Off the top of my head, there’s a hundred years between the Spaniards colonizing parts of SEAsia, and Taiwan being part of China.

EDIT:

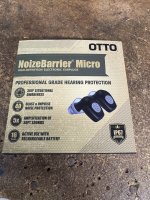

View attachment 8744787

This is what I’m familiar with.

Is there more to the story?

here is what i got in a quick look. conflict between mainland and island-2K years. original inhabitants were not Chinese or even "Asian". more like original people in Japan? they did raid Chinese coast. China sent some punitive expeditions. was a late 1500s war between Japan and Spain. Spain won and established forts in 1626. dutch drove them out in 1642. this opened the way to Chinese immigration to escape the mainland problems.

this brought conflict with the original occupants whom the Chinese considered sub human. Dutch driven out in 1642. Chinese immigrants after some threats China installed some troops. abusive and ineffective Chinese control fomented up to 30 violent uprisings in 19th cent. island was considered the most dangerous place in Asia,a lot of ship wrecks and piracy Perry tried to get compensation. England sent some gun boats in 1860s. neither got satisfaction. was raised to Chinese province from a dependency in 1887. 1895 japan got it in winning a war with China. Japan was sovereign there til 1945.

from then until the KMT retreat there they had control. was abusive,exploitative and brutal per KMT norms. it seems that a lot of trouble there after '49 was related to KMT corruption and insistence of China that Formosa was part of China. the US is what seems to have kept Formosa functional. there was a fear in the 50s that China might invade like in Korea. there were attempts to get Formosa under UN control because of KMT abuses.

so,i was wrong as Formosa was under Chinese control for spells. but it was not "part" of China til 1895. what to do about it now?

the book was originally written in 1957 (?) as a long worked on manuscript. couldn't get published til like 1997 (?). apparently concern about it being anti KMT,which it is,and pro commie,which it isn't. very complex book about a complex place and issues.