After turning 40, I decided that instead of a Corvette, I would build my dream bolt gun. No holds bar, I wanted the best money could buy but alas, I have had nothing but troubles with accuracy.

300PRC

x-caliber carbon bull barrel- 1:8 twist 5R 26" with the cryo treatment. This was a blank that I had a local (reputable) gunsmith fit and chamber for me.

Shooting Hornady 225 ELDM and its a 3-5 moa gun. I reload and made a hand load but it only gets slightly better.

I understand a sub moa gun in a 2 moa shooters hands will not get sub moa results.

I also understand that its a game of variables and that if something in the system is wrong (ie contact with the barrel to chassis) it will not have good results.

I have completely exhausted everything I can think of from shooting technique (if I didn;t have another gun- 6.5 prc that shoots amazing- I would doubt my ability to shoot) to ammo to the rest of the gun. I have a barrel cooler (motorized fan) that I let cool the barrel down.

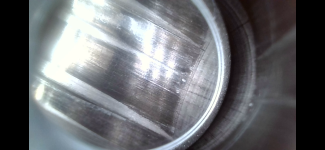

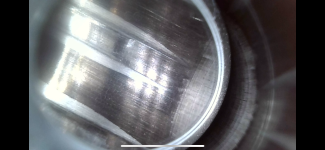

I finally got a bore scope and was pretty amazed at how poorly my throat looked. Does this look like normal throat wear? Or is this a possible manufacturing issue? Or a gunsmithing issue? There is about 450 rounds down the barrel and like I said, I didnt abuse it with excessive heat or hot loads. The gun has never shot well. Below is a image of the throat of the 300 prc. I will also include an image of the throat of my proof 6.5 prc barrel with 120 rounds down it for comparison. Thanks for the help.

300PRC

x-caliber carbon bull barrel- 1:8 twist 5R 26" with the cryo treatment. This was a blank that I had a local (reputable) gunsmith fit and chamber for me.

Shooting Hornady 225 ELDM and its a 3-5 moa gun. I reload and made a hand load but it only gets slightly better.

I understand a sub moa gun in a 2 moa shooters hands will not get sub moa results.

I also understand that its a game of variables and that if something in the system is wrong (ie contact with the barrel to chassis) it will not have good results.

I have completely exhausted everything I can think of from shooting technique (if I didn;t have another gun- 6.5 prc that shoots amazing- I would doubt my ability to shoot) to ammo to the rest of the gun. I have a barrel cooler (motorized fan) that I let cool the barrel down.

I finally got a bore scope and was pretty amazed at how poorly my throat looked. Does this look like normal throat wear? Or is this a possible manufacturing issue? Or a gunsmithing issue? There is about 450 rounds down the barrel and like I said, I didnt abuse it with excessive heat or hot loads. The gun has never shot well. Below is a image of the throat of the 300 prc. I will also include an image of the throat of my proof 6.5 prc barrel with 120 rounds down it for comparison. Thanks for the help.