I'm bringing this back

I've used probed 2000 for years but it's honestly a mess to deal with..

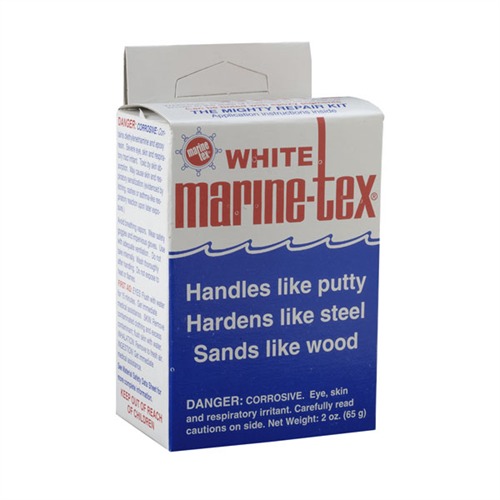

I just got a Manners stock and am considering JB weld in the putty form cuz I have it on hand and it should be easy to apply, has anyone used it?

I've used probed 2000 for years but it's honestly a mess to deal with..

I just got a Manners stock and am considering JB weld in the putty form cuz I have it on hand and it should be easy to apply, has anyone used it?