Kelbly’s Golden Girl Arcas, Nyx, and Atlas Tactical

Introduction

A lot has changed since I met Ian back in 2010. At that time I was just starting to do scope reviews and Kelbly’s was the distributor for March optics. They were one of the leading benchrest rifle makers, but benchrest is not a huge market and they were not well known outside of it. Since then they have become much better known outside of benchrest and their production has increased by more than 6x. The CNC machines have multiplied and they have entirely filled their once spacious factory capacity. I was quite surprised at the magnitude of the change. What has not changed is the basic quality product. They continue to produce rifles with exceptionally tight tolerances and with well over 30 years of knowledge about what works and why. This is an exceptional degree of experience and proven track record. Their rifles currently hold 53 world records across a variety of disciplines and have more wins than anybody bothered to keep track of. That is probably a little embarrassing in a discipline that prides itself on accounting for every round down the barrel.

Table of Contents

– Background on the Build

– Components

– – Stock and Bottom Metal (Grayboe Ridgeback stock Mesa Precision bottom metal)

– – Trigger (Bix’n Andy TacSport)

– – Barrel (Krieger)

– – Action (Kelbly’s Atlas Tactical)

– Accuracy and Ammo

– – Lapua

– – Copper Creek

– – Desert Tech

– – Hornady

– – Federal

– – Norma (Update 7-30-2019)

– The Shooting Experience

– Cost

– Summary

Background on the Build

I have been kicking around doing a Kelbly build for quite a few years now. Specifically, I wanted a .223 that could really do bug holes. .223 is far cheaper than anything else to reload. People seem more than willing to just leave me large lots of very serviceable Lake City Brass, .224 bullets are light and therefore lower cost than most other calibers, and .223 has excellent barrel life. Ballistically, it makes a good training round and is also useful for caliber limited competitions and blowing up groundhogs. Having the Grayboe stock come in for review gave me the excuse for this long wanted .223. To really do the Grayboe review properly I wanted to go the whole nine yards and bed the thing myself so I could really see how it was put together. With all that work upcoming anyway and product in hand, it seemed like the stars were aligning. Ian had also been interested in doing a review for a few years so all that was left was to round up the rest of the components.

Components

Stock and Bottom Metal

You can view the Grayboe review in its entirety at the link given here. Suffice it to say that after having the stock on hand for a bit, I was reasonably sure that it was going to work pretty well. The features were to my liking and what geometry was not could be easily fixed. Having tested the inletting on another Remington pattern action, I was also sure that the fit was good. For bottom metal, I used the Mesa Precision Arms DBM. This is what Garyboe was using at the time, is of very good quality, and, with a barricade stop and Mickey Mouse style mag release, has some features I like.

Over the course of the review, I bedded both the action and the bottom metal in the Grayboe stock using Acraglas Gel and also added a polymer clay detachable palm swell.

Trigger

For a while now I have been unable to escape talk of this Bix’n Andy trigger with balls that has been brought over from Austria.. I kept hearing that it didn’t just work differently but actually WORKED differently (you can figure that one out.) When I saw that Kelbly’s had decided to make them the standard trigger on all their rifles. This made a particular impression on me since not that long ago, Kelbly’s had actually manufactured high performing, exceptionally low pull weight, triggers themselves. I had the card of the Bix’n Andy importer Bullet Central from some year at Shot Show so I gave them a call and they told me they had a new TacSport Pro model coming that they were interested in me trying out. At that time I was intending to just do a small sub-section of the review about the trigger. However, I became more interested in the intricacies of the ball trigger concept, and the text kept growing into a full review of the Bix’n Andy TacSport product line.

Barrel

We are blessed in this country with a wide selection of truly match quality barrel makers. This has kept quality high and prices better than fair, with far lower than average rates of inflation, in an industry that has seen runaway price increases in many areas. Of these excellent barrel makers, Krieger is possibly the most well known. Their particular marketing focus is on the custom steel they use and the stress free single point cut rifling method. I went with them because they are one of several makers that I think are at the top of the heap and a blank of proper caliber, length, contour, and twist was in stock.

Action

Kelbly’s makes two actions for the tactical crowd as well as a variety of benchrest and F class actions. All of these are actually manufactured on site, to exacting tolerances of 1/1000th on the headspace, on a series of Mazak CNC machines and a brand new Sodick EDM machine. Their tolerances are such that barrels can actually be ordered from them without sending in the action to headspace as the dimensions are already known. The user can then install barrels with an action wrench and barrel vice. As barrel makers are beginning to more commonly chamber barrels, there have been discussions with a few regarding chambering to the exacting specs that Kelbly uses in the future to allow for direct user installation.

Because of the use of the Grayboe stock, which is designed for Remington semi-clone actions, I chose Kelbly’s Atlas tactical for the build. This action is also used in their popular NYX rifle that features an XLR carbon chassis. The other tactical action option is their new flagship Black Bear action. This is a rectangular footprint action that is stiffer, offers more bedding area, and features an integral recoil lug and rail.

Both of Kelbly’s tactical actions have basically the same bolt and therefore operating features. The bolt is 2 lug with 90 degree throw. In one lug, it has a springless mechanical type ejector that Kelbly calls the TG ejector. This ejector puts no pressure on the case in the chamber, is not dependent on a tightly fit spring loaded plunger, and allows the user to control how far the brass is thrown. It is actuated by a pin in the heavy duty side mounted bolt stop. If that one isn’t heavy duty enough for you, you can actually buy a stationary one which screws down. I find pin type ejectors far preferable to the spring and plunger designs that I can bind and also toss my brass to the seven winds. The other locking lug houses the extractor. It is not a Sako or m16 type, but is a spring loaded system and therefore most similar to those, though it slides in a channel rather than rotating. Housing the extractor in the lug makes for a very flat ejection that will not be interfered with by big tactical elevation knobs on scopes. There are good arguments for this type of extractor and also for the stationary Mauser claw type (though really no arguments for garbage Remington clip type). Sprung types like the Kelbly offer better cartridge head support and single load better, whereas the Mauser claw type have controlled round feed and allow for more extraction force on a stuck case.

Kelbly’s shows its benchrest background with the trigger hanger it uses on all its actions. Benchrest guys often glue their action into the stock and so must have a hanger to remove the trigger. The hanger generally makes removal and installation of the trigger easier as you are not trying to pound pins into a slick round action that likes to spin. The trigger hanger would also allow for adjustment of the firing pin fall should your trigger be a little out of spec.

A few specs on the Atlas have been altered a bit from stock 700 dimensions and I will mention them as some stocks will need a little alteration. First, the trigger hanger protrudes slightly behind the rear of the trigger and this usually necessitates a little removal of material from stocks. Similarly, the ejection port is longer than a stock 700 and so some stocks will need a little material removed at the back of the port as well. As is common, the recoil lug is thicker than a factory 700’s lug and the Kelbly one further has a trapezoidal shape which makes it almost full width at the top. This shape, combined with the fact that it is pinned, allows the bedding to be extended to under the lug as it will not lock on the sides so you get a little more bedding area from the design. The inletting in the underside of the action is also a little larger and the action can feed off AW magazines, if you are so inclined, though I recommend the more reliable AICS design that also doesn’t spill its guts when you drop a mag. The rail is also different than Remington spec as it does not have the flat drop in the back and is pinned. You can get the rail in whatever cant you want.

In the manufacture of actions, Kelbly’s has employed significant economies of scale to reduce costs and has further chosen to translate those lowered costs to lowered prices. For instance, the recent EDM machine for the bolt raceways saves a tremendous amount of time over broaching them. At $999 on the Atlas and $1,400 on the black bear these actions, especially the Atlas, are significantly less expensive than their closest competitors and very close to the lowest cost custom actions in market. It is my opinion that they therefore offer an excellent value on some of the most precise actions in the market.

Accuracy and Ammo

If you are expecting me to give you some great revelations though my testing of this rifle from a maker that holds 53 world accuracy records (actually it is more, they only update the accuracy records once a year on the web), then you’re going to be a little disappointed. I don’t personally hold any of those records and between my skill level, and shooting without free recoil from conventional bags as I did, I am not about to set any. That being said, I was interested to see what a rifle like this might be expected to do right out of the box with factory ammo. I have been hearing for awhile that through changes in the automated loading equipment available, as well as changes to importing arrangements, much better loaded ammo is now available and for more reasonable prices.

While I certainly expect that ammo, like most things that are manufactured (and, unlike say pharmaceuticals, subject to actual free market pressures), will get both better and more affordable, ammo has some unique issues to overcome regarding the getting better part. The issues stem not from making ammo more uniform but rather from its fit to any particular rifle. Much of accuracy derives not from the uniformity of the ammo but from its fit to the rifle. This is why some competitive .22lr shooters go to all the work of sending their rifle to a testing facility and then buying an entire lifetime worth of ammo in one purchase. Lot testing is a roundabout way of getting to what handloaders do for centerfire with load development. A handloader often starts with a brass and bullet he intends to use and varies the powder, charge, seating depth, and neck tension to find a combination that fits the rifle best. The theory of why this matters so much has to do with how a barrel vibrates, creating nodes and internodal spaces, as well as with how the bullet exits the case and enters the lands. Basically, you want it to enter the lands straight and exit the barrel at a node. This can all be even further complicated if you shoot long range and therefore need the standard deviation on the velocity to be low, want a high velocity, and might even be tempted to try those devilishly picky VLD bullet Oglives that make for lower drag but also make you pull your hair out. This all makes the manufacture of precision loaded ammunition much trickier than just putting some high tolerance components together carefully, within SAAMI standards, and shipping it. Some combinations have a good fit in more rifles than others but you need to do a lot of different testing to find this out and, in the end, your results will still be varied. I am saying all this because the data you are about to partake of is effected by all of these things. Being the best in one rifle does not mean the best in all rifles and being the best on average for all rifles might not mean the best for yours. This is an interesting test nevertheless for giving you an idea of the sort of results you might expect using a variety of excellent factory loaded ammo in an excellent custom precision rifle.

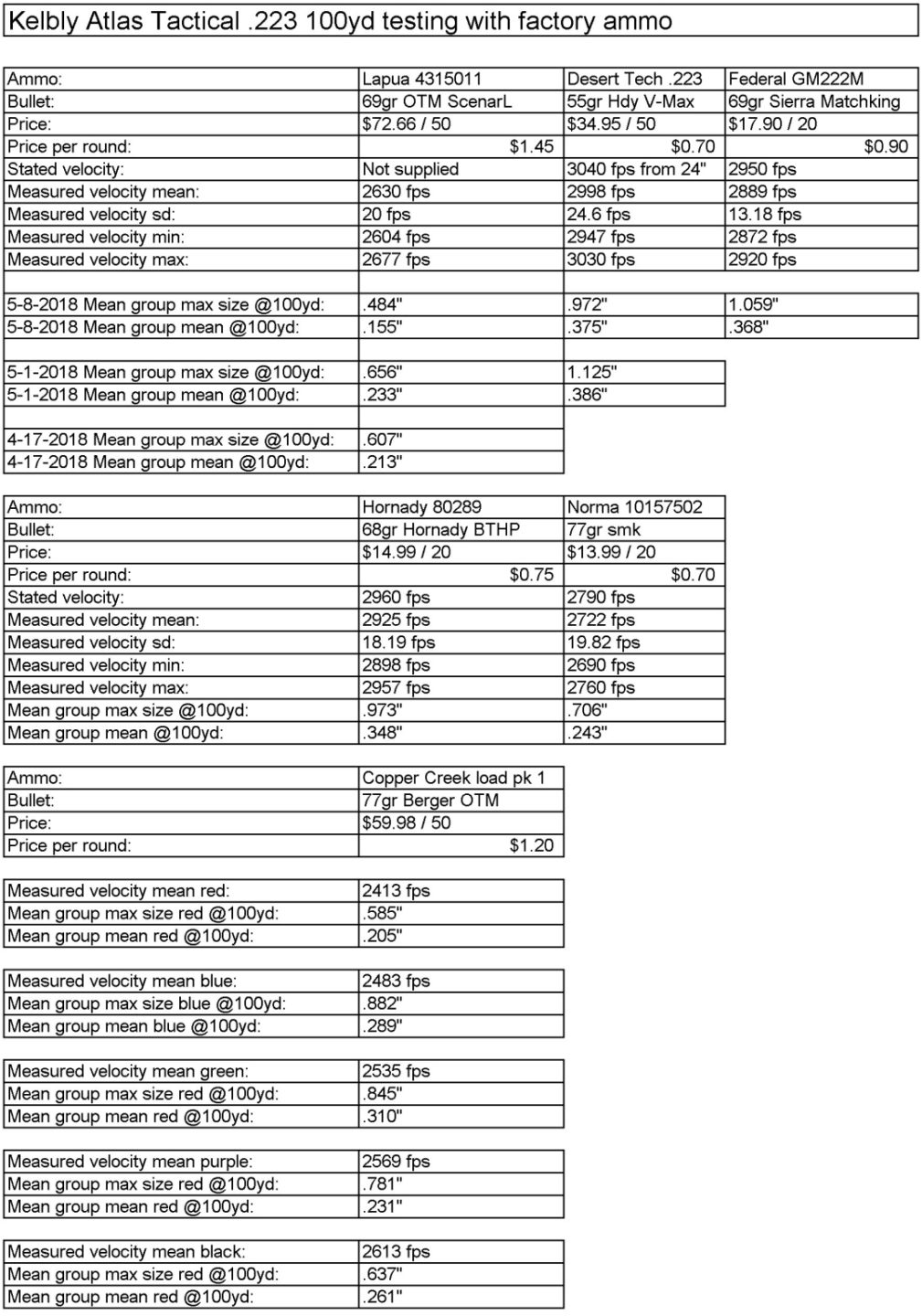

I carried out the accuracy testing with factory ammo over the course of three shooting days with the bulk being done in one marathon 7-hour day when the weather was just right. Testing was done at 100 yds shooting from a concrete bench with a Bulls Bag front and a rear bag of my own design. I tried testing both with and without the magnetospeed chronograph and saw no accuracy difference so did all of the long day with the chrono. All rounds were mag fed five at a time. I took a break every 30 – 40 rounds when the barrel started to heat up and mirage. I cleaned during each break because I had nothing else to do and wanted to keep as close to uniform conditions for each ammo as possible. The scope I used was a Sightron SIIISS624x50LRFFP/MH set to 24x mounted in a Bobro dual lever precision optic mount. Magnification, rests, and non-free recoiling position considered, I think it would be fair to say that my hold is not reliably better than .25″ in this configuration.

Lapua

Lapua is a Finnish company. This is significant as Finland is a country with a population roughly the same as Minnesota but which defeated the U.S.S.R. – in war, not hockey, which Minnesota might actually be able do. The Lapua ammunition factory, at that time a state entity, was the primary supplier to Finland for those conflicts during which sharpshooting became a key tactic of the vastly outnumbered Finnish forces. Long range precision shooting is now baked into the culture. Lapua has found a great deal of success in the U.S. market, primarily in precision .22lr and in ammunition brass. They have seen less penetration with their bullets not because they are poor but because there is actually stiff competition in domestic precision bullet manufacture. Lately, Lapua has been expanding their loaded ammunition offerings and I had heard very good things. Lapua was the best performing ammo in my rifle by a huge margin and, on the best shooting condition day, averaged better than .5″ at100 yards with the best group being under .25″. The average of the Lapua groups on that day was actually slightly better than the best single group from anything else. In general, I would be very impressed with any factory ammo that averages sub .5″, but it is even more impressive with .223 because .223, with its short neck and long skinny case, is one of the trickier things to get right.

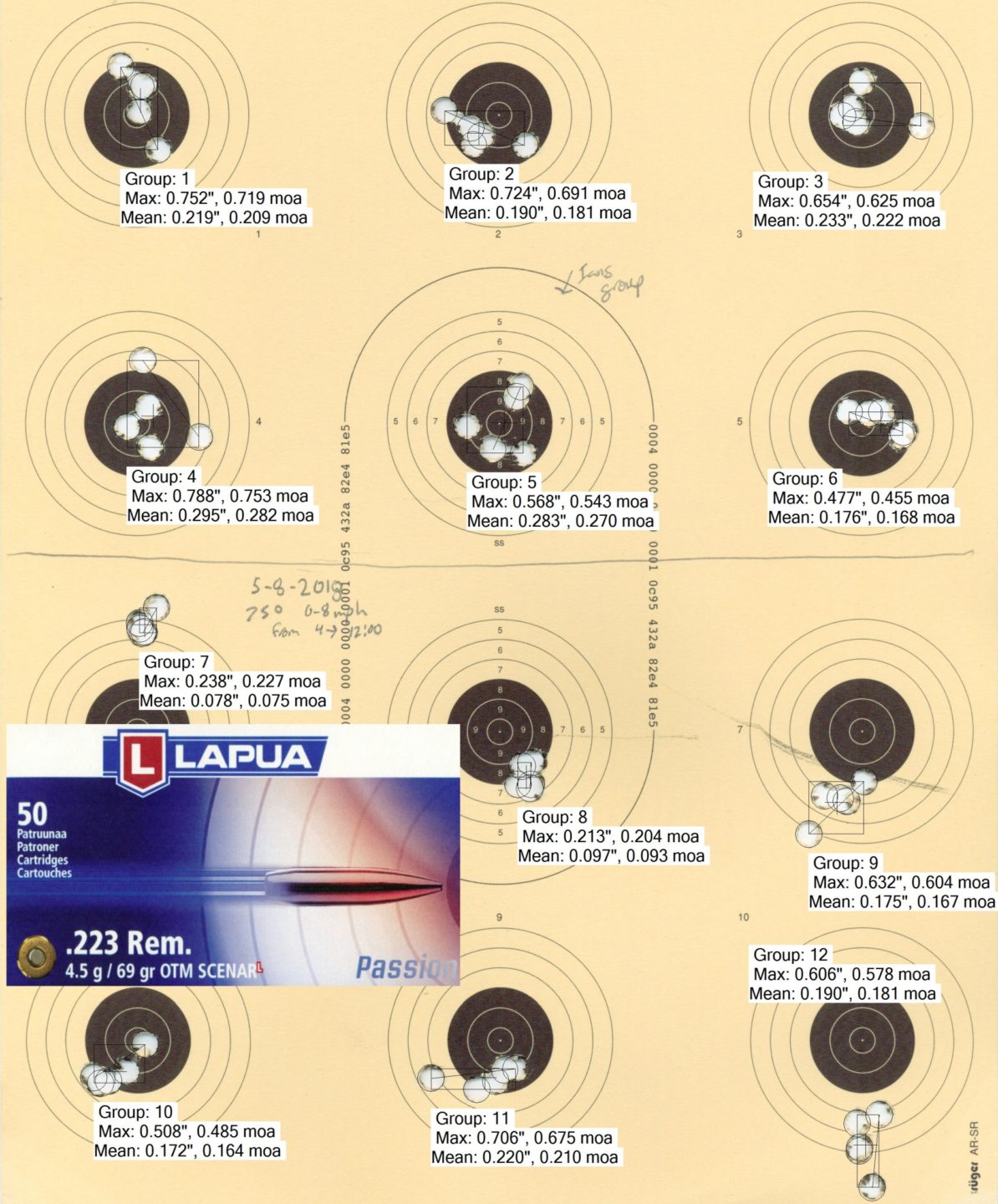

Copper Creek

Copper Creek Ammo is a relatively small scale U.S. maker that offers both standard loaded ammo and a unique two-stage load development option that sort of approximates the handloading procedure by varying first powder charge and then seating depth. In the procedure, you fire one group with each of 5 charges, pick the best, measure your chamber with the Hornady

OAL gauge, and have them send you a second set of loads. These next 5

loads each have the charge you chose but with a different depth of

seating. I was intrigued by this as it attempts to overcome the biggest

challenge that factory ammo has, namely, the aspect of fit to the rifle.

Since it has been my experience that something always goes at least a

little wrong, I had them send me 10 instead of 5 of each charge weight.

Basically, a double load development pack.

In practice, the Copper Creek load pack put me right into my

handloading mindset. What I mean by this is that there were specific

things that I wanted to do based on what I saw and felt. For instance,

one of the blue rounds closed hard and then, not surprisingly, flew out of an otherwise tight group. The Kelbly rifle has a tight chamber and it probably bumped the lands a little. I wanted to try that load but bump the rounds

back a little. The purple and black charges both were OK but not great,

leaving me to think that perhaps there was a node between them and I

wanted to split the difference in charge and try that. What I am sure of

is that, although there are certainly times in the load development

process where I have only fired 5 rounds with a particular combination, 5 is only enough to make a negative call

and not a positive one. I might move on from a bad 5 but I would never

stick with a good one without confirming it with a few more groups. The

10 rounds each that I had instead of 5 was immeasurably better, though,

and I can confidently say I am satisfied that the red loads were clearly

the best. Some of my motivation for wanting more is because of this in

that, at 2413fps, the reds are the lowest charge and provide a lower

effective range for the rifle than I could have if there does happen to

be a node between purple and black. I guess that the most insightful

thing I can say about the Copper Creek load pack experience, beyond that

you need to buy more than one, is that I think, on average, it will

yield a better load for users than not using it, but that users may not

feel like it does because the limitations of the process will be so

obvious.

Speaking of options and removing limitations, Copper Creek gives you a lot of options as they can simply make ammo for you to your own already tested load specifications. They also keep the load data for any ammo you’ve developed with them on file permanently and will give you the load recipe after you have purchased only 100 rounds of loaded ammo. This is a pretty astounding degree of customizability.

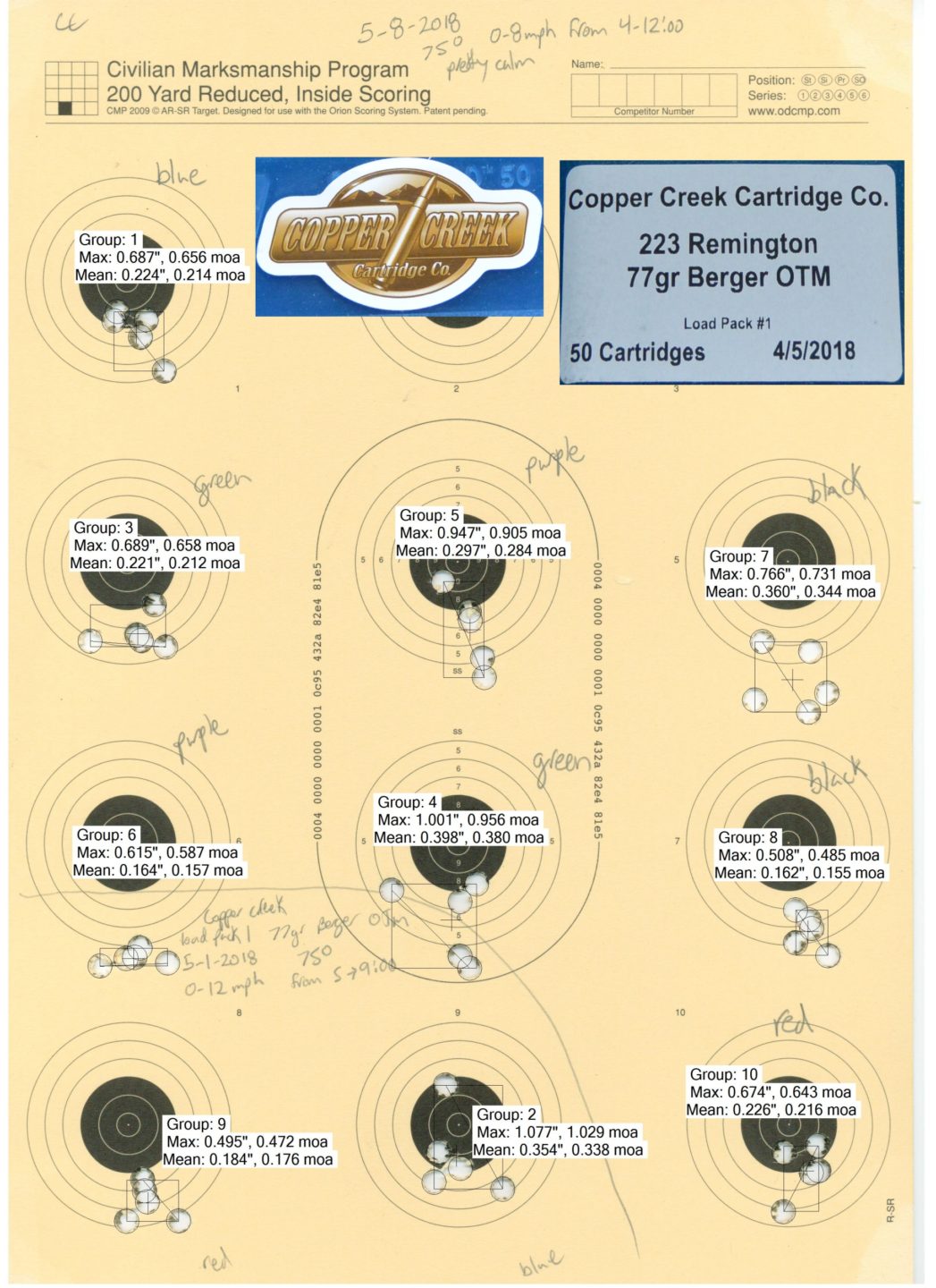

Desert Tech

Desert Tech is another smaller scale U.S. maker. They are probably better known for their rifles, which are totally unique designs that are unusual both in their focus on bull pup configurations and in their easy caliber convertibility. The rifles are quite innovative and have a very good reputation. The ammo has likewise been gaining an excellent reputation, particularly in the 6.5CM caliber which has a .5MOA guarantee. I am doing a review of a rifle in 6.5CM later this year and so contacted Desert Tech primarily for that ammo. Desert Tech was good enough to provide some .223 for this review as well. Their .223 is a much lower cost ammo than the 6.5CM ammo, is a varmint rather than match round, and uses a 55gr crimped Hornady v-max bullet. In practice, the mid priced 55gr varmint round performed pretty well for the cost at just under 1″ at 100 yds.

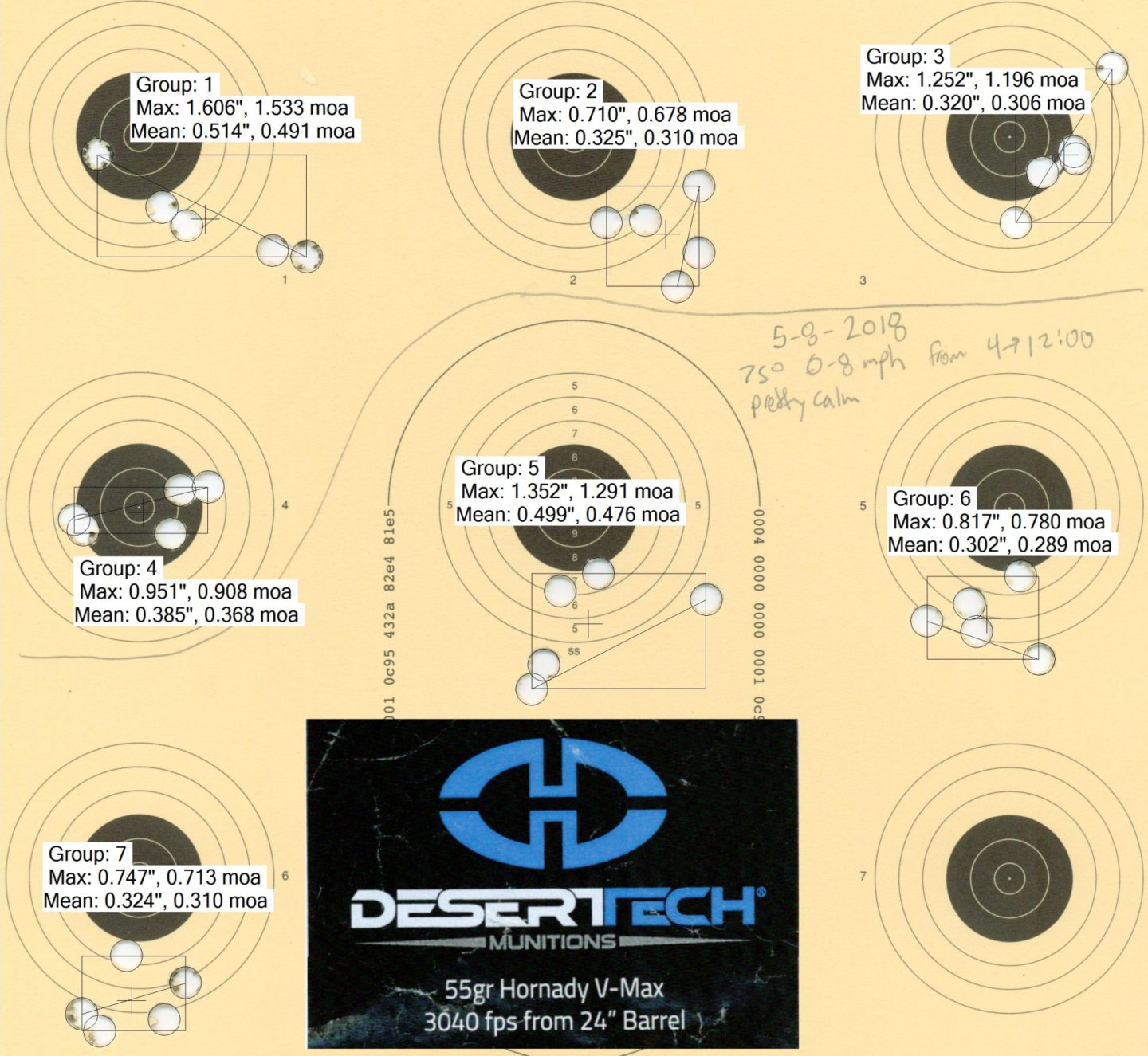

Hornady

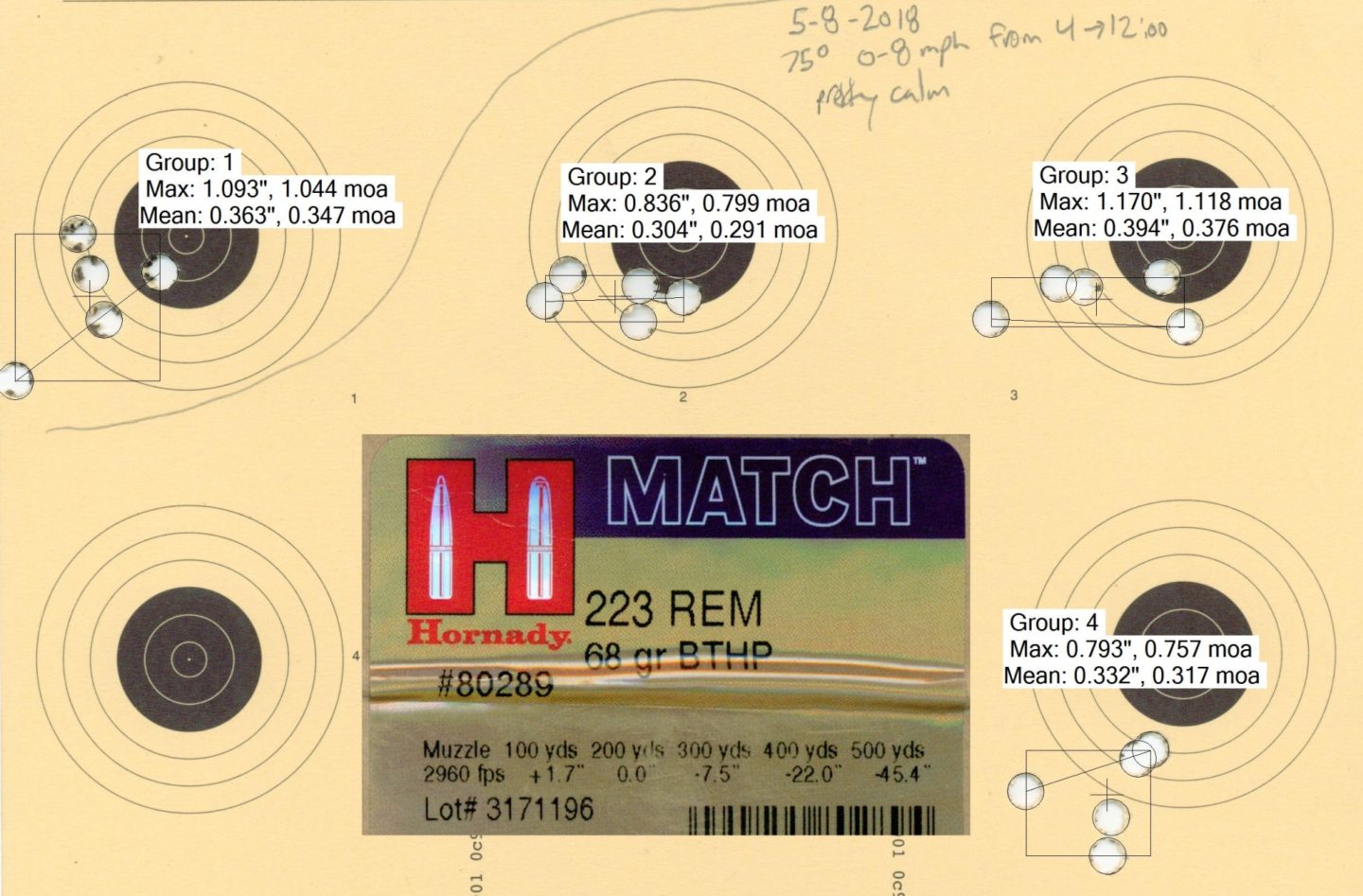

Hornady has been making a big push lately into long range precision shooting with their 6.5CM cartridge and the support they offered it at launch by providing high quality, affordable, loaded ammo for it. Hornady has also done a good deal of work on polymer tipped bullets, overcoming the intrinsic accuracy challenges in order to realize aerodynamic advantages. True to its general trend, the Hornady match ammo used here was very affordable at 75 cents a round.

Federal

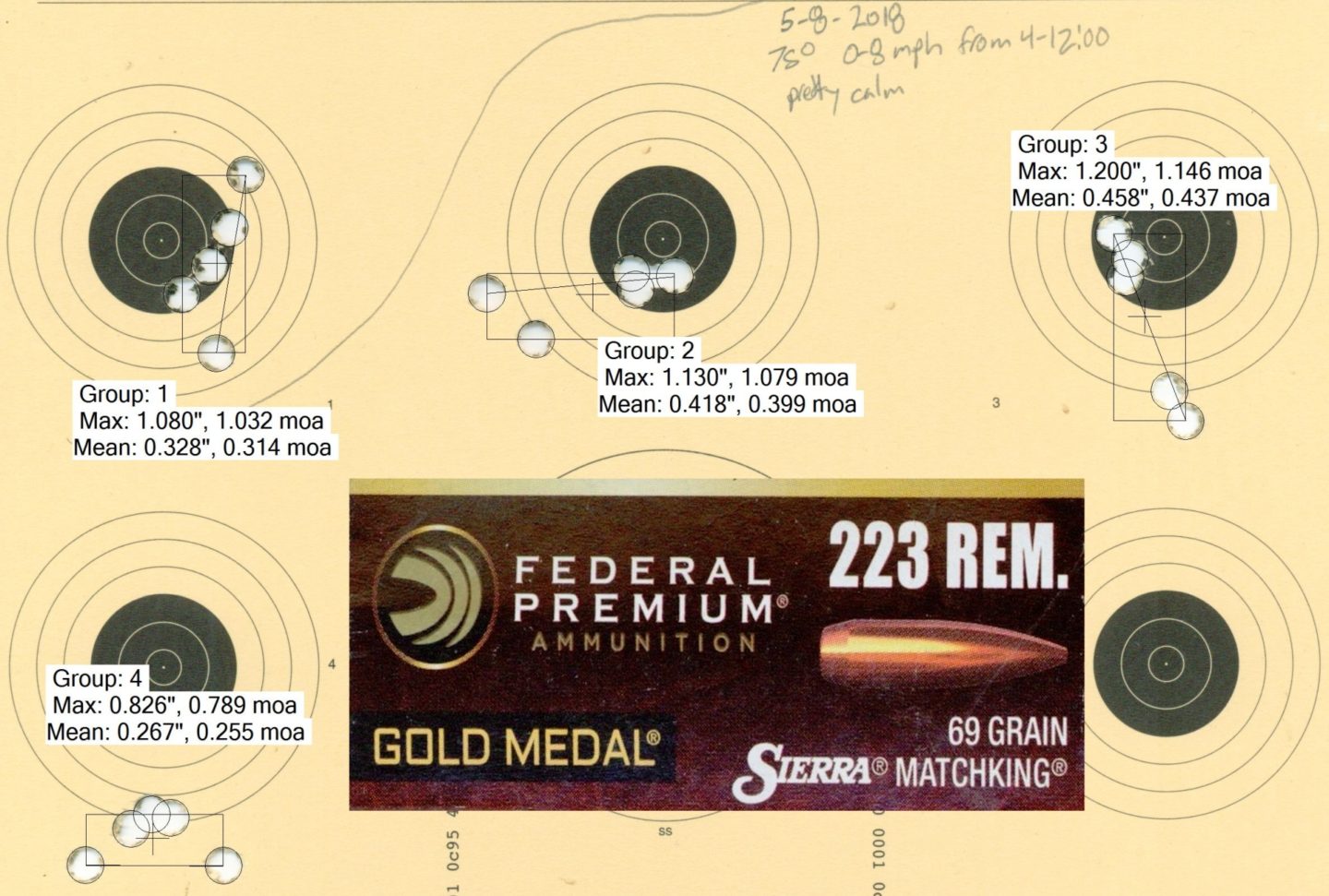

It was not that long ago that Federal Gold Medal Match was the only “premium” option for most users. There were not many quality factory loads and FGGM was the only one likely to be carried by your local retailer. Of course, a dramatic increase in interest in the shooting sports coupled with the widening of options made possible by the internet has changed all that. Strangely, though advertised as a match round, this ammo featured a sealed and crimped primer pocket. It also neither looked nor performed particularly well being the only ammo to average over 1″ groups.

Norma

No doubt most shooters are familiar with Norma. The brand has been around for more than 100 years and is probably best associated with big game ammo and ammo for the shooting sports. Norma was originally a Swedish brand and still has a factory located not very far from Oslo in the picturesque beauty Sweden is well known for. It also now has one located in the near opposite climate of Tampa Florida. Norma is now owned by the huge, diversified, multinational military industrial complex company Ruag Ammotech, and this is where things get a little complicated.

Like most big military industrial complex companies I have dealt with, Ruag is very cagey and opaque. This is probability even further complicated by their European nature along with the language barriers and different cultural and business norms associated with that. Ruag produces ammo under the brands RWS, Geco, Rottweil, Norma, Gyttorp, and Ruag. All of these it owns. Until recently, it also produced ammo marketed in the U.S. under the brand Prime, with which it had an acrimonious, very public, and lawsuit strewn divorce. Ruag has a number of different production sites in Germany, Hungary, USA, Sweden, and Switzerland. This year, when I spoke to the Ruag guys at SHOTShow, I made inquiries as to which products in which lines were produced where because the factory something is made at tends to mean more than the brand on it. I did not get anywhere. What I have learned, mostly from reading the boxes, is that both the 6.5CM Norma that I tested in the Mesa Precison Arms Crux and the .223rem that I tested in the Kelbly’s Atlas are both of Swedish production. This despite the .223rem bearing the branding “Norma USA” and Norma having a production facility in the USA. I also know that Ruag has precision rifle ammo production capability in at least one other factory. That factory being a Swiss one that produces the Ruag Swiss P line of ammo and, I believe, also produced the Prime precision rifle ammo. So, for those wondering if the Norma stuff is the former Prime stuff, I don’t believe so, though I have not reverse engineered rounds to know definitively.

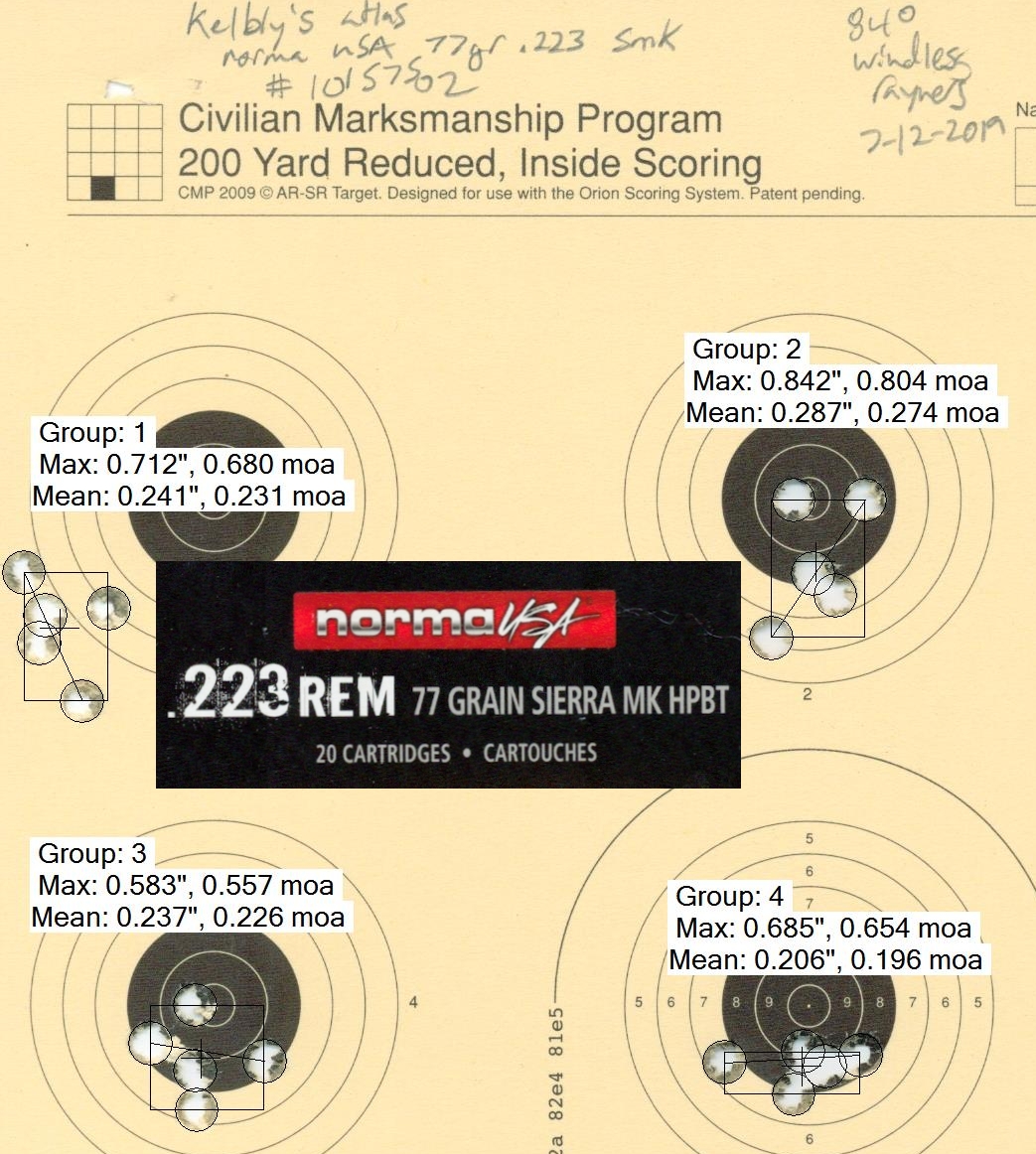

The Norma .223 proved a pretty good fit in the Kelbly. It averaged well under 3/4″ with a mean shot-to-shot distance of .243″, which suggests that over the long run the average group maximum size will be smaller. At $0.70 a round, this ammo is very affordable fodder.

The Shooting Experience

Looking through your scope at a tiny little piece of steel on the other side of the valley, there are so many ways to miss and so few ways to hit. Having all these things to think about can tempt you to doing so. Paradoxically, thinking about all of the things you must do right is also one of the many wrong things so do. To hit with any reliability, you must be focused on just the few things unique to this shot. To get this done, you have to have a lot of confidence in, and comfort with, all equipment and data involved. You need to be certain just how the whole package, rifle, scope, ammunition, and even trigger, are going to behave.

I mention all of this by way of trying to explain the pleasing confident feeling I have had shooting the Kelbly’s .223 rifle at range. It is predictable, precise, and comfortable. There are a lot of parts involved in this. My scope is one I have tested and verified. The Lapua ammo is sub .5moa and I have taken good chrono data on it to produce a good chart. I have laser verified the target ranges. Even the trigger break of the Bix’n Andy plays a part and cleanly breaks with the same feel of pressure each time I actuate it from the thick, ugly, wart of a palm swell I have screwed to the stock. The rifle is an important part of all this machinery working together to punish that little 6″ plate at 675yds. Yea, I’m enjoying shooting some steel with this rifle.

Cost

Kelbly’s builds custom rifles and the one I put together was no exception. Essentially, I had them put together a barreled action and then I added the stock, trigger, bottom metal, and, eventually, bedded it myself. The cost for all of this is broken down as follows:

Atlas Tactical action: $999.00

Krieger .22 Cal Rem Varmint contour blank: $345

Chamber, crown, thread (5/8×24), thread protector, install: $450

Bix N Andy Tacsport: $235

Grayboe Ridgeback + Mesa Precision bottom metal: $599

AICS .223 mag: $39

Acraglas gel: $22

Palm swell materials: $18

Total: $2,707 + tax

Kelbly’s does make a few rifles that are closer to models. These are the NYX, which is an Atlas tactical based rifle in an XLR chassis for $3,300 and the Arcas Tactical, which is an Atlas tactical bedded in Kelbly’s KTS composite stock for $4,500. I expect that, now that they are making the Black Bear action, the Arcas rifles will be commonly based on that.

Summary

Being an action manufacturer, rifle maker, gunsmith, shooting tournament host, and stock manufacturer, Kelbly’s does a lot of things. So many, that we really didn’t even talk about the composite stock manufacture or the shooting tournament. They have been doing all of this for so long that the third generation of Kelbly family members, in the business, are now involved in the day-to-day operations. That degree of experience breeds a great deal of competence, quality, and efficiency. I have been fortunate enough to spend a lot of hours over the years sitting in the Kelbly office in front of a wall that basically illustrates a 40 year history of competition rifles and talking concepts, tolerances, and analyzing, often with piece in hand, a variety of different products from a variety of different makers. It’s a lot of understanding, but probably even more germaine, it is perspective. This has been an important part of my education in the shooting sports. What I think Kelbly’s really boils down to, from the consumer standpoint , is a truly world class product and workmanship, for what is only an average custom rifle cost.