Just watched this video. Very interesting so I figured I would share.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

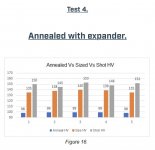

What happens if you anneal the same case twice?

- Thread starter alamo5000

- Start date

I found it most interesting to hear that sizing is where most of the hardening happens, rather than firing; means I might want to consider re-annealing cases I use to test things like shoulder bump…

Yep.I found it most interesting to hear that sizing is where most of the hardening happens, rather than firing; means I might want to consider re-annealing cases I use to test things like shoulder bump…

It's quite interesting and IMO can be taken as a definitive answer to a whole host of questions that have existed over the years.

Actually, it's a combination of the firing and sizing. As I've worked with various sheet metals over 55+ years, work hardening is a common thing one is aware of. When it comes to our cartridge brass, it's really no different in that the work performed when it's expanded, then compressed, then expanded . . . over and over, you get work hardening. The more the movement, the more the work, the more working hardening. For brass, annealing can return it back to its more pliable state. In the manufacturing process, the brass is annealed multiple times to get to the final shape, size and hardness (like at the web). If one wants their brass to last a long time, then annealing needs to be made part of brass prep process.I found it most interesting to hear that sizing is where most of the hardening happens, rather than firing; means I might want to consider re-annealing cases I use to test things like shoulder bump…

Actually, it's a combination of the firing and sizing. As I've worked with various sheet metals over 55+ years, work hardening is a common thing one is aware of. When it comes to our cartridge brass, it's really no different in that the work performed when it's expanded, then compressed, then expanded . . . over and over, you get work hardening. The more the movement, the more the work, the more working hardening. For brass, annealing can return it back to its more pliable state. In the manufacturing process, the brass is annealed multiple times to get to the final shape, size and hardness (like at the web). If one wants their brass to last a long time, then annealing needs to be made part of brass prep process.

They’ve tested this to death and even show it in the video.

A single firing doesn’t harden the brass anywhere close to the amount of sizing it.

Obviously there is some hardening from the firing. But the point was that it’s not as significant as sizing.

Ehhh so what? Is someone sizing unfired brass over and over? Which came first the chicken or the egg? It doesn't matter. You fired it you have to size it.

Ehhh so what? Is someone sizing unfired brass over and over? Which came first the chicken or the egg? It doesn't matter. You fired it you have to size it.

As mentioned above. When you’re setting your die up and use the same piece of brass or same few pieces.

The difference in hardening can lead to quite a bit of frustration when you think you have the die setup and then it over sizes the fresh pieces.

Knowing that the sizing is the more significant hardening help iron all that out.

They’ve tested this to death and even show it in the video.

A single firing doesn’t harden the brass anywhere close to the amount of sizing it.

Obviously there is some hardening from the firing. But the point was that it’s not as significant as sizing.

Hardening is proportional to the amount of brass movement. Firing a round moves the brass maybe .005” or so. Sizing a case moves the brass .020” or more depending on the die.

Hardening is proportional to the amount of brass movement. Firing a round moves the brass maybe .005” or so. Sizing a case moves the brass .020” or more depending on the die.

Their testing seems to point more towards the interference sizing operations being the culprit.

IE, if you use a bushing and no expander ball and mandrel, sizing and firing harden close to the same. Since you size the neck one time as well as fire it one time.

Once you size it smaller than your intended final ID and run a mandrel or expander ball back through, you now have two processes of hardening vs the one of the firing.

Attachments

How far the brass moves when fired depends on barrel chamber dimensions. And how far sizing moves the brass also depends of the dimension of the die. If one want to minimize the amount of work being done on the brass, then one can customize both the barrel chamber and the die so that very little movement is taking place, which could mean having very little if any need for annealing to have decent brass life.Hardening is proportional to the amount of brass movement. Firing a round moves the brass maybe .005” or so. Sizing a case moves the brass .020” or more depending on the die.

In a factory barrel, movement can be substantial. Like in a .308 case a loaded round might have a neck size of .334 and expand to .343 when fired. The sizing process of standard .308 die often squeezes the neck down to .328 and is expanded to .332 before bullet seating. So the difference between .343 and .328 is .015 of total movement (in a typical SAAMI spec factory case and chamber).

Last edited:

I have always annealed before sizing. Going to have to re-think that.

I don't think any of this info suggests you shouldn't; if anything, I'd say for max consistency you'd want to anneal twice to three times, depending on if you're expanding or not.I have always annealed before sizing. Going to have to re-think that.

If you're not expanding (bushing die), then I could see a case for annealing pre-sizing (to get minimal spring-back and max consistency on post-sizing dimensions) then again after sizing to get max neck tension consistency.

If you're expanding as a separate step, then I could see annealing before sizing, before expanding, and before seating. That sounds like a nightmare to me; I'd just stick with a sizing operation that minimizes expansion (a honed die with an expander mandrel that opens back up 0.002" is my system, many others just use a bushing with no expansion). Granted, I'm not shooting 1000-yd F-Class, so ymmv.

I like that the video showed via testing what sizing does the hardness. I think the original question of "can you over anneal" was answered solidly. I feel more comfortable annealing a batch a brass a second time if I've forgotten to mark that buck as annealed. I don't think the point of the video was that you need to anneal multiple times but that you won't hurt it if you do.

I don't think any of this info suggests you shouldn't; if anything, I'd say for max consistency you'd want to anneal twice to three times, depending on if you're expanding or not.

If you're not expanding (bushing die), then I could see a case for annealing pre-sizing (to get minimal spring-back and max consistency on post-sizing dimensions) then again after sizing to get max neck tension consistency.

If you're expanding as a separate step, then I could see annealing before sizing, before expanding, and before seating. That sounds like a nightmare to me; I'd just stick with a sizing operation that minimizes expansion (a honed die with an expander mandrel that opens back up 0.002" is my system, many others just use a bushing with no expansion). Granted, I'm not shooting 1000-yd F-Class, so ymmv.

I’d imagine they have determine the 150 or so hardness you get from sizing and expanding operations isn’t high enough to warrant multiple anneal before firing.

I’d also imagine if it was, they would target something around 80 and not around 98 hardness. That would allow for more hardening before it’s too close to spring.

I like that the video showed via testing what sizing does the hardness. I think the original question of "can you over anneal" was answered solidly. I feel more comfortable annealing a batch a brass a second time if I've forgotten to mark that buck as annealed. I don't think the point of the video was that you need to anneal multiple times but that you won't hurt it if you do.

Would be interesting to see this testing done with flame annealers and salt bath.

Of course, anytime they do that they get torn apart as it looks like they are just trash talking other methods.

your arms will fall off , your crops will wither and die , your women will become infertile and barren and you will pay them all alimony for the rest of there lives for the destruction you have caused to the very fabric of the universe lol probably not much .

How far the brass moves when fired depends on barrel chamber dimensions. And how far sizing moves the brass also depends of the dimension of the die. If one want to minimize the amount of work being done on the brass, then one can customize both the barrel chamber and the die so that very little movement is taking place, which could me having very little if any need for annealing to have decent brass life.

In a factory barrel, movement can be substantial. Like in a .308 case a loaded round might have a neck size of .334 and expand to .343. The sizing process of standard .308 die often squeezes the neck down to .328 and is expanded to .332 before bullet seating. So the difference between .343 and .328 is .015 of total movement (in a typical SAAMI spec factory case and chamber).

I think the problem doing this test in that way is how much time do you want to spend getting the same annealing every time on each case.Would be interesting to see this testing done with flame annealers and salt bath.

Of course, anytime they do that they get torn apart as it looks like they are just trash talking other methods.

My hypothesis says the principle would be the same no matter the method. The heat relieves the stored energy in the brass. Doesn't matter how that heat gets there I would imagine.

If I were to predict the outcome (or what they would say) is this method vs that method would give the same result, but the difference would be the inconsistency from case to case in the process of annealing.

To me I think you are on the wrong line of thought. Absolutely everything I've seen from top level shooters (the usual suspects) is that consistency matters more than absolute metal hardness. If the brass is too hard it will have excessive spring back during the sizing process. You could have physical case sizes all over the place even in resized brass.I have always annealed before sizing. Going to have to re-think that.

Someone might come up with some data that shows a certain hardness is best for bullet seating but so far I haven't seen anything to that effect. At least nothing that translates to more accuracy downrange.

On the flip side though it's pretty much a proven thing that if your cases vary in length or whatever, even due to spring back, it will have the greatest negative impact.

I am shooting 1,000 yard F class and the common theme is to full length size with bushing die and expand slightly to desired diameter.I don't think any of this info suggests you shouldn't; if anything, I'd say for max consistency you'd want to anneal twice to three times, depending on if you're expanding or not.

If you're not expanding (bushing die), then I could see a case for annealing pre-sizing (to get minimal spring-back and max consistency on post-sizing dimensions) then again after sizing to get max neck tension consistency.

If you're expanding as a separate step, then I could see annealing before sizing, before expanding, and before seating. That sounds like a nightmare to me; I'd just stick with a sizing operation that minimizes expansion (a honed die with an expander mandrel that opens back up 0.002" is my system, many others just use a bushing with no expansion). Granted, I'm not shooting 1000-yd F-Class, so ymmv.

Nice, similar to my process. Having seen this discussion that each steps work-hardens the brass (which I guess most of us figured), would you ever consider annealing between sizing/expanding/seating to get max consistency? Asking out of curiosity, genuinely interested to hear an F-Class or similar perspective.I am shooting 1,000 yard F class and the common theme is to full length size with bushing die and expand slightly to desired diameter.

When I think I've gone the rabbit hole testing everything I can for this class, might need to do some more.Nice, similar to my process. Having seen this discussion that each steps work-hardens the brass (which I guess most of us figured), would you ever consider annealing between sizing/expanding/seating to get max consistency? Asking out of curiosity, genuinely interested to hear an F-Class or similar perspective.

How far the brass moves when fired depends on barrel chamber dimensions. And how far sizing moves the brass also depends of the dimension of the die. If one want to minimize the amount of work being done on the brass, then one can customize both the barrel chamber and the die so that very little movement is taking place, which could mean having very little if any need for annealing to have decent brass life.

In a factory barrel, movement can be substantial. Like in a .308 case a loaded round might have a neck size of .334 and expand to .343 when fired. The sizing process of standard .308 die often squeezes the neck down to .328 and is expanded to .332 before bullet seating. So the difference between .343 and .328 is .015 of total movement (in a typical SAAMI spec factory case and chamber).

It also depends on brass thickness. Lapua, Fed, LC are .335-336” after expanding.

So, .345” down to .328” and back up to .335” is .024” of movement.

To me I think you are on the wrong line of thought. Absolutely everything I've seen from top level shooters (the usual suspects) is that consistency matters more than absolute metal hardness. If the brass is too hard it will have excessive spring back during the sizing process. You could have physical case sizes all over the place even in resized brass.

Someone might come up with some data that shows a certain hardness is best for bullet seating but so far I haven't seen anything to that effect. At least nothing that translates to more accuracy downrange.

On the flip side though it's pretty much a proven thing that if your cases vary in length or whatever, even due to spring back, it will have the greatest negative impact.

If you are into jamming bullets

I like when someone backs up what I’ve said forever with some actual tests:

I anneal factory brass because it ensures it will be at minimum my baseline hardness that the case will be treated to for the rest of its firing life. And if I don’t anneal as far as the factory did then it does nothing but waste a little of my time.

I anneal factory brass because it ensures it will be at minimum my baseline hardness that the case will be treated to for the rest of its firing life. And if I don’t anneal as far as the factory did then it does nothing but waste a little of my time.

I like when someone backs up what I’ve said forever with some actual tests:

I anneal factory brass because it ensures it will be at minimum my baseline hardness that the case will be treated to for the rest of its firing life. And if I don’t anneal as far as the factory did then it does nothing but waste a little of my time.

Our amp press graphs look much better with virgin brass after it’s annealed before a mandrel and first firing.

Haven’t been able to correlate it to any advantage on paper yet. But the difference is noticeable on the traces.

Soooo, when to Anneal? I use a universal deprimer die, then run brass thru the Anneal process before inspection and full length resizing

Before you begin any sizing operation. But no need to anneal between things like sizing and mandrel.

And don’t use the same piece/s of brass over and over to set your shoulder bump. You’ll be sizing brass with different work hardening that the rest of your batch. Which is why you’ll think you have it set up right and the first piece from the pile that hasn’t been touched will over size.

You lost me there. I am not following.If you are into jamming bullets

I am not sure how jamming bullets has absolutely anything to do with the price of tea in China.

You lost me there. I am not following.

I am not sure how jamming bullets has absolutely anything to do with the price of tea in China.

If you’re jamming bullets annealing for consistent neck tension/release is much less meaningful.

As the lands/rifling are much stronger than the brass. So consistent velocity won’t be dependent on the brass neck release.

When you’re jumping bullets then consistent neck release is very important and the less consistent the release, the wider your velocity spreads will be. A tighter gripped bullet will have a higher velocity as more pressure built up before release.

Not sure if that’s what he was getting at. But that’s how jamming changes the dynamic of what controls the pressure buildup.

Definitely before.So to summarize...

Anneal before resizing or anneal after resizing ?

Ah. I am connecting the dots now (in your post). The other person responded to me and I wasn't following the line of reasoning.If you’re jamming bullets annealing for consistent neck tension/release is much less meaningful.

As the lands/rifling are much stronger than the brass. So consistent velocity won’t be dependent on the brass neck release.

When you’re jumping bullets then consistent neck release is very important and the less consistent the release, the wider your velocity spreads will be. A tighter gripped bullet will have a higher velocity as more pressure built up before release.

Not sure if that’s what he was getting at. But that’s how jamming changes the dynamic of what controls the pressure buildup.

If you anneal then size the brass then anneal a 2nd time I would think that the heat would distort the brass that you just sized. You could also anneal a third time before you seat the bullet.

Would this distortion be enough to affect accuracy, I don't know. It would need some testing for sure and it would add a couple more steps to your reloading process.

Would this distortion be enough to affect accuracy, I don't know. It would need some testing for sure and it would add a couple more steps to your reloading process.

You lost me there. I am not following.

I am not sure how jamming bullets has absolutely anything to do with the price of tea in China.

Shoulder length variance which you say is caused by springback only affects accuracy when you’re jamming bullets.

The time to anneal is before you perform a lot of work on the brass, same as what is done when the brass is being formed by the manufacturer. You want to brass to be softer when doing the sizing, though the sizing process performs a "little" work hardening. As mentioned in a previous post, you want to get as much consistency as possible. You really don't want the necks to be fully annealed where it's really soft as the neck would then have a hard time just holding onto the bullet.So to summarize...

Anneal before resizing or anneal after resizing ?

Annealing is the first operation I do to my brass (after depriming) so that they're ready for sizing. But I don't size them until I clean them after the annealing as the annealing process leaves an oxidized coating on the surface of the neck and shoulder, which is rather rough like sandpaper that's not good for the sizing die and makes for a lot of resistance when seating bullets. If one does a really good job of cleaning, then that oxidation layer is less, but still presents those issues.

If you’re going to anneal multiple times then you’re going to need to deprime multiple times too.

2 times needed.

The last step of annealing should be after the bullet is seated.

This will insure the bullet jacket is annealed too. Especially in the brass neck where you cannot see it.

Makes the most consistent neck tension you will ever see.

The last step of annealing should be after the bullet is seated.

This will insure the bullet jacket is annealed too. Especially in the brass neck where you cannot see it.

Makes the most consistent neck tension you will ever see.

Should we anneal the powder and primers too?2 times needed.

The last step of annealing should be after the bullet is seated.

This will insure the bullet jacket is annealed too. Especially in the brass neck where you cannot see it.

Makes the most consistent neck tension you will ever see.

Send them my way, I'll do it for you, free of chargeShould we anneal the powder and primers too?

It is interesting that sizing hardens more than firing. Check out some YT Eric Cortina vids on the subject.I found it most interesting to hear that sizing is where most of the hardening happens, rather than firing; means I might want to consider re-annealing cases I use to test things like shoulder bump…

It is interesting that sizing hardens more than firing. Check out some YT Eric Cortina vids on the subject of multiple annealings. I just watched the beginning of the video and was glad to see this guy concurred. I re-anneal every 5-8 firings. I use Hornady, Lapua and Norma brass. It seems to last forever. I don't max load my cartridges, that might help longevity. My annealer is the Giraud Cartridge Case Annealer. Really like it. I'm a low volume precision shooter and don't turn my cases frequently, which might impact my longevity perception a bit. But what I look for when I shop is powder, bullets and primers, not cases.

Last edited:

It is interesting that sizing hardens more than firing.

Several people have claimed that so far, but you can’t say this is a universal truth.

Whatever moves the brass most is what does the most hardening.

You can set the rifle up with almost no neck clearance, so the brass moves very little if any. That won’t harden it much. But then run it through a common full length sizer; that moves the brass a lot and does a bunch of hardening.

Or go the other way, with a loose milsurp chamber and neck turned brass - maybe .015”-.020” clearance if it’s extreme. That’s gonna move the brass a fair amount, and harden it a bunch. Then size it with a carefully set up bushing die so the neck isn’t moved any more than necessary; no need to use an expander ball or mandrel - that’s not hardening the brass nearly as much as the FL die.

The more realistic and useful takeaway isn’t whether firing or sizing is worse, but just that minimizing brass movement in both operations will minimize hardening.

Whoa, I just got schooled! Thanks for the education on case hardening. That's what I love (and hate, wish I had started forty years earlier) about gun collecting and shooting.......AM CONSTANTLY LEARNING !!! Thanks again.Several people have claimed that so far, but you can’t say this is a universal truth.

Whatever moves the brass most is what does the most hardening.

You can set the rifle up with almost no neck clearance, so the brass moves very little if any. That won’t harden it much. But then run it through a common full length sizer; that moves the brass a lot and does a bunch of hardening.

Or go the other way, with a loose milsurp chamber and neck turned brass - maybe .015”-.020” clearance if it’s extreme. That’s gonna move the brass a fair amount, and harden it a bunch. Then size it with a carefully set up bushing die so the neck isn’t moved any more than necessary; no need to use an expander ball or mandrel - that’s not hardening the brass nearly as much as the FL die.

The more realistic and useful takeaway isn’t whether firing or sizing is worse, but just that minimizing brass movement in both operations will minimize hardening.

Movement! Stick THAT in the memory box!

Can I watch you do this?2 times needed.

The last step of annealing should be after the bullet is seated.

This will insure the bullet jacket is annealed too. Especially in the brass neck where you cannot see it.

Makes the most consistent neck tension you will ever see.