Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do in the reloading room today?

- Thread starter Kisssofdeath

- Start date

I disposed my Varget Powder which was in my Autotrickler inside my Retumbo powder pot...

That's what I did today...

?

I dumped 1/3 Lb of Varget into a Varget tin I pulled out to dump garbage mix powder in. It wasn't much but I am butthurt a bit. Boot move for sure.

I made my first, tiny baby step toward reloading today. My reloading “room”, for now, is just a bench in my garage. I measured and cut some 2x6 board into pieces to make a mount for my press. This is not an ideal or good looking mount by any stretch of any imagination, but it will be sturdy. I may get some time tonight to work on the pieces some more of my little monsters go to bed in a timely fashion(bwaaaahahaha!). I’ll at least get to mark and maybe drill some holes tomorrow then get the needed hardware sometime this week. I have quite a lot of work to do before I fire my first homemade round. But, the journey of eating an elephant begins with a first step... Or something like that

I might have sat around thinking how fast a Dillion 650 could turn all this 223 brass into ammo.

that really Is a slick machine!Getting used to the ins and outs of this machine

I might have sat around thinking how fast a Dillion 650 could turn all this 223 brass into ammo.

I really want to get a 550 someday.

I have loaded a lot of pistol ammo on me Lee Loadmaster. Around the 20k mark, but at the end of the day. I look at it and all I see is 200 dollars that could have went toward a Dillon progressive machine.

I’m still rocking my Lee Classic Turret.I have loaded a lot of pistol ammo on me Lee Loadmaster. Around the 20k mark, but at the end of the day. I look at it and all I see is 200 dollars that could have went toward a Dillon progressive machine.

I maybe load 1000 rounds of pistol a year though and that’s definitely a factor.

I have a turret head with a case actvated through Expander powder drop.

That vastly helps on a turret with pistol.

If I loaded more I’m sure I wouldn’t have pony’s up for the blue kool aid.

35 nosler 140rdfs RL16 seating 10 thousands deeper with each set of 5.

I WILL get these to group, damnit.

I WILL get these to group, damnit.

Last bunch of those I shot I jump something like .08 and they loved it.35 nosler 140rdfs RL16 seating 10 thousands deeper with each set of 5.

I WILL get these to group, damnit.

I have 2 sets of 3 rounds one 2 and 5 thousands off and then 5 shot groups at 10 thousands off until I get to 70 off.

Well.. I got an old Bonanza co ax delivered yesterday, So it begins! Waiting on more deliveries and then to set up an area in the shop to start rollin my own again. Keeping it simple. A press, a scale, trickler, and tooling...lol

And I just thought of the perfect little project for the shop today! Will report back later.

And I just thought of the perfect little project for the shop today! Will report back later.

Last edited:

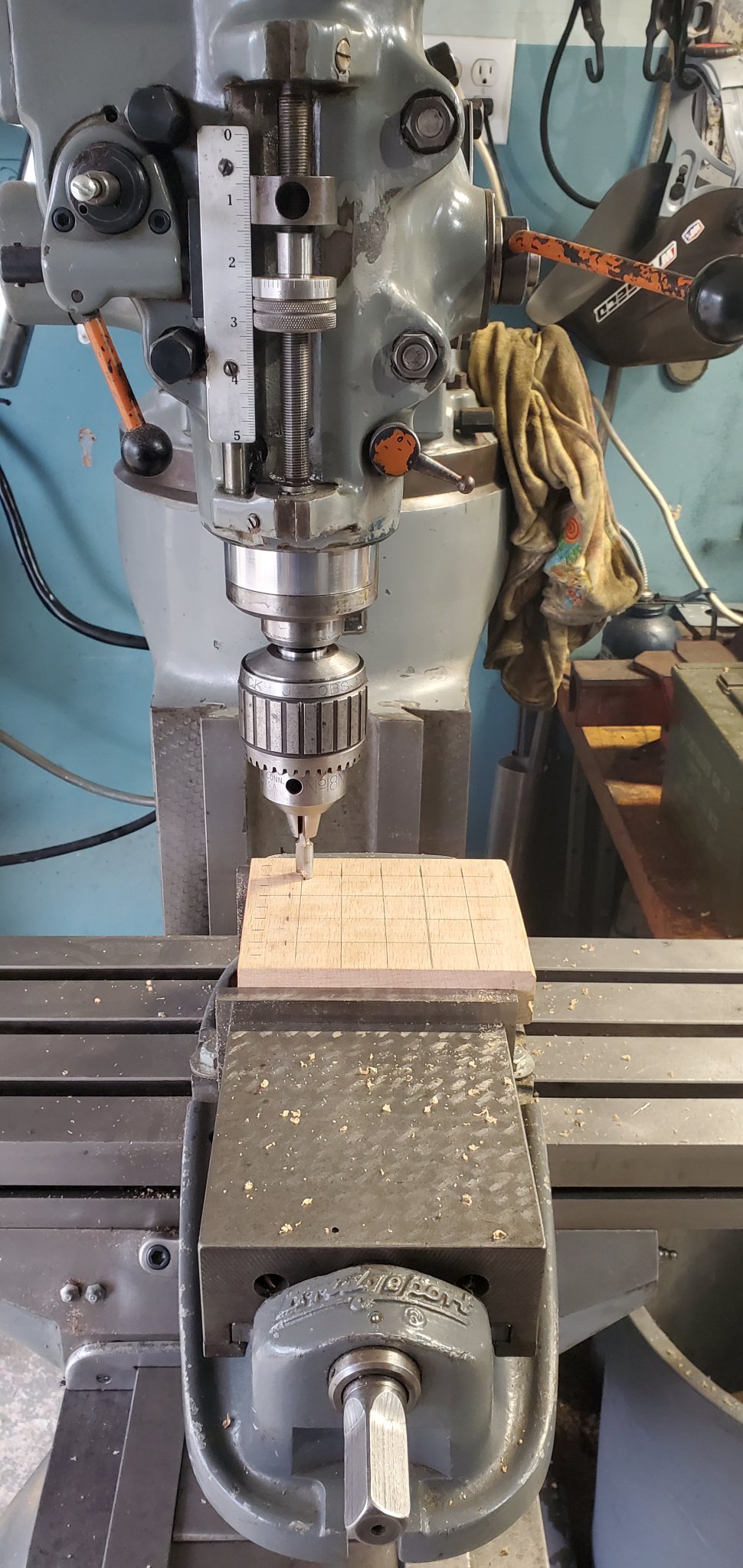

I had some scrap hardwood and made 2 20 round loading blocks. I like to work in small batches. I milled the top clean and bored some holes!

I have a bad habit of sitting in my reloading room trying to decide what I want to mess with next instead of actually getting anything done. Then I spend more money and have more stuff that I’m probably never going to get around too! Today has been no different

Glad to hear I'm not the only one who does this.I have a bad habit of sitting in my reloading room trying to decide what I want to mess with next instead of actually getting anything done. Then I spend more money and have more stuff that I’m probably never going to get around too! Today has been no different

I found out that marking your brass makes you look super pro, even if you are just loading bulk 3gun ammo for "long range"=450 on a progressive

Sat here case gauging all of the .40 ammo that I will be shooting in the SC sectional uspsa match coming up in a few weeks. It’s boring, but needs to be done. Having malfs at a state match will send you straight to the bottom of the score sheet.

- Mar 15, 2018

- 1,397

- 5,541

Charged 89 rounds of 6.5CM with 41.5gr of H4350 and 129gr SP Interlocks. I ran out of the 140gr ELD-M's I had been using, but got the 129's for free so figured I try them. Shot 11 rounds of them the other day and was pleasantly surprised (2800 fps). Anyway, can't stand waste so they're all getting fired tomorrow!

I got my press mounted Thursday night, it looks like some unholy abomination but it works. Yesterday I went to Murdoch’s and got a .40 s&w die set & shell holder. Today I cleaned and cobbled together a way to de-prime some 9mm and .40 s&w cases. Also got to organize a lot of my spent cases into ziplock bags, I have a shitload of .223 & .30-06 cases.

This Monday or next I’ll take those pistol cases to work and clean them in the sonic cleaner. I work a 4x10 schedule and there’s a fucking narc-ing cunt that works tue-fri so this has to be done on a Monday

Damn, I got quite a bit accomplished

This Monday or next I’ll take those pistol cases to work and clean them in the sonic cleaner. I work a 4x10 schedule and there’s a fucking narc-ing cunt that works tue-fri so this has to be done on a Monday

Damn, I got quite a bit accomplished

I resized 100 .270 cases into 6.5-06 yesterday. Such a simple way to make an old gun feel like new again. Bedded the action on Thursday so it’ll be ready to shoot by next weekend

You can’t tell them that...lolJust don't tell your wife that thing cost twice as much as a new oven.

Let's see what she says when you dry wet tumbled brass in the oven?!! "See? I bake too!"

A super cheap food dehydrator is one of the best purchases I've made....gets brass super dry in no time...and saves on the electric bill.

thats what I use.A super cheap food dehydrator is one of the best purchases I've made....gets brass super dry in no time...and saves on the electric bill.

I took a 20 minute drive, scored a tumbler for 25 bucks off FB marketplace, stopped at the pet store and grabbed a bag of crushed walnut, added a shot of nu-finish and started cleaning some brass!

I got a bunch of bulk 223 bullets so I’ll be loading up some pew pew 223 ammo when I get home from work.

I got a bunch of bulk 223 bullets so I’ll be loading up some pew pew 223 ammo when I get home from work.

I should let you borrow my Corbin dies...for turning 22lr spent brass into .224 projectiles...you can literally make tens of thousands...quickly.

Of Hearst if that before but never looked into it. Can you give a brief synopsis? Just one case makes a brass bullet?I should let you borrow my Corbin dies...for turning 22lr spent brass into .224 projectiles...you can literally make tens of thousands...quickly.

I disassembled 500 rounds of .223 that a friend gave me that a friend gave him. Handloads that nobody had any idea what they were. Now I have 500 primed brass and 500 bullets to reassemble.

@Nodakplowboy , have you used the primer seater on the top? You have the early style like mine. Curious to know how yours works. I did 100 the other day. I thought the primer cup part is supposed to be screwed all the way in but had to back it out about 2 turns to get the primers in deep enough. Couldn't find anything online about it.

Of Hearst if that before but never looked into it. Can you give a brief synopsis? Just one case makes a brass bullet?

It's a multi-die set. The first die simply takes a spent piece of 22lr brass....shoves a pin into the brass and rounds off the head of the brass to form a nice brass cylinder and increases the diameter to close to your finished diameter of .224. Then you have a lead mold that you pour your little lead cores...just a small cylinder of lead. Then you have a die where you drop the lead core into the brass and it pushes the lead down into the brass....fills in everthing....and continues to increase the diameter of the brass...with now lead core...to the final dimension. The next die points the bullet.

You control the weight of the bullet with how much lead you put in. I generally make a ~60 grain bullet with a slight open tip....you need to use all the same head stamp brass....because some brass is thicker or thinner....or longer...and you can really tell the difference by whether the lead wants to come out the end....or sit down further giving you more of a hollow tip.

I've had decent accuracy with them...but they are for cheap blasting....now...I have another die set that when I show people in person...and put the projectile in their hands...their brain doesn't fully wrap around the concept right away...and that is taking 9mm spent brass...and turning it into a 40 cal bullet. Here is a nice 180 grain xtp hollow point....made from some nickle coated 9mm brass.

Made a mini "tactical" bolt knob for a CZ 527.

Lump of burl:

Glue-in threaded insert:

FIrst coat of lacquer:

Update. 4th coat. Mmmm, hard candy shell...

Lump of burl:

Glue-in threaded insert:

FIrst coat of lacquer:

Update. 4th coat. Mmmm, hard candy shell...

Last edited:

That's pretty wild. Where do you procure the lead rods?

I pour the lead into a mold...I can do 6-7 lead cores each pour...depending on which mold I use....I have two...one set for a weight to give me a 55gr finished product...and another set to give me a 60gr finished product with most of the jackets I use....+/- a grain really.

@Nodakplowboy , have you used the primer seater on the top? You have the early style like mine. Curious to know how yours works. I did 100 the other day. I thought the primer cup part is supposed to be screwed all the way in but had to back it out about 2 turns to get the primers in deep enough. Couldn't find anything online about it.

Nice press, a lot cleaner than mine.

I used it for awhile when the press was new, 1977-78, then switched to the Lee handheld, which was about the only other tool back then. Not that the press seater was bad, just found the Lee easier. I believe you are correct, the seater had to elevated to fully seat the primer. If memory serves, I recall one had to keep a eye on the seater, it tended to want to screw down.

Sometime in the 80's I bought the Bonanza co-ax primer seater and used that for many years. I was doing lots of P. dog shooting, need to prime faster for the large volume of ammo. One night I was going to fast, hit a primer wrong, on set off a stack of primers. No lost digits, but the ears were ringing for awhile. End of that.

I think I've used most every tray style primer tool out there, Lee, RCBS, Lyman, never real satisfied with any of them. Found a Primal Rights CPS in the PX last year, have never looked back.

Sorry for the long winded reply. Sometimes I can't shut up when traveling down memory lane.