That only took two years...lol.

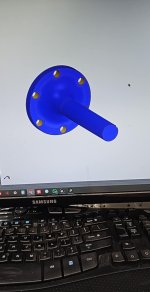

Once all the mechanical things were handled, the fun started....(software, lol) Holley parrots much of its software off of GM LS based stuff. Reluctor wheel/Cam sensor latency was the bug we had to squash in order to get it to fire. The magnet triggered reluctor I'm using on the crank has a different input interval compared to a 58T OEM piece. Then you have to decide if you want the trigger to command the signal when the sensor initially sees the magnet, or when it's passing by and about to break the signal. We lied to the computer and changed the firing order by one cylinder. (8, 7, 2, 6, 5, 4, 3, 1 instead of 1, 8, 7, 2, 6, 5, 4, 3) and then command it to be 180*.

Not the first time this has happened. Ford Coyote engines are kind of known for this on the Holley because Ford has a different means of reading data from the crank/cam signal. It's not a big deal as the software handles it fine. It does screw with your head a little when its your first attempt at sorting it all out.

Next was the injector timing. According to Holley, we are 63* before top dead center. The intake valve would be almost closed. Again, it's not happening there, but that is what the software is outputting.

The good news is that the pair of wide-band O2 sensors collects data and modifies fuel tables in real time. I was worried that the short collector length would create a condition where the sensors were sniffing some outside atmosphere vs actual exhaust. That doesn't seem to be happening. We were way too lean on the initial fuel tables. It was making the thing a real bitch to start. Turning on the O2s immediately fattened the motor by 25% once it was running.

Once fired, we created an additional table to try and lean it out a bit so that it'll make some heat quickly while at idle. The intent being to warm the thing up faster and to mitigate fuel contamination to the oil. (methanol is notorious for pissing past the rings and collecting in the oil. I have a couple ideas on how to reduce this further. The oil tank has a heater. We're keeping it plugged in between rounds with the cap off to sweat fuel/water out of the oil. Next, the burn-down breathers I made are QD style. I can disconnect them from the valve covers. I made an additional plug that adapts to a shop vac hose. Between rounds, we'll hook it up and turn the vacuum on to pull fuel/water vapor out of the crank case.

Lots of work to do yet, but at least it makes noise now. It idles surprisingly well for an engine with a .800" lift/290* duration camshaft. Having heads that can actually move some air sure has seemed to tone down the harsh "snap" that the exhaust used to have. 2-1/4" primaries to a 4-1/2" collector probably helps a bunch too.

www.facebook.com

411885246_2483033688542698_8958027980227625341_n.jpg440.1 KB · Views: 279

411885246_2483033688542698_8958027980227625341_n.jpg440.1 KB · Views: 279 411916709_2483033755209358_4374825243801791857_n.jpg367.2 KB · Views: 293

411916709_2483033755209358_4374825243801791857_n.jpg367.2 KB · Views: 293 416091871_709008671377990_1126643507205977622_n.jpg184.4 KB · Views: 273

416091871_709008671377990_1126643507205977622_n.jpg184.4 KB · Views: 273 418731175_1441315033433620_775652118322435634_n.jpg186.7 KB · Views: 294

418731175_1441315033433620_775652118322435634_n.jpg186.7 KB · Views: 294 418861144_928810124829925_3990547064657196644_n.jpg195.9 KB · Views: 285

418861144_928810124829925_3990547064657196644_n.jpg195.9 KB · Views: 285 420709033_1529757611152365_4848849660007108029_n.jpg157.4 KB · Views: 300

420709033_1529757611152365_4848849660007108029_n.jpg157.4 KB · Views: 300