Crazy guy, always had one hand on the door and the other on the wheel.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s Motivational Pic Thread v2.0 - - New Rules - See Post #1

- Thread starter Snake-Eyes

- Start date

-

- Tags

- motivational pictures

Should have turned her ass in for littering

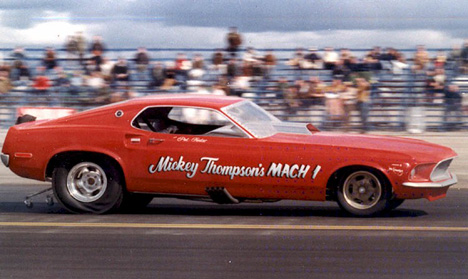

The good old days. I watched this one disintegrate at Dallas in 1969. The blue Mustang went on to become famous. Few remember the red one.View attachment 7889393

View attachment 7889394

Crazy guy, always had one hand on the door and the other on the wheel.

I feel like I need to add this, sorry.Well those weren't good motors for anything but planes the nitro boat motors they made definitely weren't sought after for racing and they won't handle a ton of nitrous, it's 45cc but rated 4-4.5hp they weren't high output engines. A stock well tuned 26cc Zen with a proper length pipe will run those numbers.

Stuff doesn't work the way your saying. If you knew enough to make a boat that more than likely wouldn't go in the 90s do that you'd know adding drag from wings doesn't help you go faster in a boat that's already pushing a lot of air and water. You don't want any of the hull in the water other than a few inches of ride pad and the bottom half of the prop. You adjust the outdrive pitch and tabs to keep it from blowing over.

My boat ran on 2-3" of pad on a 41" hull built for lift, but you made a wet riding design have more drag...

I'm not trying to be a dick it's just odd everything you mention is so fantasticle.

Horsepower will not move a motorized vehicle 1 inch.

It's torque that matters, and it's torque that is measured on a dyno.

Horsepower is nothing but a mathematical equation derived from the torque measurement.

Ask any *real* engine builder.

To make torque, the reciprocating assembly must have inertia.

The more inertia, the more torque.

Ah hell....not much use attempting to explain physics on a gun forum is there ?

The reciprocating assembly must have inertia. The more inertia, the more torque.

Yes.

You can’t get them during pride month.

Long ago in a state far far away Louie Unser described torque angle to me this way...

When you're young and have morning wood, torque angle is defined by how far your heels come off the ground when you push down on your erection to take a leak.

Just thought I'd pop that in there (see what I did there?).

Louie was one cantankerous old fart with a great sense of humor, and when it came to engines he was a no bullshit, take it or leave it, quadriplegic in a wheelchair.

And good, insanely good.

When you're young and have morning wood, torque angle is defined by how far your heels come off the ground when you push down on your erection to take a leak.

Just thought I'd pop that in there (see what I did there?).

Louie was one cantankerous old fart with a great sense of humor, and when it came to engines he was a no bullshit, take it or leave it, quadriplegic in a wheelchair.

And good, insanely good.

Then they would be creamyThey’re only boneless because you didn’t have time to open the box before the picture

That's the hydro just in front of the Goodyear, that's the crankshaft just behind the front tire.

Boss : If you can not get all 3 of these vehicles delivered today you will have to come in this weekend to finish the deliveries.

Russian's leaving Ukraine ?

Linda Vaughn used to be at the Speedway in Indy for the month of may when I was with a race team in the 90s. She would wander the pits and the garages and was a really nice lady.For you old farts, the real reason you got a Hurst Shifter in your car.

View attachment 7889181

Maybe you were a Jungle Pam guy.

Frank

That engine still wouldn't do what you claim, you feel slighted and want the last word is all lol.I feel like I need to add this, sorry.

Horsepower will not move a motorized vehicle 1 inch.

It's torque that matters, and it's torque that is measured on a dyno.

Horsepower is nothing but a mathematical equation derived from the torque measurement.

Ask any *real* engine builder.

To make torque, the reciprocating assembly must have inertia.

The more inertia, the more torque.

Ah hell....not much use attempting to explain physics on a gun forum is there ?

Horsepower does matter in this case, all the torque in the world won't make that too small prop push that boat in the 90s. So it does matter in this case.

Last edited:

You and Frank both.I hate anyone over 5’2 1/2”!

What liquid?Took me forever to finally notice the two cups of liquid.

Can't believe this thread is still going and still epic.

And do we know what the pitch was on the prop ?That engine still wouldn't do what you claim, you feel slighted and want the last word is all lol.

Horsepower does matter in this case, all the torque in the world won't make that too small prop push that boat in the 90s. So it does matter in this case.

Nah, it probably makes no difference, you just want to argue.

Doesn't matter, that engine wouldn't push that hull those speeds. If it did everyone would be running 4500 plane engines and scale deep vee hulls for racing.And do we know what the pitch was on the prop ?

Nah, it probably makes no difference, you just want to argue.

Why spend hours and hours tuning a light lay up race hull with a top end built motor when you can just cobble some shit together?

See, I called that one, right ?Doesn't matter, that engine wouldn't push that hull those speeds. If it did everyone would be running 4500 plane engines and scale deep vee hulls for racing.

I've been trying to be nice, but your full of shit. Everything you own is the coolest and fastest.See, I called that one, right ?

Even talking about illnesses on another thread pretty sure it was you and you're also the sickest, you're the best at everything we get it.

All you have to do is stop making shit up and exaggerating

For you old farts, the real reason you got a Hurst Shifter in your car.

View attachment 7889181View attachment 7889182

Maybe you were a Jungle Pam guy. View attachment 7889184

You could fill 55 gallon drums with all the clam chowder pumped into these two women over 30 years of racing.

But the op of this is stupid just for making the meme. They were trying to sound smart and edgy

They know there's intelligent life here if scientists are doing the searching. Lol

Nah, it probably makes no difference, you just want to argue.

That's exactly what I did when I read that, even if it's also towards me lol

You say that like you wouldn't have pumped some in given the chance.You could fill 55 gallon drums with all the clam chowder pumped into these two women over 30 years of racing.

Jungle Pam was a butter face though.

Not a very good advertisement for their stroker motors. When the crank is laying on the ground they should have blurred the sponsor ad on the hoodView attachment 7889493

That's the hydro just in front of the Goodyear, that's the crankshaft just behind the front tire.

That happens sometimes running nitro. It's the magic muffler AA/Fuel altered, this wasn't an out of the ordinary situation.Not a very good advertisement for their stroker motors. When the crank is laying on the ground they should have blurred the sponsor ad on the hood

That pictures passed around a lot, it was a fill in driver and they didn't torque the bottom end, supposedly.

Last edited:

Some of y’all might like this YouTube channel.

@168BTHPM youd like it probably guy goes around searching for old drag cars

@168BTHPM youd like it probably guy goes around searching for old drag cars

Ahhh, the serbu of the auto world.

Yeah that's it

It was a bad load... I mean, it was the driver's fault, no wait... It was the fuel.That happens sometimes running nitro. It's the magic muffler AA/Fuel altered, this wasn't an out of the ordinary situation.

That pictures passed around a lot, it was a fill in driver and they didn't torque the bottom end, supposedly.

Yeah that's it

Yup.Ahhh, the serbu of the auto world.

It was a bad load... I mean, it was the driver's fault, no wait... It was the fuel.

Yeah that's it

Ripping 10-20 1/2 high strength bolts out (depending on if it's 2 bolt or 4 bolt mains), or breaking them off....ripping the entire bottom 1/2 of the engine block apart.

You do know that pistons don't come out the bottom....so it broke 8 rods,or ripped apart 8 pistons too.

I'm wagering the crankcase filled with fuel and then ignited.

It used to happen with older Chevy engines and a bad fuel pump diaphragm.

I've only seen it once, but it blew upwards splitting the intake down the middle and pushing it thru the hood, the valve covers were lifted about 3-4 inches and held on by little strips of metal where the bolts actually held on.

Quite the scene.

Similar threads

- Replies

- 0

- Views

- 44K

- Replies

- 64

- Views

- 21K