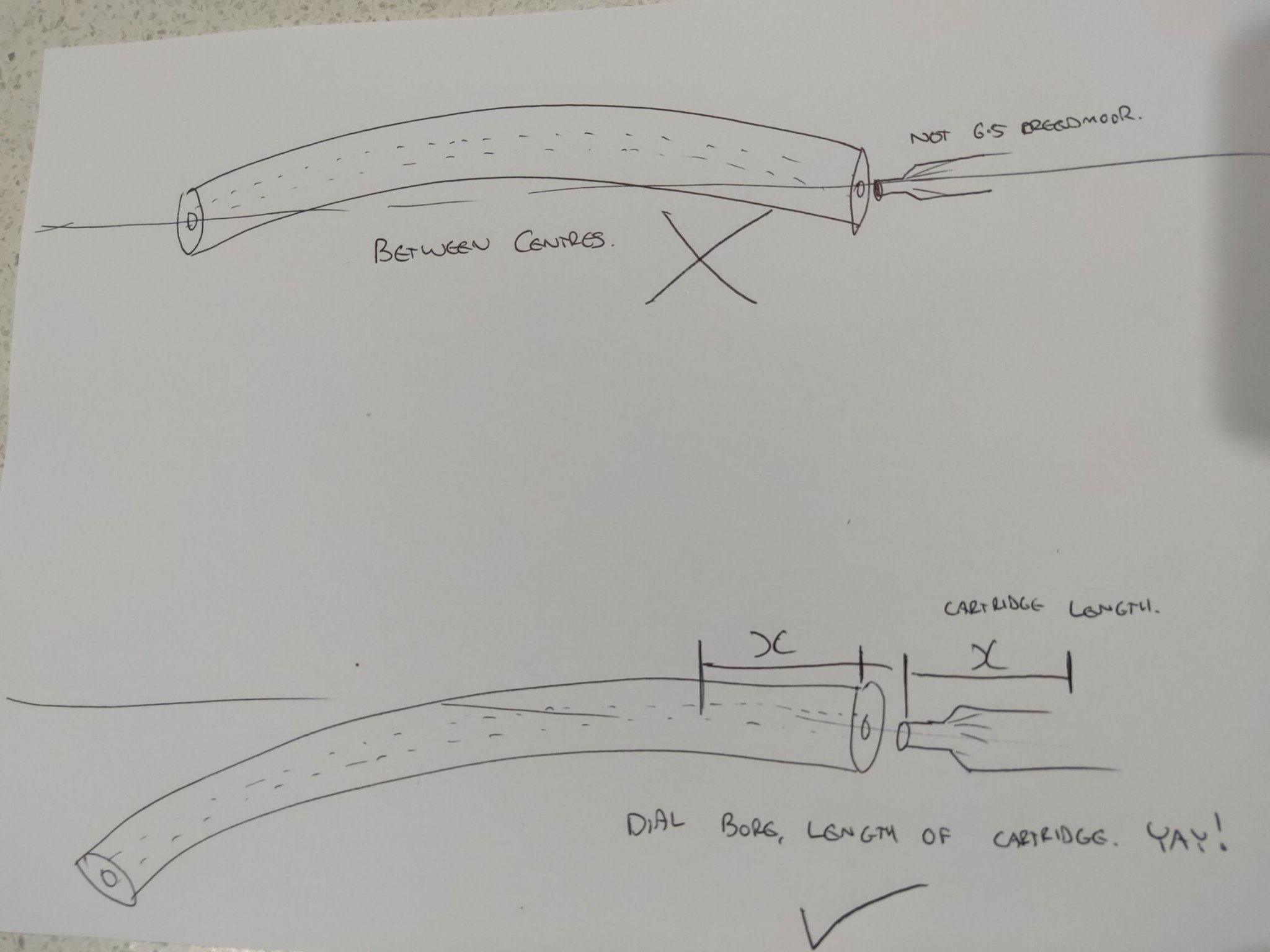

Now dial that up. 2 methods exist.

The first being dialling between centres. It may look ok at the chamber and muzzle, however because the barrel is bent, the reamer will go in as a cork screw.

Another method is to dial in the chamber end, and about 4" Infront of the chamber. This is the path the reamer will follow. The reamer will be concentric to the bore. This is desirable.

Here, have a shitty drawing.

Get an old barrel, put 2 bricks on the ground, and place the barrel on it so one brick is under the muzzle, and one under the chamber. The barrel should be supported at each end.

Hit the middle of the barrel with a big hammer, or stand on it so you can put a bend in the barrel. If you were to lay the barrel on a flat surface and roll it, it should have a noticeable wobble or "lump" in it.

Now dial that up. 2 methods exist.

The first being dialling between centres. It may look ok at the chamber and muzzle, however because the barrel is bent, the reamer will go in as a cork screw.

Another method is to dial in the chamber end, and about 4" Infront of the chamber. This is the path the reamer will follow. The reamer will be concentric to the bore. This is desirable.

Here, have a shitty drawing.

Maybe I’m expecting too much. After dialing in a couple of places on the grizzly rod maybe I shouldn’t remove it and then replace it to make certain the previous readings were correct. It’s always a slightly different reading when I do that. I’m not a machinist or gunsmith so I always measure at least twice.Pro tip. You only want the chamber concentric. You don't want the muzzle and chamber to be "concentric" in the way you think.

Get an old barrel, put 2 bricks on the ground, and place the barrel on it so one brick is under the muzzle, and one under the chamber. The barrel should be supported at each end.

Hit the middle of the barrel with a big hammer, or stand on it so you can put a bend in the barrel. If you were to lay the barrel on a flat surface and roll it, it should have a noticeable wobble or "lump" in it.

Now dial that up. 2 methods exist.

The first being dialling between centres. It may look ok at the chamber and muzzle, however because the barrel is bent, the reamer will go in as a cork screw.

Another method is to dial in the chamber end, and about 4" Infront of the chamber. This is the path the reamer will follow. The reamer will be concentric to the bore. This is desirable.

Here, have a shitty drawing.

View attachment 7666339

I’m pretty certain the reamer is gonna follow the bore unless it’s an extremely rigid reamer holding setup. However all bores are slightly banana shaped and slightly off center. The initial clean up turning between centers should cause the OD to be concentric to the bore/id.

Like I mentioned before I’m not an experienced Smitty so I’m asking for clarification more than making statements of fact.

You should just dump the grizzly rods. Even Gordy Gritters who popularized the grizzly/range rod says that they're good for rough dialing a bore in, not for final dial which should be done with a long reach indicator.

It appears you haven't read the 130 page PDF with a bunch of high profile gunsmiths saying how and why they do their process, its worth the time to read it all - a bunch of your questions are answered in there multiple times (and with different solutions).

It appears you haven't read the 130 page PDF with a bunch of high profile gunsmiths saying how and why they do their process, its worth the time to read it all - a bunch of your questions are answered in there multiple times (and with different solutions).

The reamer can act as a center. Some people actually use this method and have the barrel floating in the steady rest.You can't ream between centers thats why you have to indicate the bore for a prefect reamer cut.

Did you get those drawings off the Peyronie's Barrel site ?Pro tip. You only want the chamber concentric. You don't want the muzzle and chamber to be "concentric" in the way you think.

Get an old barrel, put 2 bricks on the ground, and place the barrel on it so one brick is under the muzzle, and one under the chamber. The barrel should be supported at each end.

Hit the middle of the barrel with a big hammer, or stand on it so you can put a bend in the barrel. If you were to lay the barrel on a flat surface and roll it, it should have a noticeable wobble or "lump" in it.

Now dial that up. 2 methods exist.

The first being dialling between centres. It may look ok at the chamber and muzzle, however because the barrel is bent, the reamer will go in as a cork screw.

Another method is to dial in the chamber end, and about 4" Infront of the chamber. This is the path the reamer will follow. The reamer will be concentric to the bore. This is desirable.

Here, have a shitty drawing.

View attachment 7666339

Pro tip. Many people are probably bending barrels when working between spiders to try to get a "straight section" of bore for the chamber. A relatively small diameter bar being jacked around between two points about 20" apart is a recipe for a false sense of security.Pro tip. You only want the chamber concentric. You don't want the muzzle and chamber to be "concentric" in the way you think.

Get an old barrel, put 2 bricks on the ground, and place the barrel on it so one brick is under the muzzle, and one under the chamber. The barrel should be supported at each end.

Hit the middle of the barrel with a big hammer, or stand on it so you can put a bend in the barrel. If you were to lay the barrel on a flat surface and roll it, it should have a noticeable wobble or "lump" in it.

Now dial that up. 2 methods exist.

The first being dialling between centres. It may look ok at the chamber and muzzle, however because the barrel is bent, the reamer will go in as a cork screw.

Another method is to dial in the chamber end, and about 4" Infront of the chamber. This is the path the reamer will follow. The reamer will be concentric to the bore. This is desirable.

Here, have a shitty drawing.

Wonder if anyone has gone back to check their "straight bore/straight chamber" when the barrel is free hanging from the threaded tenon? Wonder if anyone has even gone back and verified their "timed muzzle end" is still at TDC when free hanging from the threaded tenon?

Damn good read thanks! I just learned a lot about chambering so now I can ask questions to possible smiths down the road to make sure I’m getting the work done properly.

PDF of chambering methods from accurate shooter

A worthwhile read if you’re getting started

I was warned that grizzly rods aren’t repeatable by my barrel cutting mentor.Maybe I’m expecting too much. After dialing in a couple of places on the grizzly rod maybe I shouldn’t remove it and then replace it to make certain the previous readings were correct. It’s always a slightly different reading when I do that. I’m not a machinist or gunsmith so I always measure at least twice.

I’m pretty certain the reamer is gonna follow the bore unless it’s an extremely rigid reamer holding setup. However all bores are slightly banana shaped and slightly off center. The initial clean up turning between centers should cause the OD to be concentric to the bore/id.

Like I mentioned before I’m not an experienced Smitty so I’m asking for clarification more than making statements of fact.

That’s why I use a long stem indicator.

It wasn’t cheap but it was definitely worth it.

I got kinda lucky as when I bought it MSC had them on sale.

All good points that experienced Smith's know about. There's loads of "secret" techniques they use, you just have to find a way to give you consistent repeatable results for the job at hand.Pro tip. Many people are probably bending barrels when working between spiders to try to get a "straight section" of bore for the chamber. A relatively small diameter bar being jacked around between two points about 20" apart is a recipe for a false sense of security.

Wonder if anyone has gone back to check their "straight bore/straight chamber" when the barrel is free hanging from the threaded tenon? Wonder if anyone has even gone back and verified their "timed muzzle end" is still at TDC when free hanging from the threaded tenon?

I’ve found the best method for myself is to dial in a point just in front of the throat and the muzzle and prebore. Some of these guys have probably forgotten more than I’ll ever know though.

You’re right. I’ll locate a copy of it and give it a read. I have a long tip for my dti so no problem giving that a go. I’d like to be able to get the same reading when I re-check everything. Old school sayings like, measure twice & cut once are great rules of thumb when what you’re cutting really matters. Thanks brother for your helpYou should just dump the grizzly rods. Even Gordy Gritters who popularized the grizzly/range rod says that they're good for rough dialing a bore in, not for final dial which should be done with a long reach indicator.

It appears you haven't read the 130 page PDF with a bunch of high profile gunsmiths saying how and why they do their process, its worth the time to read it all - a bunch of your questions are answered in there multiple times (and with different solutions).

Is it better to work between centers when threading and chambering a barrel? If the reamer follows the bore does indicating really change anything?

How are you going to do any ID work between centers? Think about it.

Yes, you can thread between centers. As long as the centers are in line it saves the time to indicate the bore in.

I’m glad you weighed in 308pirate. You’re right. I wasn’t clear. My thoughts were this, after cleanup passes to get the od concentric to the bore, bring in the steady rest and cut & thread the tenon. Remove the center, slide the steady rest closer to the tail for added support and use the reamer like a center.How are you going to do any ID work between centers? Think about it.

Yes, you can thread between centers. As long as the centers are in line it saves the time to indicate the bore in.

That’s what I think might be best with my limited skill set anyway. I ordered a gunsmithing barrel from green mountain last night to practice on before I get back to the more expensive stuff.

I’m glad you weighed in 308pirate. You’re right. I wasn’t clear. My thoughts were this, after cleanup passes to get the od concentric to the bore, bring in the steady rest and cut & thread the tenon. Remove the center, slide the steady rest closer to the tail for added support and use the reamer like a center.

That’s what I think might be best with my limited skill set anyway. I ordered a gunsmithing barrel from green mountain last night to practice on before I get back to the more expensive stuff.

There are gunsmiths that do it exactly that way but its definitely not considered best practice by the accuracy crowd. I've actually tested how close the pre-drilled center is to the bore and it can be out a lot. I measured up to 5 thou. The additional problem is that this method can't fix the problem if it exists, nor can it handle curvature in the barrel as previously mentioned.

Is there any reason you can't work through the headstock on your lathe? This is definitely the preferred way to do it by 99% of gunsmiths if possible. Not just because it improves your ability to dial in, but because its one less step of turning OD to (sort of) ID, then having to remove it and re-dial the OD in yet again.

The reamer IS the center.How are you going to do any ID work between centers? Think about it.

Yes, you can thread between centers. As long as the centers are in line it saves the time to indicate the bore in.

I could work through my head stock but I haven’t been able to get repeatable results using rods in the bore to indicate off.There are gunsmiths that do it exactly that way but its definitely not considered best practice by the accuracy crowd. I've actually tested how close the pre-drilled center is to the bore and it can be out a lot. I measured up to 5 thou. The additional problem is that this method can't fix the problem if it exists, nor can it handle curvature in the barrel as previously mentioned.

Is there any reason you can't work through the headstock on your lathe? This is definitely the preferred way to do it by 99% of gunsmiths if possible. Not just because it improves your ability to dial in, but because its one less step of turning OD to (sort of) ID, then having to remove it and re-dial the OD in yet again.

I bought a inexpensive practice barrel to help me figure out what method works best with my skills and such.

Are you suggesting he chuck the muzzle and then use no support except for a reamer in the tailstock 24 inches away? Please take a video of that being done so I can watch the hilarity that is sure to ensue...The reamer IS the center.

I could work through my head stock but I haven’t been able to get repeatable results using rods in the bore to indicate off.

I bought a inexpensive practice barrel to help me figure out what method works best with my skills and such.

Do you have -any- dial test indicator at all? You're going to need -something- to get reasonable results.

If you're counting on the barrel's factory center cut to "dial you in" - you might as well just do that 3 inches from the headstock and then clamp the barrel down in the 4 jaw. That way you don't have to cut the outside and then try and re-dial it it in in a steady rest. But again - using the center on the barrel as your dial in point is unlikely to yield you the results you're hoping for. I don't mean to be negative nancy here, just trying to save you a barrel (even a cheap one).

There is a reason people talk about the OD of a barrel not being centered, nor coaxial with the bore. Even on high end barrels.

Lmmfao. I knew what he meant, at least I think I did.Are you suggesting he chuck the muzzle and then use no support except for a reamer in the tailstock 24 inches away? Please take a video of that being done so I can watch the hilarity that is sure to ensue...

I was talking about between centers but I did see a YouTube video of a guy using an adjustable 3 jaw. The muzzle was in the chuck, the steady rest near the tail stock and the reamer in a floating holder in the tail stock. Then he showed the Damn thing shoouting 1 ragged hole groups.

A Mitutoyo 513-504 dial indicator that reads in .0001 is only $128 on amazon prime (at lot cheaper than a long reach interapid). With this alone you can at least reach .375 into both bore and muzzle for working through the headstock. If you do the "dial both ends in" method and forget about the bore curvature (or look at .375's woth of curve), I'll claim your results are going to be significantly better than trying to use the barrel center.

While we're at it though - do you have a depth mic to be able to check headspace? Mitutoyo 128-105 is $103 bucks amazon.

I can't imagine trying to do anything with <=.001 precision for barrel work on the lathe without these two tools as a bare minimum.

While we're at it though - do you have a depth mic to be able to check headspace? Mitutoyo 128-105 is $103 bucks amazon.

I can't imagine trying to do anything with <=.001 precision for barrel work on the lathe without these two tools as a bare minimum.

Lmmfao. I knew what he meant, at least I think I did.I don’t care how big your lathe is, with that much space between support you gotta use a rest.

I was talking about between centers but I did see a YouTube video of a guy using an adjustable 3 jaw. The muzzle was in the chuck, the steady rest near the tail stock and the reamer in a floating holder in the tail stock. Then he showed the Damn thing shoouting 1 ragged hole groups.

Right- but think about the setup you just described. The reamer can't be a rigid center (no floating holder) unless you've got no other support on the barrel. If you turn the OD like you initially describe, now the reamer isn't a center - the barrel is centered by the OD, the reamer is nominally following the bore, but you better use a floating reamer holder to account for any discrepency in ID/OD alignment.

In addition you now have the OD of the muzzle in a 3 jaw (lets assume your 3 jaw is perfect), have you also turned the OD of the tapered muzzle to match the ID of the muzzle? If you're turning a flat there, you're gonna have to cut it off later unless or it will look goofy, how are you going to get the muzzle dialed in after you've cut off the OD flat you were using?

I'm not saying it can't be done - there are a bunch of gunsmiths who still do it this way and have a specific process they use to do it. I'm saying for $129 to buy a single DTI (link above) you can save a lot of time/hassle and get better results since your lathe is capable of chambering through the headstock.

Hell - save the money on the green mountain blank, spend it on the DTI instead and i'll send you a used barrel blank to practice on.

Unfortunately I have decent tools so I won’t have that for an excuse. I have an old starrett dti with long tip and a holder that rocks like a seesaw. One end in the bore the other rocking on the dti to provide my reading. I’ll see if I like the results I get that way.Do you have -any- dial test indicator at all? You're going to need -something- to get reasonable results.

If you're counting on the barrel's factory center cut to "dial you in" - you might as well just do that 3 inches from the headstock and then clamp the barrel down in the 4 jaw. That way you don't have to cut the outside and then try and re-dial it it in in a steady rest. But again - using the center on the barrel as your dial in point is unlikely to yield you the results you're hoping for. I don't mean to be negative nancy here, just trying to save you a barrel (even a cheap one).

There is a reason people talk about the OD of a barrel not being centered, nor coaxial with the bore. Even on high end barrels.

I don't personally do it this way, but plenty of people do, and do so successfully.Are you suggesting he chuck the muzzle and then use no support except for a reamer in the tailstock 24 inches away? Please take a video of that being done so I can watch the hilarity that is sure to ensue...

To do it "between centers" without a floating reamer holder, you hold the reamer rigid and float the barrel instead. Relieve the steady rest a bit so the barrel can do what it needs to do, but is close enough to catch it when you pull out the reamer.Right- but think about the setup you just described. The reamer can't be a rigid center (no floating holder) unless you've got no other support on the barrel. If you turn the OD like you initially describe, now the reamer isn't a center - the barrel is centered by the OD, the reamer is nominally following the bore, but you better use a floating reamer holder to account for any discrepency in ID/OD alignment.

In addition you now have the OD of the muzzle in a 3 jaw (lets assume your 3 jaw is perfect), have you also turned the OD of the tapered muzzle to match the ID of the muzzle? If you're turning a flat there, you're gonna have to cut it off later unless or it will look goofy, how are you going to get the muzzle dialed in after you've cut off the OD flat you were using?

I'm not saying it can't be done - there are a bunch of gunsmiths who still do it this way and have a specific process they use to do it. I'm saying for $129 to buy a single DTI (link above) you can save a lot of time/hassle and get better results since your lathe is capable of chambering through the headstock.

Hell - save the money on the green mountain blank, spend it on the DTI instead and i'll send you a used barrel blank to practice on.

The fella uses a floating reamer holder. Check it outRight- but think about the setup you just described. The reamer can't be a rigid center (no floating holder) unless you've got no other support on the barrel. If you turn the OD like you initially describe, now the reamer isn't a center - the barrel is centered by the OD, the reamer is nominally following the bore, but you better use a floating reamer holder to account for any discrepency in ID/OD alignment.

In addition you now have the OD of the muzzle in a 3 jaw (lets assume your 3 jaw is perfect), have you also turned the OD of the tapered muzzle to match the ID of the muzzle? If you're turning a flat there, you're gonna have to cut it off later unless or it will look goofy, how are you going to get the muzzle dialed in after you've cut off the OD flat you were using?

I'm not saying it can't be done - there are a bunch of gunsmiths who still do it this way and have a specific process they use to do it. I'm saying for $129 to buy a single DTI (link above) you can save a lot of time/hassle and get better results since your lathe is capable of chambering through the headstock.

Hell - save the money on the green mountain blank, spend it on the DTI instead and i'll send you a used barrel blank to practice on.

To do it "between centers" without a floating reamer holder, you hold the reamer rigid and float the barrel instead. Relieve the steady rest a bit so the barrel can do what it needs to do, but is close enough to catch it when you pull out the reamer.

I can believe it could be done, but certainly not my first, or even 3rd choice!

I think everyone finds the way that works best for them and their skills and equipment. The results are what matters most and if you watch the videos you’ll see his way worked great for him although it wouldn’t even be a third choice for many people.I can believe it could be done, but certainly not my first, or even 3rd choice!

I can believe it could be done, but certainly not my first, or even 3rd choi

What are the faults with it?

To do it "between centers" without a floating reamer holder, you hold the reamer rigid and float the barrel instead. Relieve the steady rest a bit so the barrel can do what it needs to do, but is close enough to catch it when you pull out the reamer.

I haven’t been able to find any. I’m glad you responded because you understand what I’m talking about. Did you have inconsistent numbers using indicating rods in the bore also? If it wasn’t $400 of my money and weeks of waiting for another barrel I’d let chips fall where they fall. Maybe I should just volunteer and help the local gunsmith clear his backlog of barrel jobs.What are the faults with it?

That's not turning between centers.To do it "between centers" without a floating reamer holder, you hold the reamer rigid and float the barrel instead. Relieve the steady rest a bit so the barrel can do what it needs to do, but is close enough to catch it when you pull out the reamer.

I think we all know what we mean by "between centers". One end either in a center and driven by a dog or in a chuck and the other end outside the headstock.That's not turning between centers.

Exactly. It's for OD work.I think we all know what we mean by "between centers". One end either in a center and driven by a dog or in a chuck and the other end outside the headstock.

I don't personally use that method, but I don't really see any faults with it (I may have argued otherwise years ago, but I've gained much experience since then).I haven’t been able to find any. I’m glad you responded because you understand what I’m talking about. Did you have inconsistent numbers using indicating rods in the bore also? If it wasn’t $400 of my money and weeks of waiting for another barrel I’d let chips fall where they fall. Maybe I should just volunteer and help the local gunsmith clear his backlog of barrel jobs.

But you can ream a chamber with no external support at the breech end.Exactly. It's for OD work.

That's not turning between centers.

A bunch of guys said to use the rods. When I asked how to get repeatable readings with rods, I heard indicate a couple of spots in the bore. What do you do and what do you see as possible problem in the way I said.I think we all know what we mean by "between centers". One end either in a center and driven by a dog or in a chuck and the other end outside the headstock.

I work through the head stock and use a long stem interapid to dial it in.I could work through my head stock but I haven’t been able to get repeatable results using rods in the bore to indicate off.

I bought a inexpensive practice barrel to help me figure out what method works best with my skills and such.

I indicate the lands at the rear and also in the future throat area, on long cartridges I pre bore a bit so I can get the indicator where I want.

Are you using the wedge in rods or the rods with bushings that you hold one end rigidly in the tail stock.

The latter have a good reputation, the former are for joe blow wanting easy setup.

Are you talking about the tapered caliber specific rods, or the long rod held in a chuck at one end and a bushing in the bore at the other?A bunch of guys said to use the rods. When I asked how to get repeatable readings with rods, I heard indicate a couple of spots in the bore. What do you do and what do you see as possible problem in the way I said.

I won't go into the method I currently use since it is machine specific, and honestly, not very practical for most. I do recommend people be cautions about getting too hung up on how the internet says to chamber a barrel. Look at all the ways people are doing it, and choose what makes the most sense to you. You're method should be repeatable, as you are finding some aren't.

I call bullshit on that.You should just dump the grizzly rods. Even Gordy Gritters who popularized the grizzly/range rod says that they're good for rough dialing a bore in, not for final dial which should be done with a long reach indicator.

If he feels he now has a better method, so be it. But, it obviously "works", and works just fine.

Try dialing in the throat for a long magnum with an Interapid.

Ain't happening unless you can strap it to yo dick and run it that far up the bore

I've used mine, don't like that method, and went back to the rod.

I intentionally use an undersize pilot with Grizzly rods. I want the bushing to just ride the bottom center of the bore. I sling a weight (cut-off barrel shank) from the rod just ahead of the barrel to keep downward tension on it.

At the end of the day, the indicator and borescope don't lie. Zero runout, and borescope confirming perfectly concentric throat means it's "right"- no matter how anyone gets there.

So here's the thing- I honestly don't care what anyone says- the vast majority of "what works best" is subjective.

Nothing related to the barrel chambering process can be replicated under tightly controlled conditions.

Because every barrel is different, and once you cut a chamber in it, it's done- using a different method, on a different barrel, won't tell you shit when it comes to the minutiae we all seem to love discussing.

Plenty of record-setting rifles have been chambered between centers- and I could post up some links from some major, well-known players that do it this way today- paying no attention to the "my way is the best way" noise.

Just understand the objectives, the geometries involved, and decide how you want to get there.

Get a cheapo GM blank, chamber it- then check your results. If you have runout, or the throat isn't concentric, try to understand what you may have done wrong in your setup.

Soooo much exaggeration, bores that look like fucking bananas... I don't buy into any of it.

QUALITY blanks are lapped, inspected/AIR GAUGED to consistency of no more than .0001.

Flame suit on. I'm getting old and don't give a fuck

Similar threads

- Replies

- 10

- Views

- 679